U.S. Department of Transportation

Federal Highway Administration

1200 New Jersey Avenue, SE

Washington, DC 20590

202-366-4000

Federal Highway Administration Research and Technology

Coordinating, Developing, and Delivering Highway Transportation Innovations

| REPORT |

| This report is an archived publication and may contain dated technical, contact, and link information |

|

| Publication Number: FHWA-HRT-13-046 Date: October 2013 |

Publication Number: FHWA-HRT-13-046 Date: October 2013 |

Generic applications of DMM include the following:

The generic applications encompass the specific embankment foundation applications listed in table 1 in chapter 1. Frequently, DMM has more than one function on any particular project (e.g., excavation support in combination with retaining wall support).

DMM has been used on at least 21 U.S. transportation projects since 1991, as shown in table 2. Projects are listed in chronological order, and the primary and secondary applications of DMM for each project are identified. The primary application reflects the main function of DMM as designed and constructed. The secondary application reflects associated functions and benefits provided by DMM.

Table 2. Summary of DMM usage for U.S. transportation projects.

Application of DMMa |

Year |

Project and Location |

Owner |

Quantity |

Cost of DMMb |

|||||

|---|---|---|---|---|---|---|---|---|---|---|

Ground Improvement |

Ground Treatment |

Liquefaction Mitigation |

Excavation Support Walls |

Hydraulic Cutoff Walls |

Environmental Remediation |

|||||

|

|

|

|

|

P |

1991 |

Allegheny County Jail, Pittsburgh, PA(11) |

Pennsylvania Department of Transportation (PennDOT) |

1,800 m3 |

$147,600 |

P |

S |

|

S |

|

|

1992-1995 |

Bird Island Flats, Central Artery Tunnel, Boston, MA (12-14) |

Massachusetts Turnpike Authority and Massachusetts Department of Transportation (MassDOT) |

3.,180 m2 |

$35.8 million |

|

|

|

S |

P |

|

1996-1997 |

7th Street seal slab, San Francisco, CA |

California Department of Transportation (Caltrans) |

N/A |

N/A |

|

|

|

P |

|

|

1997 |

Lake Parkway, Milwaukee, WI(15,16) |

Wisconsin Department of Transportation (WisDOT) |

20,900 m2 |

$4 million |

P |

|

|

|

|

|

1997 |

I-15, Salt Lake City, UT(17,18) |

Utah Department of Transportation |

3.,500 m3 |

$2.2 million |

P |

|

|

|

|

|

1997-2002 |

Fort Point Channel, Boston, MA(14) |

Massachusetts Turnpike Authority and MassDOT |

420,000 m3 |

$72 million |

P |

|

S |

|

|

|

1998 |

San Francisco Bay Area Rapid Transit (BART) Culvert, |

Caltrans |

170,500 m3 |

$2.6 million |

|

|

|

P |

|

|

1999 |

Danville, PA(20) |

PennDOT |

4,000 m2 |

$700,000 |

P |

|

|

|

|

|

2000 |

Woodrow Wilson Bridge, Alexandria, VA(18,21,22) |

Virginia Department of Transportation (VDOT) |

124,300 m3 |

$11.4 million |

|

|

|

|

P |

|

2000 |

Doolittle Drive and Airport Drive Interchange, Oakland Airport, Oakland, CA(23) |

Caltrans |

N/A |

N/A |

P |

|

|

S |

|

|

2000 |

Hackensack Meadows, Hoboken, NJ(24) |

New Jersey Department of Transportation |

9,500 m3 |

$364,000 |

P |

|

|

|

|

|

2001-2002 |

Airport Drive overcrossing Air Cargo Road, Oakland Airport, Oakland, CA(23) |

Caltrans |

15,000 m3 |

$1.2 million |

S |

|

|

P |

|

|

2001-2002 |

Taxiway B and Air Cargo Road Grade Separation, Oakland Airport, Oakland, CA(23,25) |

