Archived: FHWA Asphalt Intelligent Compaction Demonstration

What is Intelligent Compaction (IC)

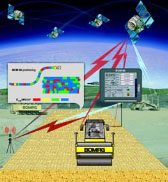

A typical IC System (courtesy of Bomag)

Intelligent Compaction (IC) is an equipment-based technology for better quality control that results in longer pavement lives. IC machines are vibratory rollers with accelerometers mounted on the axle of drums, global positioning system, infra-red temperature sensors (for asphalt), and on-board computers that can display color-coded maps in real-time to track roller passes, asphalt surface temperatures, and stiffness of compacted materials.

Who We Are

The FHWA has been leading a national effort to advance the IC technology through numerous projects since 2008 to improve compaction quality of materials that include granular soils, cohesive soils, stabilized base, and asphalt pavements. To further accelerate the implementation of IC, FHWA is conducting IC research to further investigate the correlation between IC and in-place asphalt densities.

Asphalt IC Field Projects Wanted

The FHWA IC research team is seeking eight (8) asphalt projects in 2012 and 2013 for this study. The requirements for the projects are two (2) lifts, 1 mile or more asphalt construction as extensive coring would be conducted at the base course (further details on page 2). The steps for an IC demonstration are:

- Select an asphalt paving project

- Provide a special provision document (including IC training)

- Convene planning meetings

- Perform field demonstration

- Conduct an open house event

Contacts

If you are interested in participating in this study and providing candidate asphalt projects, please contact:

Dr. George Chang, P.E., Principal investigator (PI) Transtec Group, 6111 Balcones Drive, Austin TX 78731

(512) 451-6233 gkchang@thetranstecgroup.com

IC Project Requirements

Project Materials/Layers/Length

The requirements of the IC demonstration projects include:

- Materials: Hot mix asphalt (HMA) or warm mix asphalt (WMA) overlay or full depth construction

- Layers: at least two (2) lifts of construction while the bottom lift will be the focus of this study

- Length: at least 1 mile or more of the projects will be used for detailed study

Recommended IC Systems

All systems must be equipped with RTK GPS, accelerometer-based measurement systems, infra-red temperature sensors, and an on-board computer display system. The IC data outputs should also be compatible with the Veda IC software. The recommended double-drum IC systems include but not limit to the following (in order of trade names): Bomag, HAMM/Wirtgen, and Sakai.

Field Demonstration

The activities during the demonstration consist of:

- Day 1 : IC setup and training

- Day 2: IC compaction (at breakdown position), and GPS/field point tests

- Day 3: IC compaction (at breakdown position), GPS/field point tests, and coring at about 50 locations within the Day 2 section (coring locations coincide with previous field point tests)

- Day 4: Open House event (optional)

Depending the actual progress, the coring may be conducted for the Day 3 section instead. Along with IC and field point measurements during breakdown rolling, other compactions (asphalt densities after screed, intermediate rolling, and finish rolling) will be monitored during construction in order to relate the majority of factors to the core densities

Who are welcome to participate

- DOT Construction Engineers, QC/QA Personnel, Spec Writers

- Paving Managers, Superintendents, QC Personnel

- Earthworks Managers, Superintendents, QC Personnel

- IC Roller Vendors

Recommended Double-drum IC Systems

Bomag

HAMM/Wirtgen

Sakai

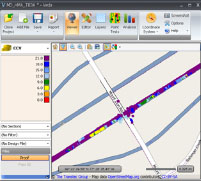

Veda IC Software

Sponsored by

- U.S. Department of Transportation, Federal Highway Administration

Supported by

- Asphalt Institute

- NAPA National Asphalt Pavement Association

More information is available at: www.fhwa.dot.gov/pavement/ic