U.S. Department of Transportation

Federal Highway Administration

1200 New Jersey Avenue, SE

Washington, DC 20590

202-366-4000

Federal Highway Administration Research and Technology

Coordinating, Developing, and Delivering Highway Transportation Innovations

| REPORT |

| This report is an archived publication and may contain dated technical, contact, and link information |

|

| Publication Number: FHWA-HRT-14-094 Date: February 2015 |

Publication Number: FHWA-HRT-14-094 Date: February 2015 |

The lateral stress at a GRS facing is different from that in the soil portion. The internal lateral stress in the GRS soil is governed by compaction-induced stresses (CIS) and by additional confining effects that the reinforcement provides to the soil. The pressure at the facing is governed by these two factors as well as the movement of the facing especially in facings that have little or no connection strength. The effects of CISs on the internal lateral stress of both the unreinforced and reinforced soil is discussed. Measured thrusts against facing elements with and without purely frictional connection are presented. Methods for estimating this thrust are used to compare with the measured values.

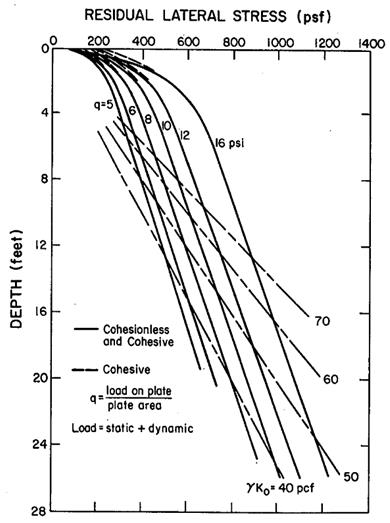

Based on Duncan and Seed's work on CISs, Williams developed simple charts to estimate the residual lateral earth pressures on a nonyielding wall due to compaction.(60,61) An example of a chart for residual lateral stress due to vibratory plate compactors, usually used in GRS construction, is shown in figure 26. At shallow depths, the CIS is a function of the load from the vibratory plate (q) and it exceeds the at-rest value. The family of curves represents different values of q ranging from 5 to 16 psi (34.5 to 110.3 kPa). At greater depths, the lateral pressures revert to the at-rest value once the overburden pressure exceeds the preconsolidation pressure generated during compaction (by the vibratory plate compactor). The family of dashed lines represents the at-rest stresses for varying soil unit weight and friction angles, φ (Ko = 1 - sinφ). Figure 26 is applicable to compaction of unreinforced soil.

