U.S. Department of Transportation

Federal Highway Administration

1200 New Jersey Avenue, SE

Washington, DC 20590

202-366-4000

Federal Highway Administration Research and Technology

Coordinating, Developing, and Delivering Highway Transportation Innovations

|

Research & Technology Transporter This newsletter is an archived publication and may contain dated technical, contact, and link information. |

|

| Publication Number: N/A Date: April 2004 |

Publication Date: April 2004

|

In a time of rapidly evolving technologies, many bridge engineers and other professionals responsible for bridge design and construction can find it challenging to keep up to date on the newest materials and methods of design and construction. To help improve communication and collaboration between the Federal Highway Administration (FHWA) and the concrete bridge industry, FHWA and the National Concrete Bridge Council (NCBC) recently held their annual meeting. The meeting, convened at the Turner-Fairbank Highway Research Center in McLean, VA, provided FHWA and NCBC with a forum for sharing information and identifying opportunities to support and advance concrete bridge technology.

At the meeting, the two parties discussed the status of activities such as the Innovative Bridge Research and Construction (IBRC) Program, ultra-high performance concrete research and projects, implementation of specifications for load and resistance factor design, accelerated bridge construction technologies, and legislation and funding for various bridge projects across the country.

In particular, the two groups have promoted several projects in FHWA’s IBRC Program, which provides direction and funding to help State, county, and local bridge owners incorporate innovative materials and technologies in their bridge projects. The two groups currently are working together to complete several other projects. The meeting enabled both FHWA and NCBC to present information about the IBRC Program and other important issues to a wide range of interested individuals.

The two groups outlined several projects with potential for joint action, including developing uniform guidelines for achieving a 100-year service life for new concrete bridges. Another opportunity is development of uniform guidelines for performing life cycle cost analyses—economic analyses for quantifying the differential costs of alternative investment options for a given project. In addition, meeting participants discussed cooperatively supporting various industry certification programs for bridge materials, plants, inspectors, and construction personnel. In the future, the groups also will jointly sponsor workshops on prefabricated bridges.

Although FHWA does not provide formal funding or guidance to NCBC and its associated groups, it does promote some of NCBC’s programs and proposals. FHWA has, in the past, entered into cooperative agreements with NCBC and individual member organizations for specified services, such as arranging for professional conferences, publishing informational literature relative to concrete bridge issues, and providing training in selected subject areas. At the most recent meeting, NCBC representatives asked FHWA to keep them updated on new State and local conferences on bridge construction and design.

Participants at the meeting included representatives of several of the 11 industry associations that make up NCBC and representatives from FHWA’s Offices of Pavement and Bridge Technology and the Office of Infrastructure Research Development and Technology. At the first meeting between FHWA and NCBC, which occurred in 1987, representatives from both organizations concluded that an annual meeting would be a constructive forum for continuing dialogue between the two groups and for developing and promoting concrete bridge technology. “We want to explore problems and solutions, and then plan ahead for activities that will most effectively deploy the newest technological innovations for concrete bridges,” says Myint Lwin, director of the FHWA’s Office of Bridge Technology.

Jerry Potter

|

| Participants at the recent annual meeting between FHWA and the National Concrete Bridge Council learned about new programs and technologies to improve concrete bridges, such as this one in Houston, TX. |

Each year, State and local road agencies across the country install box culverts— structures that look like boxes with open ends—to pass drainage under roadways. The design coefficients that computer programs use to size the culverts, however, are based on research from the 1950s and 1960s, which did not include information about many of the end sections commonly used today. In particular, today’s design coefficients do not reflect the advantages that might be gained by using edge treatments, which can readily be built into forms for precast culverts. As a result, highway agencies may be building box culverts that are larger and more expensive than necessary.

To help solve this problem, the Federal Highway Administration (FHWA) and the South Dakota Department of Transportation (SDDOT) are partnering on a project to investigate a number of design issues for box culverts. Researchers at FHWA are conducting a series of tests on models of box culverts in the Hydraulics Laboratory at FHWA’s Turner-Fairbank Highway Research Center in McLean, VA. Designers and researchers from SDDOT and representatives from the precast concrete industry are observing and evaluating the tests. Together, the research team will develop recommendations for updating the design manual and analysis programs used to design culverts.

