U.S. Department of Transportation

Federal Highway Administration

1200 New Jersey Avenue, SE

Washington, DC 20590

202-366-4000

Federal Highway Administration Research and Technology

Coordinating, Developing, and Delivering Highway Transportation Innovations

| REPORT |

| This report is an archived publication and may contain dated technical, contact, and link information |

|

| Publication Number: FHWA-HRT-14-065 Date: February 2015 |

Publication Number: FHWA-HRT-14-065 Date: February 2015 |

Roadway safety is a complicated issue to say the least. Any time human behavior is a factor, predicting how drivers will respond to road conditions is difficult at best. Variables such as weather, roadway geometry, visibility issues, pavement surface conditions, and the like, further complicate the ability to quantify the safety of a particular roadway.

One factor that is fairly well understood is the link between pavement friction and safety, or more specifically, the probability of wet-weather skidding crashes. The probability of wet-skidding crashes is reduced when friction between a vehicle tire and pavement is high. The FHWA and National Transportation Safety Board estimate that up to 70 percent of wet-pavement crashes can be prevented or minimized (in terms of damage) by increasing pavement friction.(1) While we cannot control human response to road conditions, we can control the properties of pavement surfaces to help reduce the probability of skid-related crashes.

Pavement surfaces affect several factors related to roadway safety. First, the frictional properties of pavement surfaces affect the resistance to tires sliding across the pavement surface. Pavement friction helps to keep vehicles on the road when brakes are applied, particularly when the wheels lock up, and when navigating curves or steering aggressively. This is particularly important in wet weather when a thin film of water on the surface of the pavement reduces contact between the tire and pavement surface. Another important factor is the ability of the pavement surface to channel water out from beneath the tire. The texture and porosity of a pavement surface help to provide a path to channel water away from beneath the tire to reduce the potential for hydroplaning. Texture and porosity also affect the splash and spray potential of a roadway in wet conditions, which can significantly impact visibility in wet weather.

Pavement surface characteristics are primarily functional parameters that affect the safety and comfort of the road user. The most commonly studied surface characteristics are friction, smoothness, tire-pavement noise, and texture. Briefly summarized below are two key characteristics as they relate to roadway safety: friction and texture.

In short, pavement friction is the force that resists the relative motion between a vehicle tire and pavement surface. This force is generated when a tire rolls or slides over the pavement surface and is measured as the nondimensional coefficient of friction.(2) Although a number of factors affect the actual frictional resistance in a given situation, in general, the higher the coefficient of friction of a pavement surface itself, the lower the probability that a tire will slide across the surface in a fully locked braking condition.

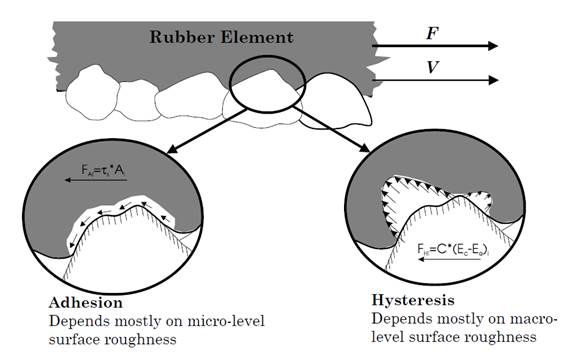

The two key mechanisms involved in tire-pavement friction are adhesion and hysteresis, as illustrated in figure 1 . Adhesion is the friction that results from the small-scale bonding/interlocking of the tire rubber and pavement surface. Hysteresis is the frictional force that results from energy loss during deformation (or enveloping around the pavement texture) as the tire moves across the surface.(2) In general, for wet conditions, the adhesion component decreases with speed while the hysteresis component increases. Both mechanisms are directly affected by pavement texture, as discussed below.

