U.S. Department of Transportation

Federal Highway Administration

1200 New Jersey Avenue, SE

Washington, DC 20590

202-366-4000

Federal Highway Administration Research and Technology

Coordinating, Developing, and Delivering Highway Transportation Innovations

| REPORT |

| This report is an archived publication and may contain dated technical, contact, and link information |

|

| Publication Number: FHWA-HRT-13-046 Date: October 2013 |

Publication Number: FHWA-HRT-13-046 Date: October 2013 |

This chapter provides recommendations for designing deep mixing to support embankments and structures in transportation applications. These recommendations do not address all the factors that should be considered when designing deep mixing for other applications, such as stabilizing dam foundations. For support of transportation embankments, the recommendations in section 6.1 include detailed, step-by-step analysis and design procedures. Additional considerations that apply when DMM is used to support structures are described in section 6.2. Section 6.3 discusses the use of DMM to mitigate liquefaction potential, and section 6.4 provides comments about the use of DMM for excavation support. The procedures described in this chapter are for use by experienced geotechnical engineers. Consequently, being familiar with common geotechnical terminology and possessing the ability to perform earth pressure calculations, bearing capacity analyses, and slope stability calculations are prerequisites.

Deep mixing for support of embankments is designed using allowable stress design methodology. Recommended steps in the design process are as follows:

For unusually complex or critical projects, consideration should be given to supplementing the procedures with numerical analyses (e.g., Filz et al).(34)

The following subsections describe the seven steps and provide the references that form the basis for the design procedure.

In step 1, the project requirements are established, including the following:

Several factors of safety values are required in steps 4.2 and 6. Table 11 lists typical design values of safety factors for transportation embankments supported on DMM columns. By iterative analyses, values of the shear strength and geometry of the deep mixed material should be selected such that the calculated factor of safety values equal or exceed the design values.

Table 11. Typical design values of safety factors for design of deep mixing to support embankments.

Symbol |

Description |

Typical Minimum Value for Design |

|---|---|---|

Fcc |

Factor of safety against crushing of the center isolated deep mix columns |

1.3 |

Fs |

Factor of safety against slope stability failure, including global stability and shearing through the deep mixed zone |

1.5 |

Fo |

Factor of safety against combined overturning and bearing capacity failure of the deep mixed shear walls |

1.3 |

Fc |

Factor of safety against crushing of the deep mixed ground at the toe of the deep mixed zone |

1.3 |

Fv |

Factor of safety against shearing on vertical planes through the deep mixed zone |

1.3 |

Fe |

Factor of safety against soil extrusion through deep mixed shear walls |

1.3 |

It is recommended that Spencer's method be used to calculate Fs values because it satisfies all conditions of equilibrium and results in more realistic factor of safety values than some of the more simplified methods of slope stability analysis .(87) The design value of Fs in table 11 is based on using Spencer's method for the slope stability calculations. The analysis methods for the other failure modes listed in the table incorporate conservative assumptions. Consequently, lower design values of factor of safety are recommended for these failure modes.

An engineer may deviate from the recommended design values of factor of safety in table 11. For example, if subsurface conditions are well known, soil parameter values are selected conservatively, and the facility performance is not critical, then lower design values than those listed in table 11 can be considered. Conversely, if subsurface conditions are not well known, soil parameter values are not selected conservatively, or the facility performance is especially critical, then higher design values than those listed in table 11 can be considered. An experienced geotechnical engineer should make the selection of the design factor of safety for each of the failure modes and should justify the selection based on project-specific considerations.

In step 2, the engineer establishes the soil material property values to be used in geotechnical analysis and design, including stratigraphy, groundwater conditions, and foundation material property values, as discussed in chapter 4. For the settlement calculations described in step 5, values of the compression ratio, recompression ratio, and preconsolidation pressure are necessary for the soils underlying the deep mixed zone. For the stability analyses described in step 6, end-of-construction conditions are typically critical, so undrained shear strength parameters would be used for saturated clays, and drained strength parameters would be used for permeable sands and gravels.

In step 3, the engineer establishes trial property values for the deep mixed ground and for the composite deep mixed zone for use in the analyses described in steps 4.2 and 6. Background information about property values for deep mixed ground is provided in chapter 5, and the necessary property values for design are established in this section. The design value for the shear strength of the deep mixed ground (sdm) is estimated from the unconfined compressive strength to be specified (qdm,spec), considering fc and differences between unconfined peak and confined large-strain strengths (fr). Factor fv is also discussed and subsequently applied as appropriate to the analysis of each failure mode that involves the strength of the deep mixed ground.

A trial value of the 28-day qdm,spec is assumed based on the background information provided in chapter 5. Typical values of qdm,spec range from about 75 to 150 psi (0.52 to 1.03 MPa) for soft ground conditions. The necessary property values for design are established as follows:

Figure 30 can be used from 28 to 365 days between mixing and application of 75 percent of the proposed embankment height. The fc value ranges from 1.00 for 28 days to 1.48 for 365 days.

![]()

Figure 33. Equation. Shear strength of the deep mixed ground.

Values of fr typically range from 0.65 to 0.9, and a value of fr equal to 0.8 is recommended for application to transportation embankments.

