U.S. Department of Transportation

Federal Highway Administration

1200 New Jersey Avenue, SE

Washington, DC 20590

202-366-4000

Federal Highway Administration Research and Technology

Coordinating, Developing, and Delivering Highway Transportation Innovations

| REPORT |

| This report is an archived publication and may contain dated technical, contact, and link information |

|

| Publication Number: FHWA-HRT-11-062 Date: November 2011 |

Publication Number: FHWA-HRT-11-062 Date: November 2011 |

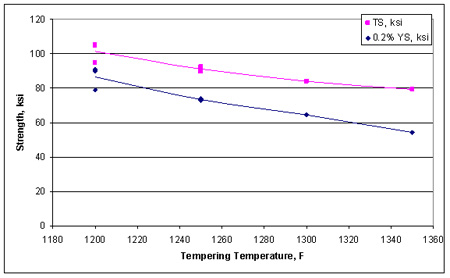

As-normalized coupons of the 11Cr experimental steel and commercially produced ASTM A1010 plates were tempered and tensile tested. The raw tensile data are presented in table 22, and the YS data are presented in figure 46.

Table 22. Tensile test results of 11Cr and ASTM A1010 steels.

Steel |

Tempering |

Hardness (HBW) |

0.2 Percent YS (ksi) |

0.5 Percent Elongation Under Load (EUL) YS (ksi) |

TS (ksi) |

EL (percent) |

RA (percent) |

Base ASTM A1010 |

As-normalized |

285 |

91.9 |

97.8 |

134.5 |

23.1 |

57.8 |

Base ASTM A1010 |

1,200 |

200 |

79.1 |

79.5 |

94.4 |

33.6 |

67.0 |

11Cr |

1,200 |

nd |

89.9 |

89.7 |

104.9 |

21.0 |

57.1 |

11Cr |

1,200 |

nd |

90.8 |

90.5 |

105.3 |

24.2 |

63.1 |

Base ASTM A1010 |

1,250 |

190 |

73.8 |

74.1 |

89.7 |

30.5 |

59.4 |

11Cr |

1,250 |

nd |

73.1 |

74.0 |

92.4 |

29.8 |

72.0 |

11Cr |

1,250 |

nd |

73.2 |

73.9 |

91.7 |

29.4 |

57.1 |

Base ASTM A1010 |

1,300 |

177 |

64.4 |

64.9 |

83.8 |

32.7 |

65.7 |

Base ASTM A1010 |

1,350 |

171 |

54.3 |

55.0 |

79.1 |

39.1 |

72.3 |

°C = (°F-32)/1.8 1 ksi = 6.89 MPa nd = Not determined | |||||||

°C = (°F-32)/1.8

1 ksi = 6.89 MPa

Figure 46. Graph. Tensile properties of normalized and tempered 11Cr steel.

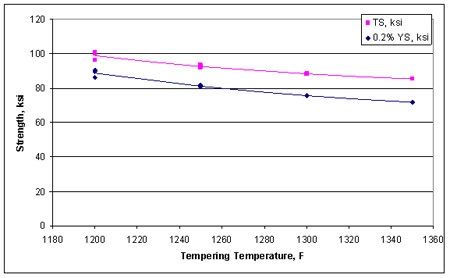

As-normalized coupons of the 9Cr experimental steel plates were tempered and tensile tested. The raw tensile data are presented in Table 23 and the YS data are presented in figure 47.

Table 23. Tensile test results of 9Cr steel.