Source: National Cooperative Highway Research Program

Figure 1. Illustration. Key mechanisms of pavement-tire friction.2

As documented in the AASHTO Guide for Pavement Friction, although a basic relationship exists between pavement friction and wet-crash rates, no specific threshold values have been established for pavement friction that make a pavement more or less safe.(3) Pavement friction demand, which is specific to the characteristics of a particular roadway, must be considered when establishing any sort of threshold. Pavement friction demand is dictated by site conditions (grade, superelevation, radius of curvature, terrain, climatic conditions, etc.), traffic characteristics (volume and mix of vehicle types), and driver behavior (prevailing speed, response to conditions, etc.). These conditions are continually changing over time and are different for every roadway, making it difficult to establish a "one size fits all" friction threshold.

Although one could err on the side of providing a level of friction that is exceptional and expected to be above friction demand for the vast majority of situations, there are other considerations and potential costs associated with this approach. The cost to construct these types of treatments could potentially be much higher than for a conventional surface treatment if nonconventional and/or nonlocally available materials are required. There are also the costs to the users, such as increased rolling resistance and therefore decreased fuel economy, and increased tire wear.

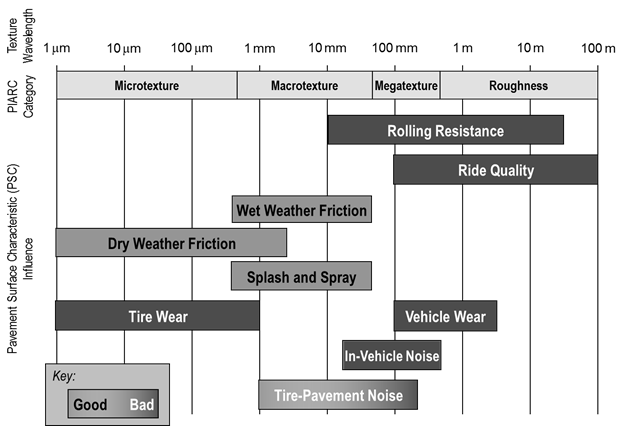

Pavement surface texture directly affects pavement friction as well as other factors related to roadway safety. Texture affects not only the coefficient of friction of a pavement surface, but also the ability of the pavement to shed or channel water away from beneath the tire. Pavement texture is typically broken up into four different types, as illustrated in figure 2 . Of primary concern for pavement safety are microtexture and macrotexture.

Source: The Transtec Group, Inc.

Figure 2. Graph. Pavement texture categories and their effect on surface characteristics (adapted from Henry).(4)

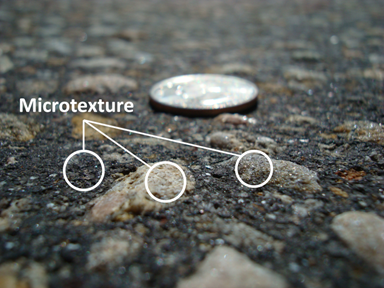

Microtexture-Microtexture is the fine-scale roughness that is not necessarily visible to the naked eye, but is apparent to the touch (see figure 3). It provides a degree of "sharpness" necessary for the tire to break through any residual water film that remains after the bulk water has run off and interacts directly with the tire rubber on a molecular scale to provide adhesion.(3) Microtexture is affected primarily by the surface properties of the aggregate particles that make up the pavement surface, and primarily affects the frictional properties of a pavement surface at lower speeds.

For asphalt pavements and asphalt surface treatments, the coarse aggregate generally provides microtexture. For concrete pavements, the mortar (fine aggregate and cement paste) provides microtexture until the coarse aggregate is exposed (e.g., through diamond grinding or polishing), at which point the coarse aggregate also contributes to microtexture. For this reason, there are generally very restrictive requirements on the coarse aggregates for asphalt pavements and fine aggregates for concrete pavements.

Source: The Transtec Group, Inc.

Figure 3. Photo. Microtexture provided by aggregates on an asphalt pavement.

