U.S. Department of Transportation

Federal Highway Administration

1200 New Jersey Avenue, SE

Washington, DC 20590

202-366-4000

Federal Highway Administration Research and Technology

Coordinating, Developing, and Delivering Highway Transportation Innovations

| REPORT |

| This report is an archived publication and may contain dated technical, contact, and link information |

|

| Publication Number: FHWA-HRT-17-109 Date: January 2018 |

Publication Number: FHWA-HRT-17-109 Date: January 2018 |

The condition of each individual strand was documented before any destructive testing was performed. This included disassembling the bundles if they were intact, recording the type and severity of visual damage, and photographing the strands from the blast bundles. This chapter discusses the methods used to document the visual condition of strands retrieved from the thermal lance bundle and select blast bundles of interest and the data that were collected from that effort.

The bundle was cut into three sections that isolated each of the two thermal lance cuts into roughly 36-inch-long segments. Each segment was centered around each of the two thermal lance zones, as noted in figure 2. The strand ends were numbered to facilitate mapping damage throughout the cross section of the bundle. Due to the large amount of heat input from cutting with the thermal lance, the bundle became a fused mass of melted steel and HDPE, and thus individual strands did not separate easily from the bundle. Separating the strands required effort using crowbars, utility knives, and reciprocating saws.

Figure 3 and figure 4 provide a map of the damage throughout the cross section for cut A. In both figures, each circle represents an individual strand, and the overall arrangement of circles represents the cross-sectional shape of the bundle. The top of each circle has an underlined alphanumeric code designating the strand and will be used to reference individual strands throughout this report. The letter in the alphanumeric code refers to a particular qualification test applied to a bundle, while the number refers to a strand within that bundle. In figure 3, the number shown at the bottom of each circle represents the number of cut wire(s) within that strand, and the color shading of each circle is also keyed to this value. A cut wire is defined as one that has been physically severed into two pieces. In figure 4, the number at the bottom of each circle represents the number of wire(s) with observed damage. In this case, damage is defined as a nick or gouge in an individual wire and not severed. Likewise, color shading of these circles is also linked to a color scale based on the number of damaged wires. Circles shaded black in figure 4 indicate strands that are completely severed and do not contribute separately to the total number of damaged wires. The damage distribution in figure 3 and figure 4 suggests that the thermal lance likely entered the right side of the bundle as depicted in the damage map and moved right to left as it cut through more and more strands.

