U.S. Department of Transportation

Federal Highway Administration

1200 New Jersey Avenue, SE

Washington, DC 20590

202-366-4000

Federal Highway Administration Research and Technology

Coordinating, Developing, and Delivering Highway Transportation Innovations

| REPORT |

| This report is an archived publication and may contain dated technical, contact, and link information |

|

| Publication Number: FHWA-HRT-14-094 Date: February 2015 |

Publication Number: FHWA-HRT-14-094 Date: February 2015 |

The W equation is used to estimate the vertical capacity of footings on a GRS wall and was first published by Pham in his Ph.D. thesis entitled Investigating Composite Behavior of Geosynthetic Reinforced Soil (GRS) Mass.(85) In this equation, the W term accounts for the fact that an increase in the reinforcement strength does not have the same effect as a proportional decrease in the reinforcement spacing, as has been traditionally assumed in simplified GMSE design. This is a significant difference between GMSE and GRS design. Results of mini-pier experiments performed by Adams, Adams et al., and Elton and Patawaran, and plane strain tests on GRS performed by Pham, showed that the contributions of the reinforcement spacing to the strength of the GRS is much greater than that of the reinforcement strength. (See references 86, 6, 87 through 91, and 85.) The various terms in the W equation and previous research and theory leading to its development are discussed. The reliability of this equation is demonstrated based on load test results from the literature.

In reality, the capacity of a GRS is related to the effects of confinement (due to CISs and the lateral restraint offered by the reinforcement internally, and confining stress at the facing), reinforcement spacing, strength and stiffness, shape and location of the failure surface, stress-strain behavior of the soil, and degree of mobilization of shear resistance along an assumed failure plane. The W equation was derived using limit equilibrium analysis. This type of analysis assumes a linear failure surface, assumes a rigid-plastic soil behavior, neglects soil-reinforcement stiffness, and assumes full mobilization of shear strength along the failure surface. Despite the many assumptions that may not reflect reality, limit equilibrium analysis is popular among practitioners because it provides a solution that is simple and easy to use.

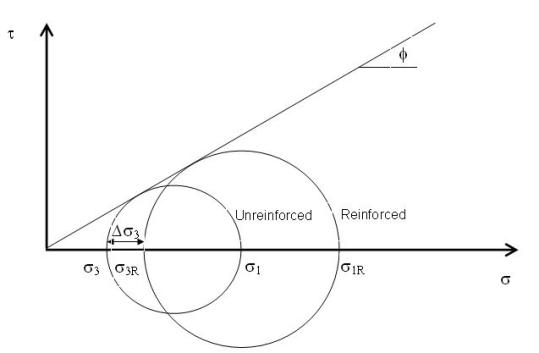

The W equation can be derived by first considering the Mohr-Coulomb failure envelope and the Mohr circle at failure for an unreinforced cohesionless soil (figure 45).

Figure 45. Drawing. Mohr circles for unreinforced and reinforced soil.

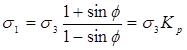

If the soil friction angle is φ, the equation in figure 46 shows that at failure:

Figure 46. Equation. Major principal stress σ subscript 1.

σ1 and σ3 are the major and minor principal stresses respectively, and Kp equals the Rankine passive earth pressure coefficient. If the soil were reinforced, Yang indicated that the friction angle of the reinforced soil is approximately the same as the unreinforced soil if no slippage occurs between the soil and reinforcement.(64) A GRS is stronger than the unreinforced soil, and hence the major principal stress at failure is higher than σ1, say σ1R in figure 45.

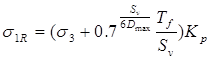

For this to occur, the confining stress in the soil must effectively increase due to the presence of the reinforcement as shown in the equation in figure 47:

![]()

Figure 47. Equation. Confining stress due presence of reinforcement, σ subscript 3R.

The reinforcement restrains lateral movement of the soil. Thus, Δσ3 represents the additional confining stress that is imposed due to the reinforcement. Therefore, the capacity of the GRS can be expressed as the equation in figure 48:

![]()

Figure 48. Equation. Capacity of the GRS,σ subscript 1R.

Δσ3 is analogous to a prestress in the reinforced soil equal to the frictional force developed between the soil and the reinforcement with a maximum value determined by the tensile strength of the reinforcing material. At failure, this prestress will be at its maximum and is related to the reinforcement tensile strength per unit wall length (Tf). If it is assumed that one-dimensional expansion in the horizontal direction occurs over a tributary area of reinforcement equal to spacing Sv per unit wall length, then Δσ3 can be expressed as shown in figure 49:(92)

![]()

Figure 49. Equation. Additional confining stress as a function of reinforcement tensile strength divided by the reinforcement spacing Δ σ subscript 3.

