ENHANCED IN-PLACE DENSITY SERIES

Why is it so important?

As one of the most important factors influencing the performance of asphalt pavement today, in-place density has a significant impact on rutting, cracking, and moisture damage. Relatively small improvements in in-place density can mean great benefits – a cost savings of approximately 8.8 percent for each percent density increase.

Demonstration Projects

This three-phase, multi-year effort engaged 26 state DOTs at 29 workshops and field demonstrations, with 121 experimental sections constructed. FWHA worked to identify minimum in-place density for asphalt mixtures, methods for improving density, and ways to overcome obstacles to achieving in-place density.

Specification Types

An analysis of DOT practices across the U.S. found that the most effective approach to in-place density specifications were the percent within limits (PWM) approach, which uses statistical concepts like mean and standard deviation to calculate percentage, and the lot average approach – a simple calculation of average in-place density.

Example Approaches to Density Specifications

Review a table outlining data from 10 state DOTs with in-place density specifications that minimized the amount of test results below the 92.0 percent threshold. Examine the effectiveness of your in-place density specification by calculating the percentage of individual results below 92.0 percent as well as the average.

Ensuring Adequate Density

Accurately measuring in-place density during production is vital to achieving long-lasting pavements. The key specification properties are mixture bulk specific gravity (Gmb) and maximum theoretical specific gravity (Gmm).

Material Challenges

The three major challenges to mixtures for optimized in-place density are stiff mixtures, tender mixtures, and aggregate degradation. Paying close attention to specific factors during paving can minimize those factors.

Placement Challenges

Three aspects of the pavement placement (optimizing the number of lifts and lift thickness without excessive rolling, strength of the subgrade or foundation, and consideration of daily factors when determining the optimal number of roller passes) impact in-place density.

Potential Solutions

A recent series of FHWA Demonstration Projects has identified 11 considerations during placement that can increase in-place density and resulting service life of asphalt.

SPOTLIGHT ON PAVEMENT DENSITY SERIES

Use of Dielectric Profiling Systems (DPS) for Asphalt Density

Improving pavement performance can extend maintenance cycles and save millions of dollars in transportation budgets. DPS are an innovative, nondestructive solution that collects dielectric values to measure air voids of nonuniformity of newly laid hot-mix asphalt. Learn more about DPS functionality and benefits.

Minnesota DOT:

Working with Dielectric Profiling Systems (DPS)

Minnesota DOT (MnDOT) says DPS is the “final piece of the puzzle of getting expanded assessment of placed pavement.” Learn more about the state’s history of proven results with DPS since 2016 – including example projects for which DPS provided insight on roller passes and roller techniques.

Status of Dielectric Profiling Systems (DPS) in the State

MnDOT is the lead agency for a national transportation pooled fund study to address research gaps and share resources in pavement construction. Learn about more than 20 projects that have led to advancements in AASHTO standards, data management hardware and software, protocols, and incorporating DPS into project acceptance.

New York State DOT:

Working with the Dielectric Profiling System (DPS)

The New York State Department of Transportation (NYSDOT) first started using a dielectric profiling system (DPS) with ground penetrating radar in 2020. Learn more about how NYSDOT has conducted several shadow projects with DPS annually across the State.

Next Steps with the Dielectric Profiling System

The NYSDOT shares its process for exploring the innovative DPS technology, such as by publishing a new specification, partnering with stakeholders, testing the specification out on projects, documenting opportunities for specification improvement, and more.

North Dakota DOT:

Working with the DPS

NDDOT was concerned about the limitations collecting one set of cores every 2,000 feet to evaluate pavement uniformity. Read more about how using DPS helped to solve this problem by collecting continuous data, with shorter analysis turnaround, and using an extra set of batteries to avoid downtime.

Findings and Next Steps with the DPS

Since acquiring the DPS in 2020, NDDOT has found that uploading and analyzing the comprehensive amount of data is the biggest issue with DPS. Learn how NDDOT has been reducing turnaround time through practice and other tools.

Ohio DOT:

Starting Out with Dielectric Profiling Systems (DPS)

The Ohio DOT (ODOT) purchased its first DPS unit in late 2018 and immediately started seeing results in the areas of density and uniformity. Read more about why ODOT initially turned to DPS, purchased a second unit in 2019, and continues to rely on DPS for effective results today.

Status of Dielectric Profiling Systems (DPS) in the State

Since 2018, the Ohio DOT (ODOT) has tracked use of its two DPS units on at least 10 projects and is working to develop standard procedures for DPS use and participate in a national pooled study. Learn more about the differences ODOT is seeing between DPS evaluation and sample cores, as well as the planned future next steps for DPS in Ohio.

SPOTLIGHT ON PAVEMENT UNIFORMITY SERIES

Use of Paver-Mounted Thermal Profiler (PMTP) for Asphalt Uniformity

The PMTP provides real-time thermal images to map non-uniform areas of the freshly-paved asphalt mat that are lower in temperature than the surrounding mat. This tool enables faster identification of mat differences, without destructive methods such as coring, so paving contractors can adjust operations in real-time.

Maine DOT:

Working with a PMTP

Since obtaining a PMTP in 2015, MaineDOT has used it on 20-30 projects where the technology provides holistic information on pavement uniformity, insight on problem areas, and paving progress. Learn more about the opportunities, limiting factors, and MaineDOT’s suggestions for other agencies.

