U.S. Department of Transportation

Federal Highway Administration

1200 New Jersey Avenue, SE

Washington, DC 20590

202-366-4000

Federal Highway Administration Research and Technology

Coordinating, Developing, and Delivering Highway Transportation Innovations

| TECHNICAL NOTE |

| This technical note is an archived publication and may contain dated technical, contact, and link information |

| Publication Number: FHWA-HRT-16-081 Date: January 2017 |

Publication Number: FHWA-HRT-16-081 Date: January 2017 |

PDF Version (2.66 MB)

PDF files can be viewed with the Acrobat® Reader®

FHWA Publication No.: FHWA-HRT-16-081

FHWA Contact: Ben Graybeal, HRDI-40, 202-493-3122, benjamin.graybeal@dot.gov

The performance of connections between prefabricated concrete elements constructed using field-cast cementitious grouts and grout-like materials is becoming a focus area for accelerated bridge construction (ABC) projects. These connections are required to provide sufficient strength and long-term performance equal to or better than the adjacent concrete elements that they are connecting to assure adequate stress transfer and long-term performance throughout the life of the bridge. Many aspects need to be taken into consideration when specifying the material to make these connections. This TechNote focuses on the aspects related to the bonding interface between the previously cast concrete element and the field-cast connection grouts, including test methods, factors affecting bond, and best practices for detailing and construction.

In recent years, ABC has become increasingly popular for both new and replacement bridge construction throughout the United States. ABC projects typically use innovative planning strategies, novel materials, and innovative structural designs to expedite completion and reduce the onsite impacts of bridge construction.(1) Many ABC projects use prefabricated bridge elements (PBEs). These elements are typically produced under controlled environmental conditions either off or near site and can offer improvements in quality and the expectation of better long-term performance. Once fabricated, PBEs are delivered and rapidly assembled. To create structural continuity, PBEs are typically connected using interlaced reinforcing bars and field-cast grout closure pours (see figure 1). The ideal closure material for PBE connections is self-consolidating; has high early-age strength; and offers exceptional durability, dimensional stability, and a bond that is stronger than the tensile capacity of the element to which it is connected. The most common connection grouts are cement-based, low-shrinkage grouts that are commonly referred to as “non-shrink” cementitious grouts. However, other grout materials have recently emerged as alternatives. Examples include epoxy-based grouts, ultra-high performance concretes (UHPCs), and grouts that employ alternative binder systems (e.g., micro-silica) with or without the use of fiber reinforcements.

Figure 1. Photo. Casting of the grout connection between two adjacent

precast concrete bridge deck panel elements.

Design, detailing, and proper material specification of field-cast grouts are critical for a number of reasons. First, connections typically coincide with regions expected to experience high force demands and must be resilient against repeated load cycles. Second, connection interfaces between the prefabricated concrete elements and the field-cast closure grouts are unavoidable, which can result in premature debonding at the concrete-grout interface. Thus, the closure grout material must not only be able to transfer structural loads between the adjacent elements, but it must also be able to bond well at the precast concrete interface.

Local behaviors occurring between the substrate concrete and the field-cast material are central to this document. Herein, the cold joint between the previously cast concrete and the field-cast connection grout is referred to as “interface” or “concrete-grout interface.” Furthermore, the term “bond” refers to the chemical and/or mechanical connection at the grout-concrete interface.

The primary performance objective of PBE connections is to achieve, at a minimum, behavior and performance equal to or better than that of the components being connected. Cold joints between precast concrete and field-cast connection grouts are susceptible to premature cracking as a result of bond failure. Thus, a good bond between precast concrete and the connection grout is important. Prevention of premature interface cracking prevents salt and other contaminants from infiltrating connections. This is important because the infiltration of such materials can cause premature material degradation and corrosion of reinforcing bars, thus decreasing both the durability and service life of the structural element and the structure as a whole. In general, if cracking is to occur, the design objective should dictate that cracks from within the precast concrete elements and not at the concrete-grout interface.

