U.S. Department of Transportation

Federal Highway Administration

1200 New Jersey Avenue, SE

Washington, DC 20590

202-366-4000

Federal Highway Administration Research and Technology

Coordinating, Developing, and Delivering Highway Transportation Innovations

| REPORT |

| This report is an archived publication and may contain dated technical, contact, and link information |

|

| Publication Number: FHWA-HRT-14-088 Date: March 2015 |

Publication Number: FHWA-HRT-14-088 Date: March 2015 |

Some dubious sensor trace patterns were encountered in the processing of the Ohio SPS-1 and SPS-2 DLR data. For example, some sensor traces exhibited a flat unresponsive pattern. Other sensor traces indicated the mislabeling of a transverse strain gauge as a longitudinal strain gauge.

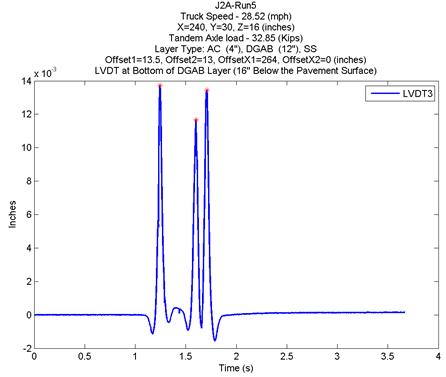

All of the LVDTs were buried deep in the subgrade or close to the interface between the subgrade and the base layer in the Ohio test sections. Thus, LVDT traces should not contain any trace valleys (no tensile strains) but only peaks (compressive strains). However, the LVDT3 sensor for tests J2A, J2C, J2D, J2E, J2F, and J2G (test section 390102) showed a trace pattern similar to a longitudinal strain gauge trace that assumes valleys. Figure 16 shows LVDT3 trace in test J2A with a trace pattern similar to a longitudinal strain gauge trace.

Figure 16. Graph. Transverse LVDT3 longitudinal strain gauge trace that assumes valleys

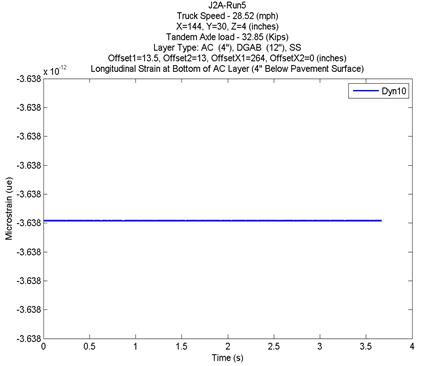

Strain Gauge Trace Pattern Issue

Strain gauge sensors Dyn10 and Dyn11 for tests J2A, J2C, J2D, J2E, J2F, and J2G in test section 390102 showed a flat unresponsive trace pattern. The assumption was that the sensors were not connected properly. Figure 17 shows flat strain gauge sensor Dyn10 trace in test J2A.

Figure 17. Graph. Unresponsive strain gauge trace

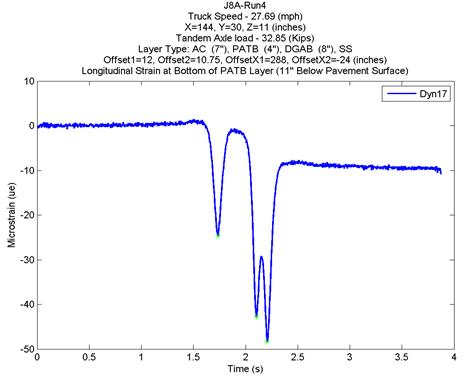

Longitudinal strain gauges are expected to assume trace valleys, whereas transverse strain gauges are not. However, longitudinal strain gauge sensor Dyn17 for tests J8A, J8D, J8E, and J8G (test section 390108) showed a trace pattern that, if flipped, is similar to a transverse strain gauge trace that assumed no valleys. Figure 18 shows the longitudinal Dyn17 strain gauge trace in test J8A exhibiting an upside down transverse strain gauge trace pattern.

