U.S. Department of Transportation

Federal Highway Administration

1200 New Jersey Avenue, SE

Washington, DC 20590

202-366-4000

Federal Highway Administration Research and Technology

Coordinating, Developing, and Delivering Highway Transportation Innovations

| REPORT |

| This report is an archived publication and may contain dated technical, contact, and link information |

|

| Publication Number: FHWA-HRT-14-088 Date: March 2015 |

Publication Number: FHWA-HRT-14-088 Date: March 2015 |

This section presents the results from the application of the methodology described in chapter 5 to process DLR raw data. The results were useful in making decisions as to which quality DLR data (good and maybe traces by test job and by sensor type) should be included into SDR 27.0.(1) Also, the QC-processed DLR data can be used to determine the approaches and methodologies most appropriate for applications in pavement analysis and design processes.

Each of the 23 tests in the SPS-1 DLR data was separately processed using Matlab®.(8) Test J2F, which had eight test runs (AJ2F.001 through AJ2F.008) is used to illustrate the working of the methodology described in chapter 5 in Matlab®. The peak finding algorithm developed was test specific; that is, the algorithm ran through all the test runs (files) in a particular test. It imported all the runs in test J2F into the Matlab® environment. Calibration factors discussed in the first step of the methodology were applied to LVDT and PC sensors to convert them into pavement deflection in inches and test vehicle loading in pounds per square inch. As discussed in the third step of the methodology, sensor traces for three sensor types-strain gauge, LVDT, and PC-for all runs in test J2F were smoothed using the mslowess function available in the Matlab® bioinformatics tool box.(10)

The QC part of the methodology checked trace quality categorization for all smoothed sensor traces in test J2F based on three criteria: good, maybe, and not good. The QC results were saved separately into a Microsoft Excel® file using sensor type and test name as the file name (e.g., LVDT_J2F_QC for an LVDT sensor in test J2F). QC results in the Microsoft Excel® file were checked manually for each smoothed trace to correct any improperly categorized traces.

Table 5 shows the summarized QC results for each run number and sensor type for test J2F. Numbers 1 through 3 for strain gauge (Dyn7 to Dyn12), LVDT (LVDT1 to LVDT2), and PC (PC1 and PC2) sensors in table 6 represent the trace quality in good, maybe, and not food trace categories respectively. In test J2F, there were 48 strain gauge traces of which 16 traces were good (the eight "1s" or good traces in the Dyn9 column plus the eight "1s" in the Dyn12 column).

Table 5 . Summarized QC results for smoothed traces in Ohio SPS-1 test J2F.

Run No. |

Dyn |

LVDT |

PC |

|||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|

7 |

8 |

9 |

10 |

11 |

12 |

1 |

2 |

3 |

4 |

1 |

2 |

|

1 |

3 |

3 |

1 |

3 |

3 |

1 |

1 |

2 |

1 |

1 |

1 |

1 |

2 |

3 |

3 |

1 |

3 |

3 |

1 |

1 |

1 |

1 |

1 |

1 |

1 |

3 |

3 |

3 |

1 |

3 |

3 |

1 |

1 |

2 |

1 |

1 |

1 |

1 |

4 |

3 |

3 |

1 |

3 |

3 |

1 |

1 |

1 |

1 |

1 |

1 |

1 |

5 |

3 |

3 |

1 |

3 |

3 |

1 |

1 |

2 |

1 |

1 |

1 |

1 |

6 |

3 |

3 |

1 |

3 |

3 |

1 |

1 |

1 |

1 |

1 |

1 |

1 |

7 |

3 |

3 |

1 |

3 |

3 |

1 |

1 |

1 |

1 |

1 |

1 |

1 |

8 |

3 |

3 |

1 |

3 |

3 |

1 |

1 |

1 |

1 |

1 |

1 |

1 |

Total |

||||||||||||

Good |

0 |

0 |

8 |

0 |

0 |

8 |

8 |

5 |

8 |

8 |

8 |

8 |

Maybe |

0 |

0 |

0 |

0 |

0 |

0 |

0 |

3 |

0 |

0 |

0 |

0 |

Not good |

8 |

8 |

0 |

8 |

8 |

0 |

0 |

0 |

0 |

0 |

0 |

0 |

Table 6. Peaks and valleys extracted for smoothed traces in test J2F (µe).