Bond between existing and fresh cement-based materials is a topic that has been researched in the past.(2, 3) However, despite a relatively large body of knowledge, practical issues related to achieving long-lasting bond in PBE connections are still inadequately addressed. Previous studies on bond have focused on bond between existing concrete and repair materials and not bond in PBE connections. Although there are some similarities between the two cases, there are significant differences that require studying bond in the context of PBE connections separately.

Understanding the factors that affect bond behavior between precast concrete and PBE connection grouts is critical for proper design and detailing of connections. Previous research identified several of these factors.(3–5) Of equal importance is the test methods used to evaluate the bond strength. Both of these topics are discussed in subsequent sections.

Numerous test methods are available for measuring the bond strength between two cementitious-based materials. The primary difference among test methods is the state of stress at the interface between the two materials during testing (e.g., tensile, shear, and flexure). Furthermore, for a given stress state such as tension, there are multiple available methods, making it difficult for a user to select the most appropriate test method. In practice, a test method should be selected so that it best simulates the onsite loading conditions experienced by the structural element or so it provides a conservative estimate of the bond strength. While some of the methods discussed are based on ASTM standard test methods, others are non-standardized tests developed by different research groups aiming to identify the most appropriate method to assess bond strength. Past research has shown that measured bond strength is greatly dependent on which test method is used, making it difficult to obtain a clear and conclusive assessment of the bond performance.(6)

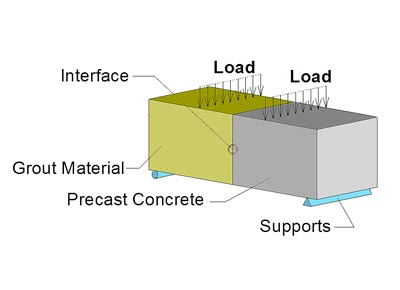

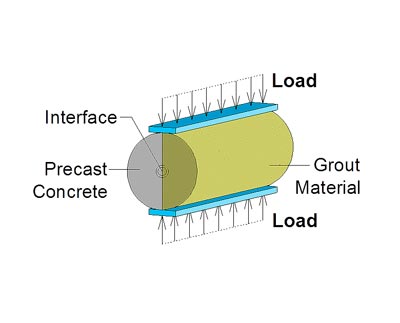

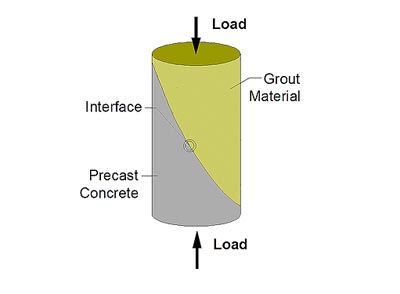

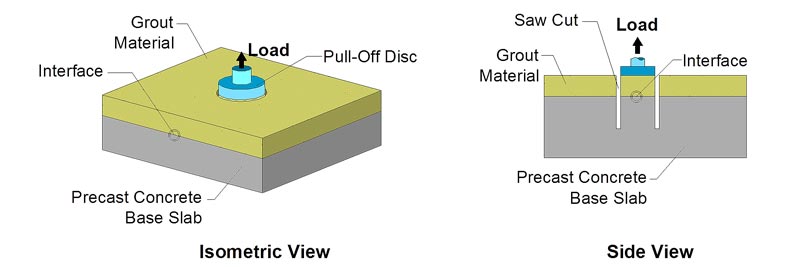

The research performed at Turner-Fairbank Highway Research Center (TFHRC) has focused on addressing some of the questions related to the proper selection and execution of the most appropriate bond test methods to use for PBE connections. Four different test methods were investigated (see figure 2 through figure 5). Each test is based on an existing ASTM standard test method and may have been modified from its original purpose to study bond strength for PBE applications. Although a number of different test methods exist, these four were selected because they can be easily conducted in most State transportation department material laboratories and because they attempt to replicate stress states that could occur at the interface in PBE connections.

