U.S. Department of Transportation

Federal Highway Administration

1200 New Jersey Avenue, SE

Washington, DC 20590

202-366-4000

Federal Highway Administration Research and Technology

Coordinating, Developing, and Delivering Highway Transportation Innovations

| REPORT |

| This report is an archived publication and may contain dated technical, contact, and link information |

|

| Publication Number: FHWA-HRT-13-085 Date: October 2013 |

Publication Number: FHWA-HRT-13-085 Date: October 2013 |

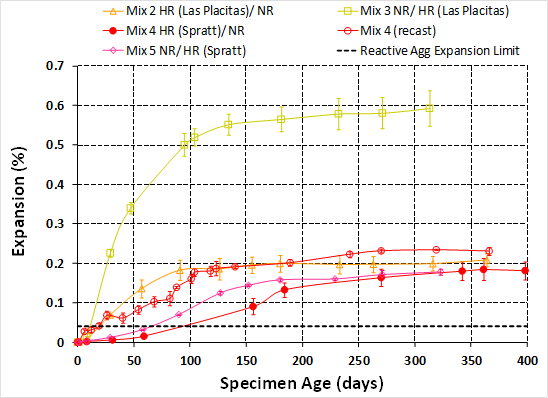

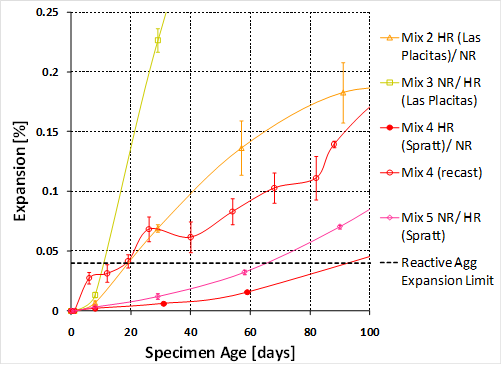

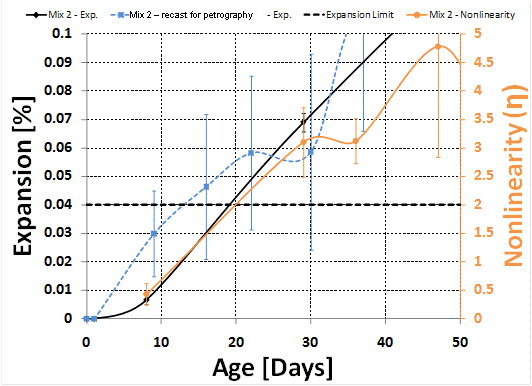

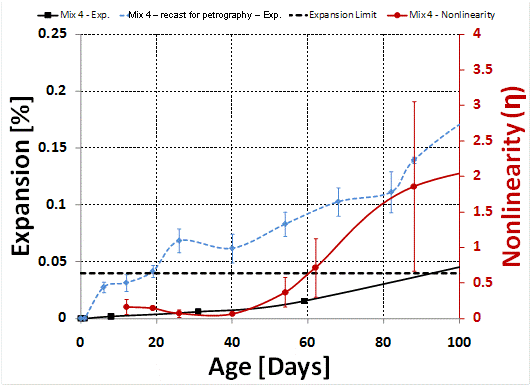

This section presents the expansion measurement results for the concrete mixtures described in table 2. Note that in this study, the expansion measurements are taken more frequently than required in the ASTM C1293 standard. Figure 63 shows the results of the expansion measurements for the HR mixtures. Comparing the results from ASTM C1260 (table 2) and the measured expansions in figure 63, it is evident that there is good agreement for the classification of the HR mixtures (i.e., mixes 2 through 5). Figure 64 shows results up to 100 days to facilitate identification of the specimen age at which the 0.04-percent expansion limit, indicating aggregate reactivity, is crossed. Mixes 2 through 5 have expansions that cross this limit during the test period. Also, the relatively rapid expansion rate for these mixes further suggests the relatively high reactivity of these aggregates. There also appears to be some observation of more rapid and, in one case, larger expansion when the reactive aggregate is crushed and used as the fine in the mixture. This is demonstrated when comparing mixes 2 and 3 as well as mixes 4 and 5. However, an exception to this observation is the behavior for Mix 4 when recast, to better evaluate the early (<100 days of age) expansion behavior; that sample set has an uncharacteristically high rate of expansion compared with previous results for Mix 4. The underlying cause for this difference in behavior between the two sample sets is not clear; it may simply be related to the variability inherent in concrete and in reactive aggregates in particular.