Tempering |

Hardness (HBW) |

0.2 Percent YS (ksi) |

0.5 Percent EUL YS (ksi) |

TS (ksi) |

EL (percent) |

RA (percent) |

As-normalized |

313 |

109.7 |

106.5 |

148.3 |

9.0 |

39.7 |

1,200 |

211 |

86.1 |

86.4 |

96.4 |

14.4 |

36.9 |

1,250 |

200 |

81.4 |

81.5 |

92.6 |

28.8 |

62.9 |

1,200 |

nd |

89.4 |

89.2 |

100.2 |

22.6 |

63.7 |

1,200 |

nd |

90.2 |

89.8 |

100.6 |

25.9 |

63.7 |

1,300 |

190 |

75.8 |

76.0 |

88.3 |

30.8 |

64.3 |

1,350 |

191 |

71.8 |

71.9 |

85.6 |

34.7 |

62.4 |

1,250 |

nd |

81.8 |

81.9 |

93.3 |

24.1 |

68.0 |

1,250 |

313 |

80.6 |

80.8 |

92.0 |

26.6 |

65.3 |

°C = (°F-32)/1.8 1 ksi = 6.89 MPa nd = Not determined | ||||||

°C = (°F-32)/1.8

1 ksi = 6.89 MPa

Figure 47. Graph. Tensile properties of normalized and tempered 9Cr steel.

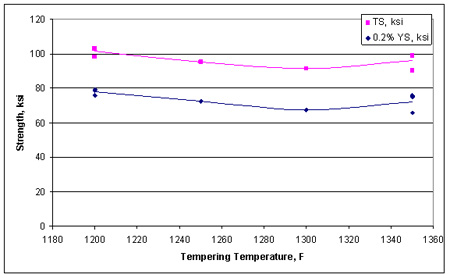

As-normalized coupons of the 9Cr2Si experimental steel plates were tempered and tensile tested. The raw tensile data are presented in table 24, and the YS data are presented in figure 48.

Table 24. Tensile test results of 9Cr2Si steel.

Tempering |

Hardness (HBW) |

0.2 Percent YS (ksi) |

0.5 Percent EUL YS (ksi) |

TS (ksi) |

EL (percent) |

RA (percent) |

As-normalized |

256 |

80.4 |

80.1 |

121.7 |

29.6 |

64.0 |

1,200 |

209 |

75.8 |

76.3 |

98.1 |

38.1 |

72.9 |

1,200 |

nd |

79.1 |

79.6 |

103.0 |

32.8 |

79.7 |

1,200 |

nd |

78.9 |

79.4 |

102.8 |

30.7 |

62.8 |

1,250 |

198 |

72.6 |

72.9 |

95.3 |

36.7 |

73.9 |

1,300 |

190 |

67.2 |

67.3 |

91.4 |

42.4 |

79.8 |

1,350 |

192 |

65.8 |

65.9 |

90.1 |

40.8 |

78.3 |

1,350 |

nd |

76.0 |

76.5 |

98.9 |

34.6 |

73.0 |

1,350 |

256 |

74.7 |

75.5 |

98.7 |

37.2 |

76.6 |

°C = (°F-32)/1.8 1 ksi = 6.89 MPa nd = Not determined | ||||||

°C = (°F-32)/1.8

1 ksi = 6.89 MPa

Figure 48. Graph. Tensile properties of normalized and tempered 9Cr2Si steel.

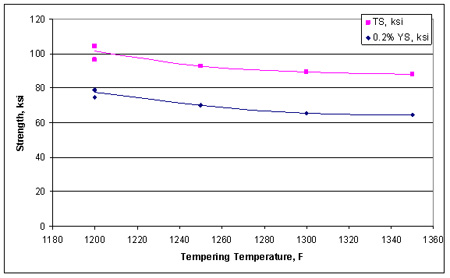

As-normalized coupons of the 7Cr2Si experimental steel plates were tempered and tensile tested. The raw tensile data are presented in table 25, and the YS data are presented in figure 49.

Table 25. Tensile test results of 7Cr2Si steel.

Tempering |

Hardness (HBW) |

0.2 Percent YS (ksi) |

0.5 Percent EUL YS (ksi) |

TS |

EL (percent) |

RA (percent) |

As-normalized |

nd |

76.4 |

75.6 |

115.8 |

28.9 |

58.5 |

As-normalized |

nd |

76.4 |

75.4 |

115.8 |

29.7 |

67.4 |

As-normalized |

258 |

79.1 |

78.1 |

121.1 |

29.9 |

68.8 |

1,200 |

209 |

74.7 |

75.3 |

96.7 |

35.9 |

78.8 |

1,200 |

nd |

78.7 |

79.2 |

104.5 |

30.7 |

62.2 |

1,200 |

nd |

78.8 |

79.5 |

104.0 |

31.4 |

79.7 |

1,250 |

198 |

70.0 |

70.4 |

92.8 |

37.5 |

64.9 |

1,300 |

196 |

65.5 |

65.8 |

89.4 |

38.3 |

50.7 |

1,350 |

194 |

64.5 |

65.2 |

88.0 |

37.9 |

59.4 |

°C = (°F-32)/1.8 1 ksi = 6.89 MPa nd = Not determined | ||||||

°C = (°F-32)/1.8

1 ksi = 6.89 MPa

Figure 49. Graph. Tensile properties of normalized and tempered 7Cr2Si steel.

