U.S. Department of Transportation

Federal Highway Administration

1200 New Jersey Avenue, SE

Washington, DC 20590

202-366-4000

Federal Highway Administration Research and Technology

Coordinating, Developing, and Delivering Highway Transportation Innovations

| REPORT |

| This report is an archived publication and may contain dated technical, contact, and link information |

|

| Publication Number: FHWA-HRT-13-046 Date: October 2013 |

Publication Number: FHWA-HRT-13-046 Date: October 2013 |

The purpose of this section is to provide an approach to determine realistic ranges of material property values that can be used in designing DMM projects. At this stage in the design and construction process, it is important to understand the relationship between treatment regimes (e.g., wet versus dry method, mixing energy, binder type and amount, etc.) and the range of engineering property values that can realistically be achieved for the specific soils at a project site. After realistic ranges of property values are established, an engineer determines the particular property values, replacement ratios, and column arrangements that are necessary to achieve the desired performance for a specific project using the methods outlined in chapter 6. The final required property values then form the basis for the construction specifications, as described in chapter 9.

Laboratory testing is performed by the engineer as part of the design process to verify the feasibility of using DMM and to assess a reasonable range of property values for design. Laboratory testing may be performed again by the contractor as part of the construction process. Laboratory testing is discussed in this chapter and again in chapter 10.

On large or innovative projects, it may be advantageous to perform field trials in which one or more DMM contractor would construct DMM columns at the project site, and the columns would be cored and tested in the field or laboratory. This was performed on the I-95/US Route 1 interchange project in Alexandria, VA.(22) More commonly, the construction contract will require that the contractor perform a field demonstration of capability to achieve the design strength. Field trials for design and field demonstrations during construction are both discussed in chapter 10.

This chapter describes phase relationships for the dry and wet methods of deep mixing as well as engineering property values of strength, modulus, Poisson's ratio, permeability (hydraulic conductivity), and unit weight.

Detailed descriptions of soil stabilization using portland cement concrete (PCC) and lime are provided by Rafalko et al.(41) Stabilization reactions using slag-cement are provided by Vanzler and Filz.(42)

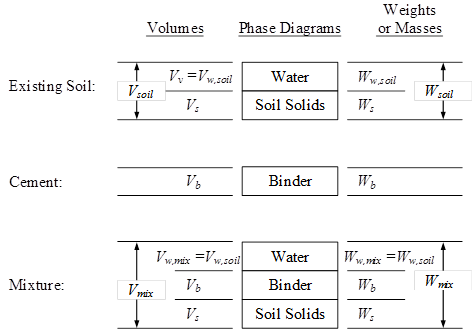

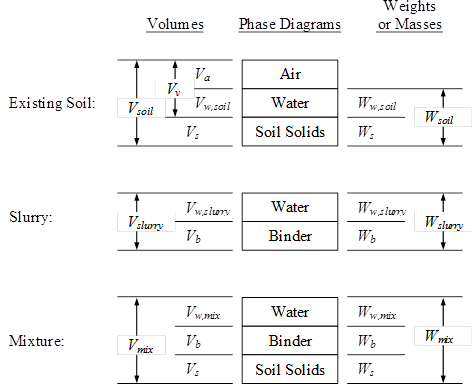

When binders like cement, lime, and slag cement are mixed with soil, the result is a multiphase material, as shown in figure 13 for dry mixing and figure 14 for wet mixing. Dry mixing is generally used in soft, saturated, or nearly saturated soil, so the phase diagram in figure 13 shows a saturated soil to which dry binder is added. Wet mixing can be applied to soils with any degree of saturation. The phase diagram in figure 14 shows an unsaturated soil to which the binder-water slurry is added, and this can represent a saturated soil by setting the volume of air equal to zero. For wet mixing, whether the base soil is saturated or unsaturated, the resulting mixture is generally saturated or nearly saturated, which is the outcome in figure 14.

Figure 13. Illustration. Phase diagrams for dry mixing.

Figure 14. Illustration. Phase diagrams for wet mixing.

Figure 13 and figure 14 illustrate the following definitions of component volumes and weights:

Va = Volume of air.Aggregates of these quantities include the following:

Vv = Volume of voids in the soil before mixing (Va + Vw,soil).These quantities are useful in the equations in figure 15 and figure 16.

![]()

Figure 15. Equation. Specific gravity of soil solids.