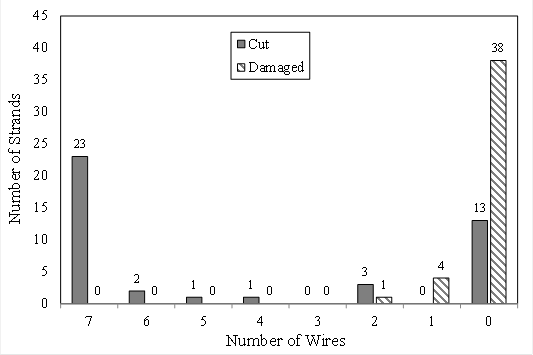

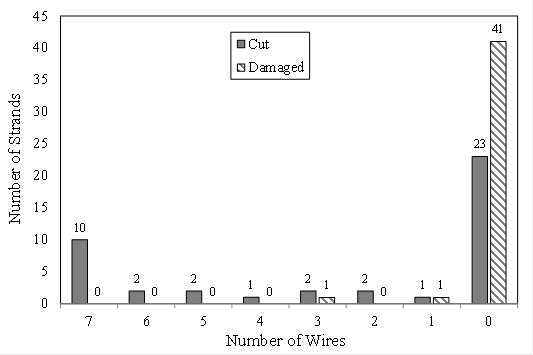

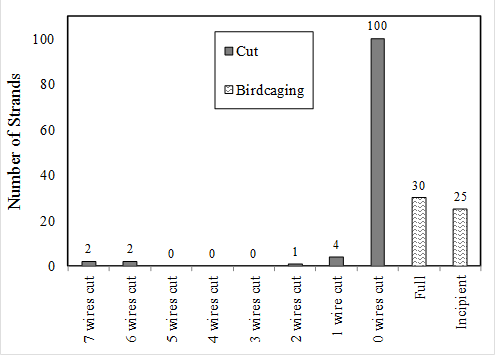

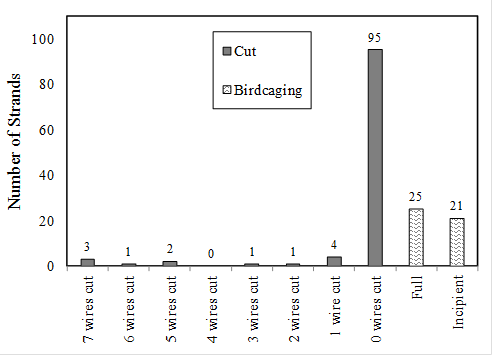

Figure 5 and figure 6 present similar maps of severed and damaged wires for cut B. The extents of cut and damaged wires were much less for this cut, particularly as evident in figure 6. As shown in figure 2, cut B happened to coincide with the location of a bundle retaining plate, and this greatly impeded the thermal lance operator’s ability to compromise the bundle. The same data on cut and damaged wires are replicated with histograms in figure 7 and figure 8, respectively, for cut A and cut B.

Tabulated data represented in figure 3 through figure 6 can be found in appendix A.

Source: FHWA.

Figure 7. Histogram. Enumerated strands categorized by the number of cut and damaged wires in thermal lance cut A.

Source: FHWA.

Figure 8. Histogram. Enumerated strands categorized by the number of cut and damaged wires in thermal lance cut B.

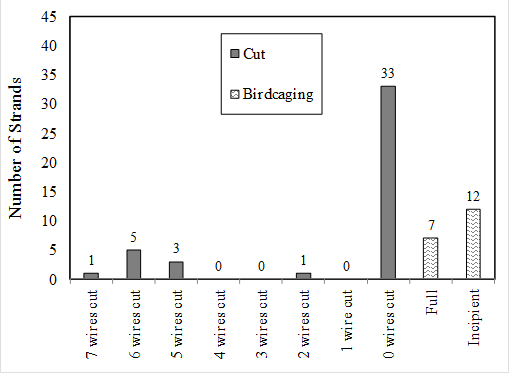

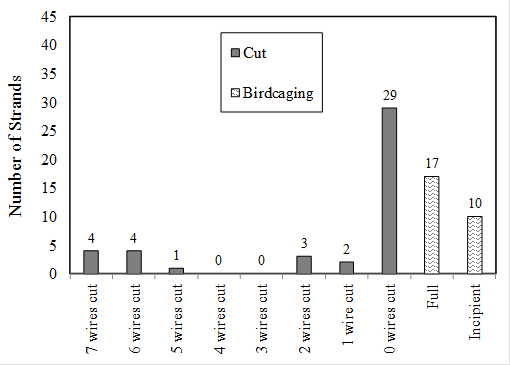

The four bundles subjected to blast are called “D,” “E,” “F,” and “G.” Bundles D and E were 43-strand bundles, and F and G were 109-strand bundles. The strands from bundles D, F, and G were not received as an intact bundle, so it was not possible to create a map of damage relative to the as-constructed bundle. Therefore, for these three bundles, only a histogram can be presented for cut and damaged wires. The term “cut” wires refers to those individual wires that were completely severed into two pieces from the blast event. This is consistent with the definition of cut wires identified after the thermal lance tests. Strands with cut wires were not of interest for further testing (because tension testing them would be difficult), and only strands with all seven wires intact were further categorized for damage. For strands with no wires cut, two levels of damage were assigned: incipient birdcage (IBC) and full birdcage (FBC). The term “birdcaging” refers to a general untwisting of the strand to the point where some wires are not touching each other. An IBC is when one wire has some visible separation from the others; an example is shown in figure 9. An FBC strand is when two or more wires have visible separation from the others; an extreme case is shown in figure 10 where all wires are not touching. If a strand had no cut wires and no signs of birdcaging, it was referred to as an “intact” strand.

Figure 11 through figure 14 show histograms of cut and damaged wires for bundles D, E, F, and G, respectively. The number of intact strands is not shown in the bar charts, but it would merely be the number of strands with zero cut wires, minus all those with FBCs and IBCs. It must be noted that bundle G was a 109-strand bundle, though adding up all the strands in figure 14 sums to only 107 because 2 strands were missing from the delivered bundle.

Source: FHWA.

Figure 11. Histogram. Enumerated strands categorized by the number of cut wires and number of birdcaged strands in blast test D.

Source: FHWA.

Figure 12. Histogram. Enumerated strands categorized by the number of cut wires and birdcaged strands of the bundle from blast test E.

Source: FHWA.

Figure 13. Histogram. Enumerated strands categorized by the number of cut wires and number of birdcaged strands in blast test F.

Source: FHWA.

Figure 14. Histogram. Enumerated strands categorized by the number of cut wires and number of birdcaged strands in blast test G.