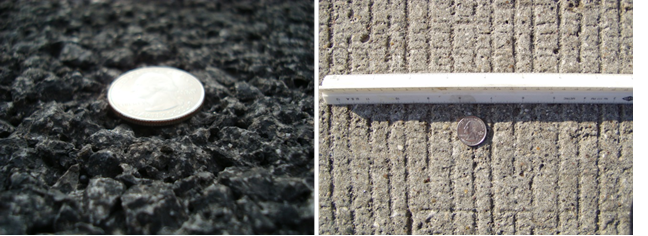

Macrotexture-Macrotexture is a larger-scale, visible roughness component of pavement texture formed by the size and shape of the aggregate particles themselves, the porosity of the pavement surface, or from texture imparted to the pavement surface from grooving, tining, etc. (figure 4). The primary function of macrotexture is to provide a path for bulk water drainage from beneath the tire so that the adhesive component of friction provided by microtexture is reestablished.(3) However, macrotexture also affects the hysteresis component of friction because macrotexture causes the deformation of the tire rubber. As such, macrotexture has a significant effect on friction at higher speeds.

Source: The Transtec Group, Inc.

Figure 4. Photo. Macrotexture for an asphalt pavement surface (left) and concrete surface from tining (right).

For asphalt pavements and surface treatments, macrotexture is primarily controlled by aggregate properties (size, shape, gradation) as well as the porosity of the finished surface. For concrete pavements, macrotexture is primarily controlled by the finish or texture imparted to the surface (carpet/turf drag, tining, diamond grinding, grooving, etc.).

Pavement texture is typically quantified in terms of macrotexture depth, reported as either mean texture depth, measured using volumetric techniques such as ASTM E 965, or mean profile depth, measured using laser-based devices and quantified according to ASTM E 1845.(5,6) Chapter 2 discusses some previous studies that have examined the relationship between macrotexture depth and crash rates, and chapter 3 presents some typical macrotexture depths for the various treatments considered under this effort.

As discussed above, properties of pavement surface treatments have a direct impact on texture, friction, and ultimately safety. As such, selection of the materials used in a pavement or surface treatment is a critical aspect of pavement design and treatment selection. Constituent materials and mixture designs must provide the necessary microtexture and macrotexture components to ensure good friction.

Materials must also be durable, however, if pavement friction is to be sustained over time. Pavements, by their very nature, are completely exposed to weather and are subjected to potentially millions of wheel passes over their lifespan. The repeated application of wheel loads tends to wear down or wear away paving materials. Weather, likewise, can slowly wear away pavement surfaces through oxidation, erosion, or freeze-thaw related deterioration. There must be a balance between providing the necessary friction characteristics and providing a durable, long-lasting surface, while not ignoring the importance of cost.

Although not explicitly considered a pavement surface characteristic, drainage is a critical factor in pavement safety. Even the most aggressive (high-friction) pavement surface can be rendered ineffective if water does not drain from the pavement surface. While the porosity of a surface or drainage "channels" (e.g., tining or grooving) imparted to the pavement surface can aid with channeling water from beneath a tire, pavement cross-slope is a key component of drainage and may need to be addressed first for any low-cost surface treatment to be effective. (Note: Because of a lack of cross-slope information on the pavement surfaces analyzed in this study, the effect of inadequate cross-slope could not be accounted for.)

In 1997, the AASHTO Standing Committee on Highway Traffic Safety, with the assistance of the FHWA, the National Highway Traffic Safety Administration, and the Transportation Research Board Committee on Transportation Safety Management, met with safety experts in the field of driver, vehicle, and highway issues from various organizations to develop a strategic plan for highway safety. These participants developed 22 key areas that affect highway safety. The NCHRP published a series of guides to advance the implementation of countermeasures targeted to reduce crashes and injuries. Each guide addresses 1 of the 22 emphasis areas and includes an introduction to the problem, a list of objectives for improving safety in that emphasis area, and strategies for each objective. Each strategy is designated as proven, tried, or experimental. Many of the strategies discussed in these guides have not been rigorously evaluated; about 80 percent of the strategies are considered tried or experimental.