Design Factor of Safety |

Coefficient of Variation of the Deep Mixed Strength |

fv |

||

|---|---|---|---|---|

pdm = |

pdm = |

pdm = |

||

1.2 |

0.4 |

0.93 |

1.05 |

1.25 |

0.5 |

0.88 |

1.02 |

1.26 |

|

0.6 |

0.83 |

0.99 |

1.27 |

|

1.3 |

0.4 |

0.89 |

1.01 |

1.19 |

0.5 |

0.82 |

0.95 |

1.17 |

|

0.6 |

0.75 |

0.90 |

1.15 |

|

1.4 |

0.4 |

0.85 |

0.97 |

1.14 |

0.5 |

0.76 |

0.89 |

1.09 |

|

0.6 |

0.69 |

0.82 |

1.05 |

|

1.5 |

0.4 |

0.82 |

0.93 |

1.10 |

0.5 |

0.72 |

0.83 |

1.03 |

|

0.6 |

0.63 |

0.75 |

0.96 |

|

1.6 |

0.4 |

0.79 |

0.90 |

1.06 |

0.5 |

0.68 |

0.79 |

0.97 |

|

0.6 |

0.58 |

0.69 |

0.89 |

|

pdm = Probability that the actual deep mixed strength exceeds the specified deep mixed strength.

Note: Values of fv larger than 1.0 are possible even though the coefficient of variation of the deep mixed strength is larger than the coefficient of variation of the soil strength because pdm is larger than the design strength of the untreated soil.(74)

The value of fv depends on the following:

Engineers wishing to consider input values different from those used to develop table 12 are referred to Filz and Navin.(74)

It is recommended that a well-written and properly applied specification and a well-qualified DMM contractor should be used on all DMM projects. When this happens, values of fv corresponding to the midrange of inputs listed in table 12 (pdm = 80 percent and Vdm = 0.50) are reasonable. Higher values of fv may be appropriate during the later phases of a multiphase project involving the same participants and conditions as QC/QA procedures become more reliable. Alternatively, if the engineer is concerned that QC/QA will not be well executed, lower values of fv (corresponding to pdm = 70 percent and/or Vdm = 0.60) can be considered.

![]()

Figure 34. Equation. Young's modulus of deep mixed ground for wet mixing.

![]()

Figure 35. Equation. Young's modulus of deep mixed ground for dry mixing.

Figure 34 and figure 35 are correlations for E50 of the unconfined compressive strength. Estimating E50 of the deep mixed ground is discussed in more detail in chapter 5.

In step 4, the engineer establishes a trial geometry of deep mixing to support the embankment. Step 4.1 discusses the general layout of the embankment and deep mixed zone and defines the geometric parameters. A procedure for establishing the minimum area replacement ratio beneath the central portion of the embankment is discussed in step 4.2, and a procedure for estimating the minimum area replacement ratio beneath the side slopes of the embankment is discussed in step 4.3.

It is not necessary for the engineer to specify all of the geometric parameters defined in step 4.1. In fact, by determining and specifying only the minimum and/or maximum allowed values for certain geometric parameters, the engineer permits the DMM contractor flexibility in construction while still assuring that the final design will satisfy the requirements for settlement and stability.

Step 4.1—General Layout and Definitions

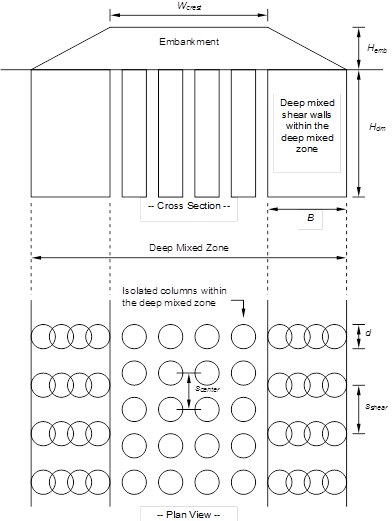

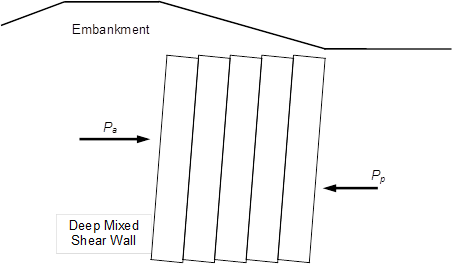

The overall dimensions and location of the deep mixed zone are generally selected to satisfy settlement and stability requirements, which are analyzed in steps 4.2, 5, and 6. Isolated columns and continuous shear walls are the most common configurations for transportation embankments. A cost effective combination uses isolated columns under the central portion of the embankment to control settlement and continuous shear walls oriented perpendicularly to the embankment centerline under the embankment side slopes to improve stability, as shown in figure 36.

Figure 36. Illustration. Typical arrangement for deep-mixed zone beneath an embankment.

Where:

Wcrest = Width of embankment crest.

Hemb = Height of embankment.

Hdm = Height of the deep mixed zone.

B = Length of the shear wall.

d = Column diameter.

scenter = Center-to-center spacing of isolated columns.

sshear = Center-to-center spacing of shear walls.

The continuous shear walls can be constructed from overlapping columns or by using overlapping barrettes. Longitudinal walls can also be constructed to prevent ground extrusion between parallel shear walls, although this is not necessary unless the untreated soil between the shear walls is very soft and the spacing between shear walls is large. A method to calculate the factor of safety against extrusion is provided later in this chapter. The spacing between shear walls under the side slopes of the embankment does not need to be the same as the spacing between isolated columns under the central portion of the embankment.

