The expected maintenance-free life span of a noise barrier varies considerably based on many factors, including the barrier material type, surface texture, color, and component parts. Climatic conditions and the barrier's relationship to the roadway also play a role in the durability of most barriers. Many of these issues have been discussed elsewhere in this manual. Additional considerations are discussed below.

Noise barriers will become damaged at some point in their life, either from handling mishaps during construction, installation defects that appear well after the barrier has been installed, vehicles or debris hitting the wall, or simply from old age and exposure to the elements over time (see Figures 242 to 245). The reasons to initiate a repair may vary depending on the severity and extent of the damage and the policies of the governing responsible organization. In all cases, the following factors should be considered in the decision to repair. The relative weight that each of these factors is assigned may vary locally. However, the order of importance should not deviate significantly from the order in which they are presented.

Figure 242. Repairs

photo #736a

Figure 243. Repairs

photo #2488

Figure 244. Repairs

photo #1052

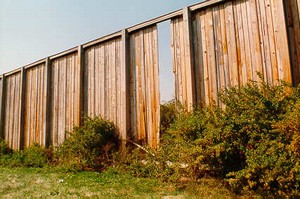

Figure 245. Repairs

photo #450

Since replacement of barrier elements may be required throughout the life of the noise barrier, the availability of replacement parts becomes a critical issue. If the components are standard products, such as steel "I" beams for posts, this issue will have very little importance. However, if the components are custom made for a specific project, then the issue becomes very critical (see Figure 246).

Figure 246. Availablility of replacement parts

photo #226

To address this concern, some agencies have instituted a stock piling policy where the contractor/ manufacturer, at the time of construction, supplies additional components to the organization responsible for maintenance. Typically, an additional 10 percent would by supplied to the responsible organization for stock piling purposes. The disadvantage to this type of practice is that the responsible organization, after several years of constructing noise barriers, may end up with an excessively large amount of varying stock on hand that has the potential of never being used.

The issue of future availability becomes even more critical when the components have to be custom fitted with either very few or none of the pieces the same. In this situation, stock piling may not be an option. This consequence should be seriously considered during the design stage and should be avoided if at all possible.

Section 9.4 discussed a variety of means for providing access to both sides of noise barriers for general maintenance and emergency access purposes. These requirements exist for both ground-mounted and structure-mounted noise barriers. The placing of a noise barrier is usually dictated by the results of acoustical analyses which are aimed at determining the best location to block line-of-sight between the noise source and the receivers. This location may or may not be the most accessible from either a construction or maintenance standpoint. These accessibility issues should be considered in the design phase in conjunction with the acoustical, construction, maintenance, and barrier material selection issues. If the only location to place an effective noise barrier is relatively inaccessible, then the design should focus on developing a barrier and related surface treatment and landscaping which is relatively maintenance free.

All noise barrier materials will wear over time. The severity is dependent on the type of material, proximity to the roadway, exposure to deicing chemicals, climate, and component design. Typical damage associated with wear are:

Deterioration from Moisture - Rusting, usually caused by excessive exposure to moisture and road salt, will slowly degrade or penetrate metal coatings such as galvanizing and paints (see Figure 247). The typical repair is to remove the rust and repaint with a zinc rich paint. Also, if the design of the components promotes the ponding of moisture on its surface, consideration should be given to redesign replacement parts to eliminate this. If left unattended, the metal components of a barrier will continue to rust until there is no metal left. At that stage, the only repair option is to replace the affected components. This type of aging initially affects the aesthetics of the barrier but, if left unchecked, could compromise safety and performance.

In some cases and climatic conditions, surfaces of barriers may never completely dry or may require extended periods of dry weather before drying. The resulting mildew and mold can compromise the aesthetic appearance of the barrier (see Figure 248). In such areas, consideration should be given in the design phase to selecting a barrier and surface treatment which can minimize such conditions and be capable of being cleaned on a regular basis.

