| << Previous | Contents | Next >> |

Prefabricated Bridge Elements and Systems Cost Study: Accelerated Bridge Construction Success Stories

Chapter 6

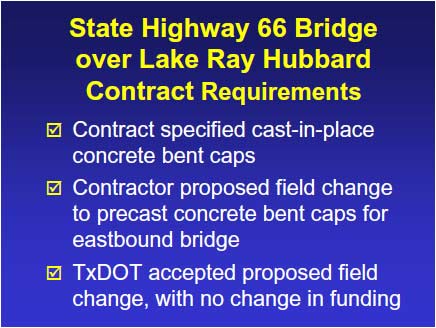

The contract specified conventional cast-in-place construction for the substructures. Early in the project the contractor, Traylor Bros., Inc., proposed a field change to precast reinforced concrete bent caps as a way to speed construction of the eastbound bridge, to avoid the difficulties in handling formwork and materials over water, and to minimize the construction workers' exposure to high-voltage transmission lines running adjacent to the bridge. TxDOT approved the contractor's proposal with no change in funding.

The contract did not include incentives or disincentives.

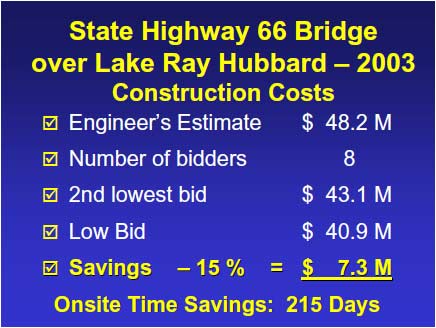

The engineer's estimate for this project was $48.2M. The low bid of $40.9M was 15% or $7.3M less than the engineer's estimate. There were 8 bidders on this project, with the 2nd lowest bid about 5% or $2.2M more than the awarded low bid.

Using the 43 precast bent caps reduced onsite construction time by 215 days. TxDOT obtained the bridge ahead of schedule and under budget.

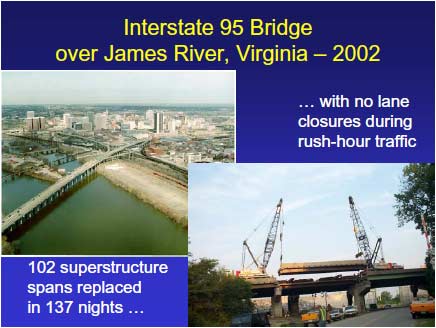

Interstate 95 over the James River in the City of Richmond, Virginia, consists of twin 4,185-ft long bridges with 3 lanes in each direction and a total width of 90 ft. In 1997 the bridges carried 110,000 vehicles daily. Nearly 50 years old, the superstructures had significant structural deterioration and needed to be replaced.

In 2002 the Virginia Department of Transportation completed replacement of the superstructure and rehabilitation of the substructure. The 102 superstructure spans were replaced in just 137 nights during 17 months, with no impact to rush-hour traffic. Conventional construction would have required 24 to 36 months and significant impact to traffic.

Public participation was solicited at the beginning of plan development to limit the impact to motorists. A community advisory group was given several construction options for the replacement. Their preferred option, which VDOT used, was night construction with all three lanes open in each direction during the day. Construction took place from 7 p.m. to 6 a.m. only. During the night work, traffic was shifted to one of the bridges, with one lane in each direction remaining open.

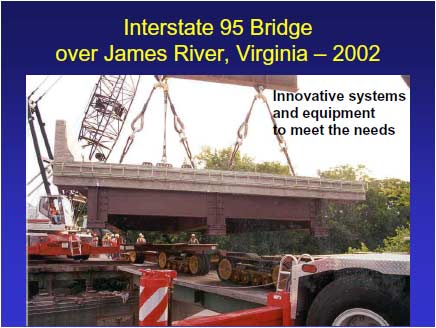

The bridges are composed of multiple steel plate girder simple spans ranging from 44 ft to 114 ft in length, and a 243-ft truss span. The typical steel plate girder span was replaced with 2 full-span-length prefabricated superstructure segments. Each prefabricated segment consisted of 3 steel plate girders with an 8.75-inch deck, complete with bridge railing, and weighed approximately 100 tons. The segments were fabricated by the contractor at a nearby casting yard.

During the night, the existing superstructure was cut longitudinally at every other girder. The old segments were removed using high-capacity cranes and conventional flatbed trailers. The cranes then installed the new prefabricated superstructure segments. After the two segments were in place, the span was transversely post-tensioned and connected longitudinally with bars running through pockets cast into the ends of the segments. The deck of the truss span was replaced with a filled-grid deck system because mechanical and geometrical requirements precluded the use of the prefabricated superstructure segments. The substructure was also rehabilitated as needed.

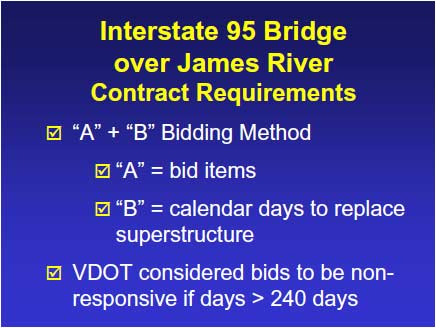

VDOT utilized the "A" + "B" bidding method, where "A" equals the bid items and "B" equals the number of calendar days with nighttime lane closures for the superstructure replacement and rehabilitation.

The Department considered bids greater than 240 days to be non-responsive.

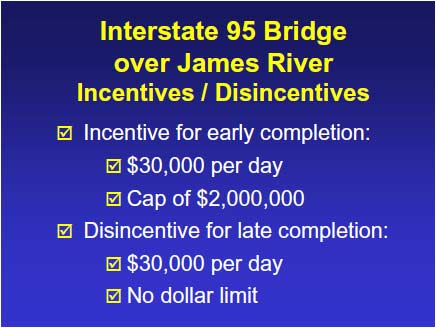

The contract included an incentive of $30,000 for each day the work was completed ahead of the time that was bid in the contract, not to exceed $2.0M. The contract also included a disincentive of $30,000 for each day the work was completed past the bid time, with no dollar limit.

| << Previous | Contents | Next >> |