![]()

Figure 16. Equation. Specific gravity of the binder.

Where:

Gs = Specific gravity of the soil solids.

Gb = Specific gravity of the binder.

γw= Unit weight of water (Ww/Vw).

Ratios that are useful for controlling deep mixing operations and reporting results from tests on laboratory or field-mixed materials are listed in table 8.

Table 8. Definitions of deep mixing parameters.

Item |

Applicability |

|

|---|---|---|

Dry Method |

Wet Method |

|

Binder factor: |

Yes |

Yes |

Binder factor in-place: |

Yes |

Yes |

Binder content: |

Yes |

Yes |

Total water-to-binder ratio: |

Yes |

Yes |

Water-to-binder ratio of the slurry: |

No |

Yes |

Volume ratio: |

No |

Yes |

For dry mixing, the contractor controls the rate of delivery of dry binder during mixing, which means that the contractor is directly controlling the binder factor ( α ). For a saturated soil, as shown in figure 13, α is related to the binder factor in-place ( α in-place), binder content ( α w), and total water-to-binder ratio (wT:b), as indicated in the equations shown in figure 17 through figure 19.

![]()

Figure 17. Equation. Binder factor in-place.

![]()

Figure 18. Equation. Binder content.

![]()

Figure 19. Equation. Total water-to-binder ratio.

Where:

γb = Unit weight of the binder solids (Wb/Vb).

γd,soil = Dry unit weight of the soil (Ws/Vsoil).

w = Water content of the soil (Ww,soil/Ws).

For wet mixing, the contractor controls the water-to-binder ratio of the slurry (w:b) and the volume ratio (VR). The outcome of controlling these parameters can be expressed in terms of α , αin-place, αw and wT:b, all of which describe the mix proportions in various ways. For a specific value of w:b, the contractor controls VR to achieve target values of α , αin-place, αw and wT:b. The values of VR to achieve target values of α , αin-place, αw and wT:b are given by the equations in figure 20 through figure 24. Figure 20 and figure 22 through figure 24 provide equations for any degree of saturation of the soil. Figure 21 provides an equation for a soil saturation (S) = 1.

![]()

Figure 20. Equation. Volume ratio expressed in terms of binder factor for any degree of saturation.

![]()

Figure 21. Equation. Volume ratio expressed in terms of binder factor in-place for S = 1.

![]()

Figure 22. Equation. Volume ratio expressed in terms of binder factor in-place for any S.

![]()

Figure 23. Equation. Volume ratio expressed in terms of binder content for any S.

![]()

Figure 24. Equation. Volume ratio expressed in terms of total-water-to-binder ratio for any S.

Where:

γd, slurry = Dry unit weight of the slurry (Wb/Vslurry).

S = Degree of saturation of the soil (Vw,soil/Vv).

Conversion among α , αin-place, αw and wT:b. for wet mixing can be done easily by using the equations in figure 25 through figure 28. Figure 25 is for S = 1, and figure 26 through figure 28 are for any value of S.

![]()

Figure 25. Equation. Binder factor expressed in terms of binder factor in-place for S = 1.

![]()

Figure 26. Equation. Binder factor expressed in terms of binder factor in-place for any S.

![]()

Figure 27. Equation. Binder factor expressed in terms of binder content for any S.

![]()

Figure 28. Equation. Binder factor expressed in terms of total-water-to-binder ratio for any S.

Figure 20 through figure 28 for wet mixing are based on the assumption that neither water nor binder from the mixture moves out into the soil beyond the deep mixed element. It is recognized that in sand and gravel soils, water probably moves into the soil beyond the element in response to excess pore water pressure in the freshly mixed element from slurry pumping pressure and mixing action. If the soil is coarse enough to allow water to flow out of the element prior to the binder setting up and if the soil is also fine enough that the binder particles are restrained from moving with the water flow, then the flow of water into the soil beyond the element would decrease wT:b in the element and increase the strength of the element. Thus, this assumption is either realistic or conservative for mixture strength, provided that binder particles do not move into the ground beyond the limits of the deep mixed element. If the soil is so coarse that the binder particles are not retained in the deep mixed element, then the process becomes a combination of deep mixing within the element limits and grouting outside the element limits, and the relationships given for the mixture would not apply.

