U.S. Department of Transportation

Federal Highway Administration

1200 New Jersey Avenue, SE

Washington, DC 20590

202-366-4000

Federal Highway Administration Research and Technology

Coordinating, Developing, and Delivering Highway Transportation Innovations

|

R&T NOW This newsletter is an archived publication and may contain dated technical, contact, and link information. |

|

| Publication Number: Date: May/June 2019 |

Publication Date: May/June 2019

|

PDF files can be viewed with the Acrobat® Reader®

In this issue…

On May 2, 2019, U.S. Transportation Secretary Elaine L. Chao swore in Nicole R. Nason as the 20th Administrator of USDOT’s FHWA.

Administrator Nason has served as Assistant Secretary of the Bureau of Administration at the U.S. Department of State since June 2017. She served as Administrator of USDOT’s National Highway Traffic Safety Administration from 2006 to 2008, and was USDOT’s Assistant Secretary for Government Affairs from 2003 to 2006.

“Working with our many State and local partners,” Nason said in her speech after her swearing in, “I look forward to leading the FHWA and to developing a strong, safe, and modern transportation network that meets the needs of our 21st-century Nation.”

Source: USDOT

U.S. Secretary of Transportation Elaine L. Chao swears in Nicole R. Nason (far left) as Administrator for the Federal Highway Administration. Nason’s husband, David, and children, Abby, Alex, and Brady, are in attendance.

The Federal Highway Administration’s EAR Program funded a research project titled “Novel Alternative Cementitious Materials (ACMs) for Development of the Next Generation of Sustainable Transportation Infrastructure.” The goal of the project was to facilitate infrastructure construction and rehabilitation using concrete made with ACMs instead of portland cement by developing a greater understanding of the scalability, long-term performance and durability in a range of environments, and structural response under transportation-relevant loading conditions of ACMs.

Source: FHWA

A slump test performed on freshly mixed concrete made with magnesium phosphate (top) and calcium aluminate (bottom) cements, two of the cements the researchers tested as potential alternatives to portland cement in concrete construction.

The initial research demonstrated a growing interest in using ACMs for large-scale transportation projects, particularly in large urban areas that benefit from the rapid setting characteristics and early strength of the materials. In the first phase of the study, researchers from the Georgia Institute of Technology, in partnership with Oklahoma State University, Tourney Consulting, and the U.S. Army Corps of Engineers, used ordinary portland cement as a control measure and tested nine commercially available ACMs. From those nine, the team identified five ACMs for further testing: two calcium sulfoaluminate cements, two calcium aluminate cements, and a chemically activated Class C fly ash.

During the project’s second phase, the researchers gauged how the materials withstood various external and internal threats to concrete, such as physical abrasion and freezing and thawing.

In the third phase of the project, the researchers conducted additional corrosion tests, extended lab tests, long-term field exposure studies, and forensic analysis of samples obtained from ACM pavements that had been in service for an extended period.

For more information, download the fact sheet or contact Richard Meininger at 202–493–3191, Richard.Meininger@dot.gov.

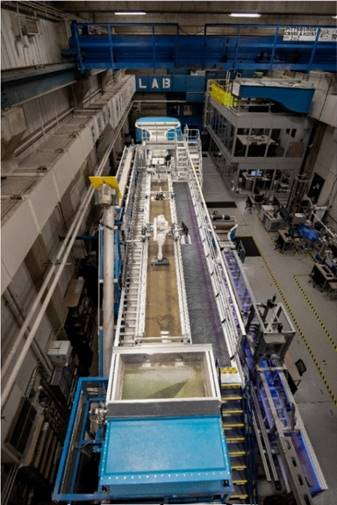

The U.S. Army Corps of Engineers’ Engineer Research and Development Center (ERDC) visited the J. Sterling Jones Hydraulics Research Laboratory on May 7, 2019, to see a demonstration of the laboratory’s Multifunctional Flume System (MFS) and to discuss the design of the new ERDC Coastal and Hydraulics Laboratory (CHL) flume. The J. Sterling Jones Hydraulics Research Laboratory (Hydraulics Laboratory) at FHWA’s Turner-Fairbank Highway Research Center (TFHRC) is providing technical assistance for the design of the new flume.

Source: FHWA

Overhead shot of the MFS in TFHRC’s Hydraulics Laboratory.