The analysis and design procedures in this report are for the combination of isolated columns and shear walls shown in figure 36. Other configurations are also possible, but they may require other analysis and design procedures.

The area replacement ratio beneath the central portion of an embankment, as,center, is defined as the ratio of the column area to the tributary soil area surrounding the column. Where isolated columns are placed in a square array, as in figure 36, as,center can be calculated using the equation in figure 37. Typical values of as,center for deep mixing support of embankments range from about 0.2 to 0.4. The minimum value of as,center is established in step 4.2.

![]()

Figure 37. Equation. Area replacement ratio beneath the central portion of an embankment.

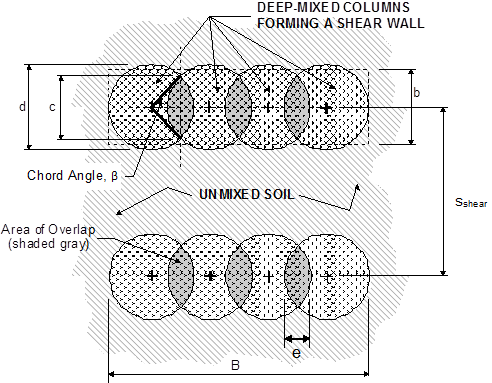

The geometry of overlapping columns used for shear walls under the side slopes of an embankment is shown in figure 38.

Figure 38. Illustration. Definition sketch for column overlap calculations.

Where:

e = Overlap distance.

β = Chord angle in radians.

c = Chord length.

b = Average shear wall width.

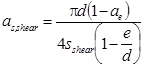

The area replacement ratio under the side slopes of the embankment, as,shear, is defined as the ratio of the area of the shear wall to the tributary soil area surrounding the shear wall. Where overlapping columns are arranged to create shear walls that are oriented perpendicularly to the embankment centerline, as in figure 36 and figure 38, as,shear is defined according to figure 39. Typical values of as,shear for deep mixing support of embankments are greater than or equal to as,center and range from about 0.2 to 0.4. The minimum value of as,shear is estimated in step 4.3.

![]()

Figure 39. Equation. Area replacement ratio under the side slopes of the embankment.

When the shear walls are constructed of overlapping columns, the extent of the overlap influences the minimum and average widths of the shear walls. The values of d, e, and sshear can be used to calculate β , c, the overlap area ratio (ae), and as,shear, as shown in figure 40 through figure 43.

![]()

Figure 40. Equation. Chord angle expressed in radians.

![]()

Figure 41. Equation. Chord length.

![]()

Figure 42. Equation. Overlap area ratio.

Figure 43. Equation. Area replacement ratio of the shear walls.

To illustrate the relationships in figure 40 through figure 43, values of β , c/d, and ae are listed in table 13 for selected values of e/d. Typical values of e/d for shear walls beneath embankment side slopes range from about 0.2 to 0.35. Two important design parameters for embankment slope stability are the area replacement ratio for the shear walls, as,shear, which is provided by figure 43, and the ratio of the chord length to wall spacing, c/sshear, which is obtained by dividing figure 41 by sshear. Values of as,shear and c/sshear are listed in table 14 and table 15, respectively, for selected values of e/d and d/sshear. The value of as,shear is important for resistance to shearing through the deep mixed shear wall zone. The value of c is important for shearing on vertical planes in the deep mixed shear walls. Table 14 shows that as,shear is sensitive to d/sshear, but it is not strongly dependent on e/d. Table 15 shows that c/sshear is sensitive to both d/sshear and e/d, especially for low values of e/d. Small column overlaps should be avoided in circumstances where shearing on vertical planes is an important design consideration.

Table 13. Values of β, c/d, and ae for selected values of e/d.

e/d |

β (radians) |

c/d |

ae |

|---|---|---|---|

0 |

0.000 |

0.000 |

0.000 |

0.1 |

0.902 |

0.436 |

0.037 |

0.2 |

1.287 |

0.600 |

0.104 |

0.3 |

1.591 |

0.714 |

0.188 |

0.4 |

1.855 |

0.800 |

0.285 |

0.5 |

2.094 |

0.866 |

0.391 |

Table 14. Values of as,shear for selected values of e/d and d/s.

e/d |

as,shear |

||||

|---|---|---|---|---|---|

d/sshear = 0.1 |

d/sshear = 0.2 |

d/sshear = 0.3 |

d/sshear = 0.4 |

d/sshear = 0.5 |

|

0 |

0.079 |

0.157 |

0.236 |

0.314 |

0.393 |

0.1 |

0.084 |

0.168 |

0.252 |

0.336 |

0.420 |

0.2 |

0.088 |

0.176 |

0.264 |

0.352 |

0.440 |

0.3 |

0.091 |

0.182 |

0.273 |

0.364 |

0.455 |

0.4 |

0.094 |

0.187 |

0.281 |

0.375 |

0.468 |

0.5 |

0.096 |

0.191 |

0.287 |

0.383 |

0.478 |

Table 15. Values of c/sshear for selected values of e/d and d/s.