Caltrans |

30,500 m3 |

$1.83 million |

P |

|

|

|

|

|

2001-2003 |

Glen Road interchange, |

Minnesota Department of Transportation (MnDOT) |

22,770 m3 |

$2 million |

P |

|

S |

|

|

|

2002-2003 |

I-5 expansion, |

Caltrans |

21,300 m3 |

$1.7 million |

|

P |

|

S |

S |

|

2003 |

Tukwila, WA(23) |

Washington State Department of Transportation (WSDOT) |

44,000 m3 |

$5 million |

|

P |

|

|

|

|

2004-2005 |

4th Street exit of I‑80, San Francisco, CA(28,29) |

Caltrans |

N/A |

$16 million |

P |

|

|

|

|

|

2005-2006 |

Route 1 over Jewfish Creek(30) |

Florida Department of Transportation (FDOT) |

275,400 m3 |

$11.9 million |

|

|

|

P |

|

|

2007 |

North Shore connector, |

Port Authority of Allegheny County |

10,200 m2 |

$4 million |

|

|

|

P |

S |

|

2010 |

Warm Springs |

Bay Area Rapid Transit Authority |

24,600 m3 |

$5.5 millionc |

P |

|

P |

|

|

|

2011 |

1-5 high-occupancy vehicle extension, Tacoma, WA(33) |

WSDOT |

11,095 m3 |

$1.35 million |

N/A = Not available.

a P indicates primary application, S indicates secondary application, and blank cells indicate that DMM application was not used.

b Cost does not include mobilization.

c Cost includes jet grouting at utility crossings and setting of soldier beams.

1 ft3 = 0.028 m3

1 ft2 = 0.093 m2

The feasibility of using DMM for any given project is dependent on a number of diverse factors, including practical project considerations (i.e., cost, schedule, performance, geotechnical, logistical, accessibility, and environmental) and conventional considerations (i.e., regional and historical practices and preferences and the degree of influence of local contractors, consultants, and owners).

The relative advantages and potential limitations of using DMM for embankment and foundation support are listed in table 3. DMM, similar to any geotechnical construction technique, is not a solution for all soft ground treatment, improvement, retention, and containment problems. However, for certain applications, it can be more practical, more economic, faster, or otherwise preferable to competing technologies. Typical alternative technologies are listed in table 4.

In the most general terms, DMM may be attractive for the following project conditions:

DMM is especially useful for embankment support under the following conditions:

Table 3. Relative advantages and disadvantages of DMM for general transportation project applications (adapted from FHWA).(1)

Item |

Application |

||

|---|---|---|---|

Ground Treatment and Improvement |

Liquefaction Mitigation |

Excavation Support Walls |

|

Relative advantages/benefits |

|

|

|

Potential |

|

|

|

*DMM techniques designed to produce walls may be capable of penetrating denser or stiffer materials or strata with cobbles. (See technical data in appendix D.)

Table 4. Alternative technologies to DMM.

Application |

Alternative Technology to DMM |

|---|---|

Ground treatment |

|

Ground improvement |

|

Liquefaction mitigation |

|

Excavation support walls/cutoff walls |

|

The factors listed in table 5 should be considered when assessing the feasibility of using DMM for a project.

Table 5. Factors to consider in feasibility assessment for using DMM.