Figure 2. Illustration. Flexural beam test for characterizing bond

between precast concrete and field-cast connection grouts.

Figure 3. Illustration. Splitting cylinder test for characterizing bond

between precast concrete and field-cast connection grouts.

Figure 4. Illustration. Slant-shear compression test for characterizing bond

between precast concrete and field-cast connection grouts.

Figure 5. Illustration. Direct tension pull-off test for characterizing bond between precast concrete and field-cast connection grouts.

The following steps, regardless of the test method selected, are required to collect and interpret results from interface bond tests:

Figure 6. Photo. Typical failure modes exhibited in bond testing—failure location 1:

bond failure at the interface.

Figure 7. Photo. Typical failure modes exhibited in bond testing—failure location 2:

partial substrate failure.

Figure 8. Photo. Typical failure modes exhibited in bond testing—failure location 3:

failure in substrate.

Flexural beam bond tests can be conducted using the specimen geometry and loading protocols described in ASTM C78, Standard Test Method for Flexural Strength of Concrete (Using Simple Beam with Third-Point Loading).(7) This test puts a portion of the interface into a state of flexural tension. Specimens are constructed by first casting a concrete half-beam. Once the concrete half-beam has cured and the substrate surface has been prepared, the remaining beam half can be cast using the connection grout material in question.

Research has demonstrated that this test method can be used to compare different grout materials with different concrete substrate surface preparations for bond improvement.(8) However, in some cases where the bond between the two materials is not strong enough (e.g., poor surface preparation), specimens fail during handling prior to loading. When this occurs, specimens typically exhibit bond failure at the interface.

Bond strength can also be measured with cylindrical specimens tested in accordance with ASTM C496, Standard Test Method for Splitting Tensile Strength of Cylindrical Concrete Specimens.(9) This test puts the interface into a state of indirect tension. Again, specimens consist of a precast concrete half and a grout half. The final geometry of specimens can use standard 4- by 8-inch (101.6- by 203.2-mm) or 6- by 12-inch (152.4- by 304.8-mm) cylinder molds. Similar to flexural beam bond tests, splitting cylinder specimens have been observed to exhibit failures at the three locations identified in figure 6 through figure 8.

Ongoing research at TFHRC has demonstrated that this test is an easy way to measure the bond strength of a concrete substrate to different grout-like materials. However, it has also shown deficiencies in the proper evaluation of other parameters that affect bond (e.g., surface preparation) because the results do not show significant differences. It also must be recognized that differences in elastic moduli between the substrate and the secondary cast materials can induce unanticipated strains and stresses into the specimen.

ASTM C882, Standard Test Method for Bond Strength of Epoxy-Resin Systems Used with Concrete by Slant Shear, is commonly used to assess the compression shear bond strength of an interface.(10) Similar to the splitting test, specimens can use standard 4- by 8-inch (101.6- by 203.2-mm) or 6- by 12-inch (152.4- by 304.8-mm) cylinder molds typically used for compressive strength testing according to ASTM C39, Test Method for Compressive Strength of Cylindrical Concrete Specimen, with a precast concrete half and a grout half.(11)

While the stress states replicated in this test method can occur in real structures, it is not clear that this stress state is a likely limit state for commonly deployed connection interfaces.(5) Some research groups have concluded that the test is highly influenced by several factors and thus not able to capture the true bond strength between the two materials. Some of these factors include the interface surface preparation and the angle of the contact plane.(12)

The pull-off test method is based on ASTM C1583, Standard Test Method for Tensile Strength of Concrete Surfaces and the Bond Strength or Tensile Strength of Concrete Repair and Overlay Materials by Direct Tension (Pull-Off Method).(13) The test can be performed either in situ or on a prepared sample; however, an in-situ test requires the repair of the tested location. As the name implies, this test method puts the interface into a state of pure tension. The test specimen is formed by partially drilling a shallow core perpendicular to the interface. Finally, a tensile load is applied to a steel disc that was previously bonded to the top surface of the test specimen.