Figure 18. Graph. Longitudinal Dyn17 strain gauge trace exhibiting an upside down transverse pattern

The LVDT3 and Dyn17 strain gauge sensors for test sections 390102 and 390108 may have been mislabeled inadvertently. The data collection dates match for tests in both test sections. For example, the data collection date for tests J2A (LVDT3) and J8A (Dyn17) were the same. Similarly, data collection dates for tests J2D, J2E, and J2G (LVDT3) were the same as for tests J8D, J8E, and J8G (Dyn17), respectively.

The peak data information contained in Ohio truck peak (TruckPeak.txt) file was unclear. The data have peak values recorded for the same sensor number and run number but at different sensor locations. Table 18 shows sample truck peak data for test section 390102 strain gauge sensor Dyn12 run 1. The column labeled "X" represents the estimated position of the front-axle at the time when the peak occurred. Specifically, it is the X-coordinate measured from the southernmost deep LVDT in the AC sections. The column labeled "Peak Value" shows the recorded front-axle peak values. The actual location of strain gauge sensor Dyn12 from the measured southernmost deep LVDT in the AC sections was 192 inches (X = 192 inches), but the truck peak data showed multiple sensor locations (X values). Also, the peak value of 411.40 µe at X = 194.7 inches closely matched the first peak value extracted from the DLR data process, which was 433.04 µe at X = 192 inches.

Table 18. Sample Ohio SPS-1 truck peak data for test J2F.

Series |

Subseries |

Run |

Section |

Sensor Name |

Sensor Number |

X (inches) |

Peak Value |

|---|---|---|---|---|---|---|---|

2 |

F |

1 |

390102 |

Dyn |

12 |

30.0 |

-118.60 |

2 |

F |

1 |

390102 |

Dyn |

12 |

55.8 |

758.00 |

2 |

F |

1 |

390102 |

Dyn |

12 |

71.0 |

-203.30 |

2 |

F |

1 |

390102 |

Dyn |

12 |

120.1 |

5.03 |

2 |

F |

1 |

390102 |

Dyn |

12 |

171.5 |

-57.61 |

2 |

F |

1 |

390102 |

Dyn |

12 |

194.7 |

411.40 |

2 |

F |

1 |

390102 |

Dyn |

12 |

209.9 |

-114.10 |

The beginning offset, ending offset, and range values for strain gauges, LVDTs, and PCs obtained from the DLR raw traces did not match the beginning and ending offset and range values in SDR 22.0.(6) Per the technical support service contractor's recommendations, the beginning offset, ending offset, and range columns were removed and do not show up in SDR 27.0.(1)

The DLR SPS-2 data information was reviewed for data discrepancies before processing. Data information included the SPS-2 TCS raw data, the OU data, SDR 22.0 DLR data, and information from Evaluation of Pavement Performance on DEL 23.(12) Site visits A, B, and C of SPS-2 tests J1, J5, J8, and J12 (test sections 390201, 390205, 390208, and 390212, respectively) were inconsistent with SPS-2 subseries H, I, and J of the OU file. In contrast, site visits A through G of SPS-1 tests J2, J4, J8, and J10 (test sections 390102, 390104, 390108, and 390110, respectively), had matching subseries in the OU data file. The data collection dates of the SPS-2 test section visits A, B, and C, however, matched subseries H, I, and J, respectively, of the OU data file. Since subseries A through G had already been used for SPS-1, the assumption is that OU assigned H, I, and J in place of A, B, and C for SPS-2. Also, the wheelpath offset values in SDR 22.0 for SPS-2 were populated from subseries H, I, and J of the data file for test sections A, B, and C, respectively. Table 19 shows the inconsistencies between the SPS-2 test section visits and the OU subseries.

Table 19 . Ohio SPS-2 inconsistencies between test section visits and subseries.