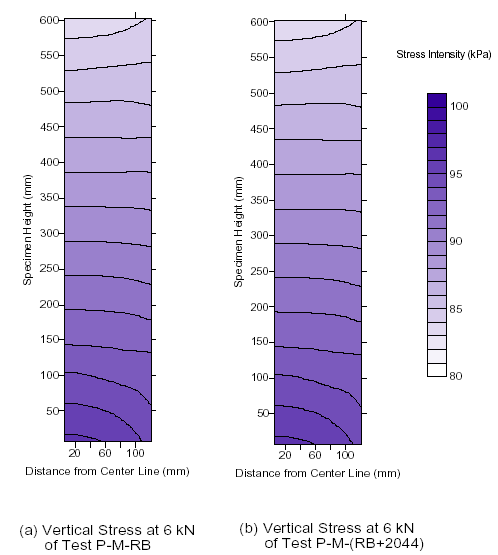

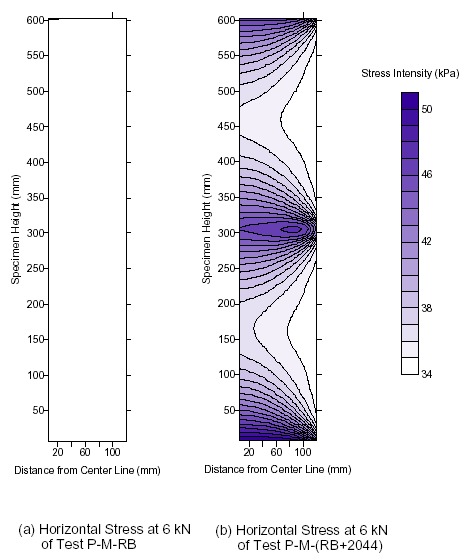

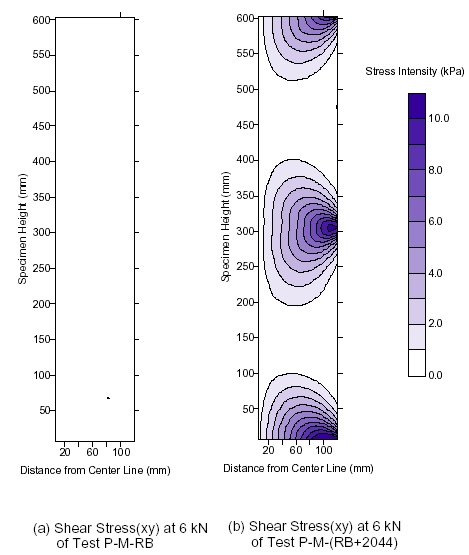

CIS in GRS is likely to be higher than in the same soil unreinforced because the reinforcement-soil-interface friction restrains soil movement thereby producing larger values of soil confining stress, which manifests in the form of greater CIS. Evidence of increased lateral stress has been demonstrated by numerical analysis performed by Ketchart and Wu for a compacted GRS mass loaded to 6 kN (1.35 kips).(62) The vertical stress distribution in the loaded unreinforced soil and GRS are similar, as shown in figure 27. However, the horizontal (figure 28) and shear (figure 29) stresses are higher in the GRS than in the same soil unreinforced. They are higher near the reinforcement and decrease with increasing distance from the reinforcement. The increase in lateral stress will result in increased strength of the GRS. Based on these results, Ketchart and Wu recommended that reinforcement spacing be limited to 12 inches (30.48 cm) for improved performance-hence the advent of closely spaced reinforcement, more commonly called GRS.(62)

Even though CIS clearly adds an important contribution to the vertical capacity of a GRS wall, one drawback when considering CIS in design is that the compaction equipment is seldom known a priori. Therefore, any quantitative analysis of the contribution of compaction to enhance the lateral stresses, and hence capacity in a GRS in the field, is speculative at best.

Source: Francis Group LLC Books

1 ft = .305 m

1 psf = .05 kPa

1 psi = 6.89 kPa

1 pcf = 16.02 kg/m3

Figure 26. Chart. Residual lateral stress induced by vibratory plate compaction.(63)

©K. Ketchart and J.T.J.H. Wu

1 kPa = 20.89 psf

1 mm = .039 inches

1 kN = 0.23 kips

Figure 27. Chart. Vertical stress distribution at 6-kN (1.35-kips) vertical load on the GRS (a) without and (b) with reinforcement.(62)

©K. Ketchart and J.T.J.H. Wu

1 kPa = 20.89 psf

1 mm = .039 inches

1 kN = 0.23 kips

Figure 28. Charts. Horizontal stress distribution at 6-kN (1.35-kips) vertical load on the GRS (a) without and (b) with reinforcement.(62)

©K. Ketchart and J.T.J.H. Wu

1 kPa = 20.89 psf

1 mm = .039 inches

1 kN = 0.23 kips

Figure 29. Charts. Shear stress distribution at 6-kN (1.35-kips) vertical load on the GRS (a) without and (b) with reinforcement.(62)

Lateral stresses in a reinforced soil mass were measured by Yang.(64) He conducted footing model tests on both reinforced and unreinforced soil using a rigid 8-inch- (20.3-cm-) diameter stainless steel plate as a footing. The soil consisted of a dry sand with an average density of 92 pcf (1,474 kg/m3) (corresponding to a relative density of 70 percent (γd min = 81.5 pcf (1,306 kg/m3, and γd max = 96.5 pcf (1,546 kg/m3)). This density was achieved by pluviation, raining the sand from a height of 9 inches (22.9 cm). Compaction-induced stresses were nonexistent in this study. Therefore, any difference in lateral stress between the reinforced and unreinforced sand was purely a result of the effect of the reinforcement. The reinforcement consisted of six 20-inch-(50-cm-) diameter fiberglass nets having average tensile strengths of 202 lb/inch (35.4 kN/m) in one direction and 178.5 lb/inch (21.3 kN/m) in the other. The first reinforcing was placed 2 inches (5.1 cm) below the footing. The additional reinforcings were spaced at 2 inches (5.1 cm).