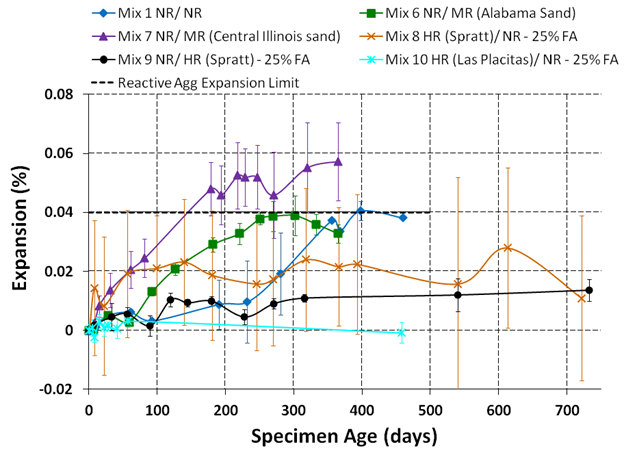

Results for the NR Mix 1, the MR mixes 6 and 7, and SCM-containing mixes 8 and 9 are presented in figure 65. The average expansion of mixes 1 and 6 has not crossed the expansion limit at 1 year; therefore, these are classified as nonreactive by the CPT standard. Mix 6 was expected to experience more expansion than Mix 1 because, according to ASTM C1260, the aggregate in Mix 6 was classified as innocuous or potentially deleterious. According to these concrete prism results, the aggregate is nonreactive but it does come very close to the expansion limit, demonstrating perhaps some of the challenges associated with determining reactivity through expansion measurements alone. The 25-percent replacement of cement with fly ash (FA) in mixes 8 and 9 appears to be effective in mitigating expansion with the Spratt aggregate because the expansion limit has not been crossed. For comparison, mixes 4 and 5, using the same aggregate, crossed the limit before 100 days. Mix 7 crossed the limit at about 150 days and can be classified as reactive using the CPT standard.

Figure 63. Graph. ASTM C1293 expansion results up to 400 days

Figure 64. Graph. ASTM C1293 expansion results up to 100 days

Figure 65. Graph. ASTM C1293 expansion results up to 750 days for NR, MR, and SCM mixes

NIRAS results are presented in a similar manner as the expansion measurements, that is the average measured nonlinearity, performed on the same three samples as CPT expansion, is plotted versus age at each test date. With this representation, the nonlinearity parameter is shown as a function of time that samples were exposed to ASTM C1293 testing conditions. For Mix 4, note that because the NIRAS measurements did not start on Mix 4 until after the expansion was greater than 0.04 percent, that mix was recast to gather early age data for that mix.