Raw Ohio-TCS Data |

Test Truck |

OU Data |

|||

|---|---|---|---|---|---|

Test Job |

No. of Files/Runs |

Test Date |

Subseries |

Start Time for |

|

J1A |

28 |

8/12/1996 |

2 |

H |

15:15:00 |

J1B |

26 |

8/13/1996 |

2 |

I |

11:00:00 |

J1C |

14 |

8/14/1996 |

2 |

J |

10:11:00 |

J5A |

29 |

8/12/1996 |

2 |

H |

15:15:00 |

J5B |

26 |

8/13/1996 |

2 |

I |

11:00:00 |

J5C |

14 |

8/14/1996 |

2 |

J |

10:11:00 |

J5J1M |

18 |

7/29/1997 |

4 |

M |

13:10:00 |

J5J1N |

18 |

7/30/1997 |

4 |

N |

10:20:00 |

J5J1O |

18 |

7/30/1997 |

4 |

O |

13:32:00 |

J5J1P |

18 |

8/06/1997 |

4 |

P |

07:18:00 |

J8A |

26 |

8/12/1996 |

2 |

H |

15:15:00 |

J8B |

27 |

8/13/1996 |

2 |

I |

11:00:00 |

J8C |

17 |

8/14/1996 |

2 |

J |

10:11:00 |

J8S3M |

18 |

7/29/1997 |

4 |

M |

13:10:00 |

J8S3N |

18 |

7/30/1997 |

4 |

N |

10:20:00 |

J8S3O |

18 |

7/30/1997 |

4 |

O |

13:32:00 |

J8S3P |

18 |

8/06/1997 |

4 |

P |

07:18:00 |

J12A |

4 |

8/12/1996 |

2 |

H |

15:15:00 |

J12B |

27 |

8/13/1996 |

2 |

I |

11:00:00 |

J12C |

14 |

8/14/1996 |

2 |

J |

10:11:00 |

J12J10M |

18 |

7/29/1997 |

4 |

M |

13:10:00 |

J12J10N |

18 |

7/30/1997 |

4 |

N |

10:20:00 |

J12J10O |

18 |

7/30/1997 |

4 |

O |

13:32:00 |

J12J10P |

17 |

8/06/1997 |

4 |

P |

07:18:00 |

*The dates of the runs in this column are the same as the test dates listed in column 3.

Note: Test truck series 2 and 4 were used for Ohio SPS-2.

SPS-2 DLR sensors LVDT5 and LVDT6 were unresponsive for all tests; LVDT5 and LVDT6 records all had zero values.

The ASCII files for SPS-2 tests J5J1M, J5J1N, J5J1O, J5J1P, J8S3M, J8S3N, J8S3O, J8S3P, J12J10M, J12J10N, J12J10O, and J12J10P had 32 LVDT sensors (LVDT1 through LVDT32). The other tests (J1A, J1B, J1C, J5A, J5B, J5C, J8A, J8B, J8C, J12A, J12B, and J12C) had only 16 LVDT sensors (LVDT1 through LVDT16). The DLR study team processed only the first 16 LVDTs (LVDT1 through LVDT16) based on information present in the OU EmbeddedSensor.txt file, which showed only the first 16 LVDTs.

Table 20 shows strain gauge sensors for each SPS-2 test that had time history data. For example, test J1A had eight strain gauge sensors of which only four sensors (Dyn1, Dyn4, Dyn5, and Dyn8) had time history data. The other strain gauge sensors (Dyn2, Dyn3, Dyn6, and Dyn7) did not have time history data.

Table 20 . Strain gauge sensors with time history data for each test.

