U.S. Department of Transportation

Federal Highway Administration

1200 New Jersey Avenue, SE

Washington, DC 20590

202-366-4000

Federal Highway Administration Research and Technology

Coordinating, Developing, and Delivering Highway Transportation Innovations

| REPORT |

| This report is an archived publication and may contain dated technical, contact, and link information |

|

| Publication Number: FHWA-HRT-14-052 Date: October 2014 |

Publication Number: FHWA-HRT-14-052 Date: October 2014 |

Early and continual involvement by bridge owners in the development and implementation of the LTBP Program was deemed to be critically important to the success of the program. At an early stage in the development phase, three issues were identified for which input from bridge owners was important to the pursuit of the development phase tasks. First was the need to determine what aspects of bridge performance were most important to the owners and then to determine what gaps existed in their understanding of these aspects of bridge performance. That information is the focus of this report. Second was the need to examine what information and data owners currently had for use in their decisionmaking processes and to identify where there were critical gaps. Third was to understand their decisionmaking process and business practices to help identify what products the LTBP Program could develop that would best assist bridge owners in managing their bridge programs. That information was used internally by FHWA.

The approach selected to collect this information was to hold a series of focus groups across a number of geographically distributed States. The best source of the required information was deemed to be the State transportation departments. Therefore, focus group meetings were designed to allow interviews with a group of bridge inspectors, engineers, and managers from each of the selected States. As a result of the meetings, valuable information was obtained on performance issues of concern, data needs, performance measures that the transportation departments currently use, and what those departments saw as desired outcomes of the program. Detailed records of the meeting discussions are included in appendix B.

A focus group interview process was adopted to assist the team in achieving the following objectives:

The first step was to develop a practical process to solicit the assistance of State transportation department bridge personnel (experts in bridge design, inspection, maintenance, preservation, and management) in gathering information about the processes they use and the activities they carry out related to bridge performance. To develop a program that is grounded in the real world of bridge engineering, input was needed from experienced bridge practitioners. State transportation department input was obtained to help ensure that the LTBP Program would provide practical data and results that practitioners could use in managing the performance of bridge inventories and to allow State transportation departments to share with the FHWA what they believe is needed.

It was agreed that the focus groups should represent owners of a geographically, economically, and environmentally diverse cross section of State transportation departments because they represent a majority of the custodians of the national bridge inventory. Six regions were designated across the continental United States; table2 presents the list of State transportation departments ultimately selected from each region.

Table 2. List of focus group States by region.

| Region | States |

| Northwest | Montana, Oregon, Utah |

| Southwest | California, Texas |

| North Central | Iowa, Illinois, Kansas, Minnesota |

| South Central | Alabama |

| Northeast | New Jersey, New York, Ohio |

| Southeast | Virginia, Florida |

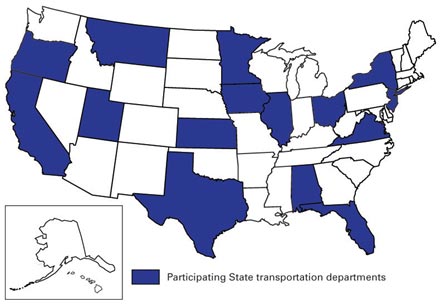

Figure 2 presents the geographic distribution of State transportation departments identified for focus group participation.

Figure 2. Map. Participating State transportation departments.

In 2008, focus group meetings were conducted in Virginia, California, New Jersey, New York, and Florida. In 2009, focus group meetings were conducted in Minnesota, Utah, Texas, Iowa, Montana, Oregon, Ohio, Alabama, Illinois, and Kansas. State transportation department bridge personnel were asked to come to the meetings ready to discuss the following:

The focus groups discussed specific modes of deterioration for bridge decks, superstructures, substructures, and ancillary systems, as well as functional and operational aspects of bridge management. Focus group meetings concentrated on the following:

Appendix A contains the specific questions asked of the focus groups. Interviews were taped and transcribed and notes were summarized. The information gathered served as a guide in identifying high priority performance issues.