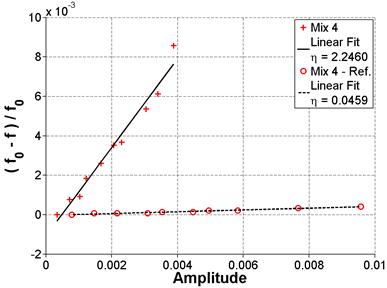

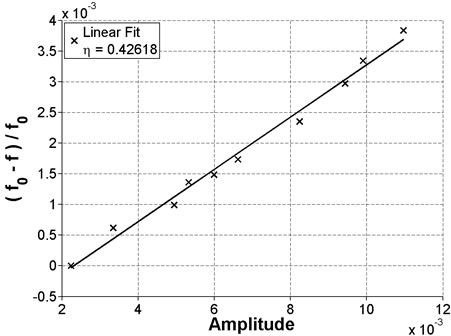

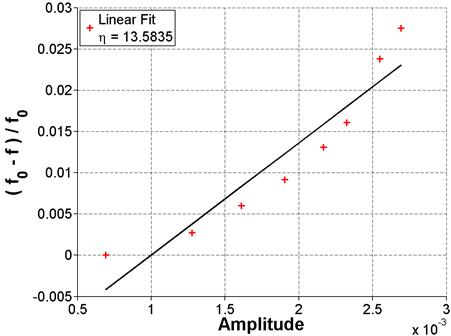

As an example of how the nonlinearity of a given sample at a given age is determined, consider Mix 3 at 47 days. The data analysis process for one of the Mix 3 prisms is shown in figure 66. The impact response for 10 separate hits is recorded and converted to the frequency domain, as described previously. The frequency shift is then normalized and plotted against the excitation, as shown in figure 66. The nonlinearity parameter (η) is the slope of the data on this plot; in this case, η is found to be 5.6082. For the other samples, the nonlinearity parameters were measured to be 7.2799 and 5.6941. The average of these nonlinearity parameters is 6.19.

Figure 66. Graph. Example of extraction of nonlinearity parameter for Mix 3 at 47 days

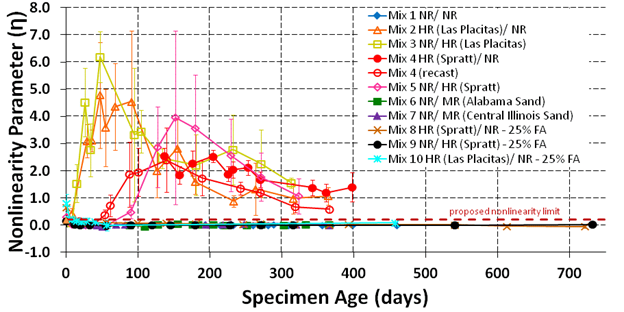

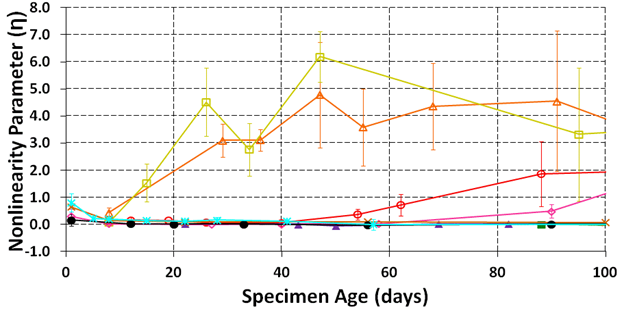

This average nonlinear parameter, along with SD at each measurement age, is then plotted versus age, as in figure 67. The average nonlinearity parameter of 6.19 at 47 days can be seen in figure 67 and corresponds to the maximum nonlinearity measured for Mix 3. Figure 67 shows the results up to 750 days while figure 68 shows a more detailed view, only up to 100 days, to better show early age behavior.

From these results, performed on a limited range of aggregates and with a limited range of binder compositions, a preliminary limit of 0.2 during the standard test duration has been proposed to distinguish between alkali reactive and non-reactive aggregates, cast, and tested according to ASTM C1293. Figure 67 shows this limit. However, significant further investigation—including ruggedness testing, round-robin testing of precision and bias, and a comprehensive assessment of more aggregate types—is clearly needed to determine the microstructural changes that contribute nonlinearity, as well as to better assess what level of nonlinearity can be used to distinguish between innocuous aggregates and those detrimental to long-term performance.

The results show that the NIRAS technique confirms the ASTM C1293 reactivity classification based on expansion results for the HR mixtures. For aggregates initially classified as HR, as with AMBT, measures of CPT expansion and nonlinearity are in agreement, as summarized in table 5. However, in some cases, there is an indication of earlier detection of reactivity using NIRAS. Comparing Mix 2 in figure 64 and figure 68, it can be seen that the NIRAS technique is capable of identifying ASR sooner than the expansion measurements; nonlinearity is detected at 8 days while the expansion limit is crossed at about 25 days. However, further investigations are clearly needed in this area to determine what kind of microstructural changes cause nonlinearity as well as what level of nonlinearity can be considered detrimental. These investigations will enable us to describe the damage in concrete in a more quantitative manner and to give a definitive criterion for reactivity of an aggregate, considering its microstructure and chemical properties.