In the first task of the study, the research team tested several sidewall edge configurations to streamline the flow of water into the culvert. To compare these configurations, researchers used particle image velocimetry, which involves using a focused light source, a high-resolution digital camera, and sophisticated computer logic to trace the movement of water particles and quantify flow patterns. Several bevel and radius edges were tested.

Researchers are conducting additional tests in a special culvert test facility, which features a headbox, tailbox, and culvert model made of Plexiglas® to facilitate flow visualization; programmable pump controls to precisely test a repeatable series of flow conditions for each model; and automated data collection and analysis. The culvert models are approximately one-twelfth the size of a typical culvert installation. Tests to be performed include comparing the performance of culverts with traditional edge bevels to culverts with the optimum edge treatments, determining the effects of corner fillets, and investigating skewed alignments.

The researchers also are trying to resolve several issues related to multiple barrel culverts—two or more box culverts lined up side-by-side. First, the researchers are trying to determine whether performance outcomes from multiple barrel culverts are the same as performance outcomes from single barrel culverts multiplied by the number of barrels. Current computer programs that engineers use to determine the size of box culverts, such as FHWA’s HY8 software program, are based on this idea. In addition, researchers want to know whether culverts will perform better if center walls are extended onto the approach section apron compared to the standard practice of cutting them off at the headwall. Under certain circumstances, box culverts must be installed at an angle other than 90 degrees (perpendicular) to the roadway. Tests will show the effects of skew, or the angle at which the culvert system is installed, on flow capacity. These tests, which involve skewing to the roadway, are not to be confused with the idea of skewing the culvert alignment to the general alignment of the stream, which is bad practice and discouraged.

FHWA and SDDOT expect to complete the tests by summer 2004. In addition to cost savings and more accurate coefficients, the tests will increase safety and improve service reliability and design procedures.

Sterling Jones

Ron McMahon 605–224–7326, ext. 3047 ron.mcmahon@fhwa.dot.gov

|

| A representative from the South Dakota Department of Transportation stands inside one of the barrels in a 2-barrel box culvert. Each barrel is 2.7 meters by 2.7 meters (9 feet by 9 feet). |

The National Highway System (NHS) carries 43 percent of the vehicle miles traveled in the United States. Given that the NHS is an essential part of the U.S. transportation infrastructure, transportation agencies need to work diligently to keep it in the best possible condition. By improving pavement conditions along the NHS, transportation agencies help not only to relieve congestion and increase driver safety, but also to improve the Nation’s economy and mobility. Learning about the latest advances in pavement materials and maintenance is essential to keeping the NHS in top working order.

Pavement and materials engineers from the Federal Highway Administration (FHWA) recently discussed developments in pavements engineering at the Fourth Annual Pavement/Materials Workshop. The workshop addressed topics such as pavement smoothness, friction, texturing, and tire and pavement noise.

FHWA Deputy Administrator J. Richard Capka, for example, discussed the importance of pavement smoothness and how smoothness can have a major effect on the traveling public. Research has shown a link between smoother roads and increased pavement life, improved gas mileage, and reduced vehicle maintenance. Capka also explained that the public’s satisfaction with a roadway is linked to the quality of the pavement.

In addition, Capka discussed the Highways for LIFE concept, which offers an integrated approach to highway construction that works toward three strategic goals—improved safety, reduced construction-related congestion, and improved roadway quality. The deputy administrator explained that Highways for LIFE would promote longer-lasting pavements and bridges that take less time to build.

Other speakers included international and national transportation experts. Steve Karamihas from the University of Michigan Transportation Research Institute discussed his research on the use of dynamic loading and pavement response to predict the effect of trucks on pavement life. His 2-year study examined the effect of road roughness on ride quality, driver perception of pavement performance, and human response to vehicle vibration. The results of the research showed that road roughness decreases pavement life, diminishes ride quality, and increases fuel consumption and vehicle and cargo damage.

