U.S. Department of Transportation

Federal Highway Administration

1200 New Jersey Avenue, SE

Washington, DC 20590

202-366-4000

Federal Highway Administration Research and Technology

Coordinating, Developing, and Delivering Highway Transportation Innovations

| REPORT |

| This report is an archived publication and may contain dated technical, contact, and link information |

|

| Publication Number: FHWA-HRT-14-087 Date: March 2015 |

Publication Number: FHWA-HRT-14-087 Date: March 2015 |

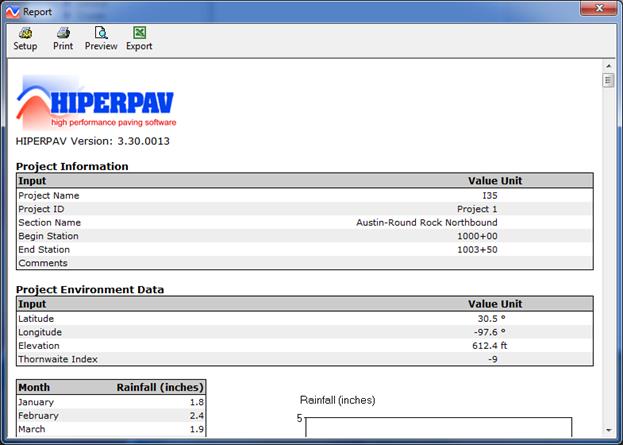

For any HIPERPAV III® version 3.3 analysis, reports can be generated by clicking the print icon in the upper icon toolbar or by selecting "Print" from the file menu. After selecting "Print" a HIPERPAV® Report window is displayed as shown in figure 69. In this window, icons in the top left allow the user to print the report as shown, preview the report, and export the results to a Microsoft® Excel spreadsheet.

Figure 69. Screen Capture. HIPERPAV® Report window.

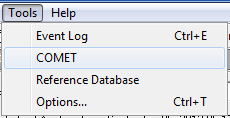

The Concrete Optimization, Management, Engineering, and Testing (COMET) module is a simplified derivation of the Concrete Optimization Software Tool that was developed by FHWA and the National Institute of Standards and Technology for optimizing concrete mixes. COMET can be accessed within HIPERPAV® by selecting "COMET" in the tools drop-down menu in the main toolbar, shown in figure 70. COMET optimizes concrete mixes based on early-age strength, 28-day strength, and cost.

Figure 70. Screen Capture. Tools drop-down menu in HIPERPAV®.

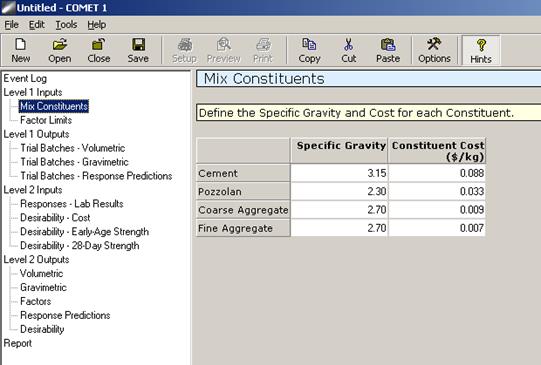

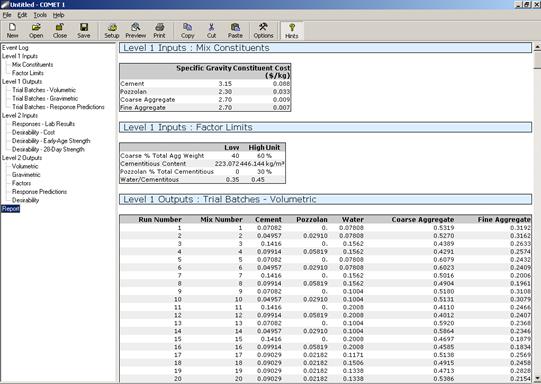

Once selected, the initial COMET window appears as shown in figure 71. Inputs and outputs can be selected from the menu-like list on the left side of the window. The inputs for the window selected are displayed on the right. The first item on the tree view, "Event Log", reports potential problems that may arise while running the software. Also, the tree view shows two levels of inputs and outputs. Level 1 inputs generate the experiment design of trial batches required for optimization. Level 2 inputs produce a set of optimum mixes based on the trial batch test results, and desirability functions defined for each response (early-age strength, 28-day strength, and cost).

As shown in figure 71, mix constituents are limited to cement, pozzolan, water, coarse aggregate, and fine aggregate. For each constituent, the specific gravity and cost is required.

Figure 71. Screen Capture. Mix Constituents input window in COMET.