Figure 67. Graph. NIRAS results up to 750 days

Figure 68. Graph. NIRAS results up to 100 days

Table 5. Summary of reactivity classifications based on AMBT, CPT, and NIRAS

Sample |

Aggregate reactivity based on ASTM C1260 |

Aggregate reactivity based on ASTM C1293 |

Aggregate reactivity based on NIRAS |

|---|---|---|---|

Mix 1 |

Innocuous |

Nonreactive |

Nonreactive |

Mix 2 |

Potentially Deleterious |

Reactive |

Reactive |

Mix 3 |

Potentially Deleterious |

Reactive |

Reactive |

Mix 4 |

Potentially Deleterious |

Reactive |

Reactive |

Mix 5 |

Potentially Deleterious |

Reactive |

Reactive |

Mix 6 |

Innocuous or Potentially Reactive |

Nonreactive |

Nonreactive |

Mix 7 |

Potentially Deleterious |

Reactive |

Nonreactive |

Table 5 also summarizes results for the NR Mix 1 and the MR Mix 6. For both Mix 1 and Mix 6, the average expansion of the specimens at 1 year is very close to the 0.04-percent expansion limit in ASTM C1293 but does not exceed that limit, indicating a nonreactive aggregate by that measure. The classification of aggregate in Mix 6 is more ambiguous because it exceeded the lower 0.1-percent expansion limit in AMBT. NIRAS shows the nonlinearity of both Mix 1 and Mix 6 specimens has remained very close to zero throughout the year of testing, indicating these are nonreactive aggregate. While the expansion for any concrete sample, including the nonreactive mixes, increases as the duration of the test increases, the nonlinearity does not change for a nonreactive aggregate, providing a more definitive and accurate result.

The only mix for which the nonlinearity measurements are contrary to expansion results is Mix 7, as shown in table 5. The expansion limit has been crossed for that mix but nonlinearity remains negligible throughout the test period. Petrography has been performed on this mix in an attempt to assess the validity of the various results for this aggregate. Those results are presented in the "Petrography Results" section of this chapter.

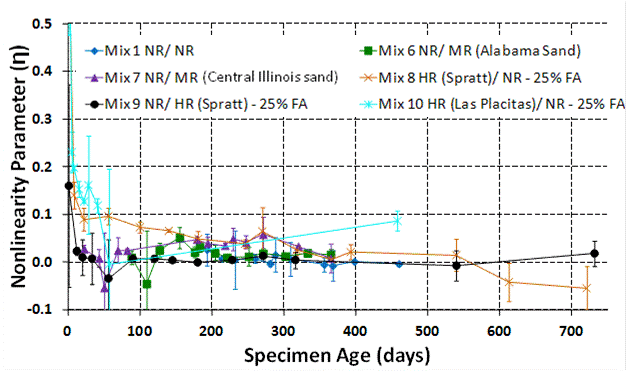

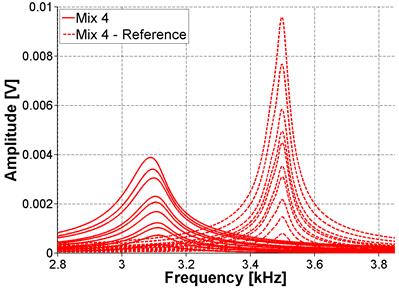

Nonlinearity was also measured on reference samples held at ambient laboratory conditions (i.e., not exposed to ASTM C1293 accelerated environmental conditions). Figure 69 shows those results. All the values of nonlinearity for reference mixtures are considerably lower than what measurements for reactive mixtures that have undergone CPT. For example, the results for Mix 4, for both CPT and reference samples, are shown in figure 70 and figure 71. Notice that in addition to a negligible frequency shift, the reference sample has a sharper resonance at a higher frequency due to lower attenuation.

