U.S. Department of Transportation

Federal Highway Administration

1200 New Jersey Avenue, SE

Washington, DC 20590

202-366-4000

Federal Highway Administration Research and Technology

Coordinating, Developing, and Delivering Highway Transportation Innovations

| REPORT |

| This report is an archived publication and may contain dated technical, contact, and link information |

|

| Publication Number: FHWA-HRT-14-061 Date: August 2014 |

Publication Number: FHWA-HRT-14-061 Date: August 2014 |

The encapsulated RFID tags were field tested to evaluate the following issues:

The pavement sections selected for the Phase II field trials included the following:

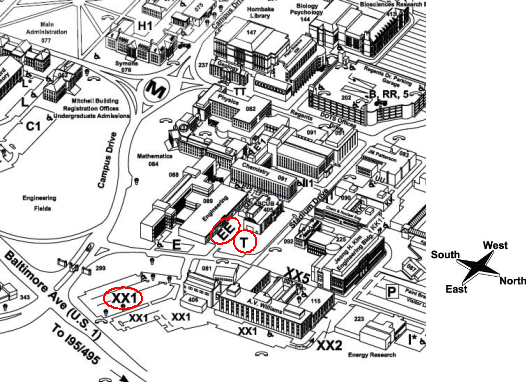

Source: http://dots.umd.edu/parking/maps/map_campus.pdf

Annotations added study team.

Figure 20. Map. Location of UMD parking lot paving projects.

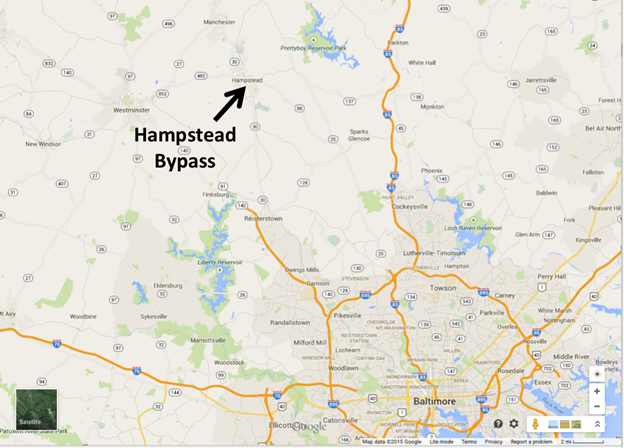

Original image: ©2015 Google®; map annotations provided by University of Maryland

Figure 21. Map. Location of Hampstead Bypass project.(5)

UMD Parking Lot XX1 is across Paint Branch Drive from the Civil Engineering Department's Pavement Materials Laboratory. The August 2007 paving work was to patch a large trench from storm drain replacement. Paving consisted of both a base and surface course. The paving contractor for the job was College Park Paving (foreman: Mr. Dennis Wilder).

Construction was begun just as Phase II of this project got underway, so there was insufficient time to prepare any tags for the base course paving and only a limited number of tags were ready in time for placement in the surface course. Six Alien® 2x2 and six Alien® 1x1 tags were pre-placed on top of the previously paved HMA base course and/or milled existing pavement. Pre-placement was performed in this initial trial so that the locations of the tags could be determined precisely during post-construction reading. The tags and their locations are summarized in table 6 and figure 22.

All tags were successfully heat tested at 347 °F (175 °C) for 1.5 h prior to placement in the field. Initially, half of the tags were placed before application of the tack coat (figure 23). However, because of the risk of sticky tags being picked up by the tires on the asphalt delivery trucks, the remaining tags were placed immediately ahead of the paver as it approached (figure 24). The tags were then covered with a 2-inch (50-mm) thick lift of 0.5-inch (12.5-mm) surface mix by the paver (figure 25) and compacted under the rollers. In a few locations, the surface lift thickness was less than 2 inches (50 mm). None of the tags protruded above or were visible within the pavement surface after compaction.

Table 6 . RFID tag identification in UMD Parking Lot XX1.

Tag Type |

Label |

Digital Signature |

|---|---|---|

Alien® 1x1 |

2 |

0200989E |

3 |

0300ABAF |

|

4 |

04003238 |

|

5 |

05000109 |

|

6 |

0600545A |

|

7 |

0700676B |

|

Alien® 2x2 |

AB |

01ABC94C |

AD |

01ADA98A |

|

BD |

01BDBBBB |

|

BE |

01BE8BD8 |

|

CA |

01CAB5CB |

|

CE |

01CEF54F |

Original image: ©2015 Google®; map annotations provided by University of Maryland

Note: Locations are approximate. Image predates August 2007 paving; the HMA patch evident in the

image is not the patch in which the encapsulated RFID tags were embedded.