e/d |

c/sshear |

||||

|---|---|---|---|---|---|

d/sshear = 0.1 |

d/sshear = 0.2 |

d/sshear = 0.3 |

d/sshear = 0.4 |

d/sshear = 0.5 |

|

0 |

0.000 |

0.000 |

0.000 |

0.000 |

0.000 |

0.1 |

0.044 |

0.087 |

0.131 |

0.174 |

0.218 |

0.2 |

0.060 |

0.120 |

0.180 |

0.240 |

0.300 |

0.3 |

0.071 |

0.143 |

0.214 |

0.286 |

0.357 |

0.4 |

0.080 |

0.160 |

0.240 |

0.320 |

0.400 |

0.5 |

0.087 |

0.173 |

0.260 |

0.346 |

0.433 |

Step 4.2—Center Replacement Ratio

A trial value of as,center should be established based on the capacity of the isolated deep mixed columns beneath the central portion of the embankment using figure 44, with the value of fv from table 12 corresponding to the design value of Fcc from table 11. Typical values of as,center for deep mixing support of embankments range from about 0.2 to 0.4.

![]()

Figure 44. Equation. Area replacement ratio beneath central portion of embankment.

Where q is the vertical stress from the embankment and surcharge.

Figure 44 is conservative because it assumes that the columns support the entire load from the embankment and surcharge without consideration of any support provided by the soil matrix.

Step 4.3—Shear Wall Zone Replacement Ratio

A minimum value of as,shear should be estimated. Typical values of as,shear for deep mixing support of embankments are greater than or equal to as,center and range from about 0.2 to 0.4.

The value of c/sshear should be calculated using figure 40 and figure 45 based on the selected value of e/d, which is typically in the range from 0.2 to 0.35, and the estimated value of as,shear.

![]()

Figure 45. Equation. Ratio of chord length to shear wall spacing.

Table 16 summarizes the geometric parameters that an engineer should specify. Again, by specifying only the minimum and/or maximum allowed values for certain geometric parameters, the engineer is affording the contractor flexibility in construction while still assuring that the final design will satisfy the requirements for performance.

Table 16. Geometric parameters necessary for design.

Parameter |

Minimum and/or Maximum |

|---|---|

Top elevation of DMM element |

Minimum |

Bottom elevation of DMM element |

Maximum |

β |

Minimum |

d |

Minimum and maximum |

e/d |

Minimum |

scenter − d |

Maximum |

sshear − d |

Maximum |

as,center |

Minimum |

as,shear |

Minimum |

c/sshear |

Minimum |

In this step, the post-construction settlement of the embankment is calculated as the sum of the compression of the deep mixed zone and the compression of the underlying ground. Differential compliance settlement between the base of the embankment and the top of the deep mixed zone is often assumed to occur during embankment construction prior to placing the pavement wearing surface. If the engineer judges that differential compliance settlement at the base of the embankment will be delayed, the procedures described by Filz and Smith can be applied to conservatively estimate this contribution to the total embankment settlement.(88) Compression of the deep mixed zone is calculated based on equal strains in the deep mixed ground and the adjacent untreated soil within the deep mixed zone underlying the central portion of the embankment. This approach is equivalent to using a composite modulus of the deep mixed ground and the adjacent soil. The composite modulus, Mcomp, can be evaluated using figure 46.

![]()

Figure 46. Equation. Composite modulus.

Where Msoil is the constrained modulus of the untreated soil.

The implicit assumptions behind using Edm and Msoil are that a stiff column is not significantly restrained from lateral expansion by the soft soil and that the overall system geometry provides lateral restraint for the soft soil in a unit cell. Msoil is the inverse of the compressibility, mv, which is obtained from an oedometer test on the untreated soil over the stress range of interest.

Compression of the treated zone, ΔHdm, can be calculated using figure 47.

![]()

Figure 47. Equation. Compression of the treated zone.

Compression of strata beneath columns installed by DMM can be computed using a load-spread method such as that employed for groups of driven piles.

If the calculated settlement exceeds the allowable settlement for a proposed embankment, then as,center, the column modulus, and/or the column length can be increased, depending on the primary source of the excess settlement.

When Hemb is at least two times the clear spacing between adjacent columns under the central portion of the embankment (i.e., Hemb ≥ 2(scenter - d)) and the embankment is constructed with typical good quality materials and procedures for placement and compaction, there is little risk of surface expression of differential settlements that occur at the base of the embankment, and special provisions for a load transfer platform at the base of the embankment are not necessary. When Hemb < 2(scenter - d), a load transfer platform can be designed using the procedures described by Sloan et al.(89) The load transfer platform should extend at least a distance scenter beyond the embankment crest beneath the embankment side slopes. If wet mixing is used, substantial spoils are produced at the ground surface, and the spoils can be used to construct all or part of the load transfer platform. The spoils should be placed and compacted as soon as they set up enough to support construction equipment, and the spoils will form a very strong embankment material.

On the embankment side slopes, there may be a potential for differential settlement of the embankment surface when Hemb becomes less than 2(sshear - d). This could result in maintenance problems such as difficulty mowing. The concern for differential settlement above embankment side slopes is reduced if there is a firm layer of existing ground at the surface through which the deep mixed shear walls are installed. If differential settlement of the embankment surface at the slide slopes remains a concern, then additional settlement-control columns can be installed between the deep mixed shear walls or a load transfer platform can be designed using the procedures described by Sloan et al.(89) Spoils from wet mixing can be used in a load transfer platform under the embankment side slopes.