Figure 69. Graph. NIRAS results for reference mixes

Figure 70. Graph. Nonlinearity comparison between reference and tested samples for HR Mix 4 at 250 days

Figure 71. Graph. Comparison between reference and tested samples for HR Mix 4 at 250 days in the frequency domain

It is interesting to note that in figure 68 and figure 69, mixtures tested at the first day show some nonlinearity that then decreases down to zero through subsequent testing. This can be caused by the continued hydration of the cement after demolding, which decreases the inherent material nonlinearity by eliminating defects present initially (i.e., before the material nonlinearity due to ASR becomes dominant). The results for the reference mixes are surprising for the NR mixture, because slightly lower nonlinearity is detected for the specimens subjected to CPT. (However, it should be noted that in both environments, the nonlinearity for the NR mix is very low.) The difference in the measurements could be related to variations in inherent defects between the two sample groups or, perhaps more likely, by more limited cement hydration during storage at drier ambient conditions, compared with the moist conditions during CPT. Because the CPT sample group has abundant moisture available to promote cement hydration (which could fill early age cracking and porosity), NR concrete can achieve more complete hydration and hence lower nonlinearity than the reference sample group, for which the drier conditions would limit hydration. Because the reference samples undergo only 1 day of moist curing, it is possible that the inadequate hydration can be the cause of the slight nonlinearity in the nonreactive reference mixtures. Overall, however, the results indicate that it may be possible to extend the use of this technique to investigations of the cement hydration process, as well as self-healing in cementitious systems.

In addition, the observed decrease in the nonlinearity parameter for reactive mixes at later ages should be considered. This underlying cause for the decrease at later ages is not yet fully understood, but it is postulated this may be related to cracks growing to larger sizes (i.e., wider cracks). The measured nonlinearity comes from the nonlinear behavior of cracks, through the interaction of crack surfaces. When a crack becomes too large, the crack faces may no longer interact and, as a result, no longer contribute to nonlinearity. It is important to notice that this decrease in nonlinearity appears to occur at about the same time the expansion rate starts to decrease and level off. Perhaps the same phenomenon is responsible for the eventual decrease in expansion rate and decrease in nonlinearity observed in the results.

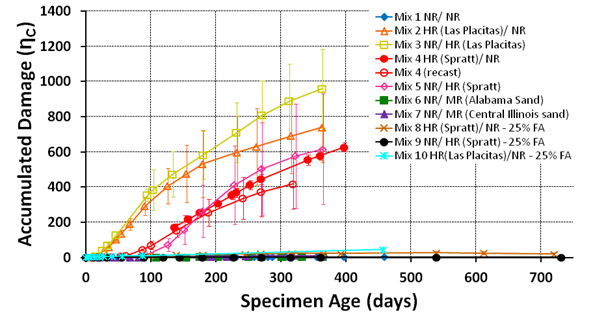

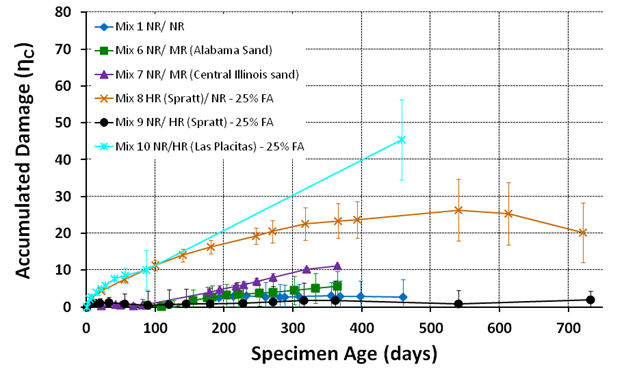

Another way to represent the nonlinearity data—and one that shows even greater distinction between the reactive and nonreactive aggregates—is through a measure of accumulated damage, ηc. This approach is described in chapter 2. Figure 72 shows accumulated damage for all samples, while figure 73 shows a detailed view of the results for the NR and MR mixtures. Using the accumulated damage for these NR and MR mixtures, some distinction can be made between the mixtures that was not clear from the instantaneous nonlinearity in figure 67 and figure 68. One observation from comparing these results is that nearly the same levels of accumulated damage and instantaneous nonlinearity have developed in HR Mix 4 (initial and recast samples). This result can be seen in figure 67, figure 68, and figure 72. The expansion measurements, figure 63 and figure 64, show more variable results when comparing the recast Mix 4 with the initially cast batch. However, with both methods of assessment, the aggregate is clearly reactive.

As noted earlier, the expansion measurements seem to indicate a faster rate of reaction when the reactive aggregate is used as a fine aggregate as compared with its use as a coarse aggregate; an exception is the case of the recast Mix 4. With the NIRAS measurements, particularly in the assessment of accumulated damage, there is no observable trend with the size of the reactive aggregate. This can be beneficial in laboratory testing because there is no effect of gradation on the results of reactivity classifications, offering benefits for the assessment of job mixtures and potentially eliminating the needed for crushing and/or grading prior to assessment.