Appendix B outlines the detailed results from the respective focus group interviews. Representatives of 5 transportation departments indicated that their departments had a centralized organizational structure for managing the bridge inventory, whereas 10 indicated such operations were distributed among operating districts or other decentralized units.

An National Bridge Inventory (NBI) bridge is defined as any structure on a public highway that meets the NBI definition of a bridge: A structure including supports erected over a depression or an obstruction, such as water, highway, or railway, and having a track or passageway for carrying traffic or other moving loads, and having an opening measured along the center of the roadway of more than 20 ft between undercopings of abutments or spring lines of arches, or extreme ends of openings for multiple boxes; it may also include multiple pipes, where the clear distance between openings is less than half of the smaller contiguous opening.(1) At the time the interviews were conducted, representatives of 12 State transportation departments indicated that they collect AASHTOWare Bridge Management® software element-level condition information during their periodic inspections of NBI bridges, and 3transportation departments did not. The representative of one transportation department indicated that the department was awaiting the release of the new national bridge elements definitions, which were expected to replace the American Association of State Highway and Transportation Officials (AASHTO) Commonly Recognized (CoRe) element definitions.(2) The other three States collect NBI condition ratings but do not collect element-level condition information.(3)

Table 3 provides information regarding the bridge inventories in the focus group States and whether they collect element-level inspection data on their bridges.

Each transportation department was asked to identify bridge performance issues it experienced on decks, superstructures, and substructures. Table 4 indicates which transportation departments experienced certain performance issues related to bridge decks. The Alabama Department of Transportation (ADOT) did not report any performance issues with decks.

Table 5 indicates the transportation departments that experienced certain performance issues related to bridge superstructures. All of the transportation departments that were interviewed reported at least one performance issue with superstructures.

Table 6 indicates the transportation departments that experienced certain performance issues related to bridge substructures. The Oregon Department of Transportation (ODOT-OR) did not identify any specific performance problems related to substructures. (Note that the Ohio and Oregon State transportation departments both use the formal abbreviation ODOT. To avoid confusion, this report uses the abbreviation ODOT-OR for the Oregon agency.)

Table 3. State transportation department bridge inventory and management structure.

| Characteristic | AL | CA | FL | IA | IL | KS | MN | MT | NJ | NY | OH | OR | TX | UT | VA |

| Transportation Department Management Structure | D | C | D | C | D | C | D | C | C | D | D | D | D | D | D |

| No. of NBI Bridges in the State | 16,070 | 24,807 | 10,845 | 24,495 | 26,056 | 24,812 | 13,121 | 5,120 | 5,391 | 16,473 | 26,573 | 7,631 | 51,467 | 2,947 | 13,965 |

| No. of Bridges under State Responsibility | 5,738 | 12,180 | 5,414 | 4,071 | 7,740 | 4,976 | 3,615 | 2,488 | 2,371 | 7,460 | 10,345 | 2,706 | 33,513 | 1,773 | 11,892 |

| No. of Bridges under Local or Other Responsibility | 10,332 | 12,627 | 5,431 | 20,424 | 18,316 | 19,836 | 9,506 | 2,632 | 3,020 | 9,013 | 16,228 | 4,925 | 17,954 | 1,174 | 1,965 |

| Collect AASHTOWare Bridge Management® Software Data | Pending | Yes | Yes | Yes | No | Yes | Yes | Yes | Yes | No | No | Yes | Yes | Yes | Yes |

| C = Centralized D = Decentralized |

|||||||||||||||

Table 4. State transportation department reported issues related to decks.