Workshop attendees also participated in a demonstration of the Pavement Profile Viewer and Analyzer (ProVAL). ProVAL is a computerized system developed for FHWA and other transportation agencies to assist with pavement rehabilitation and improve the quality of construction. Transportation agencies can use ProVAL to import, display, and analyze the characteristics of pavement profiles using information from several sources and complex filters, such as Butterworth bandpass filters. By employing ProVAL, transportation agencies also can perform American Society for Testing and Materials (ASTM) E 950 precision and bias tests and cross-correlations to find recurring patterns in pavement profiles.

FHWA’s Office of Pavement Technology and Office of Infrastructure Research and Development hosted the 3-day workshop, which attracted 70 participants from FHWA’s division offices, the Federal Lands Highway Division, and Turner-Fairbank Highway Research Center.

The Fifth Annual Pavement/Materials and Testing Workshop is scheduled tentatively for December 7–9, 2004. For more information, contact:

Gene Clark 202–266–4597 gene.clark@fhwa.dot.gov

Gone are the days when concrete was made from a simple mixture of water, cement, sand, and gravel. Today, concrete often contains several additional ingredients that are specially formulated to meet certain performance objectives, such as high strength, resistance to chloride penetration, or flowability. With more ingredients to choose from and more complex requirements to meet, it can be difficult to determine the optimal proportions that will produce concrete that meets these objectives.

To help concrete producers and materials engineers create “customized” concrete more efficiently, the Federal Highway Administration (FHWA), with the assistance of the National Institute of Standards and Technology (NIST), embarked on a research project to investigate the feasibility of using statistical experiment design and analysis methods to optimize concrete mixture proportions. The final report from the project, Concrete Mixture Optimization Using Statistical Methods (FHWA-RD 03-060), is available on the Internet at www.fhwa.dot.gov/publications/research/infrastructure/pavements/03060/. As part of the project, FHWA and NIST developed an Internet-based software program that illustrates the use of statistical methods to optimize concrete mixtures. Available at http://ciks.cbt.nist.gov/cost/, the Concrete Optimization Software Tool (COST) uses a six-step interactive procedure to help the user determine the proportions needed to meet specific performance objectives.

To run the software, users start by entering the desired performance criteria for the project. Users also input the factors or mixture components that need to be varied and the properties of the materials they will be using in the concrete, such as specific gravities and absorption rates. After these steps are complete, COST generates an experimental plan, which users then apply to fabricate trial batches of concrete. Next, users record performance data for the trial batches and enter the data into COST. The user then can analyze the data using a number of different tools and generate a report showing optimal mixture proportions.

FHWA has implemented a procedure similar to the one used in COST in its HIPERPAV software. FHWA also has a new project underway, entitled “Computer-Based Guidelines for Job-Specific Optimization of Paving Concrete,” in which the developers will incorporate the statistical methods used in COST. The computer-based guidelines will provide a comprehensive approach to concrete mixture optimization in a user-friendly format running under the Microsoft® Windows® operating system. The new application will allow users to determine the type of concrete mixture they will need based on the structural design, environmental conditions, construction requirements, and available materials that are specific to their project. FHWA anticipates that a prototype of the new system will be ready for trials in spring 2005.

Marcia Simon

Accurately predicting performance and durability is critical to improving the design of new and existing pavements. Poor performance increases traffic congestion, compromises public safety, and raises maintenance costs due to frequent repairs. During the past 50 years, pavement design engineers have used data obtained from observations and scientific experiments to improve design and construction methodologies. Today, engineers increasingly require tools that integrate scientific data with information about the real-time effects of traffic loadings, weather conditions, and roadway engineering materials.