In this step, the trial geometry established in step 4 is analyzed for stability as follows:

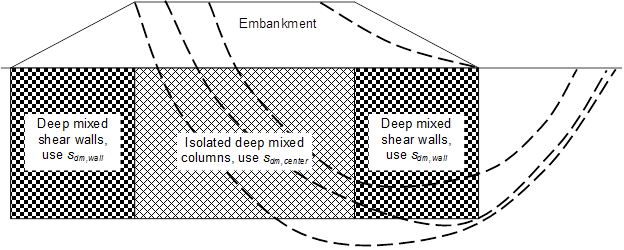

Step 6.1—Slope Stability

Slope stability analyses should be performed to determine the critical failure surface and corresponding factor of safety. Potential sliding surfaces may pass entirely beneath or entirely above the deep mixed shear walls, through the deep mixed shear walls, or partially through and partially below the deep mixed shear walls, as shown in figure 48. The composite shear strength of the deep mixed zones beneath the embankment, sdm,wall and sdm,center, should be assigned as indicated in the figure based on figure 49 and figure 50, with the value of fv from table 12 corresponding to the design value of Fs from table 11. The resulting minimum factor of safety value from a comprehensive search for the critical failure surface is represented as Fs.

Figure 48. Illustration. Potential sliding surfaces and assignment of composite shear strength, sdm,center and sdm,wall.

![]()

Figure 49. Equation. Composite shear strength of the deep mixed zone beneath the shear walls.

![]()

1 lbf/ft2 = 0.04788 kPa

Figure 50. Equation. Composite shear strength of the deep mixed zone beneath the central portion of the embankment.

Where ssoil is the shear strength of the soil through which the deep mixed columns are installed beneath the central portion of the embankment.

Figure 50 represents the isolated deep mixed elements as having a low shear strength value of 1,500 lbf/ft2 (71.8 kPa). This is done to account for failure modes like column bending that can occur in isolated columns.

The calculated value of Fs should be compared to the design value from table 11. Careful slope stability analyses can be used to optimize the design as follows:

Spencer's method is recommended for slope stability analyses because it satisfies all conditions of equilibrium and results in more realistic factor of safety values compared with some of the more simplified methods.(87) The minimum design value of Fs in table 11 is based on this recommendation. For typical project conditions, it is likely that a non-circular failure surface will be the critical surface. A careful search for the critical surface should be made using computer search and optimization routines by an experienced engineer. Critical slip surfaces should be checked for kinematic admissibility. Additional guidance for performing stability analyses is presented by Duncan and Wright.(90)

Step 6.2—Combined Overturning and Bearing Capacity

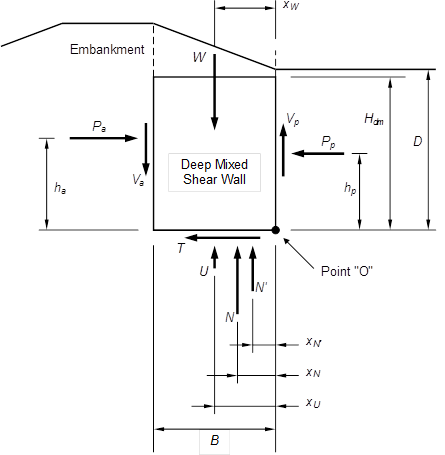

Figure 51 provides a definition sketch that includes many of the symbols used in the step-by-step procedure for combined overturning and bearing capacity.

Figure 51. Illustration. Definition sketch for combined overturning and bearing calculations.

Where:

W = Total weight of the deep mixed zone and the overlying untreated soil and embankment material.

xW = Horizontal distance from point “O” at the toe of the deep mixed zone to the line of action

of W.

B = Width of the deep mixed zone.

D = Depth to the base of the deep mixed zone at the toe of the slope.

Pa = Total active force, including the load from water pressures.

ha = Vertical distance from point “O” to the line of action of Pa.

Va = Vertical shear force on active side.

Pp = Total passive force, including the load from water pressures.

hp = Vertical distance from point “O” to the line of action of Pp.

Vp = Vertical shear force on passive side.

N = Total vertical force acting upwards on the base of the deep mixed zone.

U = Vertical water force acting upwards on the base of the deep mixed zone.

N' = Effective vertical force acting upwards on the base of the deep mixed zone.

xN = Horizontal distance from point “O” to N.

xU = Horizontal distance from point “O” to U.

xN' = Horizontal distance from point “O” to N'.

T = Horizontal shear force acting on the base of the deep mixed zone.

The following step-by-step procedure ensures that the design is sufficient to prevent combined overturning and bearing capacity failure of the deep mixed shear walls:

![]()

Figure 52. Equation. Mobilized total stress cohesion intercept.

![]()

Figure 53. Equation. Mobilized total stress friction angle.

Where:

cm = Mobilized total stress cohesion intercept.

c = Total stress cohesion intercept.

Φm = Mobilized total stress friction angle.

Φ = Total stress friction angle.

If the shear strength of the soil layer under consideration is characterized by effective normal stresses, use figure 54 and figure 55.

![]()

Figure 54. Equation. Mobilized effective stress cohesion intercept.

