U.S. Department of Transportation

Federal Highway Administration

1200 New Jersey Avenue, SE

Washington, DC 20590

202-366-4000

Federal Highway Administration Research and Technology

Coordinating, Developing, and Delivering Highway Transportation Innovations

| REPORT |

| This report is an archived publication and may contain dated technical, contact, and link information |

|

| Publication Number: FHWA-HRT-14-086 Date: November 2014 |

Publication Number: FHWA-HRT-14-086 Date: November 2014 |

This chapter addresses the issue of acid grade, that is, can all of the commercially available grades of phosphoric acid be used, how does their effect vary with asphalt from different crude oil sources, and how does the rheology of the modified binders change following addition.

When polymers such as SBS are added to asphalt binders, it usually takes several hours before the full stiffening effect is achieved. To determine whether this is the case with phosphoric acid, the stiffness (|G*|/Sinδ at 64 °C) was first measured immediately after mixing. Samples were then oven aged, in air tight containers to minimize oxidation, at 165 °C to determine whether the stiffness would be likely to change after 12 days in a storage tank.

The four SHRP reference asphalts used are shown in table 3 , and the five grades of commercially available phosphoric acid grades in table 4 .

Table 3 . Properties of the SHRP asphalt binders.

|

Origin |

Grade |

Asphaltenes (percent) |

Polar Aromatics (percent) |

Napthenic Aromatics (percent) |

Saturates (percent) |

|---|---|---|---|---|---|---|

AAD-1 |

CA Coastal |

58-28 |

20.5 |

41.3 |

25.1 |

8.6 |

AAK-1 |

Venezuelan |

64-22 |

20.1 |

41.8 |

30.0 |

5.1 |

AAM-1 |

West TX Int. |

64-16 |

4.0 |

50.3 |

41.9 |

1.9 |

ABM-1 |

CA Valley |

58-10 |

7.1 |

52.4 |

29.6 |

9.0 |

Table 4 . Commercial grades of phosphoric acid used.

Name |

Acid Strength (percent) |

Water Content (percent) |

|---|---|---|

Polyphosphoric Acid |

115 |

0 |

Superphosphoric Acid |

105 |

0 |

Phosphoric Acid |

85 |

15 |

Phosphoric Acid |

75 |

25 |

Green Acid |

50 |

50 |

Addition levels were 0.25, 0.5, and 1.0 percent normalized to 100-percent phosphoric acid. (For example, in the case of 50-percent green acid, the actual weight of acid would be doubled.)

The samples were prepared by adding acid to the asphalt at 165 °C while mixing with a mechanical stirrer running at 450 rpm. Mixing was continued for 20 min after addition. The binder stiffness, (|G*|/Sinδ at 64 °C) was measured using AASHTO test method T315.

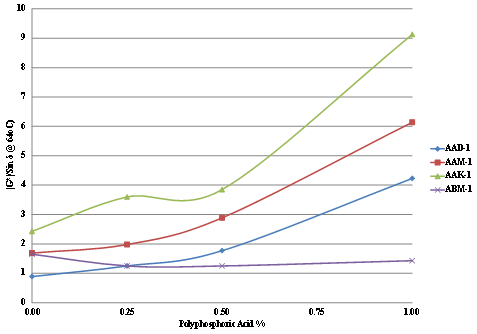

The results shown in figure 23 indicate the change in stiffness is asphalt dependent. Asphalt AAK-1 showed the greatest stiffness increase while ABM-1 was hardly affected by PPA addition.

Figure 23. Chart. Initial stiffness of SHRP reference binders modified with 115-percent phosphoric acid.

