Create a Top-Notch Pavement Network with TOPS

More than 40 percent of major roads in the United States are in poor or mediocre condition.1 The U.S. Department of Transportation’s 2015 Conditions & Performance Report estimated that America needs $836 billion to fix highways and bridges. By enhancing overlay performance in priority locations, State and local highway agencies can help ensure safer, longer-lasting roadways.

Improved overlays are now available for both asphalt and concrete pavements that enable agencies to provide long-life performance under a wide range of traffic, environmental, and existing pavement conditions. Overlays are widely used, but not always targeted, so FHWA created the Targeted Overlay Pavement Solutions (TOPS) initiative as part of Every Day Counts round six (EDC-6). “Targeted” refers to high-priority or high-maintenance locations such as primary or interstate pavements, intersections, bus lanes, ramps, and curves where the standard fix is not performing well.

Asphalt overlay mixtures have advanced significantly with the use of stone matrix asphalt, polymer-modified asphalt, and other materials and agents that reduce rutting, increase cracking resistance, and extend pavement life.

Credit: Applied Research AssociatesTargeted overlays can extend pavement life 15 to 40 years depending on the materials used. They also increase load-carrying capacity and improve safety, mobility, and user satisfaction in a cost-effective and sustainable manner.

“The use of overlays is often based on an agency’s experience and budget,” said Tim Aschenbrener, FHWA’s TOPS team co-lead. “With the Every Day Counts TOPS initiative, we’re encouraging agencies to consider the variety of overlays that are now available. We want to help them expand the types of overlays that they commonly use.”

Innovations in Overlays

The TOPS team is promoting eight asphalt overlays and two types of concrete overlays that offer many benefits to stakeholders. These overlays reduce maintenance, maximize previous investments, and reduce user delays (fewer work zones) due to extended service life of pavement structures. In addition, some TOPS products increase skid resistance, improve resiliency in flood-prone areas, reduce splash and spray, and reduce noise.

