U.S. Department of Transportation

Federal Highway Administration

1200 New Jersey Avenue, SE

Washington, DC 20590

202-366-4000

Federal Highway Administration Research and Technology

Coordinating, Developing, and Delivering Highway Transportation Innovations

| REPORT |

| This report is an archived publication and may contain dated technical, contact, and link information |

| Publication Number: FHWA-HRT-12-030 Date: August 2012 |

Publication Number: FHWA-HRT-12-030 Date: August 2012 |

PDF Version (4.44 MB)

PDF files can be viewed with the Acrobat® Reader®

|

Variable |

DF |

Estimate |

Standard Error |

t-Value |

Pr > |t| |

VIF |

|

Intercept |

1 |

4028.41841 |

1681.71576 |

2.4 |

0.0215 |

0 |

|

w/c ratio |

1 |

-3486.3501 |

2152.99857 |

-1.62 |

0.1134 |

2.40903 |

|

Cementitious content |

1 |

4.02511 |

1.32664 |

3.03 |

0.0043 |

2.40903 |

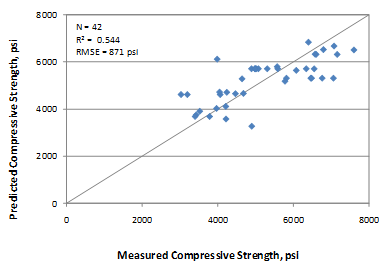

The model statistics for table 21 are as follows:

|

Parameter |

Minimum |

Maximum |

Average |

|

w/c ratio |

0.27 |

0.71 |

0.42 |

|

Cementitious content |

376 |

936 |

664 |

|

Compressive strength |

3,034 |

7,611 |

5,239 |

The recommended 28-day compressive strength model is as shown in figure 135.

Where:

f’c,28d= 28-day compressive strength, psi.

w/c = Water to cementitious materials ratio.

CMC = Cementitious materials content, lb/yd3.

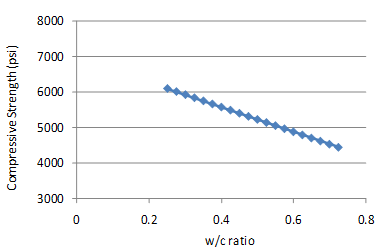

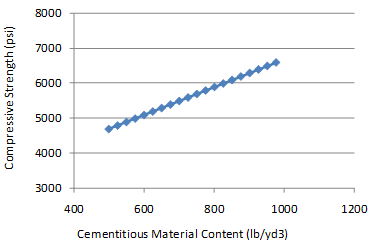

Figure 136 and figure 137 show the sensitivity of this model to w/c ratio and CMC. The change in compressive strength appears reasonable for both of the parameters for the range of values evaluated. They are also consistent with the data in the database. Within practical ranges, a change in CMC from 500 to 650 lb/ft3 increases the 28-day strength from approximately 4,700 to 5,300 psi for a w/c ratio of 0.4. Likewise, a decrease in the w/c ratio from 0.5 to 0.35 increases the strength from 4,700 to 5,200 psi.

Cylinder strength data were available for the SPS sections at pavement ages of 14 days, 28 days, and 1 year for a majority of the sections. Although two sections with strength data at 10 years were available, data in the model were limited for ages up to 1 year. Therefore, this model predicts the strength up to an age of 1 year.

Since this model utilizes only SPS data, a large set of independent variables was available for evaluation. Additionally, it is likely that this model will be used after approval of the mix design for a project or possibly even after initial construction, during which time more mix design parameters will be known for accurate prediction. The model developed includes pavement age as an independent parameter. Because the dataset includes multiple measurements or repeated readings of the same section, this parameter has been treated with a hierarchical modeling approach.

This model was established as shown in figure 138.

![]()

Where:

fc,t = Compressive strength at age t years, psi.

CMC = Cementitious materials content, lb/yd3.

w/c = Water to cement ratio.

uw = Unit weight, lb/ft3.

t = Short-term age, years.

The regression statistics for this model are presented in table 23, and details of the range of data used to develop the model are presented in table 24.

|

Variable |

DF |

Estimate |

Standard Error |

t-Value |

Pr > |t| |

VIF |

|

Intercept |

1 |

6,358.60655 |

1,213.09762 |

5.24 |

< 0 .0001 |

0 |

|

Cementitious |

1 |

3.53012 |

0.90968 |

3.88 |

0.0002 |

2.15941 |

|

(w/c) × unit weight |

1 |

-34.24312 |

11.00358 |

-3.11 |

0.0026 |

2.152 |

|

Ln(age) |

1 |

633.3489 |

87.49625 |

7.24 |

< 0.0001 |

1.00604 |

The model statistics for table 23 are as follows:

|

Parameter |

Minimum |

Maximum |

Average |

|

w/c ratio |

0.27 |

0.69 |

0.43 |

|

Cementitious content |

376 |

936 |

660 |

|

Unit weight |

124 |

151 |

143 |

|

Pavement age |

0.0384 |

1.0000 |

0.3081 |

|

Compressive strength |

2,480 |

10,032 |

5,256 |

The model was developed using 79 data points, and the prediction has an R2 value of 66.6 percent and an RMSE value of 789 psi. The reason for an improved R2 compared to the 28-day strength model is not clear from these analyses. Figure 139 and figure 140 show the predicted versus measured plot and the residual plot, respectively.