Figure 22. Photo. Location of pre-placed RFID tags in UMD Lot XX1.(6)

Figure 23. Photo. Pre-placement of tags at UMD Lot XX1 paving project.

Figure 24. Photo. Paving over pre-placed encapsulated tags.

Figure 25. Photo. Encapsulated tag beneath paver.

The tags were read in the field a few days after construction. A rolling support for the electronics was improvised using a plastic laboratory cart with one RFID antenna secured using nonmetallic rope to cantilevered wooden boards. The RFID reader and laptop computer were also placed on the cart. Power was supplied from an automobile via a power inverter and long extension cable. The cart was manually pushed in overlapping passes over the paved area. Figure 26 illustrates the final improvised apparatus for reading the RFID tags in the UMD parking lots. One complication was that Parking Lot XX1 was placed back in service immediately after paving, so the read evaluation had to be conducted at night when there were few parked cars.

The read success rate was evaluated at two antenna heights of 32 inches (810 mm) and 10 inches (250 mm) above the pavement surface. At the time of the field data collection, a portion of the parking lot containing one each of the Alien® 2x2 and Alien® 1x1 tags was fenced off and inaccessible, leaving only five each of the 2x2 and 1x1 tags available for evaluation. Details of the read success for all of the tags are given in table 7. The read success rate at the 32 inches (810 mm) antenna height was 100 percent for the Alien® 2x2 tags (i.e., all five of the 2x2 tags could be read), and 0 percent for the Alien® 1x1 tags. The lower 10-inch (250-mm) antenna height yielded better results, with 100 percent of the Alien® 2x2 tags and 40 percent (i.e., two of the five) of the 1x1 tags successfully read.

Figure 26. Photo. Hand cart for reading RFID tags in UMD parking lots with antenna in the lower position (10 inches above pavement surface).

Table 7 . Read success for RFID tags in UMD Parking Lot XX1.

Tag Type |

Label |

Digital Signature |

Read From 32-Inch Height? |

Read From 10-Inch Height? |

|---|---|---|---|---|

Alien® 1x1 |

2 |

0200989E |

No |

No |

3 |

0300ABAF |

No |

No |

|

4 |

04003238 |

No |

Yes |

|

5 |

05000109 |

No |

No |

|

6 |

0600545A |

Inaccessible |

Inaccessible |

|

7 |

0700676B |

No |

Yes |

|

Alien® 2x2 |

AB |

01ABC94C |

Yes |

Yes |

AD |

01ADA98A |

Yes |

Yes |

|

BD |

01BDBBBB |

Yes |

Yes |

|

BE |

01BE8BD8 |

Inaccessible |

Inaccessible |

|

CA |

01CAB5CB |

Yes |

Yes |

|

CE |

01CEF54F |

Yes |

Yes |

This parking lot is immediately adjacent to the Pavement Materials Laboratory. Similar to the work on Parking Lot XX1, paving consisted of base and surface courses to patch a large trench from storm drain replacement. This paving was originally scheduled for late September 2007. However, construction was subsequently delayed until October. The 4-inch (100-mm) thick layer of 0.75-inch (19-mm) dense-graded base mix was placed on October 16; the 2-inch (50-mm) thick lift of 0.5-inch (12.5-mm) dense-graded surface mix was paved the following day, October 17. The paving contractor for the job was College Park Paving (foreman: Mr. Dennis Wilder).

Two methods of tag placement were employed in Lot EE. For the base lift, 10 each of the Alien® 1x1 and 2x2 tags were pre-placed ahead of the paver, and an additional 10 each of both tag sizes were placed in the paver hopper and run through the paver. For the surface course, 10 each of both tag sizes were tossed in the paver hopper and run through the paver; none of the tags was pre-placed ahead of the paver for the surface lift. All tags were compacted into the mat by rollers behind the paver. A total of 40 tags were placed in the base course and 20 in the surface layer.