Lateral stresses were measured at several depths along the centerline of the footing using pressure cells that were 1.4 inches (3.6 cm) in diameter and 0.2 inches (0.5 cm) thick. To prevent damage to the pressure cells that were originally designed by the U.S. Bureau of Mines, the maximum applied stress on the footing was limited to 75 percent of the ultimate bearing capacity for the unreinforced sand. For the reinforced sand, the applied stress was kept below a level that corresponded to a maximum lateral pressure of 40 psi (276 kPa).

Based on the normalized measured lateral stress (lateral stress divided by the applied stress) versus the normalized depth (depth divided by the footing radius) in both the reinforced and unreinforced soil. Yang offered the following results.(64)

Lateral stresses have been measured in many reinforced soil wall systems. They include systems with reinforcing elements that are both connected and not connected to the wall face. Among the those not connected, the wall systems consisted of a concrete wall at the end of a bridge (Warren and LeGrand), an aluminum plate (Ahmadi and Hajialilue-Bonab), brick elements mortared together (Dalton, Walsh, and Pinto and Cousens), and gravity/rigid retaining walls (Saran et al., Garg and Saran, Mittal et al., and Garg et al.). (See references 65 through 73.) Among those that were connected, the wall systems consisted of a full-height plywood facing panel connected to geogrids (Shinde and Mandal), gabion walls connected to geogrids, woven and nonwoven geotextiles (Won and Kim), modular block facing frictionally connected to geogrids (Abu-Hejleh et al. and Mitchell), and full-height-panel and incremental panel walls connected to geogrids (Yogarajah and Saad). (See references 74 through 78.)

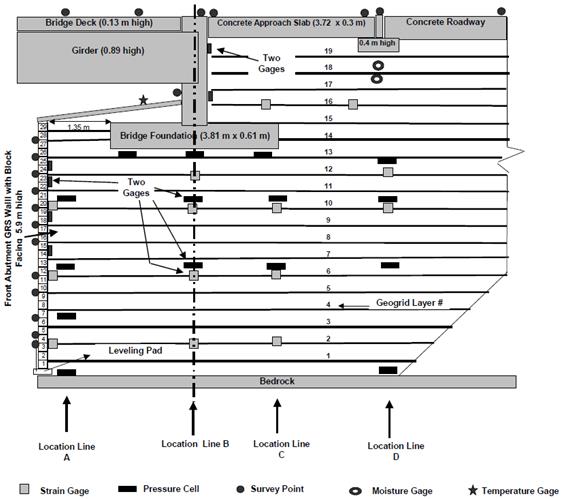

Abu-Hejleh et al. reported lateral pressures on the facing of a 19.4-ft- (5.9-m-) high segmental retaining wall reinforced with 16-inch- (40.6-cm-) spaced Tensar® UX 6 geogrids at the Founders/Meadows bridge in Denver, Colorado (figure 30).(76) These pressures were only reported at the end of construction with the bridge superstructure loading the abutment. This is not a true GRS because the spacing was greater than 12 inches (30.48 cm). The abutment fill, described as a gravelly CDOT Class 1 backfill, had a measured unit weight of 141 pcf (2,259 kg/m3) with peak shear strength parameters from large-scale triaxial tests of φ = 39 degrees and c = 1,440 psf (68.0 kPa).

Earth pressure cells were mounted above the 7th, 9th, 11th, and 12th geogrid layer from the bottom. Abu-Hejleh et al. indicated that the measured lateral pressures were significantly less (6 to 35 percent) than the Rankine active pressures plus the footing-induced pressure assumed a 2V:1H load spread (see table 6). Lateral pressures before placing the bridge footing were not reported.

Source: N.M. Abu-Hejleh et al.

Figure 30. Drawing. Founders/Meadows bridge abutment cross-section and instrumentation.(76)