There is general consensus that direct tension test methods are appropriate indicators of bond performance because they apply a single mode of stress (i.e., direct tension) at the bond interface.(14) The pull-off test method should measure the true tensile bond strength between two materials provided that any eccentricity during loading is avoided. It also provides a conservative result compared with other test methods.(6)

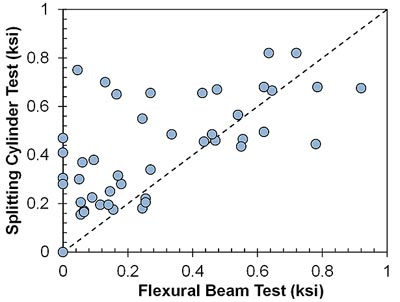

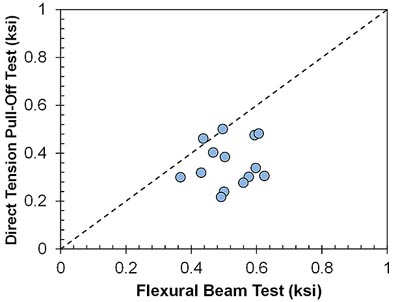

Figure 9 and figure 10 depict a comparison of three test methods that aim to assess tensile bond strength (i.e., flexural beam, split cylinder, and direct tension pull-off). This comparison only identifies the differences in apparent tensile bond strength and does not take into account other factors such as concomitant stress states that could affect the apparent tensile bond strength result. For a given comparison plot, each data point reflects the average bond strength as measured by two different tests for a given set of test variables; variables might include grout age, concrete surface preparation, and/or type of bonded grout material. In general, these plots identify how multiple tests, each purporting to deliver a tensile bond strength, can in fact provide a different result. Based on the data shown here, it can be observed that the flexure beam test and the splitting cylinder test each relate higher bond strengths than the pull-off test. This is attributed to the different stress states occurring in the different test configurations and the fact that some stress states serve to delay bond failure, thus delivering a non-conservative indication of the tensile interface bond strength.

1 ksi = 6.9 MPa.

Figure 9. Graph. Comparison between different bond test methods and the

apparent bond strength—flexural beam and splitting tensile tests.

1 ksi = 6.9 MPa.

Figure 10. Graph. Comparison between different bond test methods and the

apparent bond strength—flexural beam and direct tension pull-off tests.

It is commonly accepted that bond strength increases by increasing the surface roughness (contact area) of concrete. Various techniques have been proposed for preparing the concrete substrate surface, which may result in different degrees of mechanical and chemical bond between precast concrete and the grout material. Some of these techniques include hydrodemolition, scarification, sandblasting, hand-chiseling, and aggregate exposure using in-form retarders.(15) Although all of these methods effectively increase the contact area between the substrate and grout, some result in higher bond strengths than others. Field studies have shown that bond strengths of surfaces prepared using techniques that induce microcracking are frequently lower compared with surfaces prepared using non-impact methods, particularly for instances where the bond failure occurs partially or fully in the substrate.(15)

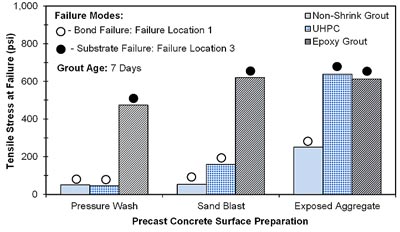

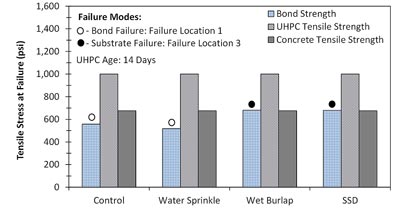

Research carried out at TFHRC has demonstrated that bond can be significantly improved by exposing the aggregate within precast concrete at the concrete-grout interface. Figure 11 shows results from flexural beam bond testing using different precast concrete surface preparations and different grout materials. The surface preparation methods were selected based on their applicability in PBE connections, yielding different concrete surface roughness (see figure 12 through figure 14). Although different failure modes were observed, use of precast concrete with exposed aggregate surfaces leads to higher flexural bond strengths compared with other surface preparation methods applicable to precast concrete elements.