![]()

Figure 55. Equation. Mobilized effective stress friction angle.

Where:

c'm = Mobilized effective stress cohesion intercept.

c' = Effective stress cohesion intercept.

Φ'm = Mobilized effective stress friction angle.

Φ' = Effective stress friction angle.

![]()

Figure 56. Equation. Vertical force.

To calculate W and xw, the unit weight of the deep mixed ground is often considered to be approximately unchanged from the unit weight of the untreated ground.

If the strength of the soil beneath the deep mixed zone is characterized by effective normal stresses, then integrate the water pressures on the base of the deep mixed zone to obtain U and determine xU. Calculate N' using figure 57.

![]()

Figure 58. Equation. Location of total resultant force.

If the shear strength of the soil beneath the base of the deep mixed zone is characterized by effective normal stresses, then determine xN' using figure 59.

![]()

Figure 59. Equation. Location of the resultant force acting on the base of the deep mixed zone.

If the calculated values of xN or xN' are less than or equal to zero, then the deep mixed zone may be too narrow. If the calculated values of xN or xN' are greater than half of B, then the deep mixed zone may be wider than necessary for overturning stability. If the values of xN or xN' are outside the range from zero to half of B, then the geometry of the deep mixed zone can be changed and the calculation process returns to step 2. However, if the minimum width B is fixed by project-specific constraints and xN or xN' is greater than half of B, then the design is safe against overturning and bearing capacity failure, and no further analysis of this failure mode needs to be done.

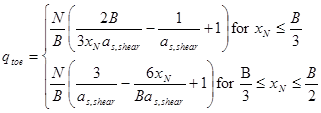

Figure 60. Equation. Bearing pressure at the toe of the deep mixed shear walls using total normal stresses.

If the shear strength of the soil beneath the deep mixed shear walls is characterized by effective normal stresses, use figure 61.

Figure 61. Equation. Bearing pressure at the toe of the deep mixed shear walls using effective normal stresses.

The expressions for qtoe in figure 60 and figure 61 are based on a linear pressure distribution, with stress concentration on the base of the shear walls having average width B, as shown in figure 38. The weight of the soil between the shear walls is assumed to be carried by the underlying soil.

![]()

Figure 62. Equation. Allowable bearing pressure at the toe of the deep mixed shear walls using total normal stresses.

Where:

Nc, Nγ, Nq = Bearing capacity factors obtained from Φm for the soil below the deep mixed shear walls using generally accepted sources for bearing capacity factors.

γbelow = Total unit weight of the soil below the shear walls.

γabove = Average total unit weight of the soils above the base of the shear walls.

bmin = Minimum allowable effective shear wall width, which can be estimated as 90 percent of the minimum allowable column diameter for typical values of e/d.

If Φm equals zero, then Nγ = 0, Nq = 1, and Nc can be approximated as 7.5(1 + 0.1bmin/xN) for bmin ≤ 2xN. In this case, figure 62 reduces to figure 63.

![]()

Figure 63. Equation. Allowable bearing pressure at the toe of the deep mixed shear walls using a total stress friction angle equal to zero.

If the shear strength of the soil beneath the deep mixed shear walls is characterized by effective normal stresses, use figure 64.

![]()

Figure 64. Equation. Allowable bearing pressure at the toe of the deep mixed shear walls using effective normal stresses.

Where:

N'c, N'γ, N'q = Bearing capacity factors obtained from Φ'm for the soil below the deep mixed shear walls using generally accepted sources for bearing capacity factors.

γb,below = Buoyant unit weight of the soil below the shear walls.

γb,above = Average buoyant unit weight of the soil above the base of the shear walls.

The bearing capacity calculations can be performed using correction factors for shape, depth, and compressibility as appropriate.

If qtoe is less than or equal to qall, then the design is sufficient to prevent combined overturning and bearing capacity failure of the deep mixed shear walls. If qtoe is greater than qall, then the geometry of the deep mixed zone can be changed to decrease qtoe and increase qall. This would typically be accomplished by increasing the width or depth of the deep mixed zone.

This procedure represents a potential failure condition for which the stabilized block overturns. This failure mode, which is not captured by ordinary limit equilibrium slope stability calculations, can control for tall and narrow deep mixed zones. By combining the overturning and bearing capacity calculations into a single calculation with the same factor of safety applied to the soils beside and below the deep mixed zone, ambiguities in the evaluation are avoided.

Step 6.3—Crushing of the Deep Mixed Shear Walls at the Outside Toe

In situations where the deep mixed ground overlies a hard bearing stratum, lateral loads could produce toe pressures that exceed the capacity of the deep mixed ground. The design factor Fc should be selected based on table 11.

If Fo is equal to Fc, then the intermediate values from step 6.2 can be used in the current step. If Fo is not equal to Fc, then steps 2-6 in step 6.2 should be repeated using Fc instead of Fo in figure 52 through figure 55. If the calculated values of xN and xN' are greater than half of B, then the design is safe against crushing at the toe of the shear walls, and no further evaluation of crushing is necessary. Otherwise, the values of qtoe (see figure 60 or figure 61) and Φm or Φ'm (see figure 53 or figure 55) for the soil adjacent to the deep mixed ground at the toe of the deep mixed zone should be used in the following calculations.