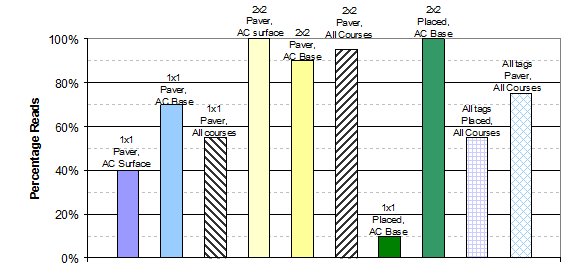

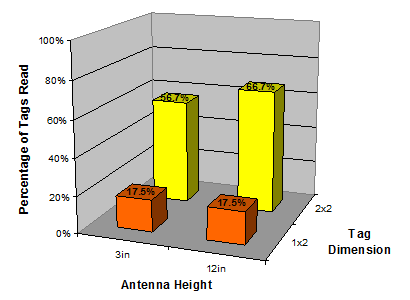

After paving of the surface lift was complete, the mobile cart with antenna, RFID reader, and computer (figure 26) was used to evaluate the read success rate for the tags. Based on the findings from Lot XX1, the height of the antennae above the pavement surface was kept constant at approximately 10 inches (250 mm). The read success rates for the different tag sizes as a function of layer (base versus surface) and method of placement (pre-placed versus through-the-paver) are summarized in figure 27. In this figure, "Placed" refers to the pre-placed tags (base lift only), and "Paver" designates the tags tossed into the pavement hopper (both base and surface lifts). Some key observations that can be drawn from figure 27 include the following:

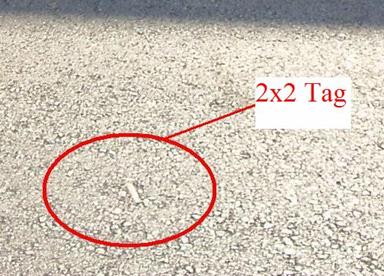

Some of the tags in Lot EE were observed to have migrated to the surface of the mat. While no tags were seen on the surface of the finished base course, one of the small tags and three of the larger tags were observed at the top of the surface course. Examples are shown in figure 28 and figure 29. Other than aesthetics, it is unclear whether these surfaced tags will have any detrimental effect on the performance of the pavements. They arguably could provide a preferential pathway for local intrusion of water into the asphalt that could produce accelerated stripping or other problems. This issue should be investigated further in the future.

Figure 27. Chart. Summary of read success rates for tags in Parking Lot EE.

Figure 28. Photo. Examples of surfaced RFID tags in Lot EE.

Figure 29. Photo. Worst-case example of surfaced RFID tag in Lot EE.

This parking lot is near the Pavement Materials Laboratory. Paving conditions are similar to those for Lots XX1 and EE, although the area of patch is smaller, and therefore only a few tags were placed. This area was paved in late October 2007. Results were comparable to those from Lot XX1 and Lot EE.

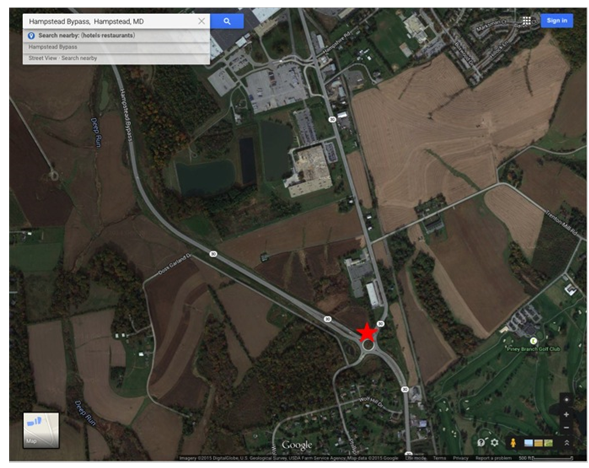

The Hampstead Bypass project lies to the east of MD 30 around the town of Hampstead, MD (figure 30). The route runs from south of Wolf Hill Drive to north of the town of Hampstead. The project included construction of two lanes of MD 30 on new alignment for approximately 4.4 mi (7 km). The new alignment incorporates three roundabouts: one near the southern terminus to provide a connection to existing MD 30; one at MD 482; and one near the northern terminus to provide a connection to existing MD 30.

Original image: ©2015 Google®; map annotations provided by University of Maryland

Figure 30. Map. Location of Hampstead Bypass project with star marking approximate location of southern entrance to construction site.(5)

The new pavement construction consisted of two 4-inch (100-mm) thick base lifts and a 2-inch (50-mm) surface layer. Nominal maximum sizes for the HMA mixtures were 0.75 inches (19 mm) for the base lifts and 0.5 inches (12.5 mm) for the surface layer. Project specifications called for a material transfer vehicle (MTV) as an intermediary between the unloading trucks and the paver. Because this project involved multiple lifts and was scheduled to be closed to traffic for several months after paving, it was ideal for detailed field evaluations.

