| Contents | Next >> |

Prefabricated Bridge Elements and Systems Cost Study: Accelerated Bridge Construction Success Stories

Chapter 1

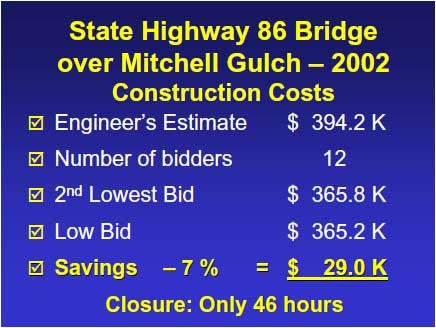

The engineer's estimate for this project was $394.2K. The low bid bid of $365.2K from Lawrence Construction Company was 7% or $29,000 less than the engineer's estimate. There was steep competition among contractors on this project. Twelve contractors bid on the project, and the 2nd lowest bid of $365.8K was just $644 higher than the awarded low bid.

The 5 p.m. Sunday opening of the new bridge was 13 hours earlier than the required 6 a.m. Monday opening. No rush hours were impacted and, therefore, no lane rental fees were charged. Motorists who traveled home from work on Friday over the existing bridge and then to work Monday morning over the new bridge never experienced a construction delay or detour.

The existing bridge was replaced with a totally prefabricated bridge in just 46 hours, and the contractor anticipates cutting the time in half on similar subsequent projects. In addition to huge savings in user costs and significantly improved safety, this bridge was also completed under budget.

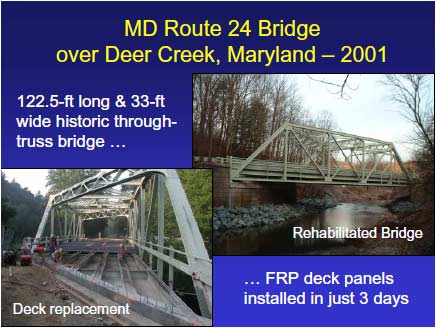

The MD Route 24 Bridge over Deer Creek near Rock State Park in Harford County in northeastern Maryland is a 122.5-ft long, 33-ft wide single-span 2-lane historic throughtruss bridge built in 1934 and eligible for inclusion in the National Register of Historic Places. In 2001 the deck was deteriorated and required a replacement that maintained the historic characteristics of the bridge. The rehabilitation project was also a challenge because the bridge was on a school bus route and could only be closed for rehabilitation a maximum of 10 weeks in the summer. Replacing the deck with one that would last longer than the typical maximum 40 years due to the harsh climate was another challenge. In addition, replacing the deck with one that did not further reduce the live-load capacity of this weight-restricted bridge was a challenge. Other challenges were the low 24.5-ft vertical clearance that restricted crane use and the 56-degree skew.

In 2001 the Maryland State Highway Administration (SHA) decided to address these challenges with fiber-reinforced polymer (FRP) deck panels. Following removal of the existing deck, steel angles were welded to the girders and the panels were installed in just 3 days. The rapid installation possible with these panels allowed the bridge to be rehabilitated during the summer and opened prior to the start of school. The corrosion resistance of the panels is anticipated to almost double the deck's service life, to at least 70 years. In addition, the significantly lighter weight of the FRP panels allowed easier placement and increased the live-load capacity of the bridge.

The project was completed in 10 weeks. Deck replacement with FRP panels was done in 1/3 the time required for a conventional concrete deck.

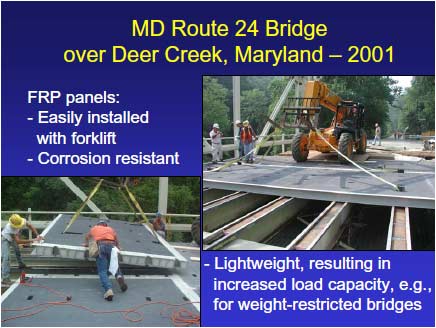

The bridge consists of two warren trusses each with five 24.5-ft long panels connected to overhead members. The trusses are supported by eight steel girders at 4-ft spacing. The FRP panels, which were manufactured by the protrusion method, are E-glass fiberglass strands and fabric coated with an isophthalic polyester resin.

Because of limited vertical clearance, the most efficient deck installation method is with a forklift to place the panels, and the use of a forklift was possible because of FRP's light weight. The FRP deck system that was selected allowed immediate construction loads without the full grouting required for some FRP deck systems. This enabled the forklift to immediately move onto the newly-placed panel to position the next panel as it progressed from one end of the bridge. The panels were installed perpendicular to the girders and act as a continuous beam across the girder supports.

The method used to attach the panels to the girders was similar to the method used in the region to construct reinforced concrete decks on steel girders. Steel angles were welded to the sides of the girders to form a haunch, the panels were placed on the angles, shear studs were installed in prefabricated pockets in the panels, and the shear stud pockets were filled with non-shrink grout. An asphalt overlay was then placed to provide the required skid resistance, to form the roadway crown, and to protect the FRP from ultraviolet radiation. While a polymer overlay is typically used in Maryland, the asphalt overlay was allowed because the FRP panels will not corrode.