The Hydraulics Laboratory will provide computational fluid dynamics (CFD) assistance to design the headworks of the new CHL flume. Argonne National Laboratory’s Transportation Research and Analysis Computing Center will conduct the CFD work. All specifications of the MFS, including screw jack design for tilting the MFS, will be provided. The labs will communicate through regular video conferences to track the status of the project.

The ERDC and CHL are conducting a series of experiments on floating bridges. The new design of the CHL flume will be based on TFHRC’s MFS, which was designed in 2014 and began operation in fall 2015.

The proposed ERDC CHL flume will have a flow cross-section that is 40 percent larger than the MFS. The biggest challenge when designing the new CHL flume is the design of the flume headworks or inlet flow accelerator. The challenge is because of the size; it gets more difficult to control the flow of the flume as the flume gets larger. The flow accelerator is needed to generate uniform flow conditions to ensure experiments are repeatable. The team will use CFD modeling to optimize the flow accelerator for the desired flow conditions in the CHL flume.

For more information, contact Kornel Kerenyi, 202–493–3142, Kornel.Kerenyi@dot.gov.

The FHWA hosted a webinar on April 30, 2019, focused on the application of Nondestructive Testing (NDT) for condition assessment of concrete bridge decks. The webinar provided an overview of the study conducted under the second Strategic Highway Research Program (SHRP2) titled “Nondestructive Testing to Identify Concrete Bridge Deck Deterioration (R06A).” The webinar presented and discussed how Oregon, Indiana, and New Mexico State departments of transportation have used NDT technologies, how the NDT technology benefits the States, and how to move forward to enhance the technology implementation.

The agenda consisted of four parts:

Each State DOT presented its experiences using NDT methods. State DOT representatives also discussed results and compared them to traditional evaluation methods, such as hammer sounding, chain drag, and visual inspection.

The webinar concluded that States’ experiences with NDT vary greatly; some NDE methods have worked well in some States while similar methods were less effective in other States when identifying bridge deck deterioration. This is primarily due to differences in geographical areas, bridge deck construction, and structural details. Participants agreed that there is no single “silver bullet” in terms of NDT testing that could work for all States in all situations.

For more information, contact Hoda Azari, 202–493–3064, Hoda.Azari@dot.gov.

Engineers from FHWA’s TFHRC successfully completed validation testing of new automated research vehicles at AutonomouStuff, a company that supplies autonomy-enabling technologies and services, during the week of April 22 to 26, 2019, in Morton, IL. The vehicles tested are part of FHWA’s Cooperative Automation Research Mobility Applications (CARMA) platform.

The TFHRC team conducted a series of validation and acceptance tests on the vehicles from AutonomouStuff to ensure that the vehicles met FHWA’s requirements. Testing consisted of safety, hardware, and software verification to confirm that requested specifications met TFHRC’s needs.

Prior to the testing, engineers developed an extensive test plan. Hardware testing consisted of verifying the functionality of the radar, LiDAR [Light Detection and Ranging], and camera sensors. The engineers completed static and dynamic testing of sensor functionality. The software testing ensured that the automated driving system software and sensor fusion applications worked properly. CARMA software developers will implement the CARMA platform and plugins to enable the research vehicles to perform cooperative automation maneuvers at level 2 and level 3 automation. Level 2 automation involves more than one automated feature in the vehicle. Level 3 automation means that the driving features are automated enough that the driver can perform other tasks.

The CARMA software platform is open source to enable collaboration with industry, academia, infrastructure owner operators (IOOs), and other public agencies on cooperative automation applications. Developed on a Robot Operating System, a flexible framework for writing software, CARMA has an innovative approach to collaboration for automated vehicle development. Early work by FHWA indicates that cooperative automation can safely improve the efficiency of the road network while reducing fuel consumption.

Beginning in late summer 2019, the CARMA research team will test the extended capabilities of the vehicles. By spring 2020, the team will test and evaluate proof-of-concept level applications that address transportation system management and operations (TSMO) use cases. The Human Factors research team at TFHRC will also use the vehicles to assess driver behavior under level 2 and level 3 automation. The vehicles tested were the first two in CARMA’s fleet. Over the next several months, AutonomouStuff will build two more light vehicles and four tractor trailers, at which point a new round of testing will commence.

Source: FHWA

The three vehicles equipped with the CARMA platform and logo.

For more information on CARMA, contact Taylor Lochrane, 202–493–3293, Taylor.Lochrane@dot.gov.