1 psi = 0.007 MPa.

Figure 11. Graph. Average tensile strength from flexural beam bond tests.

Figure 12. Photo. Example of a pressure-washed concrete surface.

Figure 13. Photo. Example of a sandblasted concrete surface.

Figure 14. Photo. Example of an exposed aggregate concrete surface.

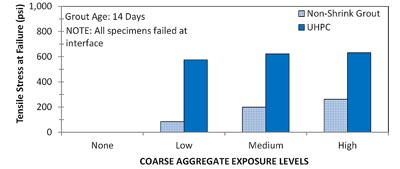

Exposed aggregate surfaces are typically created using in-form retarders, which are pressure washed after form removal to expose the aggregate. Using these retarders, it is possible to achieve different levels (or depths) of aggregate exposure depending on the type of retarder used. Levels of exposure can range from very low, which would be similar to a sandblasted finish, to high, where the coarse aggregate would be very apparent. Figure 15 through figure 17 show three different levels of exposure where three different in-form retarders were used. In this case, each exposure level reveals different degrees of fine and coarse aggregate. For example, smaller coarse aggregates can be observed in the low exposure level, whereas the larger coarse aggregates can be seen in the high exposure level. The difference among the three retarder systems is the concentration of the retarder. As previously noted, increasing surface roughness typically results in increased bond strength. Thus, the different exposure levels produce different bond strengths for different materials. This effect can be observed in figure 18, which shows that the tensile bond strength of a conventional non-shrink cementitious grout increased by increasing the depth of etch on the exposed surface of the concrete substrate. It is interesting to note that, in the case of UHPC, high-tensile bond strength is achieved without the need for a high level of substrate surface roughness (i.e., high aggregate exposure). This is indicative of the influence of other parameters that might play a more important role than surface roughness in enhancing bond (e.g., grout fineness, grout consolidation, etc.), at least for this material.

Figure 15. Photo. Example of a low coarse aggregate exposure level.

Figure 16. Photo. Example of a medium coarse aggregate exposure level.

Figure 17. Photo. Example of a high coarse aggregate exposure level.N

1 psi = 0.007 MPa.

Figure 18. Graph. Direct tension pull-off bond strength of non-shrink cementitious

grout and UHPC as a function of aggregate exposure level.

After preparing the concrete surface using any of the methods described earlier, it is becoming a common practice to moisten the concrete surface with water prior to the grout pour. The moisture content in the concrete substrate is known to affect bond strength, and the impact can be either negative or positive. When fresh grout material is cast against a concrete substrate surface that lacks moisture, moisture is absorbed (transferred) from the fresh grout material into the substrate. In this case, the moisture comes from the mixing water that the fresh grout material requires for hydration and strength-gain. Water migration from the fresh grout material can also increase local shrinkage near the interface between the two materials. This will induce tensile stresses at the interface and can cause microcracking and reduced bond strength. Research has shown that different substrates and grout materials may require different interface moisture conditions at the time of casting to achieve optimum interfacial bond.(15,16) One challenge is that there is no test method for determining the optimum concrete substrate moisture condition for a given grout type or a specification that can be used in the field to instruct contractors on the proper substrate condition needed. On one hand, an excess of free water at the interface can increase the water-to-cementitious ratio of the grout, thus reducing the material strength and possibly the bond strength. On the other hand, a concrete surface that is too dry can absorb water from the grout, resulting in the aforementioned problems. Thus, the so-called saturated surface dry (SSD) moisture condition is sometimes specified for the substrate concrete at bonding interfaces. This moisture condition provides enough moisture to saturate the capillary pores of the concrete surface (so that moisture transfer does not occur from the grout) while at the same time preventing the formation of a layer of free water at the interface.