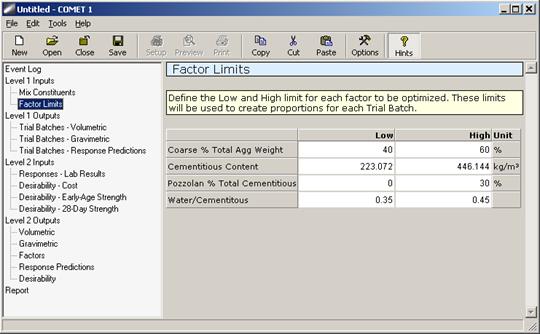

The user provides optimization ranges for coarse aggregate fraction, cementitious content, pozzolan substitution, and water-to-cement (w/cm) ratio (see figure 72).

Figure 72. Screen Capture. Factor Limits input window in COMET.

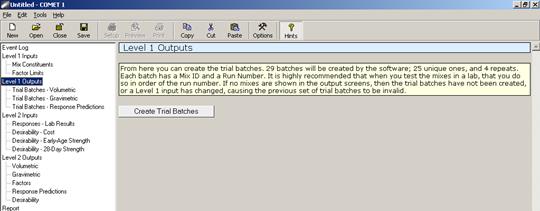

With the inputs in Level 1, trial batches are developed for the experimental program by running the "Create Trial Batches" command button in the Level 1 outputs window, as shown in

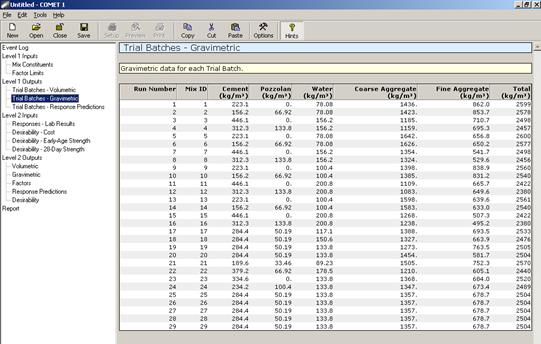

figure 73. As a result, 29 trial batches are generated, which can be displayed in volumetric (percent of total volume) and gravimetric (weight per unit of volume) form. The gravimetric form is presented in figure 74.

Figure 73. Screen Capture. Create trial batches command button in Level 1 Outputs.

Figure 74. Screen Capture. Trial batches in kg/m3, gravimetric form.

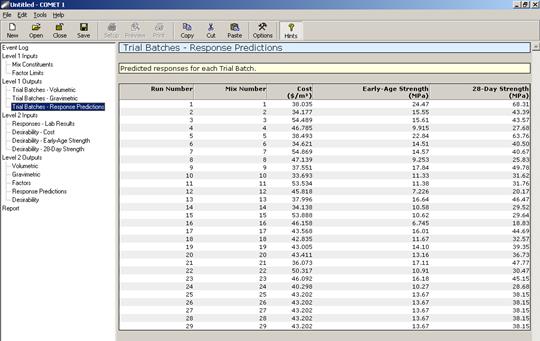

In addition, as shown in figure 75, the cost for every trial batch is computed, and default models in COMET are used to predict early-age strength and 28-day strength as a function of mix constituents. Predicted responses are only approximate and may be used in a planning stage in which the mix constituents may not be known or are not available for testing.

Figure 75. Screen Capture. Predicted responses for each trial batch.

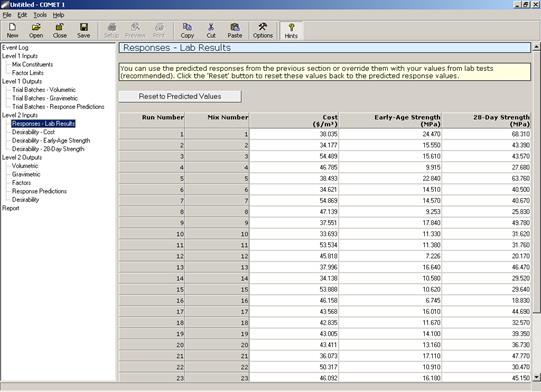

After the Level 1 inputs and outputs are complete, the user can proceed with Level 2 analysis. To continue with this analysis, the user must enter the laboratory testing results for each response for the trial batches generated in Level 1 (see figure 76). Alternatively, the user may fill in these values using default models by clicking the "Reset to Predicted Values" command button, if a preliminary analysis is desirable.

Figure 76. Screen Capture. Lab results window.

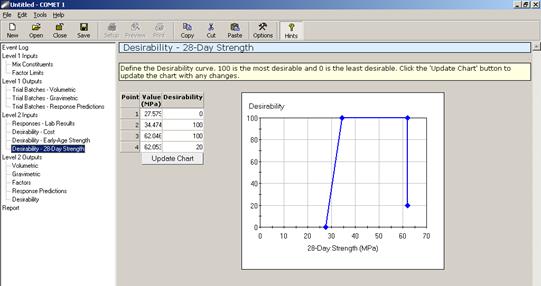

The user can assign desirability functions for each of the optimization responses under the cost, early-age strength, and 28-day strength desirability windows. (A sample desirability function is shown in figure 77 for 28-day strength.)