Figure 247. Deterioration from moisture

photo #449

Figure 248. Deterioration from moisture

photo #1008

Deterioration from Ultraviolet Light Exposure The effects of ultraviolet light are most often related to deterioration of the noise barrier's pigments and colors as opposed to its structural elements (see Figure 249). Paints, stains, graffiti coatings (both pigmented and clear), stenciled designs, and integral colors are subjected to fading over time. When using such aesthetic and/or protective treatments, consideration should be given to the eventual maintenance tasks required to retain the desired appearance and/or protection. Consideration of the effects of ultraviolet light is especially critical in the design of transparent barriers as discussed in Section 5.5.1.

Figure 249. Deterioration from ultraviolet light

photo #1501

Loss of Stains and Painted Coatings - Loss of stains and painted coating can usually be attributed to the sand blasting or small chipping effect caused by roadway dirt and debris being picked up by the air turbulence from fast moving vehicles. This is more pronounced the closer the barrier is to the roadway.

The damage is usually only to the stain or coating and is typically an aesthetic issue. However, if the coating or stain is providing protection for the barrier material, then it becomes an issue of reduced life expectancy of the material.

The typical repair is to remove any loose material from the surface and repaint or stain with an appropriate durable finish to match the surrounding colors.

Warping - Although most common with wooden noise barrier products, warping (commonly called "oil canning") can also occur with metal and concrete panels.

With wood, the common cause is excessive moisture in the wood and improper curing causing the warping. In some cases, it can also be attributed to improper fastening. This defect usually creates gaps or cracks in the noise wall affecting its performance to varying degrees. If the openings are small enough, the repairs could probably be done with caulking material or small pieces of plywood sheeting. Otherwise, the affected components may have to be replaced.

With respect to the oil canning of metal sheeting, warping is usually caused by the absence of stiffening features in the panel profile and is only evident after the panels have been subjected to stresses associated with normal temperature changes. This is a design flaw that normally only affects the aesthetics of the barrier and rarely jeopardizes its safety, durability, and performance.

Concrete warping is more noticeable in stacked panel systems. While full height panels also warps, such warping is not normally visible.

Comprehensive discussion of landscaping, its relationship to other barrier elements, and its relationship to maintenance factors is contained in Section 6.2. The issue of consistency between the barrier's aesthetic treatment, including landscaping, and the maintenance philosophy of the owner of the barrier, as discussed in Section 6.2, is critical and bears repeating here. No matter how well designed and coordinated a landscape plan may be from the aesthetic standpoint, it is only as good as the ability of the responsible organization to adequately maintain it. It is a waste of time and money to design an aesthetic treatment for which there is neither the commitment (in terms of manpower) nor the funding (long term) to adequately maintain. No matter what the desire from an aesthetic standpoint, the landscape plan needs to be responsive to these financial and manpower constraints. Such constraints may appropriately lead to the selection of vegetation that is native "maintenance free" and to a plan that will foster growth of natural vegetation.

Section 5.9.3 discusses the various maintenance aspects of the varieties of coatings, stains, and anti-graffiti coatings available for application on noise barriers (see Figure 250).

Figure 250. Graffiti

photo #757

Barrier design should consider the location of a noise barrier in terms of litter susceptibility (Is it a high litter area?), the barrier's ability to "trap" litter, and the philosophy of the responsible organization regarding cleanup of litter (see Figure 251). Often, leaves, grass clippings, and other litter tend to be dumped in the area between the barrier and the right-of-way fence ("no man's land" or "dead man's zone"). If possible, allow adjacent residents to extend their sideline fences to the barrier. Also, landscaping in a high litter area should consider what type of vegetation is best to use. A thorny type of bush may make litter cleanup more difficult than such litter removal from a grassy area. Special design features such as insert areas, planter boxes, etc., may "catch" litter or even become target areas for litterers.

Figure 251. Litter

photo #1642

When noise barriers are installed too close to the roadway it becomes difficult to store snow on the side of the road (see Figure 252). If the snow is piled up on the shoulders, it is a potential safety issue in that vehicles cannot safely pull-off of the main travel lanes during emergencies. This condition usually warrants timely removal of the snow, typically with a front end loader and dump trucks. The removal operation creates serious safety problems with heavy equipment operating so close to the roadway.