| Issue | Total States | CA | FL | IA | IL | KS | MN | MT | NJ | NY | OH | OR | TX | UT | VA |

| Spalling | 9 | ✓ | ✓ | ✓ | ✓ | ✓ | ✓ | ✓ | ✓ | ✓ | |||||

| Cracking | 8 | ✓ | ✓ | ✓ | ✓ | ✓ | ✓ | ✓ | ✓ | ||||||

| Delamination | 8 | ✓ | ✓ | ✓ | ✓ | ✓ | ✓ | ✓ | ✓ | ||||||

| Sealing | 4 | ✓ | ✓ | ✓ | ✓ | ||||||||||

| Overlays | 3 | ✓ | ✓ | ✓ | |||||||||||

| Patches | 2 | ✓ | ✓ | ||||||||||||

| Delamination of polymers overlays | 2 | ✓ | ✓ | ||||||||||||

| Carbonation of older concrete decks | 2 | ✓ | ✓ | ||||||||||||

| Fatigue cracking | 1 | ✓ | |||||||||||||

| Soffit spalling | 1 | ✓ | |||||||||||||

| Studded tires | 1 | ✓ | |||||||||||||

| Construction related issues, e.g., deck curing procedures | 1 | ✓ | |||||||||||||

| Timber replacement | 1 | ✓ | |||||||||||||

| Ingress of chlorides | 1 | ✓ | |||||||||||||

| All blank cells indicate that no issues of this type were reported by the given State transportation department. | |||||||||||||||

Table 5. State transportation department reported issues related to superstructures.

| Issue | Total States | AL | CA | FL | IA | IL | KS | MN | MT | NJ | NY | OH | OR | TX | UT | VA |

| Coating system failures, steel corrosion on steel bridge superstructure members | 11 | ✓ | ✓ | ✓ | ✓ | ✓ | ✓ | ✓ | ✓ | ✓ | ✓ | ✓ | ||||

| Joint deterioration, leakage | 11 | ✓ | ✓ | ✓ | ✓ | ✓ | ✓ | ✓ | ✓ | ✓ | ✓ | ✓ | ||||

| Impact damage; steel and/or concrete beams | 9 | ✓ | ✓ | ✓ | ✓ | ✓ | ✓ | ✓ | ✓ | ✓ | ||||||

| Deterioration of concrete and steel girder ends under joints | 4 | ✓ | ✓ | ✓ | ✓ | |||||||||||

| Prestressed concrete beams—difficulty of inspecting condition of strands | 2 | ✓ | ✓ | |||||||||||||

| Steel fatigue | 3 | ✓ | ✓ | ✓ | ||||||||||||

| Drainage off the deck | 3 | ✓ | ✓ | ✓ | ||||||||||||

| Cracked girders | 2 | ✓ | ✓ | |||||||||||||

| Spalling of beams | 1 | ✓ | ||||||||||||||

| Excessive rusting of weathering steel | 1 | ✓ | ||||||||||||||

| Concrete pop-outs due to freezing | 1 | ✓ | ||||||||||||||

| Rusting/freezing of box girder hinges | 1 | ✓ | ||||||||||||||

| Cracks in elements—impact or construction related | 1 | ✓ | ||||||||||||||

| Alkaline Silica Reactivity (ASR) | 1 | ✓ | ||||||||||||||

| Added inspection needs for fracture critical bridges | 1 | ✓ | ||||||||||||||

| Parapet spalling | 1 | ✓ | ||||||||||||||

| Deterioration of concrete in box beams | 1 | ✓ | ||||||||||||||

| Corrosion at construction joint between rail and deck | 1 | ✓ | ||||||||||||||

| All blank cells indicate that no issues of this type were reported by the given State transportation department. | ||||||||||||||||

Table 6. State transportation department reported issues related to substructures.

| Issue | Total States | AL | CA | FL | IA | IL | KS | MN | MT | NJ | NY | OH | TX | UT | VA |

| Scour | 13 | ✓ | ✓ | ✓ | ✓ | ✓ | ✓ | ✓ | ✓ | ✓ | ✓ | ✓ | ✓ | ✓ | |

| Cracking, spalling, or delaminations of components | 9 | ✓ | ✓ | ✓ | ✓ | ✓ | ✓ | ✓ | ✓ | ✓ | |||||