A significant problem developed with regard to tag availability prior to construction. The smaller Alien® 1x1 tags were taken out of production by Alien Technologies. A search of RFID tag suppliers identified several alternatives. The most promising of these were an approximately 1 by 2 inches (30 by 50 mm) "Rafsec® Web" tag from UPM Raflatac® (figure 31-see also http://www.upmraflatac.com/). Sample quantities of these tags were ordered for laboratory evaluation. The UPM Raflatac® tags had the advantage that they could still be curled into the pipe molds similar to the Alien® 1x1 tags. Laboratory read performance of the UPM Raflatac® tags was comparable to, and in some cases slightly better than, that for the Alien® 1x1 tags. The read performance of the UPM Raflatac® tags was still lower than for the larger Alien® 2x2 tags, however.

Figure 31. Drawing. UPM Raflatac® RFID tag.

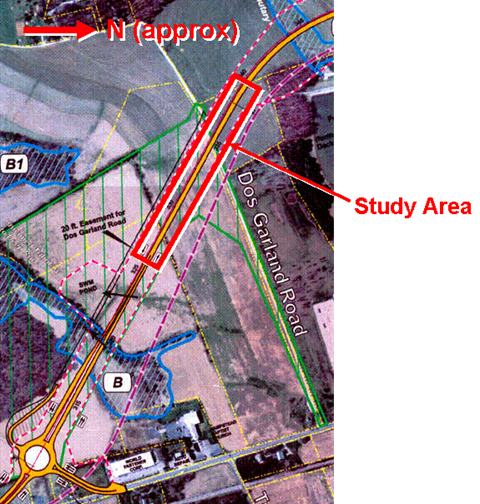

The Hampstead Bypass project was constructed in phases, the first phase of which was the leg near the southern terminus with MD 30 (figure 32). Construction delays postponed the start of paving until November 2007, and as a consequence, only the lower base lift could be placed before the end of the construction season. Both UPM Raflatac® and Alien® 2x2 tags were placed in this lower 4-inch (100-mm) base lift. Additional Alien 2x2 tags were placed in the upper 4-inch (100-mm) base lift in April 2008 at the start of the new construction season. All tags were placed in the section of pavement just north of the lane merge at the southern terminus roundabout. This is designated as the "Study Area" in figure 33.

Image from http://www.sha.state.md.us/WebProjectLifeCycle/ProjectMaps.asp?projectno=CL416536# with annotations by the University of Maryland

Figure 32. Photo. Hampstead Bypass project site.

Image from http://www.sha.state.md.us/WebProjectLifeCycle/ProjectMaps.asp?projectno=CL416536# with annotations by the University of Maryland

Figure 33. Photo. Magnified view of study area at the Hampstead Bypass project site (boxed area in figure 32).

Both UPM Raflatac® and Alien® 2x2 tags were placed in the lower base lift of the southbound travel lane in the study area (figure 33) during paving on November 28, 2007. Paving and tag placement began at the lane merge at the southern edge of the study area and proceeded northward. Note that the MTV was not used for the lower base lift because it was too heavy for the unprotected aggregate base.

The experimental plan for this field trial was as follows:

Table 8 . Log of tags in lower 4-inch (100-mm) base lift at Hampstead Bypass project (November 2007).