The SD, represented by error bars in figure 67 and figure 68, shows the variability among the measurements made on three samples for each mix at each age. Both the expansion measurements and measurements of ηc have a general trend of increasing SD with increasing expansion or nonlinearity. Because of inherent heterogeneities, the cast prisms are not identical to each other, even within the same mix. As a result, each sample represents a different material system that can accumulate damage in different ways. Because of the high sensitivity of NIRAS, the SD is larger for reactive mixes.

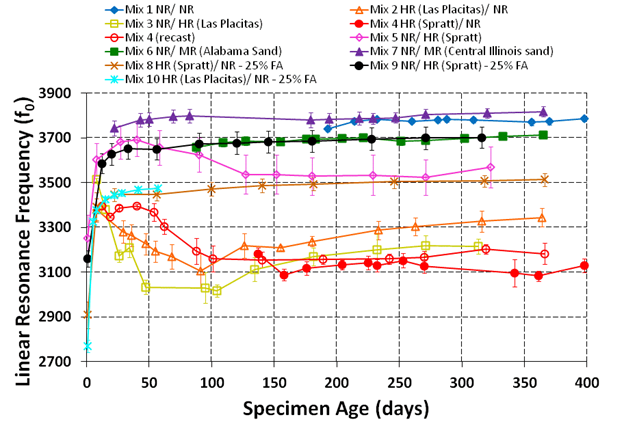

Because the lowest amplitude impact is assumed to be the approximate linear resonance frequency, this measure can also be used to track changes to the specimens. In general, these data, shown in figure 74, complement the nonlinearity measurements. Examining data for mixes 5, 8, and 9 from figure 67, figure 68, and figure 74, it is observed that these mixes start with a low linear resonance frequency and relatively high nonlinearity after demolding. Subsequently, the linear resonance frequency increases (presumably because of an increase in elastic modulus due to hydration) and nonlinearity decreases. This data supports the postulated explanation for relatively high initial nonlinearity and slightly higher nonlinearity for nonreactive reference mixes. Overall, an observed decrease in linear resonance frequency also relates to an increase in nonlinearity, demonstrating an inverse relationship between changes in linear resonance frequency and nonlinearity parameter. It is important to observe that the changes in nonlinearity are significantly larger than the changes in the linear resonance frequency. This comparison, demonstrates that nonlinearity can be used to more accurately assess changes in the specimens than changes in linear resonance frequency.

Figure 72. Graph. Cumulative nonlinearity

Figure 73. Graph. Cumulative nonlinearity for NR and MR mixes

Figure 74. Graph. Changes in linear resonance frequency

To assess whether the NIRAS technique might be used to examine ASR damage in the field or on samples obtained from in-service structures, cored samples obtained from two different pavements were also tested. The cores were supplied by the Georgia Department of transportation (GDOT). One core was taken from I-75 and another was taken from Highway (HWY) 316. The concrete from HWY 316 is suspected to have ASR damage, while that from I-75 was not expected to have ASR, based on external petrographic analysis. The cores were tested in the same manner and with the same setup as described in Chapter 4. The nonlinearity results for I-75 and HWY 316 are shown in figure 75 and figure 76, respectively.

These results clearly show that HWY 316 has a significantly higher nonlinear parameter, indicating that it has experienced damage. While the cause of damage is unclear, the measurements suggest that the result is an extensively microcracked road. This technique offers an extremely rapid and non-subjective evaluation of cores that can be used to evaluate field concrete.

Figure 75. Graph. Nonlinear measurement results on I-75 core

Figure 76. Graph. Nonlinear measurement results on HWY 316 core

As described in chapter 5 of this report, complementary assessment of the progression of damage in the concretes was performed through petrographic assessment of concrete prisms from various mixes and after various CPT durations. These results can be used to better understand the data obtained through CPT and NIRAS evaluation.