The relationships provided are based on a uniform mixture (i.e., the spoil from the wet method has the same mix proportions as the material left in the ground). This can be a conservative assumption, depending on the details of the mixing process, because some of the upper portion of the existing soil with less than average binder content can be pushed up out of the ground as a result of slurry injected at greater depths.

Engineering properties of the deep mixed soil include strength, modulus, Poisson's ratio, permeability, and unit weight. Stability analyses require material property values for strength and unit weight. Settlement analyses require material property values of modulus and unit weight. When DMM is used to construct hydraulic barriers, seepage analyses may be performed using material property values of permeability.

For large or complex projects, numerical and reliability analyses may be useful for assessing stability and settlement. Numerical analyses require values of strength, modulus, Poisson's ratio, and unit weight. Reliability analyses require knowledge of the variability of property values.

Knowing the strength of the deep mixed soil is necessary for stability analyses. This section presents information about factors that influence the strength of deep mixed soil and how to establish an appropriate range of unconfined compressive strength that can be used as input to the design process.

The strength of treated ground depends on the characteristics of the binder materials and the ground to be treated and the details of mixing, curing, and loading. Table 9, which is adapted from Terashi, lists 17 factors that affect the strength of treated ground.(43) Several of these factors depend on site and project characteristics, some may be controlled by project specifications, and several are controlled by the DMM contractor. Even though many of these factors are beyond the engineer's control, it is worthwhile for engineers to have a basic understanding of the influence of these factors on the strength of deep mixed soil.

Table 9. Factors affecting strength of deep mixed soil.(43)

Category |

Factors |

|---|---|

Characteristics of binder |

|

Characteristics and conditions |

|

Mixing conditions |

|

Curing conditions |

|

Loading conditions |

|

Numerous studies show that the strength of deep mixed materials increases with increasing αw, increasing mixing efficiency, increasing curing time, increasing curing temperature, decreasing water content of the mixture, and decreasing organic content of the base soil. (See references 1, 22, and 44-52.) One interesting interaction of these factors is that increasing the water content of the mixture can increase mixing efficiency; thus, in the case of low water content clays, adding water to the mixture can increase the mixture strength.(53) Nevertheless, it remains true that for thoroughly mixed materials, a decrease in the w:b of the mixture produces an increase in the unconfined compressive strength.

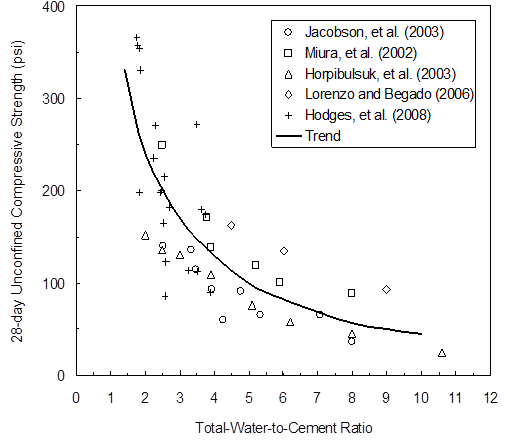

The trend of increasing unconfined compressive strength with decreasing wT:b is shown from a variety of sources in figure 29 for cement binder mixed with inorganic soils in laboratories, including samples prepared to represent both dry and wet mixing. Although there is scatter in the data, the general trend is for the 28-day unconfined compressive strength of the mixtures to decrease as the total water-to-cement ratio (w:c) of the mixture increases. This is similar to the trend of decreasing strength for increasing w:c of concrete, but typical total w:c values for deep mixing are much larger than typical w:c values for concrete.

1psi = 6.88 kPa

Figure 29. Graph. Unconfined compressive strength versus total water-to-cement ratio for laboratory-mixed and tested specimens. (See references 48 and 54-57.)

The trend in figure 29 can be used to estimate the amount of cement needed to produce a desired strength for laboratory-prepared specimens of inorganic soil. For example, suppose that an unconfined compressive strength of 150 psi (1,035 kPa) is desired for a saturated soil with w of 50 percent and Gs equal to 2.7, so γd,soil is 71.7 lbf/ft3 (11.2 kN/m3). According to the trend line in figure 29, a total w:c of about 3.4 should produce the desired strength. If the contractor uses a w:c of the slurry equal to 0.8, a specific gravity of the cement of 3.15, and γd,slurry of 55.8 lbf/ft3 (8.8 kN/m3), then figure 25 through figure 28 and figure 20 produce the following values of the other mixing parameters:

Organic soils tend to require more binder than inorganic soils, and sandy soils require less binder than clay soils. Slag-cement binders can be more effective than pure cement for treating organic soils. Mix design is not an exact science, and site-specific testing is necessary. As discussed in the following subsections, the strengths of laboratory-mixed specimens can be higher than the strengths of field-mixed specimens.