Implied in the equation in figure 49 is that a GRS with reinforcement strength Tf at spacing Sv will have the same capacity as a GRS with reinforcement strength 2Tf at spacing 2Sv, which has been shown to be untrue by Adams, Adams et al., Elton and Patawaran, Ziegler et al., and Pham. (See References 86, 6, 87 through 91, 93, and 85.) Instead, Sv has a bigger influence on the capacity than Tf. This led Pham to propose a modified version of the equation in figure 49 as shown in figure 50:

Figure 50. Equation. Modified version of equation in figure 49 for additional confining stress, Δ σ subscript 3 imposed with the W factor.

W is the factor that amplifies the contribution of Sv to the GRS capacity. The W factor was semi-empirically derived and is calculated using the equation in figure 51:

![]()

Figure 51. Equation. W factor.

Dmax is the maximum particle size of the GRS backfill used as a normalizing parameter to make the exponent dimensionless. Note that the 0.7 factor in figure 51 was theoretically derived while the exponent was empirically derived. Using the concept of "average stresses" proposed by Ketchart and Wu to estimate the average and maximum forces in a reinforcement, Pham showed, based on a load-transfer analysis, that the average reinforcement force is about 70 percent of the maximum reinforcement tensile strength; hence the 0.7 factor in figure 51.(62,85) For details on this derivation, refer to Pham.(85)

The exponent of figure 51 is a function of Sv and Dmax. Because the base term is less than unity, W, and hence the capacity, increases with decreasing Sv and increasing Dmax. This is logical because one would expect a GRS with closer reinforcement spacing and larger maximum aggregate size to have a higher capacity.

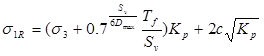

Therefore, combining the equations in figure 48, figure 50, and figure 51, the capacity of the GRS can be expressed as the equation in figure 52:

Figure 52. Equation. Capacity of the GRS, σ subscript 1R.

If the soil has cohesion, c, then the equation in figure 52 can be expanded to the equation in figure 53:

Figure 53. Equation. Expansion of the equation in figure 52 for the capacity of the GRS, σ subscript 1R, to include cohesion.

According to Pham, for a GRS wall with a dry stacked modular block facing, s3 equals the lateral stress exerted by the facing on the GRS mass, which is γbl times D times tan .(85) γbl equals the bulk unit weight of the facing block, which is the weight of block/volume of the block assuming it is not hollow. (For a 7.625- by 7.625- by 15.625-inch (19.368- by 19.368- by 39.688-cm) CMU block weighing 42 lbs (19.1 kg), bl equals 80 pcf). D equals the depth of the facing block perpendicular to the wall face. δ equals the friction angle between geosynthetic reinforcement and the top or bottom surface of the facing block. The equation in figure 53 can also be rearranged and solved for the required reinforcement strength (Tf,req) given the loads on the particular GRS composite for design.

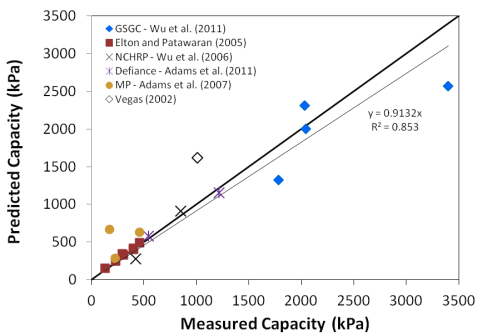

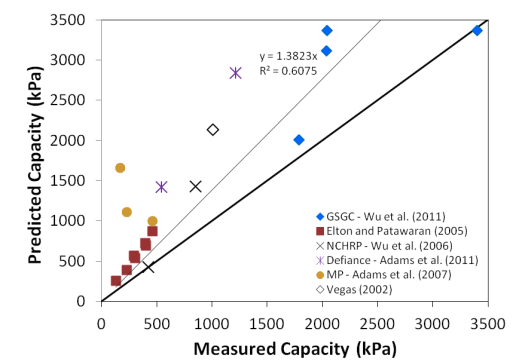

A database consisting of 19 load tests on GRS from the literature (table 7) was used to examine the reliability of the W equation or the equation in figure 52. In addition to the references already cited in this synopsis, the table contains tests from Adams et al.(6) A plot of predicted versus measured capacities is shown in figure 54. It can be seen that overall, the coefficient of determination was 0.853 with a slope of 0.913 for this dataset when the regression line was forced through the origin. To illustrate the importance of the W term, a plot of predicted versus measured capacities is shown in figure 55 with the W term eliminated from the equation in figure 53. It is apparent that the capacities are severely overpredicted with a less than desirable fit. This validates the necessity of the W term in the equation in figure 53.