EFFECT OF PHOSPHORIC ACID GRADE

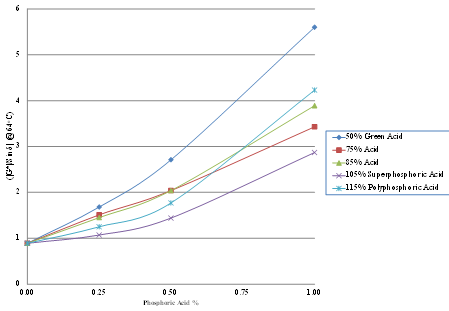

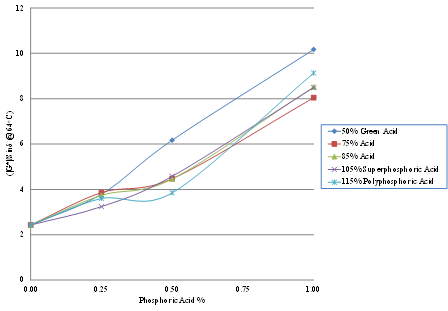

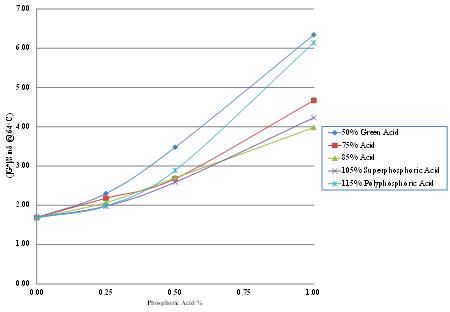

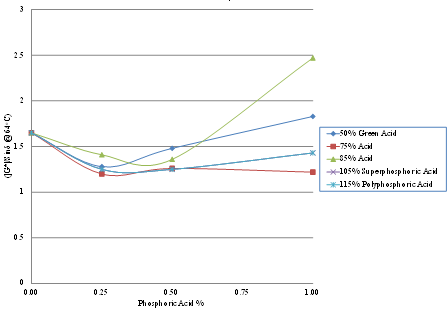

The results for each of the SHRP asphalts are shown in figure 24 to figure 27. Note that the stiffness scales on each chart are different. The stiffening effect was generally greater with the green acid, possibly because it contains some very strong acidic impurities such as sulfuric and hydrofluoric acids, which might be expected to increase the stiffening effect compared with phosphoric acid, which is a relatively weak acid. The other grades of acid showed similar effects with some minor differences. The test results indicate that any grade could be used to modify asphalt although the green acid might cause corrosion problems and the more dilute grades might cause foaming as the inherent water boils off on contact with the hot asphalt.

Figure 24. Chart. Effect of phosphoric acid grade on the stiffness of asphalt AAD-1.

Figure 25. Chart. Effect of phosphoric acid grade on the stiffness of asphalt AAK-1.

Figure 26. Chart. Effect of phosphoric acid grade on the stiffness of asphalt AAM-1.

Figure 27. Chart. Effect of phosphoric acid grade on the stiffness of asphalt ABM-1.

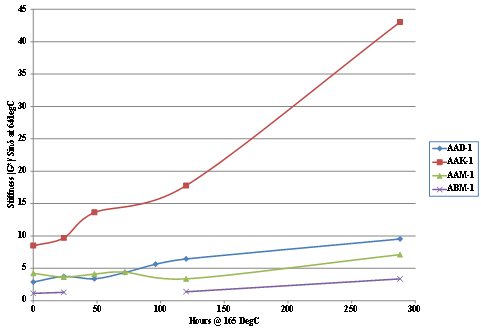

EFFECT OF TANK AGING AT 165 °C

The purpose of this test was to determine whether the stiffness of PPA-modified asphalts was likely to increase if stored in a heated tank for extended periods of time. Asphalt in storage tanks generally has a small exposed surface area to volume ratio, essentially an anaerobic condition. To simulate this condition on a small scale, samples of the four SHRP reference binders were placed in ¼-pint cans fitted with lever lids and oven aged at 165 °C. Stiffness was measured as |G*|/Sinδ at 64 °C. Tests were run with all five grades of phosphoric acid and addition levels of 0, 0.25, 0.5, and 1 percent. The results for all 20 of these combinations are given in the appendix in table 16 through table 35. To simplify this report, only the case for 1-percent superphosphoric acid is presented here in figure 28. The numerical data for this case are presented in table 5, which include the control data for zero acid modification. All unmodified binders exhibited some increase in stiffness except ABM-1, which remained almost unchanged. The modified binders all increased in stiffness; asphalt AAK-1 showed the largest change. In this case, the unmodified binder stiffness changed from 2.43 to 12.9, and the 1-percent acid modified material increased from 8.59 to 43.05. A summary chart showing the case for 1-percent superphosphoric acid is shown in table 5.

The numerical data are shown in the appendix.

Figure 28. Chart. Simulated tank aging of binders modified with 1 percent of 105-percent phosphoric acid.

Table 5 . Stiffness (|G*|/Sinδ) of simulated tank-aged binders modified with 105-percent phosphoric acid.

Hours |

AAD-1 |

AAK-1 |

AAM-1 |

ABM-1 |

||||

|---|---|---|---|---|---|---|---|---|

0-percent Acid |

1-percent Acid |

0-percent Acid |

1-percent Acid |

0-percent Acid |

1-percent Acid |

0-percent Acid |

1-percent Acid |

|

0 |

0.89 |

2.87 |

2.43 |

8.49 |

1.69 |

4.23 |

1.65 |

1.13 |

24 |

- |

3.74 |

2.80 |

9.69 |

- |

3.65 |

- |

1.28 |

48 |

- |

3.37 |

- |

13.63 |

- |

4.1 |

- |

- |

72 |

- |

4.34 |

- |

- |

- |

4.41 |

- |

- |

96 |

- |

5.62 |

- |

|

- |

- |

- |

|

120 |

1.33 |

6.44 |

10.5 |

17.77 |

1.96 |

3.36 |

1.52 |

1.37 |

288 |

5.92 |

9.52 |

12.9 |

43.05 |

11.68 |

7.11 |

1.81 |

3.36 |

- Indicates not measured.

The following conclusions can be drawn:

Table 6 . Stiffness sensitivity of reference binders to PPA modification.

|

Origin |

Grade |

Stiffening |

Asphaltenes (percent) |

Polar Aromatics (percent) |

Napthenic Aromatics (percent) |

Saturates (percent) |

|---|---|---|---|---|---|---|---|

AAD-1 |

CA Coastal |

58-28 |

2 |

20.5 |

41.3 |

25.1 |

8.6 |

AAK-1 |

Venezuelan |

64-22 |

1 |

20.1 |

41.8 |

30.0 |

5.1 |

AAM-1 |

West TX Int. |

64-16 |

3 |

4.0 |

50.3 |

41.9 |

1.9 |

ABM-1 |

CA Valley |

58-10 |

4 |

7.1 |

52.4 |

29.6 |

9.0 |