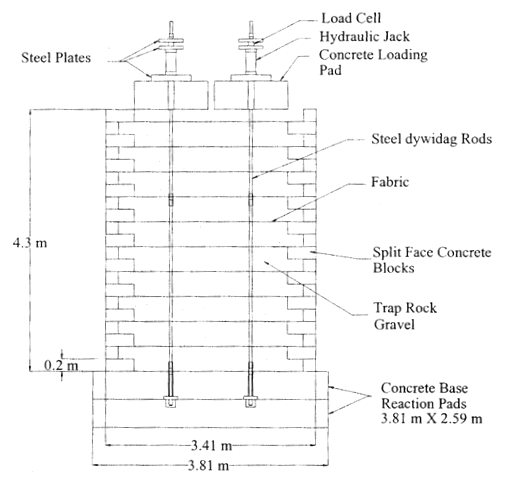

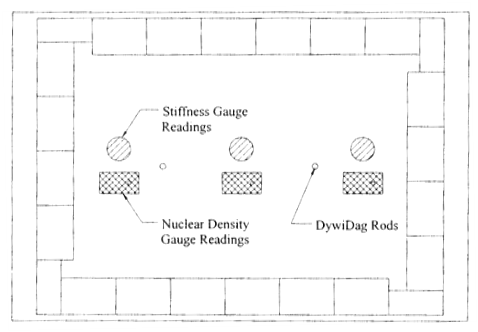

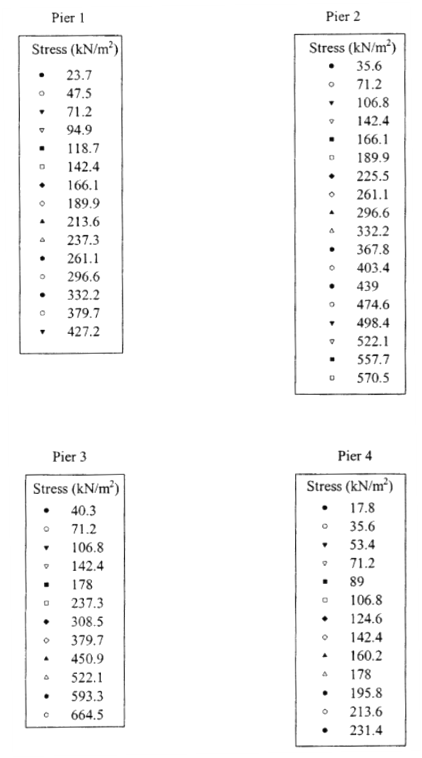

Mitchell measured lateral pressures on the concrete masonry unit (CMU) facing of four GRS mini-piers (figure 31 and figure 32).(77) The reinforcement (Amoco 2006-wide-width tensile strength = 2,100 lb/ft(30.6 kN/m)) spacings were 24 inches (60.9 cm), 16 inches (40.6 cm), 8 inches (.2 m), and 32 inches (81 cm) in piers 1, 2, 3, and 4, respectively. The facing consisted of 99-lb (45.0-kg) split-face keystone retaining wall blocks that were 18 inches (46 cm) long, 5 inches (12.7 cm) wide, and 8 inches (20.3 cm) deep with a flange protruding to the inside of the piers. Corner blocks with slightly different weight and dimensions were used.

Known as trap rock gravel (32.1 percent gravel, 56.5 percent sand, and 11.5 percent fines; Cu = 40, Cc = 3.2, Gs = 2.93; Standard Proctor γd max = 144 pcf (2,307 kg/m3); wopt = 8.75 percent; Modified Proctor γd max = 150 pcf (2,403 kg/m3); wopt = 6.5 percent), the backfill had shear strength parameters of φ = 36 degrees and c = 637 psf (30.5 kPa) based on a failure relative displacement of 10 percent of the shear box length as measured in a 12- by 12-inch (30.5- by 30.5-cm) direct shear box. The shear stress-displacement curves appear to be still strain hardening at the interpreted failure relative displacement.

Source: J.W. Mitchell

1 m = 3.28 ft

Figure 31. Drawing. GRS mini-pier elevation plan.(77)

Source: J.W. Mitchell

Figure 32. Drawing. GRS mini-pier elevation plan.(77)