Tag ID |

Test Name |

Run |

Time Smooth 1 |

Strain Value Smooth 1 |

Time Smooth 2 |

Strain Value Smooth 2 |

Time Smooth 3 |

Strain Value Smooth 3 |

Time Smooth 4 |

Strain Value Smooth 4 |

Time Smooth 5 |

Strain Value Smooth 5 |

Time Smooth 6 |

Strain Value Smooth 6 |

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

Dyn9 |

J2F |

1 |

1.58 |

228.28 |

1.85 |

333.01 |

||||||||

Dyn9 |

J2F |

2 |

1.59 |

759.57 |

1.84 |

296.37 |

||||||||

Dyn9 |

J2F |

3 |

1.52 |

709.65 |

1.76 |

301.81 |

||||||||

Dyn9 |

J2F |

4 |

1.50 |

718.30 |

1.74 |

276.85 |

||||||||

Dyn9 |

J2F |

5 |

1.60 |

1067.32 |

1.83 |

341.22 |

||||||||

Dyn9 |

J2F |

6 |

1.52 |

822.41 |

1.71 |

281.21 |

||||||||

Dyn9 |

J2F |

7 |

1.53 |

293.97 |

1.72 |

245.72 |

||||||||

Dyn9 |

J2F |

8 |

1.43 |

481.43 |

1.62 |

228.29 |

||||||||

Dyn12 |

J2F |

1 |

1.43 |

433.04 |

1.70 |

796.86 |

1.40 |

-110.72 |

1.47 |

-58.19 |

1.67 |

-196.59 |

1.75 |

-119.02 |

Dyn12 |

J2F |

2 |

1.44 |

677.99 |

1.72 |

893.38 |

1.41 |

-173.41 |

1.49 |

-60.70 |

1.69 |

-214.46 |

1.77 |

-123.61 |

Dyn12 |

J2F |

3 |

1.38 |

636.70 |

1.65 |

872.43 |

1.36 |

-167.57 |

1.43 |

-70.65 |

1.62 |

-229.22 |

1.70 |

-122.18 |

Dyn12 |

J2F |

4 |

1.35 |

641.91 |

1.62 |

937.55 |

1.33 |

-179.50 |

1.40 |

-75.22 |

1.59 |

-225.53 |

1.67 |

-129.91 |

Dyn12 |

J2F |

5 |

1.47 |

766.11 |

1.72 |

967.68 |

1.45 |

-217.15 |

1.51 |

-83.93 |

1.69 |

-242.25 |

1.77 |

-118.40 |

Dyn12 |

J2F |

6 |

1.41 |

627.06 |

1.62 |

1086.41 |

1.39 |

-225.64 |

1.45 |

-86.46 |

1.60 |

-277.34 |

1.66 |

-117.95 |

Dyn12 |

J2F |

7 |

1.42 |

441.83 |

1.62 |

1089.63 |

1.40 |

-185.48 |

1.46 |

-77.49 |

1.60 |

-280.45 |

1.66 |

-108.65 |

Dyn12 |

J2F |

8 |

1.32 |

547.97 |

1.52 |

1141.55 |

1.30 |

-212.76 |

1.36 |

-79.22 |

1.50 |

-284.95 |

1.56 |

-119.13 |

Note: Dyn 9 sensor which is laid in transverse direction for test section J2 has two trace peaks. Time stamp and strain value information for those two peaks is presented and remaining cells are shown as blank cells. Whereas, Dyn 12 sensor which is laid in longitudinal direction for the same test section has two peaks and four valleys. A total of six time stamps and strain values are shown.

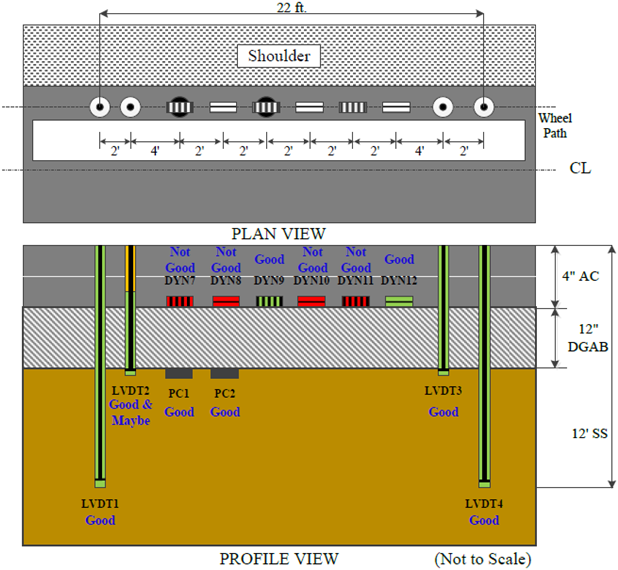

The QC results obtained for test J2F are shown in figure 15. The trace quality obtained from the two sensor types (strain gauge and LVDT) are graphically presented either in combination or separately in green, orange, and red colors to represent good, maybe and not good sensors. For example, strain gauge sensors Dyn7, Dyn8, Dyn10, and Dyn11 are in red, indicating data in the not good category, whereas Dyn9, Dyn12, LVDT1, LVDT3, and LVDT4 are in green indicating data in the good category. The LVDT2 sensor is in a combination of orange and green, meaning that the data obtained from this sensor was of good quality for some runs and of maybe quality for the remaining runs. Except for three traces, the QC results obtained for PC sensors were in the good category for all of the traces; they are not represented in colors in the drawings. Graphical representation of QC results for all 23 tests are in appendix B.