To help meet this need, the National Cooperative Highway Research Program (NCHRP) developed a new pavement design and analysis tool, The Mechanistic-Empirical Design Guide for New and Rehabilitated Pavement Structures, which is scheduled for release to State highway agencies in spring 2004. The guide employs data based on mechanistic-empirical approaches, which present a more realistic characterization of in-service pavements. It provides uniform guidelines for designing the in-common features of flexible, rigid, and composite pavements. By using these approaches, engineers can create more reliable pavement designs.

The guide also offers procedures for evaluating existing pavements and recommendations for rehabilitation treatments, subdrainage, and foundation improvements. In addition, the guide incorporates procedures for performing traffic analyses, includes options for calibrating the tool according to local conditions, and incorporates measures for design reliability. Engineers can use the guide to analyze common causes of pavement distress, including fatigue, rutting, and thermal cracking in asphalt pavements, and cracking and faulting in concrete pavements. In addition to the guide document, a software program is available that enables users to navigate the multiple inputs and monitor the analysis computations. The program is bundled with another stand-alone software tool that will enable users to conduct studies of life cycle costs and can help in making decisions about pavement structures.

The Federal Highway Administration (FHWA) has organized the Design Guide Implementation Team (DGIT) to inform FHWA division offices, State highway agencies, industry members, and other organizations and experts about the guide and to help potential users prepare for it. To introduce the guide and discuss implementation issues, the DGIT will present seven 1-day workshops across the Nation. Starting on May 25, 2004, the DGIT will conduct workshops in Biloxi, MS; Vancouver, WA (June); Indianapolis, IN (July); Hawaii (July); Mystic, CT (August); Kansas City, KS (September); and Phoenix, AZ (October).

FHWA plans to develop additional State and regional workshops, training courses, and other educational resources over the next few years, as needed. As State agencies begin to implement the guide, DGIT will arrange small working sessions to address local technical issues such as calibration, new materials, and unique load configurations.

For more information about DGIT and the workshops or to download a flyer on new pavement design and construction methodologies, visit www.fhwa.dot.gov/pavement/dgit.htm, send a message to dgit@fhwa.dot.gov, or contact:

Leslie Myers 202–366–1198 leslie.myers@fhwa.dot.gov

Katherine Petros 202–493–3154 katherine.petros@fhwa.dot.gov

Monte Symons 404–562–4782 monte.symons@fhwa.dot.gov

Sam Tyson 202–366–1326 sam.tyson@fhwa.dot.gov

|

| This screenshot shows one of the input screens from the software tool included with FHWA’s new design guide for pavement structures. |

When significant or widespread interest is shown in solving transportation-related problems, several Federal, State, regional, or local transportation agencies, academic institutions, foundations, or private firms can jointly fund research, planning, and technology transfer activities as a pooled fund study. Through the Federal Highway Administration (FHWA), these organizations can combine their resources to support research that addresses the safety, efficiency, and operational needs of the Nation’s roadways through the Transportation Pooled Fund (TPF) Program.

To find out about opportunities within the TPF Program, transportation professionals can visit the TPF Web site at www.pooledfund.org. The site provides a central location where program participants can browse ongoing projects, post new project solicitations, and sign up to receive e-mails about the new solicitations. Over the past year, FHWA, with financial support from the National Cooperative Highway Research Program Project 20-39(2), has updated the TPF site to improve access to the pooled fund program and make it easier for project managers and researchers to participate in studies or exchange information on proposed research.

Over the past year, FHWA has added approximately 20 projects to the pooled fund program. One FHWA-sponsored project will assemble a consortium of local, State, and other organizations to test innovative traffic control devices. So far, this project has attracted funding commitments from 16 States. In another project, the Wisconsin Department of Transportation (DOT) is sponsoring a study to conduct field tests on innovative materials, equipment, and methods that will help improve highway maintenance in winter. The Minnesota DOT is leading a study to develop a better understanding of what causes crashes at rural intersections.

FHWA recently conducted tutorials on the Web site during workshops on the Transportation Pooled Fund Program, at regional meetings of the American Association of State Highway and Transportation Official’s Research Advisory Committee, and at FHWA’s Turner-Fairbank Highway Research Center. Participants learned about the features of the site, which include a password-protected area where authorized users can locate partners interested in supporting their research, commit funds to proposed studies, and post project information.