The allowable capacity of the deep mixed ground can be determined based on the equation in figure 65, with the value of fv from table 12 corresponding to the design value of Fc from table 11.

![]()

Figure 65. Equation. Allowable bearing capacity of the deep mixed ground against crushing of the deep mixed shear walls at the outside toe of the embankment.

Where σh is the lateral earth pressure at the toe.

A conservative value of σh is the at-rest lateral earth pressure. If the shear strength of the soil beneath the deep mixed ground is characterized by total normal stresses, then qtoe is determined from figure 60, and qtoe is the total vertical stress. In this case, the value σh to be used in figure 65 is given by the equation in figure 66.

![]()

Figure 66. Equation. Total lateral earth pressure.

Where:

K0 = Effective stress at-rest lateral earth pressure coefficient determined based on Φ'm for the soil adjacent to the deep mixed ground at the toe of the deep mixed zone.

σ'v = Effective vertical stress in the soil adjacent to the deep mixed ground at the toe of the deep mixed zone.

u = Porewater pressure in the soil adjacent to the deep mixed ground at the toe of the deep

mixed zone.

If the shear strength of the soil beneath the deep mixed ground is characterized by effective normal stresses, then qtoe is determined from figure 61 and qtoe is an effective vertical stress. In this case, the effective lateral earth pressure, σ'h, should be used in place of σh in figure 65, and σ'h is given by the equation in figure 67.

![]()

Figure 67. Equation. Effective lateral earth pressure.

If qtoe is less than or equal to qall, then the design is sufficient to prevent crushing of the deep mixed ground at the toe of the shear walls. If qtoe is greater than qall, then the area replacement ratio, the width of the deep mixed zone, or the strength of the deep mixed ground should be increased.

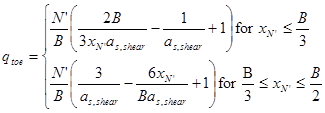

Step 6.4—Shearing on Vertical Planes in the Deep Mixed Shear Walls

Shearing on vertical planes in the deep mixed shear walls is produced by eccentric loading corresponding to xN < B/2. If the overlap between adjacent columns is insufficient, the shear walls can fail in a racking type of failure mode, as shown in figure 68. The design factor, Fv, should be selected based on table 11.

Figure 68. Illustration. Racking failure mode.

The following three-step procedure is used to determine whether the design is sufficient to prevent shearing on vertical planes in the deep mixed shear wall:

![]()

Figure 70. Equation. Allowable vertical shear stress.

If τv is less than or equal to τv,all then the design is sufficient to prevent shearing on vertical planes in the deep mixed shear wall. If τv is greater than τv,all then measures can be taken to increase τv,all, such as increasing the strength of the deep mixed ground or the chord length at column overlaps or decreasing the shear wall spacing. Alternatively, measures can be taken to decrease τv, such as by increasing B. When considering increasing the design strength of the deep mixed ground, limitations on practically achievable strengths should be carefully considered.

Step 6.5—Extrusion of Soil Between the Deep Mixed Shear Walls

Extrusion of soft ground between shear walls could occur if the shear walls are widely spaced or short in the direction perpendicular to the embankment alignment. Extrusion between shear walls is not possible for sands or stiff clays under normal conditions, so only layers of soft clay need to be checked for this failure mode. The design factor, Fe, should be selected based on table 11 and the accompanying discussion.

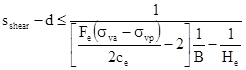

The maximum clear spacing between shear walls, sshear - d, should be limited based on the equation in figure 71 to prevent extrusion of soft clay.

Figure 71. Equation. Maximum clear spacing between shear walls.

Where:

He= Thickness of a layer of soft clay to be analyzed for extrusion.

σva = Average value of the total vertical stress in the soft clay layer to be analyzed for extrusion immediately adjacent to the active earth pressure side of the deep mixed shear walls.

σvp = Average value of the total vertical stress in the soft clay layer to be analyzed for extrusion immediately adjacent to the passive earth pressure side of the deep mixed shear walls.

ce = Average value of the total stress cohesion intercept in the soft clay layer to be analyzed

for extrusion.

This calculation should be repeated for different layers of soft clay soil to determine the critical value of sshear - d.

If there is a project-specific reason to consider a larger value of clear spacing between shear walls than indicated by figure 71, then the shear wall length could be increased. Alternatively, a continuous wall of overlapping columns parallel to the embankment alignment and located within the zone of the deep mixed shear walls could be considered to prevent extrusion.

The final design resulting from steps 1-6 is incorporated in the project plans and specifications, as described in chapter 9.

The analysis and design procedures in this section are based primarily on information provided by CDIT and with consideration of the findings of many other engineers and researchers. (See references 7, 9, 34-36, 46, 49, 56, 59, 61, 65, 68, 69, 78, 83, and 91-118.)

Deep mixing can be used to support structures such as retaining walls, bridge abutments, and bridge piers. For support of structures, deep mixed columns should always be used in groups, and they should be designed to carry the entire load from the structure without consideration of any direct support to the structure provided by the soil between columns. Down drag from settlement of adjacent soil should be considered, if applicable.

The axial capacity of the deep mixed columns is the minimum of the structural capacity and the geotechnical capacity of the columns. The allowable axial structural capacity of a deep mixed column, qall, can be determined according to figure 72, which incorporates a safety factor of 2.5 on sdm, as determined from figure 33.