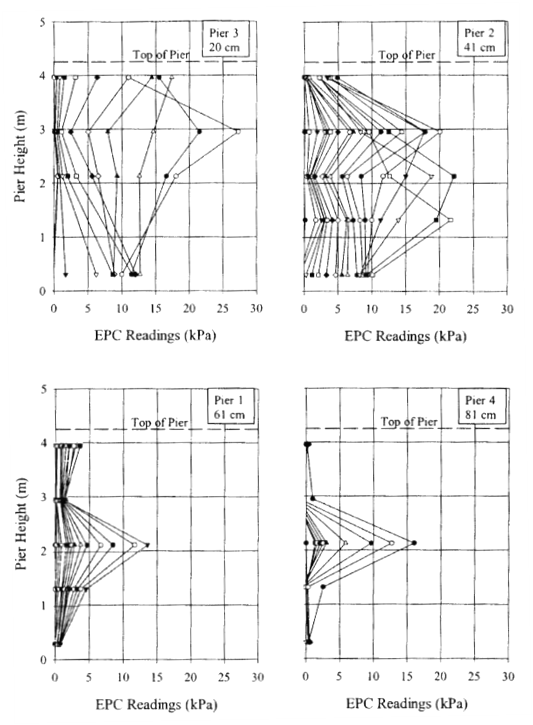

Geokon™ vibrating wire pressure transducers were placed at five elevations (1 ft (0.3 m), 4.3 ft (1.3 m), 7 ft (2.1 m), 9.7 ft (3.0 m), and 13 ft (4.0 m) above base) along the GRS wall height. The measured lateral pressures are shown in figure 33 and figure 34. These pressure readings were zeroed at zero load and represent only the increase in the lateral pressures during the load test. Mitchell noted that with a decrease in reinforcement spacing, the lateral pressures increased and became more equally distributed over the wall height.(77)

The actual measured lateral pressures at zero load were provided in appendix C of Mitchell's report and are shown in table 6. Unfortunately, they are mostly negative, with a few exceptions. When and how the zero readings were obtained could not be discerned from Mitchell's report.

Source: J.W. Mitchell

1 kPa = 20.89 psf

1 m = 3.28 ft

1 cm = 0.39 inches

Figure 33. Chart. Measured increase in lateral pressures on the facing of GRS mini-piers during load test in kPa.(77)

Source: J.W. Mitchell

1 kN/m2 = 20.9 lbs/ft2

Figure 34. Chart. Measured increase in lateral pressures on the facing of GRS mini-piers during load test in kN/m2.(77)

Yogarajah and Saad experimentally measured the lateral earth pressures on incremental panel walls backfilled with reinforced Leighton Buzzard sand.(78) The dry unit weight of the compacted sand was 104 pcf (16.4 kN/m3)corresponding to a relative density of 82 percent (peak and constant volume friction angles of 47 degrees and 34 degrees, respectively). The test walls were 5.9 ft (1.8 m) high and reinforced with three layers of 2.1-ft (0.63-m)-spaced Tensar® SR80 geogrid. Two wall configurations were used with the aid of three 4.5 in-(0.114-m)-thick wall panels. Known as single and multisegment, these two configurations include two wall panels that were 1.8 ft (0.55 m) wide and 5.9 ft (1.8 m) long. The third was 2.3 ft (0.7 m) wide and 5.9 ft (1.8 m) long. The reinforcement was attached to the facing panels through elongated holes to accommodate any vertical movement of the reinforcements during construction.

Each wall panel for the single configuration was propped vertical into position with struts at the 1 ft (0.3 m), 3.3 ft (1.0 m), and 5.3 ft (1.6 m) heights from the base. The struts were removed after construction. With the multisegment configuration, struts were used at five locations on each panel (four near the corners and one at the center) and removed once the backfill height reached the top of the panel. Hence, no more than one panel was propped at any one time during construction of the multisegment wall.

Lateral pressures were measured using six load cells placed flush with the facing. No surcharge loading was applied after strut removal. Consistent with Yang's observations on a reinforced soil wall, the lateral pressures on Yogarajah and Saad's geosynthetic reinforced wall appear to be fairly constant with depth below the top 2 ft (0.6 m).(64,78) Also below the top 2 ft (0.6 m), the lateral pressures were significantly smaller than the predicted Rankine active values.

Two methods involving the use of simple equations to estimate the lateral thrust on GRS wall facing are presented. They include the procedures developed by Wu, and Soong and Koerner.(25,79) Ehrlich and Mitchell developed charts that are quite elegant for estimating the maximum tension in a reinforced soil.(80) This study is not presented further herein for four reasons. First, although the tension in the reinforcement can be related to the lateral stress, this lateral stress represents the value within a GRS mass rather than on the wall facing. Second, the study assumes that each reinforcement layer is responsible for equilibrium with the lateral stress, meaning the tensile strength divided by the vertical spacing is equal to the average lateral earth pressure within the tributary area of the reinforcement, which is not true for closely spaced GRS. Third, this method will predict a lateral pressure that increases with depth. Finally, the compaction equipment must be known a priori.