Table 7 . Prediction data for large-scale tests.

No. |

Test |

Test Results |

Facing |

Reinforcement |

Aggregate |

Geometry |

Reference |

|||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

qult,emp |

qult calc |

σc |

Block |

Sv |

Tf |

Dmax |

c |

φtest |

φ |

Kp |

||||

1 |

GSGC 2 |

3,400 |

2,182 |

34 |

N/A |

0.2 |

70 |

0.0330 |

70 |

50 |

TX |

7.55 |

PS |

85 |

2 |

GSGC 3 |

2,040 |

1,615 |

34 |

N/A |

0.4 |

140 |

0.0330 |

70 |

50 |

TX |

7.55 |

PS |

|

3 |

GSGC 4 |

1,785 |

936 |

34 |

N/A |

0.4 |

70 |

0.0330 |

70 |

50 |

TX |

7.55 |

PS |

|

4 |

GSGC 5 |

2,034 |

1,925 |

0 |

None |

0.2 |

70 |

0.0330 |

70 |

50 |

TX |

7.55 |

PS |

|

5 |

Elton 1 |

230 |

133 |

0 |

None |

0.15 |

9 |

0.0127 |

28 |

40 |

DS |

4.60 |

Cylindrical |

91 |

6 |

Elton 2 |

129 |

33 |

0 |

None |

0.3 |

9 |

0.0127 |

28 |

40 |

DS |

4.60 |

Cylindrical |

|

7 |

Elton 3 |

306 |

207 |

0 |

None |

0.2 |

14 |

0.0127 |

28 |

40 |

DS |

4.60 |

Cylindrical |

|

8 |

Elton 4 |

292 |

222 |

0 |

None |

0.2 |

15 |

0.0127 |

28 |

40 |

DS |

4.60 |

Cylindrical |

|

9 |

Elton 5 |

402 |

281 |

0 |

None |

0.2 |

19 |

0.0127 |

28 |

40 |

DS |

4.60 |

Cylindrical |

|

10 |

Elton 6 |

397 |

296 |

0 |

None |

0.2 |

20 |

0.0127 |

28 |

40 |

DS |

4.60 |

Cylindrical |

|

11 |

Elton 7 |

459 |

370 |

0 |

None |

0.2 |

25 |

0.0127 |

28 |

40 |

DS |

4.60 |

Cylindrical |

|

12 |

NCHRP 1 |

420 |

275 |

0.97 |

CMU |

0.2 |

21 |

0.0254 |

0 |

36.5 |

LSDS |

3.94 |

PS |

94 |

13 |

NCHRP 2 |

850 |

908 |

0.97 |

CMU |

0.2 |

70 |

0.0254 |

0 |

36.5 |

LSDS |

3.94 |

PS |

|

14 |

Defiance 1 |

542 |

580 |

0.97 |

CMU |

0.2 |

35 |

0.0127 |

0 |

50.7 |

LSDS |

7.84 |

Column |

89 |

15 |

Defiance 2 |

1,213 |

1,153 |

0.97 |

CMU |

0.2 |

70 |

0.0127 |

0 |

50.7 |

LSDS |

7.84 |

Column |

|

16 |

Vegas |

1,008 |

1,231 |

2.35 |

SRW |

0.2 |

35 |

0.0254 |

70 |

50 |

TX |

7.55 |

Column |

88 |

17 |

MP A |

225 |

284 |

0 |

None |

0.6 |

70 |

0.0254 |

0 |

53.5 |

LSDS |

9.20 |

Column |

89 |

18 |

MP B |

170 |

671 |

0 |

None |

0.4 |

70 |

0.0254 |

0 |

53.5 |

LSDS |

9.20 |

Column |

|

19 |

MP C |

460 |

634 |

0 |

None |

0.2 |

21 |

0.0254 |

0 |

53.5 |

LSDS |

9.20 |

Column |

|

GSGC =Generic Geosynthetic Soil CompositeÂ

NCHRP = National Cooperative Highway Research Program

MP = Mini-Pier

TX = Triaxial

DS = Direct Shear

LSDS = Large-Scale Direct Shear

PS = Plane Strain

1 kPA = 20.89 psf

1 m = 3.28 ft

1 kN/m = 68.6 lb/ft

1 kPA = 20.89 psf

Figure 54. Chart. Predicted versus measured capacity of large-scale GRS tests using the equation in figure 52.

1 kPA = 20.89 psf

Figure 55. Chart. Predicted versus measured capacity of large-scale GRS tests using the equation in figure 52 without the W term.