The effect of curing time is to increase mixture strength. Based on a review of data by researchers, the equation in figure 30 provides a conservative estimate of the strength increase with time for cement and cement-slag treatment, except for some highly organic soils. (See references 1-3, 44, 50, 53, and 57-60.)

![]()

Figure 30. Equation. Curing factor.

Where:

fc = Curing factor, which is the ratio of unconfined compression strength at time t to the unconfined compression strength at 28 days.

t = Curing time (days).

Site-specific testing can be used to justify higher values of fc than given by figure 30.

Stabilized soils tested in triaxial conditions experience strain softening after the peak strength is reached.(61) Although soil-cement mixtures are often brittle in unconfined compression tests, the residual strength of soil-cement under low confining pressures is 65 to 90 percent of the unconfined compressive strength.(46,62) Kitazume et al. used a residual compressive strength value equal to 80 percent of the unconfined compressive strength in limit equilibrium analyses of their centrifuge test results.(63) The confined residual strength of deep mixed ground can be used in slope stability analyses to provide safety against progressive failure effects.

Values of unconfined compression strength of laboratory-mixed specimens have been reported

in the range from about 2 to 400 psi (0.01 to 2.8 MPa) for dry mixing and from about 20 to 4,000 psi (0.1 to 28 MPa) for wet mixing, depending on the base soil type and the binder type and amount, with the highest values for wet mixing occurring when sand soils are mixed using high α and low w:b values.(54,64,65)

Given all of the factors that affect the strength of treated soils, the Japanese Coastal Development Institute of Technology (CDIT) indicates that it is not possible to predict within a reasonable level of accuracy the strength that will result from adding a particular amount of binder to a given soil based on the in situ characteristics of the soil.(46) Consequently, laboratory mix design studies must be performed using soils obtained from a project site.

Laboratory preparation and testing of specimens are discussed by Jacobson et al. for dry mixing and by Filz et al. for wet mixing.(52,51) These procedures are included in appendices A and B, respectively, and only key aspects are discussed in the main text. The procedure for dry mixing is based primarily on the procedure in Swedish Geotechnical Society Report 4:95E, and the procedure for wet mixing is based primarily on the procedure published by the Japanese Geotechnical Society.(66,64)

In both cases, the procedures cover recommended methods for handling and storing the soil sample, preparing the soil sample, preparing the binder, mixing the soil and binder, forming specimens, curing specimens, performing compression test, and reducing and presenting data.

Laboratory mixing is often more thorough than field mixing. Consequently, the strength of laboratory-mixed specimens can be greater than the strength of field-mixed materials at the same mixture proportions. Conversely, the effects of confinement and potentially higher curing temperatures during field curing tend to increase the strength of field-mixed and cured materials compared to laboratory-prepared and cured specimens. Further complicating the matter is the difficulty of obtaining representative and undamaged specimens of field-mixed material.

According to EuroSoilStab, the strength of field-mixed materials may be 20 to 50 percent of the strength of laboratory-mixed specimens.(49) According to CDIT, the strength of field-mixed materials may be 20 to 100 percent of the strength of laboratory-mixed specimens.(46) The actual percentage depends on the type and operation of the mixing equipment, soil type, field curing conditions, and procedures used to prepare the laboratory specimens. In the United States, a common expectation is that the strength of field-mixed materials can consistently achieve at least 50 percent of the strength of laboratory-mixed specimens. However, engineers should consider prior experience on similar projects in similar soils when estimating the practically achievable relationship between the strength of field-mixed and laboratory‑mixed materials.

Specified 28- and 56-day unconfined compressive strengths for DMM projects in the United States have ranged from about 100 to 300 psi (0.7 to 2.1 MPa). (See references 18, 22, 53, and 67.) Examples of specified unconfined compressive strengths for deep mixed ground are provided in table 10.

Table 10. Specified strengths for selected DMM projects.