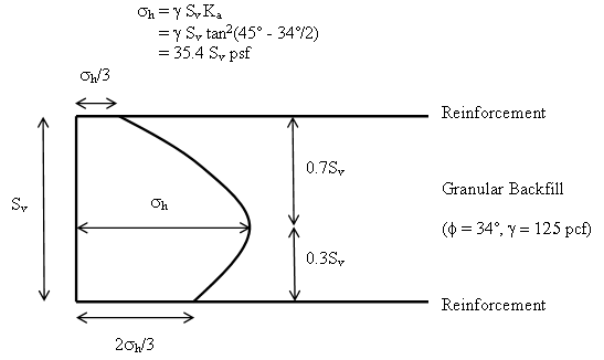

For closely spaced systems, Wu indicated that the primary function of the facing is to prevent soil sloughing.(25) It also serves as a construction aid but is not a major load carrying element. Wu further postulated based on evidence from numerous case studies that the lateral thrust against the facing is independent of the wall height.(81) Because the reinforcement effectively restrains lateral deformation of the soil, the lateral pressure on the facing is quite small in comparison to the lateral stress predicted from Rankine earth pressure theory. Its magnitude depends on the reinforcement spacing, the soil shear strength parameters, and the rigidity of the facing. Calling the magnitude "bin pressure," Wu proposed that the bin pressure diagram is near zero at the reinforcement elevation. It increases with depth below the reinforcement before decreasing to near zero at the reinforcement layer below (i.e., at the base of the facing). However, because the reinforcement may deform slightly and there may be imperfect bonding between the soil and reinforcement at the wall face, Wu proposed the bin pressure diagram as shown in figure 35.

©J.T.H. Wu

1 pcf = 16.02 kg/m3

1 psf = 0.05 kPa

Figure 35. Diagram. Bin pressure diagram.(25)

![]()

Figure 36. Equation. Total lateral thrust, F subscript bin, as a function of the spacing between reinforcements, S subscript v, and peak bin pressure σ subscript h.

![]()

Figure 37. Equation. Total lateral thrust, F subscript bin, in terms of the coefficient of active earth pressure.

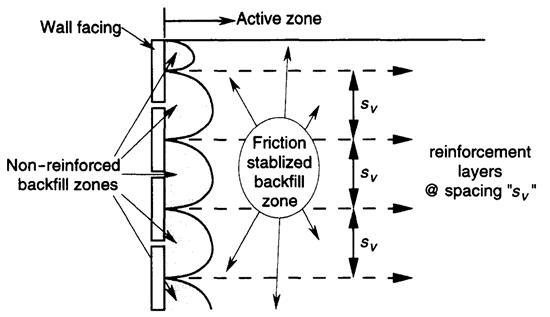

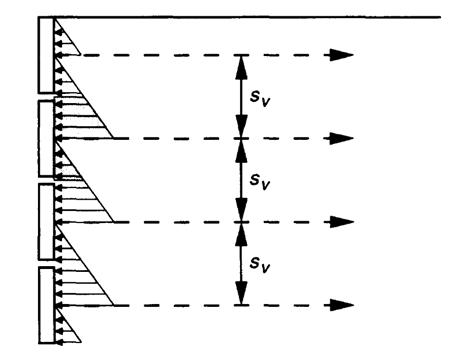

A similar concept was proposed by Soong and Koerner for GMSE walls where the reinforcement is connected to the middle of the back face of the wall facing as shown in figure 38.(79) While the reinforcements stabilize most of the soil mass through interface friction, Soong and Koerner postulated that there is a small zone of soil bearing against the wall facing that is not restrained by the reinforcement mobilized friction. Assuming that each layer acts independently from those above and below, they proposed a lateral earth pressure distribution as shown in figure 39.

Source: Elsevier Ltd.

Figure 38. Drawing. GMSE wall configuration showing nonreinforced backfill zones.(79)

Source: Elsevier Ltd.

Figure 39. Drawing. Lateral earth pressure distribution against wall facing exerted by the nonreinforced backfill.(79)

Soong and Koerner estimated the magnitude of the connection force using the equation in figure 40:

![]()

Figure 40. Equation. Connection force F.

This equation produces a thrust that is 31-percent smaller than the equation in figure 37.

Table 5 shows the lateral thrust on the facing as a function of reinforcement spacing for both Wu's and Soong and Koerner's methods for a soil with γ = 125 pcf (2,002 kg/m3), φ = 34 degrees and c = 0.