Figure 15. Illustration. QC results by sensor type for te0st section 390102 test J2F

The peaks and valleys for the smoothed traces in test J2F were extracted using the mspeaks function discussed in the fourth step listed in the methodology in chapter 5.(11) These extracted peaks and valleys for each trace were directly saved into a separate Microsoft Excel® file using a file name of sensor type, sensor number, test name, and run number (e.g., Dyn12_J2F1 is Dyn12 sensor in test J2F for run 1). Based on the QC results, the peaks and valleys extracted for good traces for test J2F are summarized in table 6 . For test J2F, a two-axle test truck was used. Because sensor Dyn9 was laid in a transverse direction, it had only two peaks, whereas sensor Dyn12 was laid in a longitudinal direction and therefore had two peaks and four valley points.

Raw (Unsmoothed) Trace Processing

The same processing steps were applied to raw (unsmoothed) traces for test J2F. The results are shown in table 7 and table 8. Table 7 has the summarized QC results for raw traces. Similar to table 5, numbers 1 through 3 for strain gauge, LVDT, and PC sensors represent good, maybe, and not good trace categories respectively. There were no differences between the QC results for raw traces and the QC results for smoothed traces. Table 8 shows the summarized peaks and valleys extracted for good raw traces.

Table 7 . Summarized QC results for raw traces in test J2F.

Run No. |

Dyn |

LVDT |

PC |

|||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|

7 |

8 |

9 |

10 |

11 |

12 |

1 |

2 |

3 |

4 |

1 |

2 |

|

3 |

3 |

1 |

3 |

3 |

1 |

1 |

2 |

1 |

1 |

1 |

1 |

|

2 |

3 |

3 |

1 |

3 |

3 |

1 |

1 |

1 |

1 |

1 |

1 |

1 |

3 |

3 |

3 |

1 |

3 |

3 |

1 |

1 |

2 |

1 |

1 |

1 |

1 |

4 |

3 |

3 |

1 |

3 |

3 |

1 |

1 |

1 |

1 |

1 |

1 |

1 |

5 |

3 |

3 |

1 |

3 |

3 |

1 |

1 |

2 |

1 |

1 |

1 |

1 |

6 |

3 |

3 |

1 |

3 |

3 |

1 |

1 |

1 |

1 |

1 |

1 |

1 |

7 |

3 |

3 |

1 |

3 |

3 |

1 |

1 |

1 |

1 |

1 |

1 |

1 |

8 |

3 |

3 |

1 |

3 |

3 |

1 |

1 |

1 |

1 |

1 |

1 |

1 |

Total |

||||||||||||

Good |

0 |

0 |

8 |

0 |

0 |

8 |

8 |

5 |

8 |

8 |

8 |

8 |

Maybe |

0 |

0 |

0 |

0 |

0 |

0 |

0 |

3 |

0 |

0 |

0 |

0 |

Not good |

8 |

8 |

0 |

8 |

8 |

0 |

0 |

0 |

0 |

0 |

0 |

0 |

Table 8 . Peaks and valleys extracted for raw traces in test J2F.