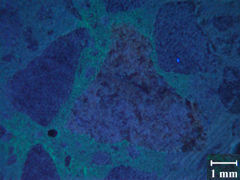

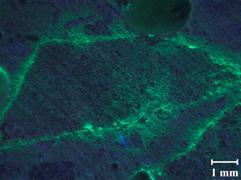

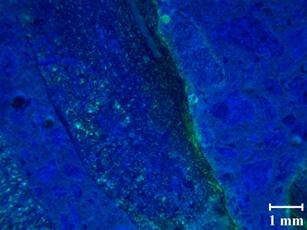

For HR Mix 2, the results of the preliminary petrographic examination, using the uranyl acetate stain on a prism, are shown in figure 77 and figure 78. For this mix, a set of five prisms was recast—with three used for expansion and two for petrography—to obtain early age images. Comparing figure 77 and figure 78 shows a clear difference in the petrographic features at different specimen ages. At 1 day, the representative cross-section in figure 77 shows only a light staining of the paste but no signs of ASR gel. At 9 days, as shown in figure 78, there is clear evidence of reaction rims forming around some aggregates, indicating ASR activity. These results are consistent with the nonlinearity results for Mix 2, for which the measurements show a detectable nonlinearity at the first measurement at 8 days. Figure 79 shows the expansion measurements for the originally cast Mix 2 samples and for the recast Mix 2 set. In addition, the nonlinearity of the original Mix 2 samples is plotted on the secondary axis. These results show that nonlinearity measurements appear to indicate reactivity at earlier ages than the expansion results; that is, the expansion limit is not crossed until about 13 days and 20 days for the recast and original Mix 2 samples, respectively, while the proposed nonlinearity limit or 0.2 was already exceeded by the time of the first NIRAS measurement, at 8 days.

At later ages, petrographic examination shows substantial staining throughout the concrete matrix, making it difficult to determine which microstructural changes are most influencing the nonlinearity measurements. As mentioned earlier, Mix 4 had been recast to gather nonlinearity data for the early ages because this mixture had been originally cast before the development of a nonlinear measurement setup. In addition to gathering nonlinear data, expansion measurements were also collected for these recast samples, and petrography was performed regularly. The expansion and nonlinearity results are shown together in figure 80.