Figure 252. Snow storage

photo #5342

The close proximity of the noise barrier will also make it susceptible to damage from snow plowing operations due to the force of the snow being thrown against the barrier and the resultant pressure of the snow piled-up against the barrier.

Depending on the height, proximity to the roadway and orientation related to prevailing winds, snow drifting may occur across the road as a result of the construction of a barrier (see Figure 253). Drifting creates not only safety problems but also difficulties for snow removal operations compounding the problems associated with snow removal.

Figure 253. Snow drifting

photo #2540

Consideration should be given to this concern at the design stage so that, in critical areas, wider shoulders, relocation of the barrier, or possible reduction in barrier heights can be incorporated.

Special or unique barrier types may sometimes have unique maintenance related issues which should be considered in the design process. Barriers in a "zig-zag" configuration (see Sections 3.5.5.2 and 4.1.2.3.1) present opportunities for plantings within the barriers "pockets" or recesses, but may make mowing operations more difficult. Barriers with large caps (see Section 6.1.3) or special barrier tops (see Section 3.5.5.3) may shade the top portion of a barrier and prevent the natural cleansing of that area by rain water (see Figure 254). Planted noise barriers (see Section 4.1.2.3.2) and noise barriers constructed behind the top of a retaining wall (see Section 4.2.2) may require irrigation and protective fencing (to prevent unauthorized access and climbing). Barriers mounted on structures (see Section 4.2.1) may create special access conflicts if utilities such as electric, gas, fiber optic lines, water lines, or sewer lines are suspended from the bridge or contained in conduits within the bridge beams or parapets.

Figure 254. Issues related to specific barrier types

photo #3125

|

Maintenance considerations for all noise barriers. | ||||

|---|---|---|---|---|

| Item# | Main Topic | Sub-Topic | Consideration | See Also Section |

| 12-1 | Availability of Replacement Parts | . | If barrier components are custom made for a specific project, then the issue of replacement parts becomes very critical. | 12.2 |

| 12-2 | Access | . | If the only location to place an effective noise barrier is relatively inaccessible, then the design should focus on developing a barrier and related surface treatment and landscaping which is relatively maintenance free. | 12.3 |

| 12-3 | Surface/ Material Wear and Deterioration | Deterioration from Moisture | If the design may result in moisture ponding on its surface, consideration should be given to redesign replacement parts. In some climatic conditions, consideration should be given in the design phase to selecting a barrier and surface treatment which can minimize mildew and mold growth and be capable of being cleaned on a regular basis. | 12.4 |

| Deterioration from Ultraviolet Light Exposure | When using paints, stains, graffiti coatings, and stenciled designs, consideration should be given to the effects of ultraviolet light, especially in the design of transparent barriers. | 12.4 | ||

| Loss of Stains and Painted Coatings | If the coating or stain is providing protection for the barrier material, then it becomes an issue of reduced life expectancy of the material. | 12.4 | ||

| 12-4 | Landscaping | . | The issue of consistency between the barrier's aesthetic treatment, including landscaping, and the maintenance philosophy of the owner of the barrier is critical. Manpower and financial constraints may appropriately lead to the selection of vegetation that is native "maintenance free" and to a plan that will foster growth of natural vegetation. | 12.5 |

| 12-5 | Litter | . | Barrier design should consider the location of a noise barrier in terms of litter susceptibility, the barrier's ability to "trap" litter, and the philosophy of the responsible organization regarding cleanup of litter. Landscaping in a high litter area should also consider what type of vegetation is best to use. A thorny type of bush may make litter cleanup more difficult than such litter removal from a grassy area. Special design features such as insert areas, planter boxes, etc. may "catch" litter or even become target areas for litterers. | 12.7 |

| 12-6 | Snow | Storage | Consideration must given to a barrier's susceptibility to damage from snow ploughing operations by both the force of the snow being thrown against the barrier and the resultant pressure of the snow piled-up against the barrier. | 12.8 |

| Drifting | Consideration should be given to snow drifting in the design stage so that, in critical areas, the possibilities of wide shoulders and minimum necessary barrier heights can be incorporated. | 12.9 |