Tag ID |

Test Name |

Run |

Time Raw 1 (s) |

Strain Value Raw 1 |

Time Raw 2 (s) |

Strain Value Raw 2 |

Time Raw 3 (s) |

Strain Value Raw 3 |

Time Raw 4 (s) |

Strain Value Raw 4 |

Time Raw 5 (s) |

Strain Value Raw 5 |

Time Raw 6 (s) |

Strain Value Raw 6 |

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

Dyn9 |

J2F |

1 |

1.58 |

229.81 |

1.85 |

333.57 |

|

|

|

|

|

|

|

|

Dyn9 |

J2F |

2 |

1.59 |

761.85 |

1.84 |

297.43 |

|

|

|

|

|

|

|

|

Dyn9 |

J2F |

3 |

1.52 |

712.71 |

1.76 |

302.67 |

|

|

|

|

|

|

|

|

Dyn9 |

J2F |

4 |

1.50 |

719.66 |

1.74 |

278.99 |

|

|

|

|

|

|

|

|

Dyn9 |

J2F |

5 |

1.60 |

1070.29 |

1.83 |

343.34 |

|

|

|

|

|

|

|

|

Dyn9 |

J2F |

6 |

1.52 |

825.52 |

1.71 |

282.34 |

|

|

|

|

|

|

|

|

Dyn9 |

J2F |

7 |

1.53 |

295.44 |

1.72 |

247.31 |

|

|

|

|

|

|

|

|

Dyn9 |

J2F |

8 |

1.43 |

483.47 |

1.62 |

229.69 |

|

|

|

|

|

|

|

|

Dyn12 |

J2F |

1 |

1.43 |

435.75 |

1.70 |

801.42 |

1.40 |

-111.18 |

1.47 |

-59.30 |

1.67 |

-196.81 |

1.75 |

-119.30 |

Dyn12 |

J2F |

2 |

1.44 |

682.82 |

1.72 |

898.46 |

1.41 |

-174.14 |

1.49 |

-61.63 |

1.69 |

-214.77 |

1.77 |

-124.14 |

Dyn12 |

J2F |

3 |

1.38 |

641.79 |

1.65 |

878.06 |

1.36 |

-168.92 |

1.43 |

-71.41 |

1.62 |

-230.17 |

1.70 |

-122.66 |

Dyn12 |

J2F |

4 |

1.35 |

647.40 |

1.62 |

942.43 |

1.33 |

-180.81 |

1.40 |

-75.80 |

1.59 |

-226.44 |

1.67 |

-130.18 |

Dyn12 |

J2F |

5 |

1.47 |

773.32 |

1.72 |

973.96 |

1.45 |

-218.65 |

1.51 |

-84.27 |

1.69 |

-243.03 |

1.77 |

-118.64 |

Dyn12 |

J2F |

6 |

1.41 |

635.66 |

1.62 |

1095.08 |

1.39 |

-226.93 |

1.45 |

-86.91 |

1.60 |

-278.18 |

1.66 |

-118.17 |

Dyn12 |

J2F |

7 |

1.42 |

446.82 |

1.62 |

1100.64 |

1.40 |

-186.37 |

1.46 |

-78.23 |

1.60 |

-282.00 |

1.66 |

-109.48 |

Dyn12 |

J2F |

8 |

1.32 |

556.01 |

1.52 |

1152.32 |

1.30 |

-214.07 |

1.36 |

-79.68 |

1.50 |

-285.95 |

1.56 |

-119.68 |

Note: Dyn 9 sensor, which is laid in the transverse direction for test section J2, has two trace peaks. Time stamp and strain value information for those two peaks is presented, and the remaining cells are left blank. Whereas the Dyn 12 sensor, which is laid in the longitudinal direction for the same test section, has two peaks and four valleys. A total of six time stamps and strain values are shown.

The first peaks extracted for good sensor traces in test J2F in table 6 and table 8 were used to check how close the processed J2F data were to the data in the Ohio data peak file (TruckPeak.txt). Table 9 shows the comparison of data peak values with first peak values of smoothed and raw traces for strain gauges Dyn9 and Dyn12 in test J2F. The column labeled "X" is the estimated x-coordinate position of the front-axle at the time the peak occurred. The X-coordinate was measured from the southernmost deep LVDT in the AC sections. For Dyn9 strain gauge, the smoothed and raw peak values were close to the Ohio data peak values. For Dyn12 strain gauge, however, there was more divergence between the smoothed and raw peak values and the data peak values.

Table 9 . Comparison of first peak smooth and raw peak values with Ohio peak values.