Project |

Soil Type/Binder Factor |

Specified Unconfined Compressive |

|---|---|---|

I-95 Route 1 in |

Wet mixing: Soft organic clay; 506 lb/yd3 |

Average qu at 28 days must be greater than |

Central Artery Project in Boston, MA(53,69,70) |

Wet mixing: Fill, organics, and Boston blue clay; |

Minimum qu at 56 days greater than or equal |

Oakland Airport Roadway in Oakland, CA(67) |

Wet mixing: Loose sandy fills and soft clay; 270 |

Average qu at 28 days must be greater than |

Lake Pontchartrain and Vicinity (LPV) 111 Earthen Levee in New Orleans, LA (71,72) |

Wet mixing: Fill, soft clay, marsh deposits, fat clay, lean clay; 303 to 674 lb/yd3 (180 to 400 kg/m3) slag-cement blend |

A total of 9 out of 10 qu values measured on core specimens must be at least 100 psi |

Note: The use of a minimum specified strength is no longer recommended for DMM projects. Instead, as shown for the LPV 111 project and as discussed subsequently, a statistically based specification is recommended.

The strength of deep mixed ground has relatively high variability. Statistical analyses were performed on 7,873 unconfined compression strength tests from 14 datasets for 10 deep mixing projects in the United States, and it was found that the coefficient of variation ranged from 0.34 to 0.79, with an average value of 0.56.(73,74) Data from a collection of international projects showed similar values.(75) For comparison, the coefficient of variation of undrained shear strength of naturally occurring clay deposits is typically in the range from 0.13 to 0.40.(76) These values indicate that the strength of deep mixed ground is about twice as variable as the strength of natural clay deposits. The relatively high variability of deep mixed ground has implications for selection of appropriate design strengths.

Variability can be taken into account by performing reliability analyses, as discussed by Navin and Filz and Navin.(77,73) Alternatively, if design is based on deterministic calculations, the specified strength of deep mixed ground should be adjusted to obtain a design value that accounts for the variability. Values of a factor to account for variability (fv) can be obtained by using the procedure described by Filz and Navin, which was applied to produce the values of fv given in chapter 6.(74)

There are differences of opinion regarding the most appropriate strength envelope for deep mixed soils for use in stability analyses. The state of practice in Japan is to use a total stress friction angle of Φ = 0 and cohesion intercept of c = 1/2 qu for deep mixed soil.(46) Broms mentions the use of total stress friction angles in the range of 25 to 30 degrees for deep mixed soils.(78) EuroSoilStab and Carlsten and Ekstrom utilize a drained effective stress friction angle of 30 degrees with a range of values for the cohesion intercept depending on the location of the failure surface.(49,66)

EuroSoilStab indicates that for dry methods of deep mixing, columns should not be used to resist tensile stresses.(49) Takenaka Civil Engineering, Kivelo, and CDIT report that the tensile strength of soil improved by the wet method is 10 to 20 percent of the unconfined compressive strength.(44,61,46) Kitazume et al. reports that a value of 15 percent is used in Japan with wet mix methods.(79) In customary U.S. practice, tensile strength of the deep mixed ground is not relied on in design.

Because there is not yet widespread agreement on a comprehensive method for strength characterization of deep mixed materials, it is recommended that a reasonable but conservative strength envelope be used for stability analyses. Short-term end-of-construction conditions govern for the applications considered in this report. Accordingly, it is recommended that a total stress characterization of deep mixed soil strength should be used for design, with a total stress friction angle of Φ = 0 and no tensile strength considered.

Design is ordinarily an iterative process in which geometry (e.g., column diameter, column arrangement, area replacement ratio, and depth) and engineering property values (e.g., strength and modulus of the treated ground) are assumed, analyses are performed (e.g., stability and settlement), and the results are compared with design criteria (e.g., factor of safety against instability and settlement magnitude). If the criteria are not satisfied, geometry or engineering property values are revised, and the analyses and comparisons with criteria are repeated. Consequently, it is often desirable to establish a range of realistically achievable strengths for use in the design process.