Table 5 . Comparison of Wu's versus Soong and Koerner's calculated lateral thrusts as a function of reinforcement spacing.(25,79)

Reinforcement Spacing, Sv |

Lateral Thrust |

|

|---|---|---|

Wu(25) |

Soong and Koerner(79) |

|

4 |

2.83 |

1.96 |

8 |

11.3 |

7.85 |

12 |

25.4 |

17.7 |

16 |

45.2 |

31.4 |

24 |

102 |

70.7 |

36 |

229 |

159 |

Note: Assumes a backfill with γ= 125 pcf (2,002 kg/m3), φ= 34 degrees and c = 0.

1 inch = 2.54 cm

1 lb/ft = 14.6 N/m

When an earth pressure cell is placed at the mid-point between two reinforcement layers on the wall facing, the measured pressures should coincide with the pressure at the middle of the pressure distribution diagrams.(82) It is estimated that the pressures mid-way between reinforcements are about 0.8 h and 0.5 h for Wu's bin pressure and Soong and Koerner's triangular pressure distributions, respectively.(25,79) A comparison of the calculated and measured lateral pressures is provided in table 6 for the case histories described previously and assuming no surcharge loading. The following should be noted:

Table 6 . Predicted versus measured lateral pressures on reinforced soil wall facing.