| Corrosion of steel pile bents | 4 | ✓ | ✓ | ✓ | ✓ | ||||||||||

| Bearing corrosion or malfunction | 7 | ✓ | ✓ | ✓ | ✓ | ✓ | ✓ | ✓ | |||||||

| Approach slab settlement | 3 | ✓ | ✓ | ✓ | |||||||||||

| Corrosion of mild steel reinforcing in components | 2 | ✓ | ✓ | ||||||||||||

| Leaking joints | 2 | ✓ | ✓ | ||||||||||||

| Seismic | 2 | ✓ | ✓ | ||||||||||||

| Leaking joints | 2 | ✓ | ✓ | ||||||||||||

| ASR | 1 | ✓ | |||||||||||||

| Beam locking on steel bridges | 1 | ✓ | |||||||||||||

| Corrosion of strands in pre-stressed piling | 1 | ✓ | |||||||||||||

| Erosion under approach slabs | 1 | ✓ | |||||||||||||

| Splash zone issues | 1 | ✓ | |||||||||||||

| Timber piles | 1 | ✓ | |||||||||||||

| Settlement | 1 | ✓ | |||||||||||||

| Cathodic protection | 1 | ✓ | |||||||||||||

| Beam locking describes a situation on a simple-span steel girder bridge where one bearing is frozen and all of the expansion must be accommodated by the other bearing; in some cases, clearance between the beam end and the abutment backwall is too small to allow full expansion and so the beam end contacts and sometimes damages the abutment backwall. All blank cells indicate that no issues of this type were reported by the given State transportation department. |

|||||||||||||||

Each State transportation department was asked to identify any issues related to functional performance of their bridges. As table 7 shows, only five State transportation departments identified any specific performance problems related to functional issues.

Table 7. State transportation department reported issues related to functional issues.

| Issue | Total States | FL | MT | NJ | NY | TX |

| Load ratings | 3 | ✓ | ✓ | ✓ | ||

| Approach versus bridge width | 2 | ✓ | ✓ | |||

| Traffic service | 2 | ✓ | ✓ | |||

| High mast illumination poles | 1 | ✓ | ||||

| Impact damage from barges | 1 | ✓ | ||||

| Railings and transitions | 1 | ✓ | ||||

| Vertical clearance | 1 | ✓ | ✓ | |||

| All blank cells indicate that no issues of this type were reported by the given transportation department. | ||||||

Functional issues represent a safety hazard (such as a narrow bridge or a poor alignment between bridge and approach roadway) or affect traffic capacity (such as insufficient lanes).

Many of the State transportation departments interviewed use performance measures by which to evaluate the effectiveness of their bridge programs. These performance measures generally fall into one of three types. The first type of measure counts the number of bridges or total deck area of bridges that meet a defined standard such as “structurally deficient.” Alternatively, the measure may be number of bridges or total deck area of bridges that are rated to be in “good,” “fair,” or “poor” condition. In this rating system “good” usually means bridges with an NBI condition rating of 9, 8, or 7; “fair” means bridges with an NBI condition rating of 6 or 5; and “poor” means bridges with an NBI condition rating of 4 or below.

A second approach is to count the number of bridges or total deck area of bridges that have a defined minimum value on a defined index such as the Federal Sufficiency Rating. A third approach tracks completion of items that have been identified as needing maintenance or repair.

Several States use multiple measures. Note that these measures do not, by and large, directly measure the performance of individual bridge engineering, maintenance, and management actions or strategies. Some of the program performance measures in use are listed in table 8.

Table 8 . Performance measures identified by focus groups.

| Type | Measure | No. of Transportation Departments Using |

| Defined Status or Condition |

Load posted bridges | 2 |

| Structurally deficient bridges | 5 | |

| Functionally obsolete bridges | 3 | |

| Bridges rated good, fair, poor | 3 | |

| Defined Index | Federal Sufficiency Rating | 4 |

| Health Index for the whole bridge | 4 | |

| Custom rating systems for bridges and components | 3 | |

Status of Maintenance Needs |

Actual versus desired maintenance response time | 3 |

| “Percentage of deficiencies ‘flagged’ for maintenance items that have been fixed” |

1 | |

| No. of critical findings resolved | 1 |