The FHWA developed the innovative CARMA platform to encourage collaboration between researchers with the goal of improving transportation efficiency and safety. FHWA seeks to advance TSMO strategies with cooperative automated driving technology focused on how vehicles communicate with other vehicles, infrastructure, and roadways to improve roadway capacity, reduce traffic, and increase driver and pedestrian safety.

The third phase of CARMA (CARMA3) will be available on GitHub in mid-July, marking a step forward in the technology and functionality available on the platform. As development continues, cooperative automation stakeholders will have more tools available at their disposal through CARMA.

CARMA3 will feature:

Additional features will be available later this year as CARMA3 moves past the beta version.

For more information, contact Taylor Lochrane, 202–493–3293, Taylor.Lochrane@dot.gov, or visit https://highways.dot.gov/research/research-programs/operations/CARMA.

The Geometric Design Laboratory (GDL) team at the Federal Highway Administration’s TFHRC is assisting Washington State Department of Transportation (WSDOT) with performing a safety analysis on a portion of the I–5 freeway in Bellingham, WA. The study, which applies the Highway Safety Manual Part C crash prediction methods, examines existing conditions along a four-mile section of the freeway, including mainline freeway segments and ramps at five interchanges.

The GDL uses data provided by WSDOT to build and evaluate highway models using the Interactive Highway Safety Design Model (IHSDM). WSDOT collected the required data (e.g., curve data; cross-sections of lanes, shoulders, and medians; median and barriers; traffic volumes; crash data) with technical support from the GDL. The GDL then used WSDOT’s data to build highway models in IHSDM for the I–5 freeway section and interchanges. The goal of the IHSDM analysis is to provide input to WSDOT for evaluating the safety of the existing I–5 corridor, and potentially for developing future design alternatives.

WSDOT chose this portion of I–5 after performing a qualitative collision analysis of the surrounding corridor. The WSDOT planning team recognizes that issues on I–5 are interconnected with the surrounding State route and local road network.

To examine the results of the analysis, the GDL team conducted a webinar on May 15, 2019, with key WSDOT staff. WSDOT will use the results of the safety analysis to determine if there are any safety issues that warrant further investigation. The results will help WSDOT evaluate how the subject location is performing in comparison with other stretches of similar freeways.

WSDOT envisions that the study could serve as a pilot to demonstrate the usefulness of the IHSDM safety analysis tool. Additionally, other States can learn from the process used to perform the safety analysis and the research conducted by WSDOT. The results could also be used to identify potential safety countermeasures and to develop alternative designs. The GDL could assist WSDOT in conducting a safety analysis of any future proposed alternative designs.

For more information, contact Abdul Zineddin, 202–493–3288, Abdul.Zineddin@dot.gov.

Wei Zhang, Highway Research Engineer at FHWA’s TFHRC, conducted a technical presentation on Northern Virginia’s first Diverging Diamond Interchange (DDI) on May 29, 2019. This presentation examined the experience gained by using aerial survey to collect various types of traffic data, and discussed the improvements observed in traffic operation and safety after the DDI opening.

The double bridge DDI configuration has become a popular option in DDI design for its ease of creating the desired crossing angle and for making the entire interchange more aesthetically appealing.

The DDI at I–66 and Route 15 in Haymarket, VA, is a $59 million design–build project that began in September 2015. The new interchange was completed in August 2017. According to the Virginia Department of Transportation (VDOT), the interchange serves approximately 95,000 vehicles per day, of which 60,000 continue to travel on I–66 and 35,000 continue to Route 15.(1) The interchange has two overpass bridges, and one 10-ft shared pedestrian and bicyclist path on the east side of Route 15.

The interchange on Route 15 and I–66 was a major bottleneck, and a train crossing located just two blocks to the southwest on Route 15 made it worse. FHWA collaborated with VDOT, Northern Virginia District, to perform before-and-after evaluations of this DDI using helicopter and drone-based aerial surveys to collect traffic data from before the DDI was constructed to after its construction. Before the DDI, there were 79 annual crashes from 2012 to 2014. After the new interchange, annual crashes in 2018 dropped to 44.

Source: FHWA

The DDI in Northern Virginia at Route 15 (elevated section) and I–66 (nonelevated).

(1) Virginia Department of Transportation, VDOT News – Northern Virginia. August 22, 2017. Available at https://www.virginiadot.org/newsroom/northern_virginia/2017/i-66-route_15_diverging-diamond_interchange118753.asp.