Test Job |

Run |

Test Section |

Sensor Name |

X |

Ohio Peak Value |

Smooth Peak Value |

Raw Peak Value |

|---|---|---|---|---|---|---|---|

J2F |

1 |

390102 |

Dyn9 |

118.3 |

224.30 |

228.28 |

229.81 |

J2F |

2 |

390102 |

Dyn9 |

121.8 |

751.90 |

759.57 |

761.85 |

J2F |

3 |

390102 |

Dyn9 |

121.5 |

702.10 |

709.65 |

712.71 |

J2F |

4 |

390102 |

Dyn9 |

121.0 |

709.90 |

718.30 |

719.66 |

J2F |

5 |

390102 |

Dyn9 |

121.8 |

1,048.00 |

1,067.32 |

1,070.29 |

J2F |

6 |

390102 |

Dyn9 |

121.5 |

814.60 |

822.41 |

825.52 |

J2F |

7 |

390102 |

Dyn9 |

118.5 |

289.50 |

293.97 |

295.44 |

J2F |

8 |

390102 |

Dyn9 |

120.5 |

475.60 |

481.43 |

483.47 |

J2F |

1 |

390102 |

Dyn12 |

194.7 |

411.40 |

433.04 |

435.75 |

J2F |

2 |

390102 |

Dyn12 |

195.4 |

629.80 |

677.99 |

682.82 |

J2F |

3 |

390102 |

Dyn12 |

195.5 |

585.00 |

636.70 |

641.79 |

J2F |

4 |

390102 |

Dyn12 |

194.5 |

591.60 |

641.91 |

647.40 |

J2F |

5 |

390102 |

Dyn12 |

194.8 |

683.80 |

766.11 |

773.32 |

J2F |

6 |

390102 |

Dyn12 |

195.2 |

581.80 |

627.06 |

635.66 |

J2F |

7 |

390102 |

Dyn12 |

194.8 |

418.80 |

441.83 |

446.82 |

J2F |

8 |

390102 |

Dyn12 |

195.2 |

509.90 |

547.97 |

556.01 |

Dyn9's actual location was X = 120 inches, and Dyn12's actual location was X = 192 inches. The Ohio peak data, however, showed multiple locations for sensors, the locations being 2 to 3 inches off the actual sensor location (see table 18 in chapter 7). It was observed that the smoothed and raw peak values are close to the Ohio data peak values such that X values are closer and below the actual sensor location. For example, the Dyn9 sensor for run 1 had a peak value of 224.30 µe at X = 118.3 inches. The X value was close to and below the actual sensor location of X = 120 inches, and the smoothed and raw peak values of 228.23 and 229.81 µe, respectively, were very close to the data peak value of 224.30 µe. Conversely, the Dyn12 sensor for run 1 had a location at X = 194.7 inches and a peak value of 411.40 µe. The location of X = 194.7 inches was above the actual location of X = 192 inches. The first peak values of the smoothed and raw traces, 433.04 and 435.75 µe, respectively, were considerably removed from the peak value of 411.40 µe.

Beginning offset, ending offset, and range values were computed for all sensor traces in test J2F. Table 10 shows beginning and ending offset and range values for a PC sensor in test J2F.

Table 10 . PC sensor begin offset, end offset, and range values.

Test File |

PC1 |

PC2 |

||||

|---|---|---|---|---|---|---|

Beginning Offset |

Ending Offset |

Range |

Beginning Offset |

Ending Offset |

Range |

|

AJ2F001 |

0.0000206 |

0.0172634 |

1.227 |

0.0000000 |

0.0223676 |

1.215 |

AJ2F002 |

0.0000675 |

0.0140629 |

1.300 |

-0.0000228 |

0.0189775 |

1.387 |

AJ2F003 |

-0.0000184 |

0.0141437 |

1.330 |

0.0000303 |

0.0200913 |

1.490 |

AJ2F004 |

0.0000341 |

0.0096094 |

1.329 |

0.0000631 |

0.0128362 |

1.495 |

AJ2F005 |

0.0000228 |

0.0115536 |

1.344 |

0.0000078 |

0.0179510 |

1.576 |

AJ2F006 |

-0.0000250 |

0.0099899 |

1.082 |

-0.0000269 |

0.0131659 |

1.336 |

AJ2F007 |

0.0000203 |

0.0076421 |

1.035 |

0.0000162 |

0.0112694 |

1.328 |

AJ2F008 |

0.0000191 |

0.0092828 |

1.126 |

-0.0000325 |

0.0102851 |

1.392 |

The preceding data processing steps for smoothed and raw traces in test J2F were repeated one by one for the remaining 22 tests. The QC results summarized for all 23 tests for both smoothed and raw traces are shown in table 11 and table 12. Similar to table 6 and table 8 for test J2F, DLR data tables were created separately for good traces of each sensor type for the 23 tests and will be included in future SDRs.

Table 11. Summarized QC results for SPS-1 smoothed traces.