It is recognized that achieving a moist surface condition in the field does require extra effort and can be impractical for connection interfaces that are not readily accessible after prefabricated component installation. Even so, the provision of extra moisture or pre-wetting the concrete surface before casting connection grouts to achieve an SSD condition has become more popular since the benefits have been more widely recognized. Pull-off tests carried out at TFHRC have shown increased tensile bond strength compared with dry interfaces when the concrete surface is pre-wetted using the following techniques:

Figure 19 shows the pull-off test results of a UHPC overlay cast over a concrete slab with exposed aggregate surface. Both wet burlap and SSD conditions enhance the tensile bond strength to the point that the failure occurred at the substrate rather than at the interface, as indicated by the concrete substrate tensile strength.

1 psi = 0.007 MPa.

Figure 19. Graph. Effect of providing extra interface moisture on the

direct tension pull-off bond strength of UHPC.

The burlap approach can be implemented in the field in some types of PBE connections; various State agencies are currently using this type of pre-moistening technique. Figure 20 depicts a method that has been used in the field to pre-wet the connection prior to casting cementitious connection grouts. Burlap sheets were placed on top of the connection between adjacent prefabricated bridge deck elements. A few hours before the closure grouting operations began, these sheets were installed and kept saturated with water to promote a moist environment within the connections.

Figure 20. Photo. Provision of extra moisture in PBE connections.

Just as structural steel requires specific interface surface preparations prior to paint application, substrate concrete requires a clean surface prior to grout casting. A surface that is contaminated at the time of grout placement can result in reduced bond strength. Loose particles have been shown to inhibit bonding, thus reducing the bond strength.(2) Avoidance or removal of any chemical debonding agent or contaminant (e.g., oil) is of upmost importance. Precast concrete connection surfaces should be prepared by removing grit and/or loose particles prior to placement of connections grouts. Examples of cleaning procedures include pressure washing or air blasting. Care must be taken not to damage the precast surface or any protruding connectors such as epoxy-coated steel reinforcements.

Differential movement of the precast elements can degrade the ability of the grout to bond to the substrate. Maintaining stable precast elements during grouting and grout curing operations is important. Limiting loads on the structure mitigates structural deformations and allows bonding to occur. For staged construction where portions of the structure remain open to traffic, it is important to mitigate differential movements within precast element connections by taking actions such as limiting truck traffic or limiting load distribution from the loaded portion of the structure into the freshly constructed portion.

Flowability and Particles Gradation

Good flowability mainly refers to the capability of the fresh grout material to consolidate and ensure a good contact and uniform bond between the grout and the substrate. This is important especially where rough surfaces are present to prevent the development of air pockets in the valleys of the surface texture. In other words, the higher the consolidation is (i.e., fresh workability), the greater the ability to bond at the contact area between the two materials.

In addition, the size gradation of the solid particles in the premixed grout can play an important role in how well the fresh grout material consolidates. The solid fraction of a grout can consist of many different materials of different sizes, such as cement and/or any other inert (e.g., finely ground silica) or amorphous (e.g., silica fume) particles. Similarly to the cement paste-to-aggregate interface in conventional concrete, a wall effect exists at the grout-concrete substrate interface when the two materials are placed in contact. The wall effect is due to the lower packing efficiency of the grout particles at the vicinity of the concrete surface. As a result, an interfacial transition layer is created where the porosity tends to be greater than in the bulk of the grout material, thus creating a layer of weakness.(17) This is the reason a fine and continuous grout particle size gradation (i.e., particles of different sizes) is a key factor in reducing the thickness of the interfacial transition layer. For instance, UHPC materials provide a wide range of very fine particles sizes, which is expected to positively contribute in the bond performance of these types of materials.