Comments and suggestions on ways to improve the Web site are welcome and can be made by selecting the “webmaster” link on the Web site. An example of user feedback that resulted in improvement to the site was the addition of a button on the site’s project solicitation page that enables project sponsors to learn quickly how many potential participants have reviewed a proposed project, even if they have chosen not to participate.

Since the site’s launch in December 2002, monthly visits have increased fivefold. The site has become an integral part of the program, especially as project managers have recognized that updating online project information is essential to administering their programs. Already, the site has improved the timeliness of communication about the TPF Program and reduced the need to create and distribute paper documents.

For more information on the TPF Program or to provide feedback on the site, contact:

Lisa Williams 202–493–3376 lisa.williams@fhwa.dot.gov

William Zaccagnino 202–493–3183 william.zaccagnino@fhwa.dot.gov

To maximize research dollars and help prevent duplication of efforts, transportation professionals share the results of their research with colleagues in other fields and from other geographic regions. This enables them to build upon the work of other researchers more efficiently and comprehensively, thereby reducing long-term costs.

In August 2003, the Iowa Department of Transportation, the Center for Transportation Research and Education, Iowa State University, and the Midwest Transportation Consortium sponsored the fourth biennial Mid-Continent Transportation Research Symposium in Ames, IA. The 1.5-day event provided a venue in the Midwest for transportation professionals from across the country to exchange research findings and hear about upcoming projects and initiatives.

Based on this year’s theme, “Practical Solutions to Real Problems,” experts from academia, government, and the private sector delivered more than 90 presentations related to basic and applied transportation research. Dennis Judycki, associate administrator for Research, Development, and Technology at the Federal Highway Administration (FHWA) and director of FHWA’s Turner-Fairbank Highway Research Center, delivered a keynote address.

Judycki discussed FHWA’s research and development plans, as described in the proposed Safe, Accountable, Flexible, and Efficient Transportation Equity Act (SAFETEA), which calls for a 30 percent increase in research and development funding. Judycki also stressed the importance of reinforcing the ties between academia and State departments of transportation. He called attention to FHWA’s continued support of educational programs. Among them are the National Highway Institute, which provides training, resource materials, and educational opportunities to members of the surface transportation community, and the Dwight David Eisenhower Transportation Fellowship Program, which supports post-graduate study and research in transportation.

One of FHWA’s strategic goals is to reduce the number of roadway departure, or run-off-the-road, crashes. Sunanda Dissanayake, assistant professor of transportation engineering at Kansas State University, presented results from new research on young drivers and run-off-the-road crashes. Dissanayake reported that the major factors influencing the severity of injuries to young drivers involved in these kinds of crashes are alcohol or drugs, ejection during the crash, the point of impact, crash location, the existence of a curve or grade in the roadway, and vehicle speed. In addition, the study found that gender—specifically, being male—and the use of restraint devices tend to reduce the severity of roadway departure crashes. Fatigue was not found to be a major factor influencing crash severity, but the research shows that fatigue does likely have an effect on the occurrence of the crash.

Ian Friedland, bridge technology engineer at FHWA’s Office of Bridge Technology and assistant director for transportation research at the National Science Foundation’s Multidisciplinary Center for Earthquake Engineering Research located at the University of Buffalo, discussed FHWA’s bridge research and technology deployment. He explained that FHWA currently is focusing on accelerated repair and construction; bridge and tunnel security; preservation of systems through management, inspection, maintenance, and rehabilitation; and implementation of load and resistance design factors. Friedland also described the future involvement of bridge engineering stakeholders in a formal process of policy and agenda setting, project scoping and merit review, research evaluation, and deployment and implementation.

In addition, researchers from the hydroscience and engineering program at The University of Iowa discussed the “Expert System,” an online database that will feature comprehensive information on highway erosion and sedimentation control measures. Contractors, inspectors, and other users will be able to access the database to help select, design, construct, inspect, and maintain control measures for erosion and sedimentation that fit various roadway construction sites and control objectives. The Expert System was prepared for the Iowa Department of Transportation and will soon be available free of charge on the Internet.