Bundle E remained intact after the blast event such that cut wires and strand damage could be mapped through the bundle cross section. Figure 15 and figure 16 show the maps of cut and damaged wires from bundle E; the maps were formed in the same manner as described in the “Thermal Lance Cut Bundle” section. Based on the cut wire map, it appears the explosive was centered above strand E1, since all cut wires were isolated within the top half of the bundle. The damaged strand map in figure 16 shades all strands that had cut wires with black, as further damage evaluation was not of concern. However, there was no clear trend on birdcage damage, as full and incipient strands seemed to occur throughout the remaining bundle cross section.

As determined prior to the qualification testing, acceptance of these tests was based on no more than 25 percent loss of wires in a bundle. On a percentage basis, the number of cut wires in bundles D, E, F, and G was 17.9, 21.6, 4.2, and 6.1 percent, respectively, so based solely on these criteria, each of the blast bundles passed the qualification tests. However, after the testing was complete, the question arose as to whether or not a birdcaged strand should be considered to have full capacity. If birdcaging does indicate a reduction of strength, it is possible that the tests may not pass the qualification criteria, since some of the bundles contain a large population of birdcaged strands.

The photo of bundle E in figure 1 shows that, after the blast event, the strands are certainly left in a residual bent or kinked shape. One of the primary questions to be explored is, Does this additional cold working from the strand being bent, along with birdcaging, affect the residual strength of the strand? To answer this question, the deformations (curvature and diameter of the strand) of each strand were measured. To characterize curvature, a jig was fabricated to consistently measure the lateral and vertical deformation of the strand relative to a fixed plane along a 24-inch-long chord distance. As illustrated in figure 17, two aluminum angles, spaced with an out-to-out distance of 24 inches, were attached to a piece of plywood. A bent strand was laid on the plywood and put into contact with these two angles. In each blast test, a charge was placed near the center of the bundle along its length, around the outermost surface of a protection device encasing the strand bundle. Thus, assuming the maximum damage was most likely aligned with the charge position, the center of each individual strand was aligned to the middle of the 24-inch-chord distance. In the plane of the plywood, the lateral deformation was measured as the distance normal to the 24-inch chord to the strand (depicted in the plan view of figure 17). The vertical deformation was measured as the distance from the plywood to the center of the strand (depicted in the elevation view of figure 17).

Unlike the lateral deformation, the vertical deformation did not necessarily capture vertical curvature within the 24-inch-chord distance. In some cases, the strand supported itself up off the plywood within the 24-inch chord, and in other cases, it supported itself at points completely off the plywood. Therefore, the vertical deformation does not depend on a specific length over which the overall deformation occurred, and the usefulness of this measurement may have little or no value in assessing strand damage; it is reported herein for completeness.

If a birdcaged strand was identified, the diameter at the midlength of that strand was measured with a circumferential tape. Since the birdcage did not necessarily occur at the exact center of the strand, the maximum observable diameter within the strand central region (not necessarily within the 24-inch-chord distance) was also measured. Typically, the blast event removed the HDPE cover from around the middle of the strand, revealing if a birdcage condition existed. No further effort was made to remove more of the HDPE cover, so it is possible that the maximum birdcage diameter could have been missed if it occurred elsewhere along the strand within intact portions of the HDPE cover. The likeliness of this was considered low, as the blast events tended to strip most of the HDPE from the center of the strand sampled for tension testing. The raw measurement data for both deformation and diameter are reported in appendix B for each bundle.

Each bundle investigated a different bundle size and standoff distance for evaluating the performance of the protection system. Damage that occurred from each test ranged from no visible damage to any wires in a strand to the severing of all seven wires in a strand. So, for this project, it was not necessary to categorize strand damage as a function of blast test—only to assess the residual strengths based on observed damage. Therefore, all the uncut (i.e., no wires cut) strands from tests D, E, F, and G were lumped together for selection of further testing. This is shown in figure 18 and figure 19. These plots show the variation between vertical deformation, lateral deformation, and birdcaging of strands. In general, FBC strands exhibited larger vertical and lateral deformations, with a maximum value of 3.5 inches. Intact strands showed the least amount of lateral deformation, generally not exceeding 1.5 inches. The IBC strands exhibited lateral deformations in between the measured deformations from the other two sets of categorical damage. The maximum measured diameter of a strand only indicated the severity of FBC. A virgin strand had a measured diameter of 40/64 inch, and all intact and IBC strands had approximately this value. Most FBC strands had diameters ranging from 43/64 to 68/64 inch.