Dimensional instability (i.e., expansion or more commonly shrinkage) of the grout can lead to poor performance of the grout, the interface, and/or the surrounding substrate concrete. Dimensional incompatibilities between the grout and the substrate can cause the development of stresses within the grout material or the substrate, leading to premature cracking, or can cause stresses at the interface leading to loss of bond between the grout and the substrate. It is desirable that shrinkage of the grout be minimized and occur before the material reaches final set so that the likelihood of good bond can be increased.

Likewise, proper curing of the grout is crucial because poor curing can lead to evaporation and drying during hydration of the grout and an increased likelihood of shrinkage cracking. Good curing procedures prevent moisture loss during the hydration of the grout and often decrease the likelihood of cracking and can translate into higher strength and better durability.

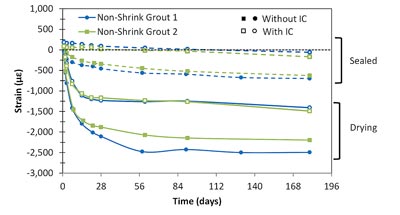

An extensive dimensional stability study was performed at TFHRC using grout-like materials for PBE connections.(18) The study showed that most conventional, non-shrink grouts undergo considerable autogenous and drying shrinkage, as shown in figure 21. These volume changes that occur as the material hardens may have a negative effect on the bond performance of these grouts.

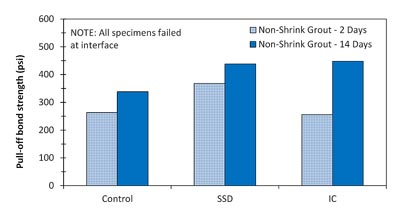

In that study, some of the cementitious grouts included internal curing (IC) through the addition of pre-wetted fine lightweight aggregates. This is proposed as a method to reduce part of the autogenous (sealed) and drying shrinkage (see figure 21) with potential improvement in the bond performance. As observed, both autogenous and drying shrinkage are considerably reduced in the IC specimens. This has been shown to be a result of the internal relative humidity in these specimens being maintained at higher levels, which directly reduces both internal (autogenous) and external drying effects.(19) IC simplifies the efforts that are needed to provide adequate curing conditions in the field for grouts poured in confined locations or at locations that make access for external (or conventional) curing difficult. Preliminary pull-off bond results obtained from a grout-concrete slab where the concrete surface was treated with an in-form retarder to expose the coarse aggregate fraction are shown in figure 22. The grout specimen was prepared in three different conditions: (1) “control,” where the grout was poured over a dry concrete surface, (2) “SSD,” where the grout was poured over an SSD concrete surface, and (3) “IC,” where IC was included in the grout and poured over a dry concrete surface. The results show increased tensile bond strength when IC was included in the grout (see figure 22), although it may take a few days until the IC effect is visible.

Figure 21. Graph. Autogenous (sealed) and drying shrinkage of

two non-shrink cementitious grouts with and without IC.

1 psi = 0.007 MPa.

Figure 22. Graph. Effect of IC on the bond strength of a non-shrink cementitious grout.

Mechanical Properties

It is commonly accepted that the tensile strength of a grout material is more important than the compressive strength in terms of bond evaluation. It is expected that the grout-concrete bond strength will increase with a stronger grout material in terms of tensile strength. The tensile properties of the grout can easily be assessed via ASTM C496, Standard Test Method for Splitting Tensile Strength of Cylindrical Concrete Specimens, or via ASTM C1583, Standard Test Method for Tensile Strength of Concrete Surfaces and the Bond Strength or Tensile Strength of Concrete Repair and Overlay Materials by Direct Tension (Pull-off Method).(9,13)

As in the case of the grout material, the tensile properties of the concrete substrate are important for improving the grout-concrete bond strength. A strong concrete substrate strengthens the vicinity of the grout-concrete interface on the concrete side. This is typically achieved by decreasing the water-to-cement ratio (w/c) in the concrete mix design. In addition, the absorption capacity of a low w/c concrete is lower than that of a higher w/c concrete, thus theoretically reducing the water migration from the grout material into the concrete substrate, which might negatively affect the bond performance (as previously mentioned). Therefore, it is important to know not only the tensile properties of the concrete substrate but also its absorption capacity.