Other topics discussed at the symposium included traffic and safety, seasonal road maintenance, and transportation security. Approximately 300 researchers and practitioners representing the public and private sectors attended the event. The next Mid-Continent Transportation Research Symposium is scheduled for August 2005 at Iowa State University in Ames, IA. For more information, contact:

Jim Brachtel 515–233–7305 jim.brachtel@fhwa.dot.gov

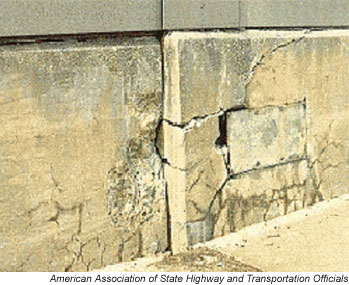

The swelling associated with an alkali-silica reaction (ASR) can cause extensive destruction of concrete. When the alkalis (potassium and sodium) in cement react with the silicate rocks used as aggregates in concrete, gels are formed that can swell and cause cracks, limiting the durability, performance, and lifespan of highways and bridges. Although researchers know that ASR results in the formation of damaging gels, the nature of these gels and reasons for their expansion are not fully understood.

To better understand why and under what circumstances ASR causes swelling, researchers at the Federal Highway Administration’s (FHWA) Turner-Fairbank Highway Research Center (TFHRC) in McLean, VA, have been studying the gels’ chemical characteristics. Information from the studies will help with the development of predictive tools and standard tests for monitoring and preventing ASRs. John Phair, a colloidal chemistry expert from the University of Melbourne in Australia who spent 2 years as a resident associate (postdoctoral fellow) at TFHRC, discussed his research at a recent seminar attended by FHWA scientists and engineers.

In his research at TFHRC, Phair focused on characterizing the swelling properties of ASR gels at the nanoscale level, which is one-billionth of a meter. The particles that make up the gels are approximately 10 nanometers in diameter. Since particles of such small dimensions are difficult to observe directly, Phair employed experimental techniques and advanced methods to characterize the materials.

In one study, Phair used neutron scattering—passing neutrons through a material to determine its nanoscale properties—and x-ray diffraction to measure the reaction rates of certain silicate materials in solutions of varying chemical composition. The results showed that under certain conditions, ASR gel changes from an amorphous material into a layered material with a greater tendency to swell.

In another study, Phair used the Brillouin scattering method to determine how various pressures can affect the elastic properties of the gels. The Brillouin method measures changes in the frequency of light scattered from vibrating atoms within a material. Predicting the swelling behavior of the gels was complicated by the fact that the bulk modulus of the gel—or the degree to which the gel could be compressed—varies with the confining pressure exerted by the concrete.

Phair also investigated a laboratory method to measure the swelling pressure of ASR gels based on dialysis membrane technology. In this method, membrane bags containing gels are placed in solutions of polyethlene molecules of various concentrations. This creates osmotic pressure, which occurs when two solutions are separated by a membrane permeable to only one of them. By varying the osmotic pressures, researchers can quantify the swelling pressures of the gels, as a function of their chemical composition. Studies performed with this method are not yet complete.

For more information on Phair’s presentation or FHWA’s research on the nanostructure of ASR gels, contact:

Dick Livingston 202–493–3063 dick.livingston@fhwa.dot.gov

|

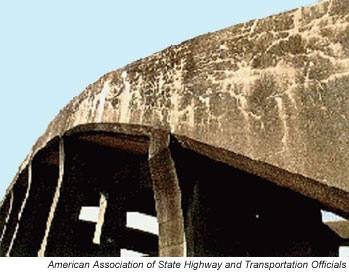

| When alkalis and silica in concrete react, the result is gels that can swell and cause damaging cracks such as these. Damage from ASR gels limits the durability and performance of concrete structures such as that shown above. |

|

| Damage from ASR gels limits the durability and performance of concrete structures such as that shown above. |