The following procedure is recommended to establish a range of strength values:

Young's modulus values of the treated ground are used to calculate the compression of the deep mixed zone, as discussed in chapter 6. Secant values of Young's modulus of elasticity at 50 percent, E50, of the unconfined compressive strength have been related to the unconfined compressive strength, qu, of deep mixed ground. For dry mixing, values of the ratio of E50 to qu have been reported in the range of 50 to 250.(52,65,78) For wet mixing, values of the ratio of E50 to qu have been reported in the range of 75 to 1,000.(80) In a study of 2,672 unconfined compression tests on core specimens from wet-mixed columns, Navin and Filz found a ratio of E50 to qu equal to approximately 300.(81)

Deep mixed ground exhibits a non-linear stress-strain response, with higher stiffness at low strains.(53,82) Tatsuoka et al. indicate that local displacement measurements taken directly on specimens can produce higher values of modulus than when displacements are based on relative movement of end platens.(82) E50 values obtained from short-duration laboratory tests do not account for the effects of long-term creep, which can decrease the effective E50 value for long-term loading. The effects of higher modulus values at low strains and higher modulus from local strain measurements tend to counteract the effects of long-term creep.

For design, reasonable estimates of the compression of the deep mixed zone can be made by estimating E50 as 150 times qu for dry mixing and by estimating E50 as 300 times qu for wet mixing.

Poisson's ratio is not needed for the routine design procedures presented in chapter 6. However, Poisson's ratio may be needed if numerical analyses are performed, and sources in the literature can provide some guidance. According to CDIT and Terashi, the Poisson's ratio of deep mixed soil ranges from 0.25 to 0.50 irrespective of the unconfined compressive strength.(46,83) For peats stabilized with dry cement, Hebib and Farrell measured the Poisson's ratio of 0.1 for strains less than 1 percent. McGinn and O'Rourke used a Poisson's ratio of 0.25 in their numerical analysis.(84,53) Porbaha et al. used seismic methods to determine a Poisson' ratio value of 0.3 to 0.4 for small strain behavior of deep mixed material created using the wet method.(10)

For dry mixing, EuroSoilStab indicates that the permeability of clay soil treated with dry lime and cement can be assumed to be 200 to 600 times the permeability of unstabilized soil.(49) Field tests performed by Baker indicated that the permeability of dry mixed columns was 10 to 100 times the permeability of untreated clay soil.(65) Consequently, dry mixed columns can serve as vertical drains to some extent.

For wet mixing applied to sandy soils, permeability values as low as 4.72 × 10-4 to 4.72 × 10-5 ft/day (10-5 to 10-6 cm/s) are routinely achievable. Increasing the binder factor and adding bentonite will serve to decrease the permeability for mixtures created by the wet method. Deep mixed columns installed by the wet method are not considered to function as vertical drains.(85)

For dry mixing, Broms reports that the unit weight of stabilized organic soil with high initial water content exceeds the unit weight of untreated soil, and it becomes greater with increasing cement and lime content.(78) However, he also notes that the unit weight of inorganic soils are often reduced by dry mix stabilization. CDIT reports that for soils treated by dry mixing, the total unit weight of the treated soil increases by about 3 to 15 percent above that of the untreated soil.(46) For an initially saturated soil treated by dry mixing, the total unit weight of a saturated mixture, γmix, is given by the equation in figure 31.

![]()

Figure 31. Equation. Total unit weight of a saturated mixture using dry mixing.

Where γsoil is the total unit weight of the soil.

For wet mixing, the Cement Deep Mixing (CDM) manual generalizes by indicating that for soils treated by wet mixing, the density change is negligible.(86) However, at the Boston Central Artery/Tunnel Project, a substantial decrease in unit weight occurred, as reported by McGinn and O'Rourke.(53) The decrease in this case was primarily a result of the initial unit weight of the clay having a relatively high value of 120 to 125 lbf/ft3 (19 to 20 kN/m3) and the need to add water to precondition the clay before wet mixing with cement grout. For an initially saturated soil treated by wet mixing, γmix is given by the equation in figure 32.

![]()

Figure 32. Equation. Total unit weight of a saturated mixture using wet mixing.

Where γslurry is the total unit weight of the slurry.

Continuing the example from section 5.4, γsoil and γslurry are 107.5 and 100.5 lbf/ft3 (16.89 and 15.79 kN/m3), respectively, and VR is 24.4 percent. According to figure 32, γmix is 106.2 lbf/ft3 (16.68 kN/m3).

In practical applications for DMM support of embankments and considering that area replacement ratios in the range of 0.2 to 0.4 are often used, the change in unit weight of the deep mixed zone is often negligible. Exceptions can occur for high values of replacement ratio when high α values are used in dry mixing or when high VR or low w:b of the slurry are used in wet mixing.