Minnesota DOT:

Using the PMTP

MnDOT began pilot testing the PMTP in 2010 and has used it as a standard part of their quality assurance procedures since 2018. Data from the PMTP has enabled MnDOT to identify and implement better construction practices in general. Read more about MnDOT’s PMTP observations and benefits.

PMTP Status and Next Steps

Learn about MnDOT’s plans to employ PMTP in the future, including its integration with data management and other intelligent construction systems, verifying contractor-furnished data, and expanding training. MnDOT also has valuable suggestions for other agencies.

Texas DOT:

Using the PMTP

TxDOT’s Abilene District began exploring PMTPs in 2015 and now apply them on 50-60 paving projects per year. Learn more about TxDOT’s observations and identified benefits, along with information on sample projects.

PMTP Status and Next Steps

Learn about TxDOT's program to expand training on PMTP use and data interpretation, and expand its use statewide, to further realize the benefits of PMTP for asphalt pavement construction in Texas.

SPOTLIGHT ON PAVEMENT SAFETY SERIES

Implementing Macrotexture in Asphalt Mixture Design

The impacts of intense and frequent rainfall events and construction delivery extensions that result in longer periods of temporary pavement surfaces are two examples of the need for enhanced pavement friction in more of the country. Learn more about tools and associated procedures that have shown effectiveness for collecting and interpreting pavement macrotexture profiles from asphalt roadway surfaces.

North Carolina DOT:

Exploring the Laser Texture Scanner (LTS)

Since borrowing a LTS from FHWA in 2021, North Carolina DOT (NCDOT) researchers have applied the technology on field pavements within work zones and on field cores extracted from a number of pavement resurfacing projects around North Carolina. Learn more about NCDOT's experience with LTS in assessing pavement macrotexture on dense-graded asphalt overlays and subsequent observations related to pavement safety characteristics after construction.

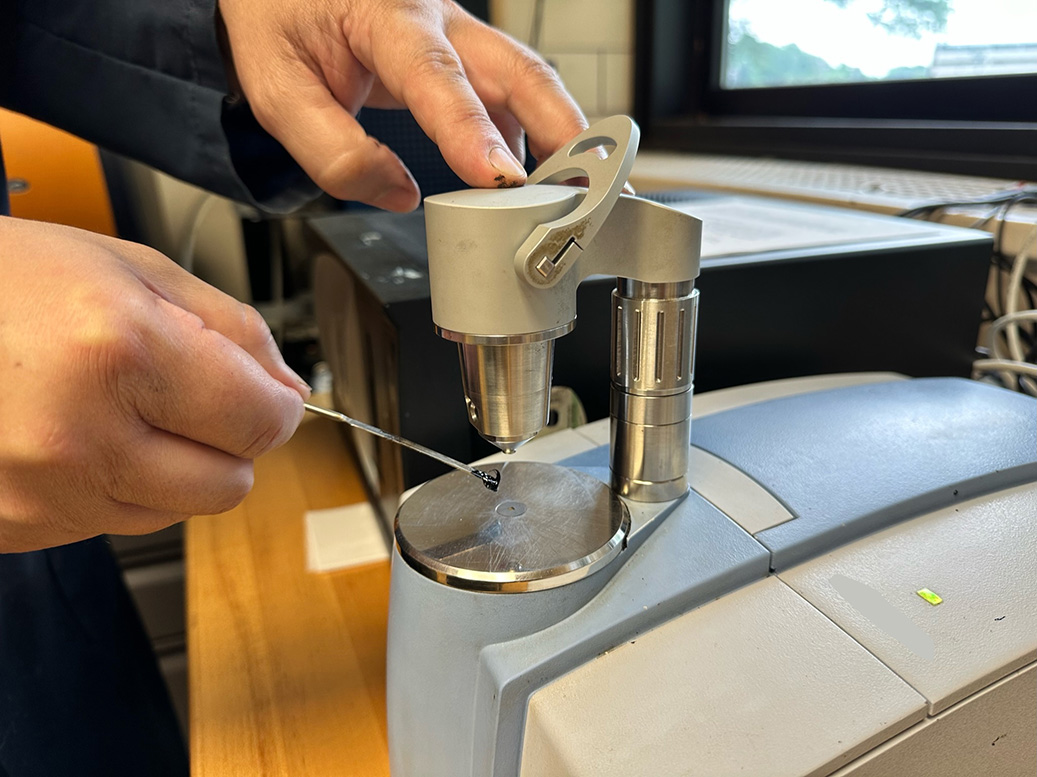

LABORATORY LOOK-INS AT ASPHALT BINDER MIXTURE LAB

Qualitative Spectral Analysis of Asphalt Binders using Fourier Transform Infrared (FTIR) Technology

Read about a collaborative case study exercise conducted by the FHWA Office of Infrastructure R&D in service to the New Hampshire DOT. The objective was to investigate Fourier Transform Infrared Spectroscopy (FTIR) as a tool to determine consistency in asphalt binder supply, assess aging potential, and identify modifications.

Assessment of Automated Extraction Technology

Learn more about the FHWA’s Asphalt Binder Mixture Laboratory (ABML) study that evaluated the automated extraction procedure and its effect on performance grading of asphalt binders.

Reach out to the MATC at FHWA-MATC@dot.gov today to learn more.

Image Source: FHWA

Back To Top