![]()

Figure 72. Equation. Allowable axial structural capacity of a deep mixed column.

The geotechnical capacity of a deep mixed column can be analyzed using procedures for drilled shafts because drilled shafts and deep mixed columns are similar in their effects on the soil between shafts or columns and in the degree of interlocking between the shaft or column and the adjacent soil.(119) A safety factor of 3 is recommended to obtain an allowable geotechnical capacity from the ultimate geotechnical capacity.

Deep mixed columns are not normally used to resist lateral loads from structures. Settlement of structures on deep mixed foundations can be estimated using the same procedures described in section 6.1.5 for embankments, with the applied structure load converted to a pressure distributed over the area of the column group.

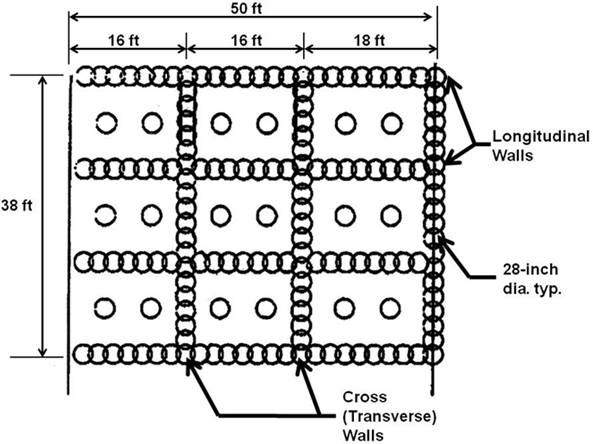

Deep mixing can be used to improve mass shear strength and contain liquefaction propagation.(9) Walls of deep mixed columns are installed in grid arrangements to contain liquefiable soils, thus preventing a shear failure during a seismic event. An example plan view of soil-cement columns used on a BART system project is presented in figure 73.

1 ft = 0.305 m

1 inch = 25.4 mm

Figure 73. Illustration. Plan view of soil-cement columns on BART project.(19)

A design procedure for liquefaction mitigation with DMM was developed in the National Deep Mixing Research Program. The design procedure and literature review are presented in Simplified Seismic Response Evaluation of Sites Improved by Deep Mixing.(4)

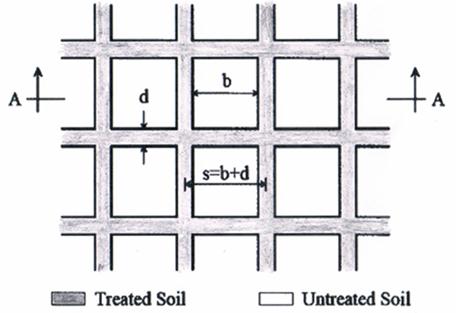

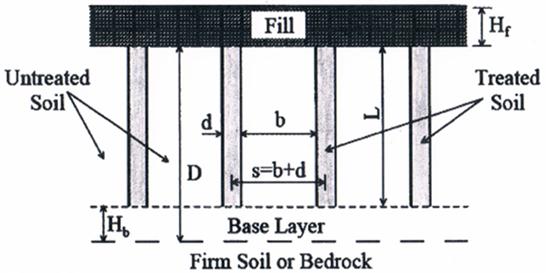

Deep mixing for liquefaction mitigation generally involves a rectangular grid or lattice pattern of columns with design dimensions of cell interior width (b), width or diameter of treatment (d), and length of treatment (L) specified to achieve a desired level of improvement, as illustrated in figure 74 and figure 75.

Figure 74. Illustration. DMM treatment plan.(4)

Figure 75. Illustration. Typical configuration of DMM for liquefaction mitigation.(4)

Where:

s = Center-to-center spacing of element walls.

D = Depth to first soil or bedrock.

Hb = Thickness of base layer.

Hf = Thickness of fill.

The seismic response characteristics of the DMM sites have been assessed based on the residual porewater pressure response (or liquefaction), which is a widely used engineering response indicator.

The steps proposed by Siddarthan and Suthahar to evaluate the residual porewater pressure response of DMM sites are summarized as follows:(4)

The objective of this work was to produce simple design guidelines that practicing engineers can readily use to evaluate the effectiveness of various configurations of DMM treatments. The aforementioned seismic response evaluation model is simple and appropriately accounts for many important factors that affect the DMM treated soil response. More details on these steps are provided by Siddarthan and Suthahar.(4)

Other important seismic design issues, such as residual strength, permanent lateral deformation (e.g., lateral spread), and ground failure (e.g., sand boils), can be investigated based on the liquefaction analysis. The design issues can be assessed based on empirical relations that have been developed to specifically address each of these failure modes. Well-documented guidelines for these analyses are available and have been incorporated into design aids such as Special Publication No. 117 developed by the Division of Mines and Geology and the Southern California Earthquake Center.(121,122)

For permanent excavation support, a bulkhead consisting of deep mixed shear walls can be designed using the procedures described in section 6.1 for embankments. In addition, one or more rows of overlapping columns should be provided along the bulkhead face perpendicular to the shear walls to prevent sloughing and raveling at the exposed face. The exposed face should be protected with shotcrete, precast concrete panels, or other protection to provide for long-term durability. Design of temporary excavation support is outside the scope of this report.