Once the existing deck was removed and the existing girders cleaned, it took only 15 working days for the bridge to be opened to traffic.

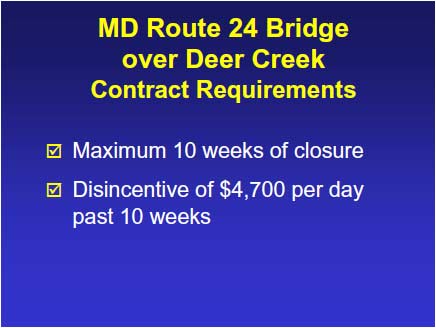

The low traffic volume of 3,700 ADT (in 2000) allowed the bridge to be closed during a 10-week period in the summer when school was out. Traffic was diverted to a 21-mile detour during this time.

A penalty for time violations was included in the contract. For every day beyond the 10-week closure period that the detour was in place, the contractor would be fined $4,700. No incentives or other accelerated construction strategies were included in the contract.

In addition to replacing the deck, the contract included cleaning and painting the truss members. During construction several steel members were found to be deteriorated and required repair. These repairs increased the time it took the contractor to complete the work, but it was still within 10 weeks. No penalties were assessed.

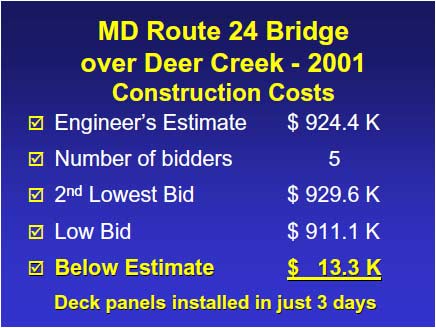

The engineer's estimate for this project was $ 924.4K. The low bid of $911.1K was slightly below the engineer's estimate. Five contractors bid on the project, and the 2nd lowest bid was only slightly higher than the low bid.

The deteriorated deck was replaced with a deck that is anticipated to last at least 70 years compared to 40 years for typical concrete decks in the region. The FRP deck, connections and grout weigh just 25 pounds per square foot (lbs/sq ft). Adding the 45 lbs/sq ft for the asphalt overlay results in a total deck weight of just 70 lbs/sq ft compared to 115 lbs/sq ft for a traditional reinforced concrete deck. This 40% reduction in deck weight increased the live load capacity of this historic bridge. In addition, the accelerated construction made possible using FRP panels allowed the bridge to be completely rehabilitated within the available 10-week period.

This project was the Maryland State Highway Administration's first use of FRP bridge decks. The FRP deck cost $88/sq ft compared to $35/sq ft average cost for a traditional concrete deck replacement in 2001. Costs for replacements with FRP deck panels are anticipated to go down with subsequent projects.

Use of FRP on this historic bridge helped the State Highway Administration maintain the heritage of the region. They partnered with the University of Maryland and received an FHWA Innovative Bridge Research and Construction Program grant that covered part of the cost to install and monitor the FRP deck. A recent inspection in 2006 found the deck still looking new, with no signs of problems. The Maryland SHA is planning rehabilitation with FRP deck panels for similar historic through-truss bridges in their State, although future availability of multiple suppliers of FRP deck panels is an concern.

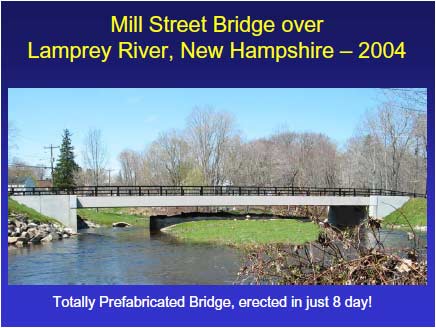

In 2003 the town of Epping's existing 28-ft wide 2-lane Mill Street Bridge over the Lamprey River consisted of two 30-ft long spans separated by a 60-ft long center pier causeway. The spans were deteriorated and required replacement. The low traffic volume crossing the bridge in combination with a short half-mile detour allowed complete closure of this bridge during its replacement. The site was selected for the New Hampshire Department of Transportation's first use of totally prefabricated cantilevered substructure construction. The location minimized the overall risk of using the precast abutment system that was newly developed by a team with members from the NHDOT, FHWA, University of New Hampshire, Precast/Prestressed Concrete Institute's Northeast Region Technical Committee, and local general bridge contractors and precasters.

In August 2004 the existing bridge was replaced with a 115-ft long and 28-ft wide 2- lane single-span pretensioned concrete adjacent box beam superstructure on fullheight cantilevered precast concrete abutments founded on precast concrete spread footings. Thirty-two precast concrete segments were used to construct the bridge.

The erection of the bridge, from start of footing placement to opening to traffic, required 8 days. The bridge was closed to traffic for a total of 2 months, compared to 5 months that would have been required for conventional construction.

| Contents | Next >> |