FHWA organized the ELCSI-PFS, consisting of 38 volunteer States, to evaluate low-cost safety strategies identified by the NCHRP Report 500 guides under this strategic highway safety effort. The intent of the work conducted under the various phases of the ELCSI-PFS is to provide a CMF and BC economic analysis for each of the targeted safety strategies identified as priorities by the PFS States.

NCHRP Report 500 Volumes 6 and 7 address pavement surfaces. Volume 6, which addresses reducing ROR crashes, presents Strategy 15.1 A7 "Skid-Resistant Pavements" as a key to reducing ROR crashes.(7) Volume 7, which addresses reducing collisions on horizontal curves, likewise discusses Strategy 15.2 A7 "Provide Skid-Resistant Pavement Surfaces" as a key strategy for reducing crashes at horizontal curves.(8) The report recognizes that there had been only limited research on site-specific treatments as of 2003. However, given the results of other research on general effectiveness of decreased skidding, the report places this strategy in the "proven" category. The report also recognizes that the effectiveness of high-friction treatments will diminish over time; therefore, States using this strategy must conduct a dynamic program to target the appropriate sites for new treatment and to maintain the safety benefit from existing treatments.

In a similar manner, the FHWA Low-Cost Treatments for Horizontal Curve Safety guide recommends "skid-resistive pavement surface treatments" as a low-cost treatment for reducing crashes at horizontal curves.(9) This guide specifically discusses remedial treatments such as asphalt overlays, surface treatments, grinding, and grooving of pavement surfaces for both concrete and asphalt pavements where friction demand is higher.

Shrinking State highway agency budgets for construction and rehabilitation is one reason for an emphasis on low-cost treatments. Another reason is that although rural roads account for the majority of highway crashes when quantified in terms of vehicle mi traveled, rural roads are often lower priority when it comes to funding rehabilitation or improvements. This was verified by a Government Accountability Office study that found that the large number of rural roads carry relatively low volumes of traffic, often making it difficult to justify the costs of improvements to these roads. Many rural roads also fall under the jurisdiction of local government entities, which do not have the resources to undertake significant projects to increase rural road safety.(10)

The goal of the Phase VI study was to isolate the effects of various low-cost pavement treatments on roadway safety, since the pavement itself plays a major role in highway safety. This unique study sought to identify any potential differences in safety performance for various types of pavement treatments because this has not been carefully examined in previous research.

The Phase VI study was a retrospective study of pavement safety performance, looking back at crash data before and after treatments were installed. No test sections were constructed explicitly for this study. Crash data were analyzed to evaluate the effectiveness of low-cost pavement improvement strategies using the EB before-after study methodology for the most part. Both flexible and rigid pavement treatment were analyzed, and CMFs for each type of pavement improvement were developed. BC ratios were developed for those applications for which there were statistically significant overall crash reduction benefits.

Although the definition of a low-cost pavement treatment is not clear in terms of a ceiling on the cost per lane-mi or cost per square yd, in general, these are treatments applied to existing pavement surfaces without substantially changing the pavement structure. These are treatments that will generally change the pavement surface characteristics, but do not necessarily add structural capacity to the pavement. Therefore, full-depth pavement reconstruction and projects that serve to realign or substantially alter the pavement cross-section (e.g., superelevation) were excluded from consideration.

The majority of the treatments considered in this effort are typically used for pavement preservation or minor rehabilitation purposes. Although State highway agencies recognize that most of these treatments generally improve pavement friction, they are not typically installed explicitly for safety improvement, with certain exceptions that are discussed below. These are also primarily treatments that are used for long stretches of pavement preservation/rehabilitation, with the exception of HFS, which is typically used solely for spot safety treatments.

The ultimate outcome of the Phase VI effort is a better understanding of the effects that various common, low-cost pavement treatments have on roadway safety. Two of the more tangible ways this is quantified is through CMFs and BC ratios for each treatment type. These products will potentially help State transportation departments in the decisionmaking process for selection of a pavement treatment for a particular project.