Success Stories

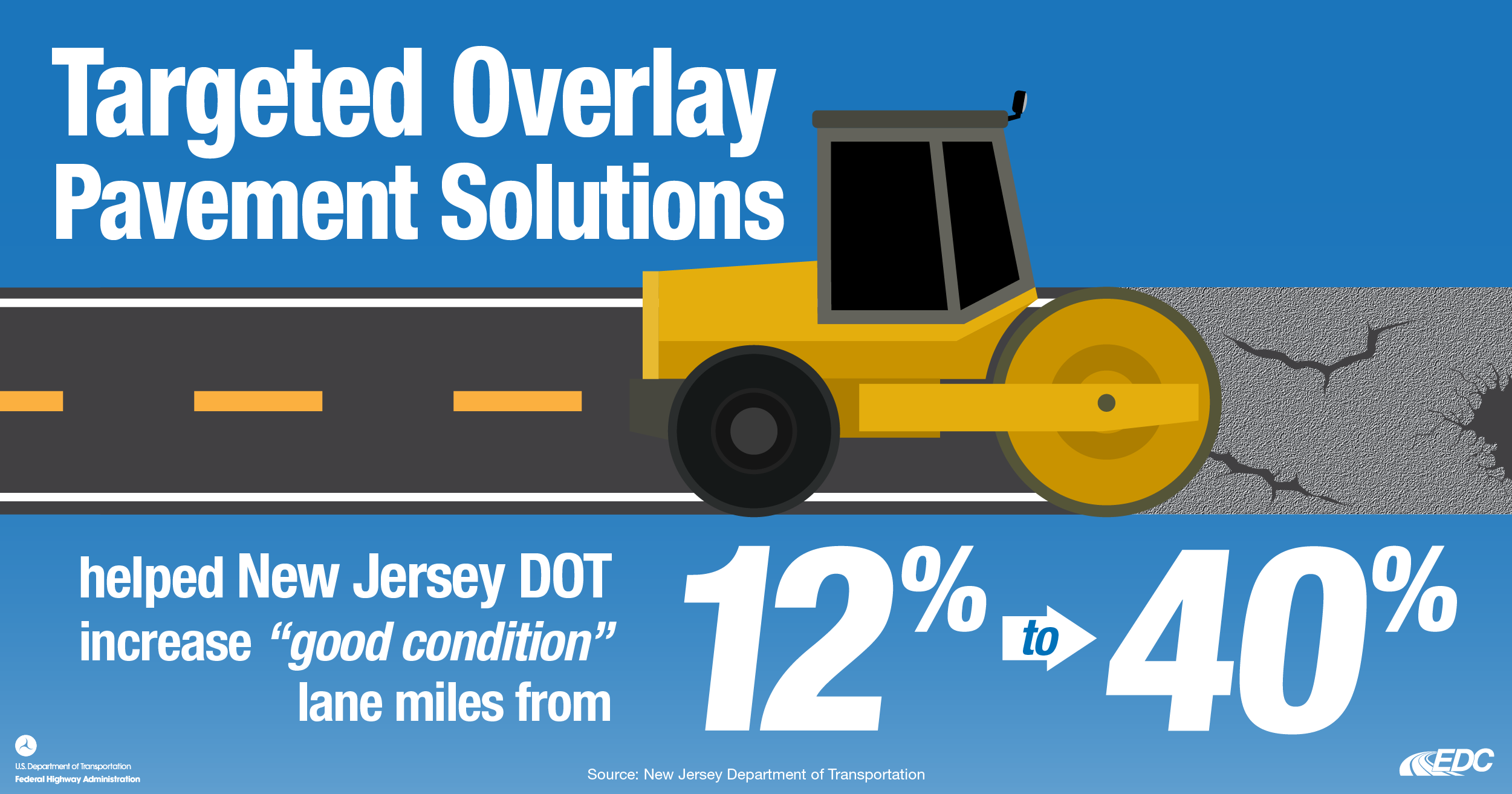

The New Jersey DOT uses a mixture called binder-rich intermediate course, which is similar to crack attenuating mix, and also uses highly modified asphalt and stone matrix asphalt. The agency’s efforts in the past decade have paid off.

“Targeted overlay pavement solutions have made a significant difference in New Jersey’s asphalt pavements,” said Robert Blight, New Jersey DOT Pavement Design and Technology Unit supervising engineer. “We’ve increased our good pavements by nearly 30 percent. Our goal is to create a balanced, cost-effective approach of preservation, resurfacing, rehabilitation, and reconstruction that best optimizes allocated funding to create the best possible roadway network condition.”

The Colorado DOT has approximately 1,000 lane-miles of concrete overlays on existing asphalt pavements. The concrete overlay can be either a bonded system that acts with the underlying asphalt or an unbonded system that is paved on top of the existing asphalt to carry ever-increasing volumes of traffic.

“We’ve had great success with concrete overlays in Colorado for more than two decades,” said Angela James Folkestad, American Concrete Pavement Association Colorado/Wyoming Chapter executive director. “They are faster and far more economical to deploy than reconstruction. The reduced frequency and duration of work zones means safer roadways for both workers and users.”

Concrete overlays now benefit from performance-engineered mixtures and new design procedures that improve durability and performance.

Credit: American Concrete Pavement AssociationEDC-6 Efforts

Twenty-eight States are participating in the TOPS EDC-6 initiative, with 26 interested in learning more about asphalt overlays, 15 focused on concrete, and 13 participating in both.

The TOPS team is developing resources to help transportation agencies select the right overlay product for the right location. The team has created fact sheets on different types of overlays and will release several case studies and how-to documents later this year. They are also planning webinars and workshops.

“While there’s no single answer for everyone,” said Aschenbrener, “by using good project selection practices, we believe every agency can find a targeted solution that is both cost-effective and durable.”

1“Key facts about the U.S. surface transportation system,” May 2021, https://tripnet.org/wp-content/uploads/2020/04/TRIP_Fact_Sheet_NATL.pdf

TOPS Fact Sheets

Asphalt

- Asphalt rubber gap-graded

- Crack attenuating mix

- Enhanced friction overlay

- Highly modified asphalt

- High-performance thin overlay

- Open-graded friction course

- Stone matrix asphalt

- Ultra-thin bonded wearing course

Concrete

Concrete on Asphalt

Concrete on Concrete

—MORE INFORMATION

Contact Tim Aschenbrener (asphalt) or Sam Tyson (concrete) of the FHWA Office of Infrastructure Pavement Materials team.

Join the FHWA Pavement and Materials email list to receive updates about the program.

Visit the EDC-6 TOPS webpage for additional resources.

Recommended Citation: U.S. Department of Transportation, Federal Highway Administration - Washington, DC (2021) Innovator Newsletter, July/August 2021, Volume 15(85). https://doi.org/10.21949/1521363