1 mm = 0.03937 inches

Figure 77. Photo. Petrographic image for Mix 2 at 1 day

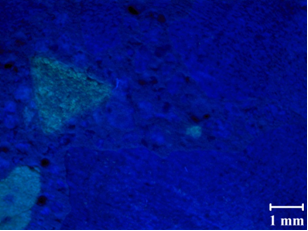

1 mm = 0.03937 inches

Figure 78. Photo. Petrographic image for Mix 2 at 9 days

Figure 79. Graph. Comparison of expansion and nonlinearity results for Mix 2

Figure 80. Graph. Comparison of expansion and nonlinearity results for Mix 4

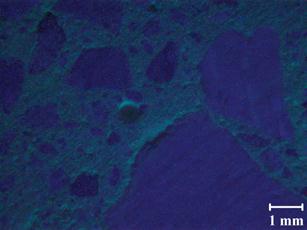

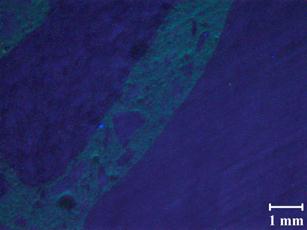

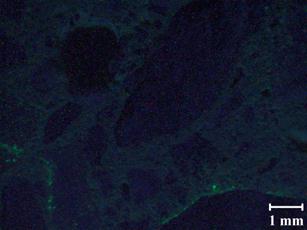

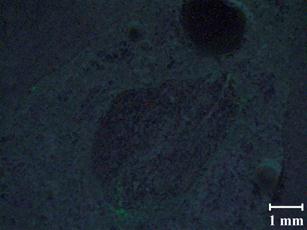

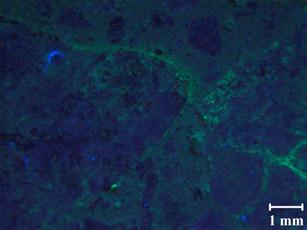

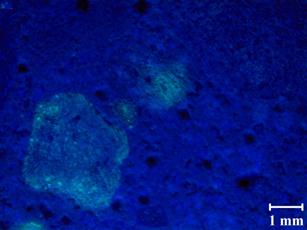

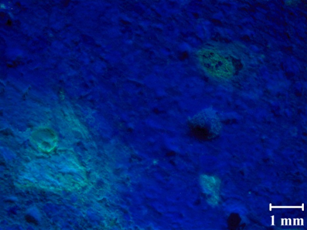

The results show that the recast Mix 4 prisms had a considerably higher expansion rate, crossing the limit at only 20 days while the originally cast mixture crossed at about 95 days. For the NIRAS measurements, the nonlinearity starts to develop at about 50 days. At 12 days, although there is a small amount of staining of the paste, there is no fluorescence, as shown in figure 81 and figure 82. At 26 days, overall, there is little fluorescence, with only a few instances of fluorescence shown in figure 83 and figure 84. At 40 days, there is still little fluorescence in the sample; only a few instances are found, shown in figure 85 and figure 86. These results are not consistent with expansion results because much more fluorescence is expected once the expansion limit is crossed. Note the nonlinearity remains low for these ages. At 54 days, there is significantly more fluorescence but it appears inside the aggregates, which was not observed in other aggregate sources examined (see figure 87 and figure 88). At about this time, nonlinearity starts to increase. At 62 days, the fluorescence is even more common and consistent with the increase in nonlinearity (see figure 89 and figure 90).

1 mm = 0.03937 inches

Figure 81. Photo. Image 1 of recast Mix 4 at 12 days

1 mm = 0.03937 inches

Figure 82. Photo. Image 2 of recast Mix 4 at 12 days

1 mm = 0.03937 inches

Figure 83. Photo. Image 1 of recast Mix 4 at 26 days

1 mm = 0.03937 inches

Figure 84. Photo. Image 2 of recast Mix 4 at 26 days

1 mm = 0.03937 inches

Figure 85. Photo. Image 1 recast Mix 4 at 40 days

1 mm = 0.03937 inches

Figure 86. Photo. Image 2 recast Mix 4 at 40 days

1 mm = 0.03937 inches

Figure 87. Photo. Image 1 of recast Mix 4 at 54 days

1 mm = 0.03937 inches

Figure 88. Photo. Image 2 of recast Mix 4 at 54 days

1 mm = 0.03937 inches

Figure 89. Photo. Image 1 of recast Mix 4 at 62 days

1 mm = 0.03937 inches

Figure 90. Photo. Image 2 of recast Mix 4 at 62 days

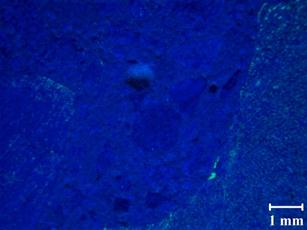

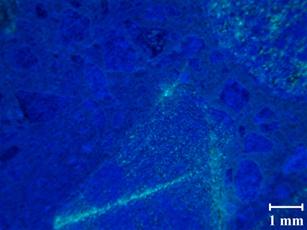

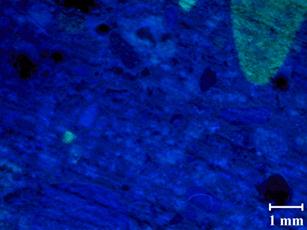

Petrography was also performed on Mix 7. Again, all samples were recast. At 218 days, after the expansion limit had been crossed, as shown in figure 91 and figure 92, some staining of certain aggregates is apparent but there is no evidence of reaction rims or cracks. This technique was also applied to the reference Mix 7 for comparison, as shown in figure 93 and figure 94. When compared, the photos of Mix 7 and those of reference Mix 7 show little difference between the features of the concrete exposed to accelerated conditions and that stored at ambient conditions. This petrographic examination does not provide evidence of ASR and, as a result, confirms the nonlinearity results but contradicts expansion results.

1 mm = 0.03937 inches

Figure 91. Photo. Image 1 of recast Mix 7 at 218 days

1 mm = 0.03937 inches

Figure 92. Photo. Image 2 of recast Mix 7 at 218 days

1 mm = 0.03937 inches

Figure 93. Photo. Image 1 for recast reference Mix 7 at 218 days

1 mm = 0.03937 inches

Figure 94. Photo. Image 2 for recast reference Mix 7 at 218 days