Test Job |

Test Section |

Strain Gauge Sensors that have Time History Data |

|---|---|---|

J1A |

390201 |

Dyn1, Dyn4, Dyn5, and Dyn8 |

J1B |

390201 |

Dyn1, Dyn4, Dyn5, and Dyn8 |

J1C |

390201 |

Dyn1, Dyn2, Dyn7, and Dyn8 |

J5A |

390205 |

Dyn1, Dyn4, Dyn5, and Dyn8 |

J5B |

390205 |

Dyn1, Dyn2, Dyn7, and Dyn8 |

J5C |

390205 |

Dyn1, Dyn2, Dyn7, and Dyn8 |

J8A |

390208 |

Dyn1, Dyn4, Dyn5, and Dyn8 |

J8B |

390208 |

Dyn1, Dyn2, Dyn7, and Dyn8 |

J8C |

390208 |

Dyn1, Dyn2, Dyn7, and Dyn8 |

J12A |

390212 |

Dyn1, Dyn4, Dyn5, and Dyn8 |

J12B |

390212 |

Dyn1, Dyn2, Dyn7, and Dyn8 |

J12C |

390212 |

Dyn1, Dyn2, Dyn7, and Dyn8 |

J5J1M |

390205 |

Dyn1, Dyn2, Dyn7, and Dyn8 |

J5J1N |

390205 |

Dyn1, Dyn2, Dyn7, and Dyn8 |

J5J1O |

390205 |

Dyn1, Dyn2, Dyn7, and Dyn8 |

J5J1P |

390205 |

Dyn1, Dyn2, Dyn7, and Dyn8 |

J8S3M |

390208 |

Dyn1, Dyn2, Dyn7, and Dyn8 |

J8S3N |

390208 |

Dyn1, Dyn2, Dyn7, and Dyn8 |

J8S3O |

390208 |

Dyn1, Dyn2, Dyn7, and Dyn8 |

J8S3P |

390208 |

Dyn1, Dyn2, Dyn7, and Dyn8 |

J12J10M |

390212 |

Dyn1, Dyn2, Dyn7, and Dyn8 |

J12J10N |

390212 |

Dyn1, Dyn2, Dyn7, and Dyn8 |

J12J10O |

390212 |

Dyn1, Dyn2, Dyn7, and Dyn8 |

J12J10P |

390212 |

Dyn1, Dyn2, Dyn7, and Dyn8 |

Note: All Ohio SPS-2 test sections had eight strain gauge sensors deployed.

Table 21 shows multiple peak values for Dyn1 run 1. Based on the Embeddedsensor.txt file, the location of the Dyn1 sensor was 84 inches from the southernmost first LVDT (the coordinate reference point), so the first peak value of -22.07 was compared to the smooth first peak values extracted from SPS-2.

Table 21 . Sample Ohio SPS-2 truck peak data for test J1A.

Series |

Subseries |

Run |

Section |

Sensor Name |

Senor Number |

X (inches) |

Peak Value |

|---|---|---|---|---|---|---|---|

2 |

H |

1 |

390201 |

Dyn |

1 |

18.6 |

3.00 |

2 |

H |

1 |

390201 |

Dyn |

1 |

82.3 |

-22.07 |

2 |

H |

1 |

390201 |

Dyn |

1 |

153.9 |

11.14 |

2 |

H |

1 |

390201 |

Dyn |

1 |

222.0 |

-44.72 |

2 |

H |

1 |

390201 |

Dyn |

1 |

311.9 |

4.95 |

Note: Subseries "H" infers "A." Please see the second bullet under Ohio SPS-2 data issues in chapter 10.

In table 22, Dyn8 strain gauge from test J5J1P runs 1-10 collected at 499.964 Hz on August 6, 1997, had significantly larger raw strain values compared to other SPS-2 strain gauge values, which were mostly less than 100 µe. Thus, further investigation is needed for this strain gauge.

Table 22 . Raw Dyn8 strain gauge values of test J5J1P.

State Code |

SHRPID |

Run Number |

Minimum Strain Raw Value ( µe) |

Maximum Strain Raw Value ( µe) |

|---|---|---|---|---|

39 |

0205 |

1 |

19,939.61 |

19,974.62 |

39 |

0205 |

2 |

20,024.00 |

20,058.39 |

39 |

0205 |

3 |

19,990.25 |

20,027.13 |

39 |

0205 |

4 |

20,066.51 |

20,097.77 |

39 |

0205 |

5 |

20,164.66 |

20,200.29 |

39 |

0205 |

6 |

20,224.04 |

20,257.80 |

39 |

0205 |

7 |

20,269.05 |

20,307.19 |

39 |

0205 |

8 |

20,340.94 |

20,372.82 |

39 |

0205 |

9 |

20,386.58 |

20,422.21 |

39 |

0205 |

10 |

20,458.47 |

20,483.47 |

The first 500 trace data points were used to average a gain adjustment factor for SPS-2 data. On average, each SPS-2 time history dataset contains close to 7,000 data points, whereas each SPS-1 time history dataset contains about 5,000 data points. Due to significant noise in the SPS-2 data, the first 500 data points may not be enough. For future research, the first 700 data points should be used to determine a gain adjustment factor for SPS-2 data, where 700 is approximately 10 percent of each SPS-2 time history dataset.

As with the SPS-1 data, the SPS-2 beginning offset, ending offset, and range values for strain gauges and LVDTs obtained from the DLR raw traces did not match the beginning and ending offset and range values in SDR 22.0. Per the technical support service contractor's recommendations, the beginning offset, ending offset, and range columns were removed and did not show up in SDR 27.0.