Test Job Name |

No. of Test Runs |

Strain Gauge |

Total |

LVDT |

Total |

PC |

Total |

||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

Good |

Maybe |

Not |

Good |

Maybe |

Not Good |

Good |

Maybe |

Not Good |

|||||

J2A |

16 |

32 |

13 |

51 |

96 |

39 |

7 |

18 |

64 |

32 |

0 |

0 |

32 |

J2C |

10 |

12 |

0 |

48 |

60 |

26 |

4 |

10 |

40 |

20 |

0 |

0 |

20 |

J2D |

16 |

17 |

8 |

71 |

96 |

45 |

11 |

8 |

64 |

32 |

0 |

0 |

32 |

J2E |

13 |

15 |

0 |

57 |

72 |

41 |

7 |

0 |

48 |

24 |

0 |

0 |

24 |

J2F |

8 |

16 |

0 |

32 |

48 |

29 |

3 |

0 |

32 |

16 |

0 |

0 |

16 |

J2G |

12 |

16 |

8 |

48 |

72 |

38 |

10 |

0 |

48 |

24 |

0 |

0 |

24 |

J4A |

16 |

46 |

5 |

93 |

144 |

32 |

32 |

0 |

64 |

32 |

0 |

0 |

32 |

J4B |

13 |

30 |

5 |

82 |

117 |

24 |

24 |

4 |

52 |

26 |

0 |

0 |

26 |

J4C |

10 |

15 |

9 |

48 |

72 |

16 |

12 |

4 |

32 |

14 |

0 |

2 |

16 |

J4D |

15 |

30 |

15 |

90 |

135 |

32 |

27 |

1 |

60 |

30 |

0 |

0 |

30 |

J4E |

13 |

26 |

15 |

76 |

117 |

40 |

12 |

0 |

52 |

26 |

0 |

0 |

26 |

J4F |

12 |

24 |

33 |

51 |

108 |

24 |

24 |

0 |

48 |

24 |

0 |

0 |

24 |

J4G |

12 |

24 |

7 |

77 |

108 |

24 |

24 |

0 |

48 |

24 |

0 |

0 |

24 |

J8A |

16 |

48 |

48 |

48 |

144 |

21 |

43 |

0 |

64 |

31 |

1 |

0 |

32 |

J8D |

15 |

45 |

45 |

45 |

135 |

22 |

38 |

0 |

60 |

30 |

0 |

0 |

30 |

J8E |

13 |

39 |

44 |

34 |

117 |

23 |

29 |

0 |

52 |

26 |

0 |

0 |

26 |

J8G |

12 |

36 |

37 |

35 |

108 |

36 |

12 |

0 |

48 |

24 |

0 |

0 |

24 |

J10A |

16 |

15 |

5 |

115 |

135 |

26 |

15 |

19 |

60 |

30 |

0 |

0 |

30 |

J10C |

10 |

10 |

0 |

80 |

90 |

6 |

19 |

15 |

40 |

20 |

0 |

0 |

20 |

J10D |

16 |

19 |

21 |

104 |

144 |

13 |

43 |

8 |

64 |

32 |

0 |

0 |

32 |

J10E |

12 |

12 |

17 |

79 |

108 |

27 |

15 |

6 |

48 |

24 |

0 |

0 |

24 |

J10F |

13 |

61 |

12 |

44 |

117 |

31 |

16 |

5 |

52 |

26 |

0 |

0 |

26 |

J10G |

12 |

12 |

34 |

62 |

108 |

36 |

12 |

0 |

48 |

24 |

0 |

0 |

24 |

Total |

301 |

600 |

381 |

1,470 |

2,451 |

651 |

439 |

98 |

1,188 |

591 |

1 |

2 |

594 |

Table 12. Summarized QC results for SPS-1 raw traces.