Factor |

Question |

Commentary |

|---|---|---|

Geologic applicability |

Are soils suitable for mixing? |

|

Geometric applicability |

Are site conditions conducive to using DMM? |

|

Project constraints |

Are construction materials readily available? |

|

Are there environmental constraints? |

|

|

Contractual vehicles |

Are performance specifications applicable? |

|

Cost considerations |

Is project cost a driving factor? |

|

Schedule considerations |

Is the project schedule a driving factor? |

|

Design constraints |

Must treated ground strengths be closely engineered? |

|

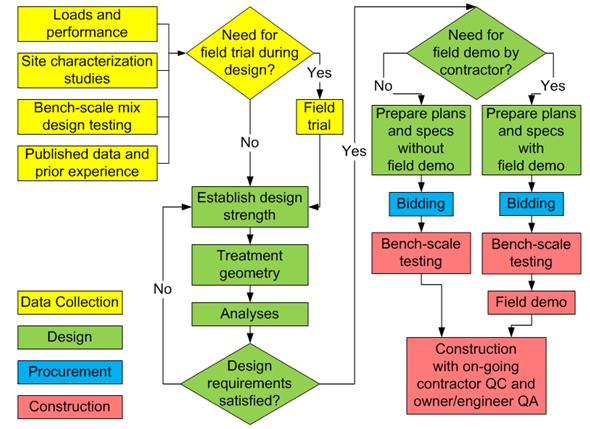

A flow chart depicting the overall process of design and construction for DMM projects is shown in figure 7. The flowchart includes four main project phases: (1) data collection (yellow), (2) design (green), (3) procurement (blue), and (4) construction with continuous QC/QA (red).(34)

Figure 7. Flowchart. Design and construction for DMM projects.(34)

The information collection process includes defining structure performance expectations, gathering site-specific soil and groundwater information, and reviewing available information related to local DMM experience. Specific considerations for site investigations for DMM projects are discussed in chapter 4. Prior experience for other DMM projects may be obtained from published literature and from discussions with experienced engineers and contractors.

Laboratory bench-scale testing and possible field trials are also part of the data collection phase. If prior experience is not available, laboratory mix design studies (i.e., bench-scale testing) should generally be conducted prior to or at the same time as analysis and design to establish a range of strengths that can reasonably be achieved in the field. A preliminary field trial including installation of full-scale DMM elements may also be performed during the design phase to ensure treated soil properties may be achieved as required. Although expensive, full-scale field trials can provide valuable data for large or complex projects. Bench-scale testing and field trial programs are discussed in chapter 10.

The analysis and design phase includes engineering evaluations of the DMM configuration being proposed for the project, laboratory bench-scale testing, possible field trials of DMM techniques to be used, and preparation of specifications for construction. Design procedures are discussed in chapter 6, field trial and validation programs are outlined chapter 10, and a guide to writing effective specifications is provided in chapter 9.

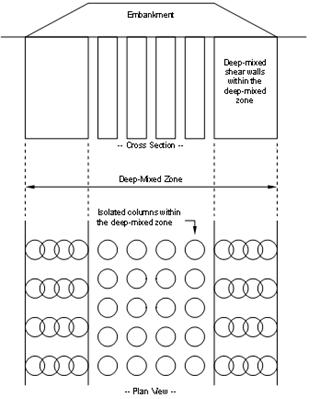

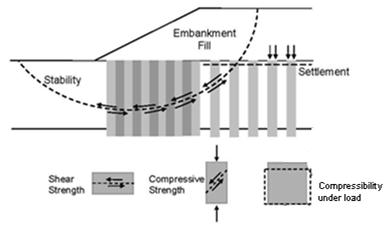

Isolated columns and continuous shear walls, as illustrated in figure 8, are the most common DMM configurations for transportation embankments. Typically, isolated columns are constructed beneath the central portion of the embankment to control settlement, and continuous shear walls are constructed beneath the side slopes (and oriented perpendicularly to the embankment centerline) to prevent embankment stability failure.

Figure 8. Illustration. Typical configuration of DMM columns for transportation applications.

The design process includes an evaluation of external (global) stability and internal stability under a variety of potential failure modes to ensure that the stresses induced within and adjacent to the treated ground do not exceed the material capacities and that settlements are limited to acceptable levels. Initial trial values of DMM properties are assumed, analyses are performed, and the results are compared with performance criteria. Analytical procedures are discussed in detail in chapter 6.