Source: FHWA

The diamond interchange before construction.

For more information, contact Wei Zhang, 202–493–3317, Wei.Zhang@dot.gov.

The FHWA Small Business Innovation Research (SBIR) program is a competitive multiphased program that encourages domestic small businesses to engage in Federal research and development with the potential for commercialization.

Phase I awards go to small businesses to determine the technical and scientific merit and feasibility of a proposed research idea. A panel of experts decides whether to grant a Phase II award to develop the idea further, which in most cases involves creating a working prototype of the proposed product. Additional Phase II funding (known as Phase IIB) is available if needs exist that will advance the proposed product toward commercialization.

It can be difficult, however, to assess the status of a given technology without a thorough review.

To address this challenge, FHWA instituted a pilot program to assess the Technology Readiness Level (TRL) for each completed Phase II project. The National Aeronautics and Space Administration developed the TRL process, which consists of a 1–9 scale. One equates to basic research and nine equates to a fully deployable product.

Five FHWA SBIR Phase II projects completed a TRL assessment within the last year under this pilot program.

For each project, representatives from the small business presented information to a panel of experts, followed by a question-and-answer session. The panel holds a closed-door session to arrive at a TRL level for the technology and reports its findings to the small business. In all cases, both FHWA and the small business find this assessment to be very informative and helpful. It helps FHWA understand how further investment would advance its goals and it provides the small business with an independent assessment of its technology.

FHWA plans to make the TRL assessment process a permanent fixture within the SBIR program, and wants to help other modes within the United States Department of Transportation and FHWA implement similar assessments.

For more information, contact Craig Thor, 202–493–3338, Craig.Thor@dot.gov.

Articles include: Virtual Public Involvement; Project Bundling; Agencies Streamline Environmental and Permitting Reviews to Deliver Projects Faster; Success Stories: Every Day Counts Advances FHWA Strategic Plan; Rhode Island Goes Digital for Interchange Projects; States Innovate!; Explore How States Innovate.

The issue is available online.

Please forward this newsletter to others you think might find it interesting and/or useful.

Suggestions may be submitted to FHWA_Now@fhwa.dot.gov.

FHWA R&T Now is a newsletter containing information and updates about research, technology, and development from the U.S. Department of Transportation, Federal Highway Administration. The newsletter is an electronic newsletter and is updated approximately every other month.

Send your comments, questions, and feedback to FHWA_Now@dot.gov.

Online access:

https://www.fhwa.dot.gov/publications/rtnow/.

Mail:

Federal Highway Administration

FHWA Office of Research, Development, and Technology

Attention: R&T Now Managing Editor

6300 Georgetown Pike

McLean, VA 22101

| ACMs | Alternative Cementitious Materials |

| CARMA | Cooperative Automation Research Mobility Applications |

| CHL | Coastal and Hydraulics Laboratory |

| CFD | Computational Fluid Dynamics |

| DDI | Diverging Diamond Interchange |

| EAR | Exploratory Advanced Research |

| ERDC | Engineer Research and Development Center |

| FHWA | Federal Highway Administration |

| GDL | Geometric Design Laboratory |

| IOOs | Infrastructure Owner Operators |

| IHSDM | Interactive Highway Safety Design Model |

| LiDAR | Light Detection and Ranging |

| MFS | Multifunctional Flume System |

| NDE | Nondestructive Evaluation |

| NDT | Nondestructive Testing |

| SHRP2 | Second Strategic Highway Research Program |

| SBIR | Small Business Innovation Research |

| TRL | Technology Readiness Level |

| TSMO | Transportation System Management and Operations |

| TFHRC | Turner-Fairbank Highway Research Center |

| USDOT | U.S. Department of Transportation |

| VDOT | Virginia Department of Transportation |

| WSDOT | Washington State Department of Transportation |

Distribution–FHWA R&T Now is being distributed according to a standard distribution. Direct distribution is being made to the FHWA Divisions and Resource Center.

Key Words–LTPP, concrete, bridges, freeways, interchanges, intersections, safety, infrastructure, operations, hydraulics, nondestructive technology, research.

Notice–This document is disseminated under the sponsorship of the U.S. Department of Transportation in the interest of information exchange. The U.S. Government assumes no liability for the use of the information contained in this document. The U.S. Government does not endorse products or manufacturers. Trademarks or manufacturers’ names appear in this document only because they are considered essential to the objective of the document.