Test Job Name |

No. of Test Runs |

Strain Gauge |

Total |

LVDT |

Total |

PC |

Total |

||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

Good |

Maybe |

Not Good |

Good |

Maybe |

Not Good |

Good |

Maybe |

Not Good |

|||||

J2A |

16 |

32 |

13 |

51 |

96 |

39 |

7 |

18 |

64 |

32 |

0 |

0 |

32 |

J2C |

10 |

12 |

0 |

48 |

60 |

26 |

4 |

10 |

40 |

20 |

0 |

0 |

20 |

J2D |

16 |

17 |

8 |

71 |

96 |

45 |

11 |

8 |

64 |

32 |

0 |

0 |

32 |

J2E |

13 |

14 |

0 |

58 |

72 |

39 |

9 |

0 |

48 |

24 |

0 |

0 |

24 |

J2F |

8 |

16 |

0 |

32 |

48 |

29 |

3 |

0 |

32 |

16 |

0 |

0 |

16 |

J2G |

12 |

16 |

8 |

48 |

72 |

38 |

7 |

3 |

48 |

24 |

0 |

0 |

24 |

J4A |

16 |

46 |

2 |

96 |

144 |

32 |

32 |

0 |

64 |

32 |

0 |

0 |

32 |

J4B |

13 |

30 |

2 |

85 |

117 |

24 |

24 |

4 |

52 |

26 |

0 |

0 |

26 |

J4C |

10 |

15 |

2 |

55 |

72 |

14 |

14 |

4 |

32 |

14 |

0 |

2 |

16 |

J4D |

15 |

30 |

15 |

90 |

135 |

32 |

27 |

1 |

60 |

30 |

0 |

0 |

30 |

J4E |

13 |

26 |

15 |

76 |

117 |

39 |

13 |

0 |

52 |

26 |

0 |

0 |

26 |

J4F |

12 |

24 |

1 |

83 |

108 |

24 |

24 |

0 |

48 |

24 |

0 |

0 |

24 |

J4G |

12 |

24 |

7 |

77 |

108 |

24 |

24 |

0 |

48 |

24 |

0 |

0 |

24 |

J8A |

16 |

48 |

48 |

48 |

144 |

21 |

43 |

0 |

64 |

31 |

1 |

0 |

32 |

J8D |

15 |

45 |

45 |

45 |

135 |

22 |

38 |

0 |

60 |

30 |

0 |

0 |

30 |

J8E |

13 |

39 |

44 |

34 |

117 |

23 |

29 |

0 |

52 |

26 |

0 |

0 |

26 |

J8G |

12 |

36 |

37 |

35 |

108 |

36 |

12 |

0 |

48 |

24 |

0 |

0 |

24 |

J10A |

16 |

15 |

5 |

115 |

135 |

24 |

18 |

18 |

60 |

30 |

0 |

0 |

30 |

J10C |

10 |

10 |

0 |

80 |

90 |

6 |

19 |

15 |

40 |

20 |

0 |

0 |

20 |

J10D |

16 |

19 |

21 |

104 |

144 |

13 |

43 |

8 |

64 |

32 |

0 |

0 |

32 |

J10E |

12 |

12 |

17 |

79 |

108 |

27 |

15 |

6 |

48 |

24 |

0 |

0 |

24 |

J10F |

13 |

61 |

12 |

44 |

117 |

30 |

17 |

5 |

52 |

26 |

0 |

0 |

26 |

J10G |

12 |

12 |

34 |

62 |

108 |

36 |

12 |

0 |

48 |

24 |

0 |

0 |

24 |

Total |

542 |

599 |

336 |

1,516 |

2,451 |

643 |

445 |

100 |

1,188 |

591 |

1 |

2 |

594 |

Table 13 shows the summarized QC results for smoothed traces for strain gauge, LVDT, and PC sensors with percentages in parentheses. Of the three sensor types, PCs had the highest percentage of good traces with 99 percent, followed by LVDTs with 55 percent, and strain gauges with 24 percent.

Table 13 . Summarized QC results for Ohio SPS-1 smoothed traces.

Sensor Type |

Good |

Maybe |

Not Good |

Total Traces Completed |

|---|---|---|---|---|

Strain gauge |

600 |

381 |

1,470 |

2,451 |

LVDT |

651 |

439 |

98 |

1,188 |

PC |

591 |

1 |

2 |

594 |

Total |

4,233 |

|||

Similarly, table 14 shows the summarized QC results for raw traces for strain gauge, LVDT, and PC sensors with percentages in parentheses. No significant difference in percentage was observed when compared to the QC results of smoothed traces. Similar to table 13, of the three sensor types, PCs had the highest percentage of good traces with 99 percent, followed by LVDTs with 54 percent, and strain gauges with 24 percent.

Table 14 . Summarized QC results for Ohio SPS-1 raw (unsmoothed) traces.

Sensor Type |

Good |

Maybe |

Not |

Total Traces Completed |

|---|---|---|---|---|

Strain gauge |

599 |

336 |

1,516 |

2,451 |

LVDT |

643 |

445 |

100 |

1,188 |

PC |

591 |

1 |

2 |

594 |

Total |

4,233 |

|||

Table 15 shows the comparison of SPS-2 first peak smooth values of test J1A and the Dyn1 sensor with Ohio data peak values. The extracted smooth values of test J1A and the Dyn1 sensor closely match the Ohio peak values.

Table 15 . Comparison of first peak smooth values with Ohio peak values.