Figure 77. Screen Capture. Desirability function for 28-day strength.

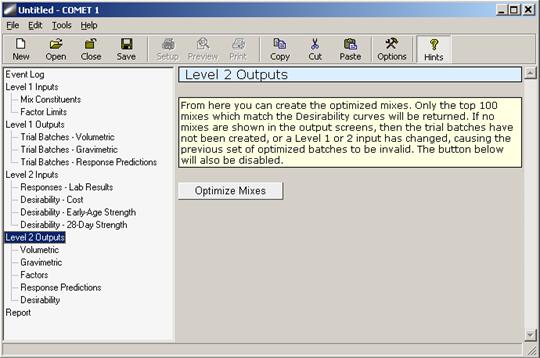

After the Level 2 inputs are entered, optimization of mixes is performed by clicking the "Optimize Mixes" command button in the Level 2 outputs window (see figure 78). With this command, regression models based on the results from the experimental program or from the predicted responses are developed as a function of the mix proportions.

Figure 78. Screen Capture. Level 2 outputs-command to optimize mixes.

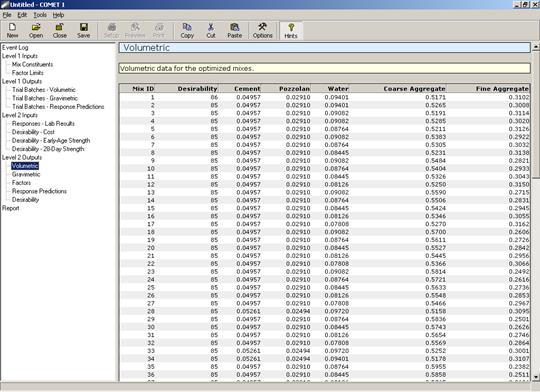

These models predict responses for a comprehensive set of mixtures within the factor limits specified in the factor limits window. Finally, optimum mixes are identified in terms of the individual desirability for every response and the maximum overall desirability for all responses, and are presented in volumetric and gravimetric form. Optimum mixes are shown in volumetric form in figure 79.

Figure 79. Screen Capture. Optimum mixes sorted by desirability in volumetric form.

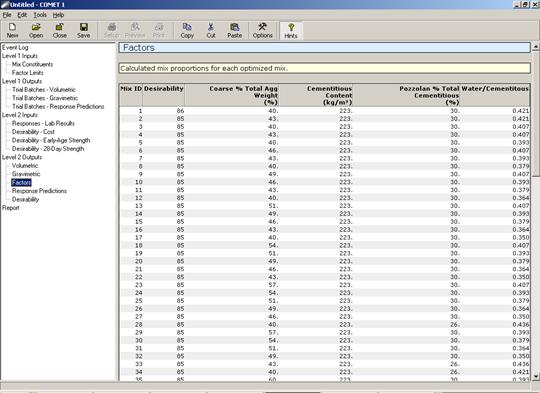

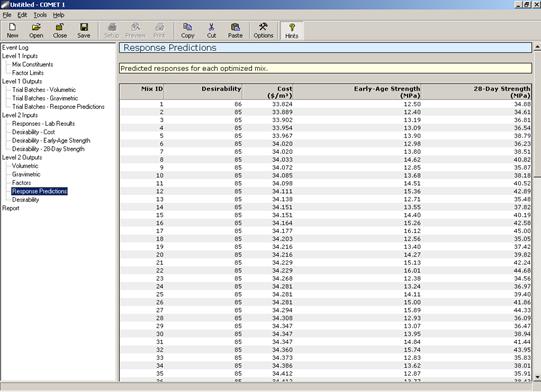

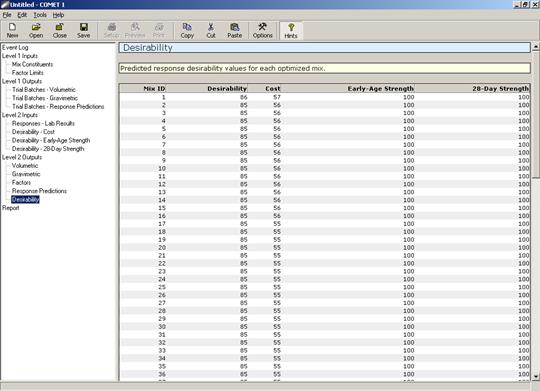

In addition, the optimum mixes are also displayed in terms of the optimization factors, predicted responses, and individual response desirabilities as shown in figure 80, figure 81, and figure 82 respectively.

Figure 80. Screen Capture. Optimum mixtures in terms of optimization factors.

Figure 81. Screen Capture. Response predictions for optimum mixtures.

Figure 82. Screen Capture. Individual response desirabilities for optimum mixtures.

A report that can be used for printing the inputs and outputs for the entire analysis is generated, as shown in figure 83. To print, click on the print icon on the upper icon toolbar.

Figure 83. Screen Capture. Report view for printing purposes.