Regarding dimensional stability, the concrete substrate is usually relatively stable, with minimal residual creep and shrinkage. However, it may sometimes experience some volume instability (thermal expansions and contractions due to environmental changes) that might affect the bond between the grout and the concrete. In this case, compatibility of thermal expansion/contraction between the grout and the substrate is advantageous.

There are different types of bonding agents available in the market: epoxy resins, latex-based agents, etc. However, there is no clear consensus as to their ability to enhance the bond strength between two materials. For instance, some researchers report that when the surface preparation is appropriate, there is no need of bonding agents. They claim that the presence of bonding agents leads to two interfaces (instead of just one), increasing the probability of interface failure. According to these researchers, bonding agents cannot compensate for a bad surface preparation. As such, they may act as bond breakers when used inappropriately.(4) Alternatively, other researchers conclude that without bonding agents, the only liquid present at the interface would be water (i.e., pore solution), and then the only bond would be that provided by Van der Waals forces. If bonding agents are present, then they can also create chemical bonds (i.e., covalent and ionic) that would theoretically enhance the bond strength.(20)

For highly fluid mixtures such as grout-like materials, the use of bonding agents might be less necessary than for cases where stiffer mixtures are used, mainly as a result of the capability of the grout to fill the cavities and voids of the substrate, increasing the effective contact area.(15) Research at TFHRC on latex-based bonding agents has not found beneficial increases in the grout-concrete interface bond strength.

Based on the information presented in this document, the following practices are recommended to promote bonding between prefabricated concrete elements and field-cast connection grouts:

Design and detailing of connections between prefabricated bridge elements is critical to achieving a functional, durable, and robust structural system. Cold joints between the prefabricated concrete elements and field-cast closure grouts are unavoidable and can result in premature cracking at the concrete-grout interface, which can reduce the system durability. This document provides insight into the different factors that influence bond between substrate concrete and field-cast connection grouts. Along with a detailed description of key factors, different test methods were discussed, and a set of recommended considerations for detailing and construction were presented.

Researchers—This document was prepared under the direction of Benjamin Graybeal at the FHWA Turner-Fairbank Highway Research Center. The document content was prepared by Igor De la Varga of SES Group & Associates, LLC, under laboratory support contract DTFH61-13-D-00007 and Zachary Haber of Genex Systems, LLC, under laboratory support contract DTFH61-16-D-00033. For additional information, contact Ben Graybeal at (202) 493-3122 or at the FHWA Office of Infrastructure Research and Development, 6300 Georgetown Pike, McLean, VA, 22101-2296.

Distribution—This TechNote is being distributed according to a standard distribution. Direct distribution is being made to the Divisions and Resource Center.

Key Words—Interface bond, cold joint, field-cast connections, bond strength, grout.

Notice—This document is disseminated under the sponsorship of the U.S. Department of Transportation in the interest of information exchange. The U.S. Government assumes no liability for the use of the information contained in this document. The U.S. Government does not endorse products or manufacturers. Trademarks or manufacturers’ names appear in this TechNote only because they are considered essential to the objective of the document.

Quality Assurance Statement—The Federal Highway Administration provides high-quality information to serve Government, industry, and the public in a manner that promotes public understanding. Standards and policies are used to ensure and maximize the quality, objectivity, utility, and integrity of its information. FHWA periodically reviews quality issues and adjusts its programs and processes to ensure continuous quality improvement.