Test Job |

Run |

Test Section |

Sensor Name |

X (inches) |

Ohio Peak Value |

Smooth Peak Value |

|---|---|---|---|---|---|---|

J1A |

1 |

390201 |

Dyn1 |

82.3 |

-22.07 |

-22.53 |

J1A |

2 |

390201 |

Dyn1 |

85.2 |

-38.20 |

-38.68 |

J1A |

3 |

390201 |

Dyn1 |

82.6 |

-20.62 |

-20.22 |

J1A |

4 |

390201 |

Dyn1 |

85.0 |

-36.42 |

-36.75 |

J1A |

5 |

390201 |

Dyn1 |

82.5 |

-20.48 |

-20.07 |

J1A |

6 |

390201 |

Dyn1 |

85.7 |

-34.08 |

-34.64 |

J1A |

7 |

390201 |

Dyn1 |

82.4 |

-20.74 |

-20.73 |

J1A |

8 |

390201 |

Dyn1 |

85.0 |

-34.25 |

-34.15 |

J1A |

9 |

390201 |

Dyn1 |

82.4 |

-21.29 |

-21.28 |

J1A |

10 |

390201 |

Dyn1 |

84.4 |

-35.69 |

-35.75 |

J1A |

11 |

390201 |

Dyn1 |

81.8 |

-18.50 |

-18.05 |

J1A |

12 |

390201 |

Dyn1 |

85.3 |

-36.14 |

-35.73 |

J1A |

13 |

390201 |

Dyn1 |

82.8 |

-21.16 |

-20.77 |

J1A |

14 |

390201 |

Dyn1 |

85.0 |

-32.30 |

-31.41 |

J1A |

15 |

390201 |

Dyn1 |

82.1 |

-20.61 |

-20.16 |

J1A |

16 |

390201 |

Dyn1 |

85.0 |

-34.77 |

-34.12 |

J1A |

17 |

390201 |

Dyn1 |

82.1 |

-20.10 |

-19.69 |

J1A |

18 |

390201 |

Dyn1 |

85.1 |

-32.73 |

-32.08 |

J1A |

19 |

390201 |

Dyn1 |

82.2 |

-20.49 |

-19.45 |

J1A |

20 |

390201 |

Dyn1 |

84.3 |

-30.04 |

-29.23 |

J1A |

21 |

390201 |

Dyn1 |

82.7 |

-22.58 |

-21.49 |

J1A |

22 |

390201 |

Dyn1 |

84.3 |

-33.11 |

-31.97 |

J1A |

23 |

390201 |

Dyn1 |

82.1 |

-22.10 |

-20.99 |

J1A |

24 |

390201 |

Dyn1 |

84.8 |

-28.67 |

-27.59 |

J1A |

25 |

390201 |

Dyn1 |

82.2 |

-21.36 |

-19.78 |

J1A |

26 |

390201 |

Dyn1 |

83.9 |

-30.20 |

-29.13 |

J1A |

27 |

390201 |

Dyn1 |

84.3 |

-35.76 |

-34.43 |

J1A |

28 |

390201 |

Dyn1 |

85.1 |

-33.05 |

-32.11 |

Table 16 shows summarized QC results for smoothed traces for all 24 Ohio SPS-2 tests.

Table 16 . Summarized QC results for Ohio SPS-2 smoothed traces.

Test Job |

No. of Test Runs |

Strain Gauge |

Total |

LVDT |

Total |

||||

|---|---|---|---|---|---|---|---|---|---|

Good |

Maybe |

Not Good |

Good |

Maybe |

Not Good |

||||

J1A |

28 |

112 |

0 |

0 |

112 |

103 |

7 |

282 |

392 |

J1B |

24 |

96 |

0 |

0 |

96 |

30 |

28 |

278 |

336 |

J1C |

14 |

56 |

0 |

0 |

56 |

55 |

34 |

107 |

196 |

J5A |

29 |

9 |

0 |

107 |

116 |

45 |

4 |

357 |

406 |

J5B |

25 |

75 |

0 |

25 |

100 |

46 |

18 |

286 |

350 |

J5C |

14 |

42 |

0 |

14 |

56 |

23 |

12 |

161 |

196 |

J8A |

26 |

78 |

0 |

26 |

104 |

68 |

13 |

283 |

364 |

J8B |

26 |

87 |

0 |

17 |

104 |

70 |

6 |

288 |

364 |

J8C |

17 |

52 |

0 |

16 |

68 |

55 |

12 |

171 |

238 |

J12A |

4 |

16 |

0 |

0 |

16 |

9 |

5 |

42 |

56 |

J12B |

26 |

102 |

2 |

0 |

104 |

75 |

10 |

279 |

364 |

J12C |

14 |

51 |

3 |

2 |

56 |

68 |

3 |

125 |

196 |

J5J1M |

18 |

72 |

0 |

0 |

72 |

67 |

8 |

177 |

252 |

J5J1N |

18 |

72 |

0 |

0 |

72 |

52 |

8 |

92 |

152 |

J5J1O |

18 |

49 |

3 |

20 |

72 |

58 |

5 |

189 |

252 |

J5J1P |

18 |

64 |

0 |

8 |

72 |

53 |

5 |

194 |

252 |

J8S3M |

18 |

16 |

0 |

56 |

72 |

10 |

7 |

235 |

252 |

J8S3N |

18 |

20 |

9 |

43 |

72 |

3 |

9 |

240 |

252 |

J8S3O |

18 |

17 |

1 |

54 |

72 |

12 |

2 |

238 |

252 |

J8S3P |

18 |

15 |

2 |

55 |

72 |

0 |

2 |

250 |

252 |

J12J10M |

18 |

0 |

11 |

61 |

72 |

24 |

20 |

208 |

252 |

J12J10N |

18 |

11 |

7 |

54 |

72 |

15 |

9 |

228 |

252 |

J12J10O |

18 |

9 |

15 |

48 |

72 |

21 |

2 |

229 |

252 |

J12J10P |

17 |

0 |

0 |

68 |

68 |

25 |

50 |

163 |

238 |

Total |

462 |

1,121 |

53 |

674 |

1,848 |

987 |

279 |

5,102 |

6,368 |

Table 17 shows summarized QC results for smoothed traces for all 24 SPS-2 tests with percentages in parentheses. A total of 61 percent of strain gauges had good traces, whereas only 15 percent of LVDTs had good traces.

Table 17 . Summarized QC results for Ohio SPS-2 smoothed traces.

Sensor Type |

Good |

Maybe |

Not Good |

Total |

|---|---|---|---|---|

Strain gauge |

1,121 (60.66%) |

53 (2.87%) |

674 (36.47%) |

1,848 (100%) |

LVDT |

987 (15.50%) |

279 (4.38%) |

5,102 (80.12%) |

6,368 (100%) |

Total |

8,216 |

|||