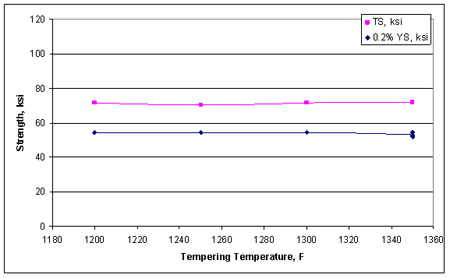

As-normalized coupons of the 7Cr2Al experimental steel plates were tempered and tensile tested. The raw tensile data are presented in table 26, and the YS data are presented in figure 50.

Table 26. Tensile test results of 7Cr2Al steel.

Tempering |

Hardness (HBW) |

0.2 Percent YS (ksi) |

0.5 Percent EUL YS (ksi) |

TS (ksi) |

EL (percent) |

RA (percent) |

As-normalized |

152 |

54.5 |

55.5 |

70.2 |

nd |

14.1 |

1,200 |

147 |

54.5 |

55.4 |

71.5 |

nd |

10.6 |

1,250 |

152 |

54.2 |

54.9 |

70.4 |

nd |

5.6 |

1,300 |

149 |

54.5 |

55.0 |

71.3 |

38.3 |

20.4 |

1,350 |

nd |

54.3 |

55.3 |

72.0 |

34.0 |

21.7 |

1,350 |

152 |

51.9 |

54.1 |

71.8 |

31.9 |

44.2 |

1,350 |

147 |

52.5 |

54.7 |

71.7 |

32.4 |

32.7 |

°C = (°F-32)/1.8 1 ksi = 6.89 MPa nd = Not determined | ||||||

°C = (°F-32)/1.8

1 ksi = 6.89 MPa

Figure 50. Graph. Tensile properties of normalized and tempered 7Cr2Al steel.

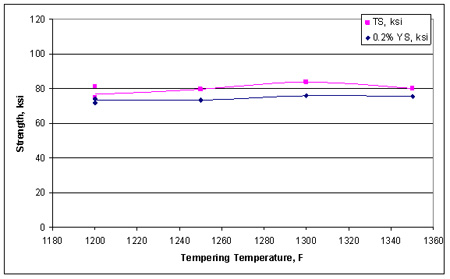

As-normalized coupons of the 5Cr2Si2Al experimental steel plates were tempered and tensile tested. The raw tensile data are presented in table 27, and the TS data are presented in figure 51.

Table 27. Tensile test results of 5Cr2Si2Al steel.

Tempering |

Hardness (HBW) |

0.2 Percent YS (ksi) |

0.5 Percent EUL YS (ksi) |

TS (ksi) |

EL (percent) |

RA (percent) |

As-normalized |

200 |

76.6 |

77.2 |

81.6 |

2.1 |

2.6 |

1,200 |

203 |

71.9 |

72.6 |

74.4 |

0.9 |

1.7 |

1,200 |

nd |

74.0 |

74.3 |

81.1 |

3.7 |

1.8 |

1,200 |

nd |

73.8 |

74.1 |

74.7 |

1.1 |

3.5 |

1,250 |

203 |

73.4 |

74.1 |

79.6 |

5.7 |

nd |

1,300 |

199 |

75.9 |

76.1 |

83.9 |

3.9 |

5.2 |

1,350 |

202 |

75.5 |

76.3 |

80.1 |

4.4 |

2.8 |

°C = (°F-32)/1.8 1 ksi = 6.89 MPa nd = Not determined | ||||||

°C = (°F-32)/1.8

1 ksi = 6.89 MPa

Figure 51. Graph. Tensile properties of normalized and tempered 5Cr2Si2Al steel.