Reference |

γ |

φ |

Sv |

0.8 σh |

0.5 σh |

Measured |

|---|---|---|---|---|---|---|

Abu-Hejleh et al. (2003)-12th geogrid |

141 |

39 |

1.33 |

34 |

21 |

31a |

Abu-Hejleh et al. (2003)-11th geogrid North |

141 |

39 |

1.33 |

34 |

21 |

177a |

Abu-Hejleh et al. (2003)-11th geogrid South |

141 |

39 |

1.33 |

34 |

21 |

163a |

Abu-Hejleh et al. (2003)-9th geogrid |

141 |

39 |

1.33 |

34 |

21 |

188a |

Abu-Hejleh et al. (2003)-7th geogrid |

141 |

39 |

1.33 |

34 |

21 |

334a |

Mitchell (2002)-Pier 1-1 ft above base |

120 |

36 |

24 |

50 |

31 |

-121b |

Mitchell (2002)-Pier 1-4.3 ft above base |

120 |

36 |

24 |

50 |

31 |

-402b |

Mitchell (2002)-Pier 1-7 ft above base |

120 |

36 |

24 |

50 |

31 |

-228b |

Mitchell (2002)-Pier 1-9.7 ft above base |

120 |

36 |

24 |

50 |

31 |

-96b |

Mitchell (2002)-Pier 1-13 ft above base |

120 |

36 |

24 |

50 |

31 |

-152b |

Mitchell (2002)-Pier 2-1 ft above base |

124 |

36 |

16 |

34 |

21 |

-127b |

Mitchell (2002)-Pier 2-4.3 ft above base |

124 |

36 |

16 |

34 |

21 |

-51b |

Mitchell (2002)-Pier 2-7 ft above base |

124 |

36 |

16 |

34 |

21 |

-89b |

Mitchell (2002)-Pier 2-9.7 ft above base |

124 |

36 |

16 |

34 |

21 |

-4b |

Mitchell (2002)-Pier 2-13 ft above base |

124 |

36 |

16 |

34 |

21 |

60 |

Mitchell (2002)-Pier 3-1 ft above base |

121 |

36 |

8 |

17 |

10 |

541 |

Mitchell (2002)-Pier 3-4.3 ft above base |

121 |

36 |

8 |

17 |

10 |

33 |

Mitchell (2002)-Pier 3-7 ft above base |

121 |

36 |

8 |

17 |

10 |

343 |

Mitchell (2002)-Pier 3-9.7 ft above base |

121 |

36 |

8 |

17 |

10 |

113 |

Mitchell (2002)-Pier 3-13 ft above base |

121 |

36 |

8 |

17 |

10 |

-25b |

Mitchell (2002)-Pier 4-1 ft above base |

122 |

36 |

32 |

67 |

42 |

-99b |

Mitchell (2002)-Pier 4-4.3 ft above base |

122 |

36 |

32 |

67 |

42 |

-222b |

Mitchell (2002)-Pier 4-7 ft above base |

122 |

36 |

32 |

67 |

42 |

-19b |

Mitchell (2002)-Pier 4-9.7 ft above base |

122 |

36 |

32 |

67 |

42 |

-653b |

Mitchell (2002)-Pier 4-13 ft above base |

122 |

36 |

32 |

67 |

42 |

-125b |

Yogarajah and Andrawes (1994)-single seg. |

104 |

47 |

2.07 |

27 |

17 |

13 |

Yogarajah and Andrawes (1994)-multi-seg. |

104 |

47 |

2.07 |

27 |

17 |

38 |

a Measured lateral pressures from Abu-Hejleh include the effects of loading from the bridge superstructure.(76) Lateral pressures before construction of the superstructure were not reported.

b Mitchell's measured lateral pressures at zero load were mostly negative.(77) When and how the zero readings were obtained could not be discerned from the report.

1 pcf = 16.02 kg/m3

1 ft = 0.3 m

1 psf = 0.048 kPa

Wu's and Soong and Koerner's calculated lateral thrusts are much smaller than the Rankine active thrust because they are a function of the reinforcement spacing and not the wall height.(25,79) If it were true that the bin pressure were not a function of wall height, GRS walls can be safely constructed to very tall heights if desired (e.g., figure 41). If the Grand County wall in Colorado illustrated in figure 41 were an externally stabilized wall designed using strictly Rankine active earth pressure theory, as in GMSE design, it would have required an enormous footing embedment and connection requirement to resist the assumed loads, which is not the case in this GRS wall.(2,81) This wall offers the most compelling field evidence that the lateral pressure exerted on the GRS facing is much smaller than that derived from classical earth pressure theory.

Source: R. Barrett

Figure 41. Photo. Grand County, Colorado, wall with a maximum height of 55 ft (16.8 m).(83)

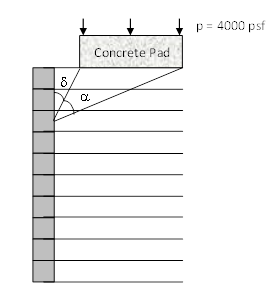

The lateral pressures on the facing of a GRS wall due to applied loading behind the facing (e.g., bridge footing on a GRS abutment) will increase with increasing footing load as seen in Mitchell's study.(77) Using linear elastic theory, the increase in lateral pressure can be approximated using Carother's equation in figure 42.(84) Assuming an allowable maximum applied bearing stress on a GRS abutment of p = 4,000 psf (191.5 kPa), the increase in lateral pressure (Δσh) on the CMU blocks can be calculated as shown in figure 42:

![]()

Figure 42. Equation. Increase in lateral pressure Δ σ subscript h.

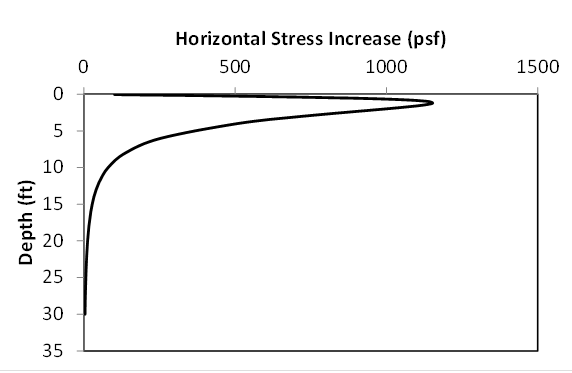

Where α and δ are angles defined as shown in figure 43. Assuming a 4-ft- (1.2-m-) wide footing with a 1-ft (.3-m) setback, the increase in lateral pressures on the CMU blocks are highest within the top 3 ft (1 m) from the facing as shown in figure 44. The maximum lateral stress was only 1,150 psf (55.1 kPa), which is 29 percent of the applied load.

1 psf = 0.048 kPa

Figure 43. Drawing. Definition of angles α and δ.

1 ft = 0.3 m

1 psf = 0.048 kPa

Figure 44. Chart. Increase in lateral stress due to 4,000-psf (191.5-kPa) vertical stress on a 4-ft- (1.2-m-) wide footing with a 1-ft (.3-m) setback.

Figure 42 and figure 44 assume a flexible wall that is free to displace laterally. If the wall were rigid (i.e., unable to displace laterally), then the pressures in figure 42 and figure 44 should be doubled.