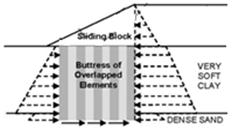

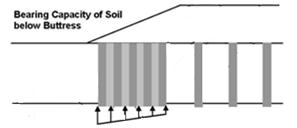

For global stability, the treated ground beneath the embankment is modeled as a rigid body, and its stability is evaluated under various modes of failures, including lateral sliding, overturning, bearing capacity, and rotation/sliding along potential sliding surfaces that pass entirely beneath or entirely above the deep mixed shear walls. Figure 9 and figure 10 illustrate overturning and sliding as well as bearing capacity modes, respectively.

Figure 9. Illustration. External stability mode of failure for overturning and sliding.(35)

Figure 10. Illustration. External stability mode of failure for bearing capacity.(35)

Settlement of the embankment is calculated based on the assumption of equal strains in the treated ground and the adjacent untreated soil within the deep mixed zone underlying the central portion of the embankment. This approach is equivalent to using a composite modulus of the deep mixed ground and the adjacent soil. Compression of soil below the deep mixed ground can be evaluated using a load spread method similar to that used for pile groups. Compliance of the embankment above the deep mixed columns can be evaluated using methods for column-supported embankments.

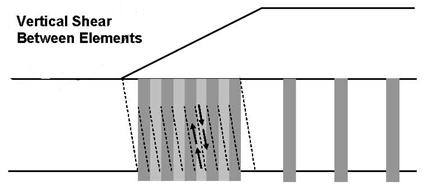

Two internal stability modes of failure are illustrated in figure 11 and figure 12—a sliding surface passing through the deep mixed zone and vertical shearing along column overlaps within the deep mixed zone. If the deep mixed ground overlies a hard bearing stratum, lateral loads could produce toe pressures that exceed the capacity of the deep mixed ground. Analyses should check for crushing of the shear walls at the outside toe of the panels. The overlap of the columns must be sufficient to prevent shearing along vertical planes within the shear walls produced by lateral loading, which could produce a racking-type failure mode. This analysis involves comparing the vertical shear stress on the critical vertical plane with the design strength value. Internal stability analyses also address potential sliding surfaces that pass through the deep mixed shear walls and adjacent soil. The geometry of the shear walls must be checked to ensure that soil does not extrude between the panels due to unbalanced forces caused by active and passive earth pressures acting on the deep mixed zone.(36)

Figure 11. Illustration. Internal stability mode of failure for circular sliding surface.(35)

Figure 12. Illustration. Internal stability mode of failure for vertical shearing.(35)

For internal stability analyses, composite shear strength and unit weight values are used to model the deep mixed zone beneath the embankment based on the configuration of the columns (i.e., area replacement ratio and spacing of the shear walls). Separate composite shear strengths for vertical and non-vertical planes are estimated for the deep mixed shear walls beneath the side slope.

Construction specifications should clearly communicate the required geometry, continuity, and strength of the deep mixed ground. The specifications should also detail the acceptance criteria to assure performance. Guide specifications are discussed in chapter 9.

Traditional design-bid-build procurement practices involve bidding on the project after the contract documents (including plans and technical specifications) are prepared. Innovative procurement vehicles involving design-build methods and early contractor involvement (ECI) have merit on DMM projects due to quality of DMM being influenced by various contractor-controlled variables. Procurement vehicles for DMM projects are discussed in chapter 8.

The contractor is responsible for controlling the geometry of the deep mixed elements by using certain tooling dimensions and installation procedures. The contractor documents the quality of the operations and provides reports of the QC data on a daily basis. The owner conducts QA activities, including sampling and testing to assure the quality of the deep mixed ground. Means and methods for construction and QC/QA are discussed in chapters 11 and 12, respectively.

A field validation program involves installing full-scale DMM elements to demonstrate that the contractor's materials and methods can satisfy the project specifications, including the strength and continuity of the deep mixed ground. Validation tests are conducted after the contract is awarded but before production mixing. Such field validation programs are much more common than trial columns installed during the design phase.