Truck Number |

Truck License Plate |

Tag Size (inches) |

Tag IDs |

Time at Unload |

Station at Unload |

Coordinates of Unload Point |

|||

|---|---|---|---|---|---|---|---|---|---|

Handheld GPS |

GPS Logger |

||||||||

N |

W |

N |

W |

||||||

1 |

109-ED97 |

2x2 |

1-10 |

02:00pm |

320+50 |

39o 44' 59.6'' |

76o 50' 44.1'' |

39° 34'5 9.6431" |

76° 50' 44.0653" |

2 |

039-ED20 |

2x2 |

11-20 |

02:04pm |

321+00 |

39o 35' 00.0'' |

76o 50' 44.6'' |

39° 34' 59.7440" |

76° 50' 44.5930" |

3 |

152-ED09 |

2x2 |

21-30 |

02:09pm |

321+50 |

39o 40' 70.8"* |

76o 22' 37.0''* |

39° 35' 00.1638" |

76° 50' 45.3763" |

4 |

127-ED60 |

2x2 |

31-40 |

02:21pm |

322+50 |

39o 35' 01.0''* |

76o 50' 774''* |

39° 35' 00.6391" |

76° 50' 46.6820" |

5 |

052-ED56 |

2x2 |

51-60 |

02:30pm |

323+00 |

39o 35' 01.0'' |

76o 50' 47.0'' |

39° 35' 01.0212" |

76° 50' 47.0927" |

6 |

152-ED10 |

2x2 |

41-50 |

02:43pm |

325+50 |

39o 35' 02.4'' |

76o 50' 49.8'' |

39° 35' 02.3407" |

76° 50' 49.8822" |

1 |

162-ED77 |

1x2 |

1-10 |

02:45pm |

326+25 |

39o 35 '02.6'' |

76o 50' 50.4'' |

39° 35' 02.4377" |

76° 50' 50.2902" |

2 |

155-ED61 |

1x2 |

11-20 |

02:50pm |

328+50 |

39o 35' 03.9'' |

76o 50' 53.2'' |

39° 35' 02.5480" |

76° 50' 50.8996" |

3 |

039-ED17 |

1x2 |

21-30 |

- |

- |

- |

- |

- |

- |

4 |

092-ED62 |

1x2 |

31-40 |

03:02pm |

329+50 |

39o 35' 04.2'' |

76o 50' 54.3'' |

39° 35' 04.2766" |

76° 50' 54.4862" |

* Indicates coordinates were read with a different GPS device

- Indicates no data collected

Note: Italics indicates possible error in data recording

1 inch = 25.4 mm

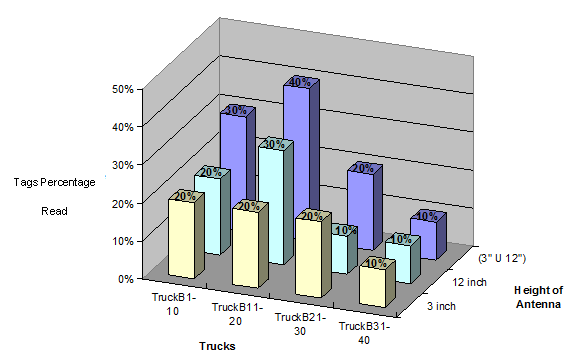

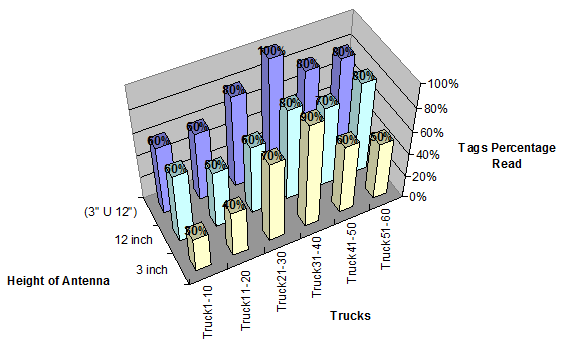

The project team returned to the Hampstead Bypass site on December 3 for preliminary read trials. The vehicle-mounted read system consisted of an adjustable wooden frame suspending the antennae above the pavement surface behind the test vehicle (figure 34). A slow vehicle speed of less than about 5 mi/h (8 km/h) was maintained for all trials. The antennae were arranged with the transmitter sides inboard (i.e., toward the centerline of the car) and the receiver ends outboard. Two antenna heights of approximately 3 inches (75 mm) and 12 inches (300 mm) were evaluated. Because the limited tag read range and antenna configuration made it unlikely that the entire lane width could be read successfully from a single position, three vehicle passes along the southbound travel lane were made for each antenna at each height. Note that a production data collection system could be designed with a wider antenna array that would minimize or eliminate the need for multiple passes.

Figure 34. Photo. Vehicle-mounted antennae and RFID reader.

Key observations from the read trials include the following:

Figure 35. Chart. Percentage of UPM Raflatac® tags read in each truck versus height of antennae (Hampstead Bypass, November 2007).

Figure 36. Chart. Percentage of Alien® 2x2 tags read in each truck versus height of antennae (Hampstead Bypass, November 2007).

Figure 37. Chart. Overall read success rate for lower base lift at Hampstead Bypass (November 2007).

Thirty-two Alien® 2x2 tags were placed in the upper base lift of the northbound travel lane in April 2008. The experimental plan for this field trial was similar to that for the lower base lift placed the preceding November: eight Alien 2x2 tags with prerecorded digital IDs were placed into each of four sequential truckloads, and spatial location of each truck along the alignment during unloading was recorded. A key difference for the upper base lift paving was the use of the MTV. The RoadTec® SB-2500D MTV used on this project (figure 38) is more than 50 ft (15 m) long and has a 25-T (22.7-t) surge capacity; potential spatial lag and mixing of HMA truckloads because of the use of the MTV were among the issues evaluated in this field trial.

Figure 38. Photo. RoadTec® SB-2500D material transfer vehicle used in April 2008 paving at the Hampstead Bypass project.

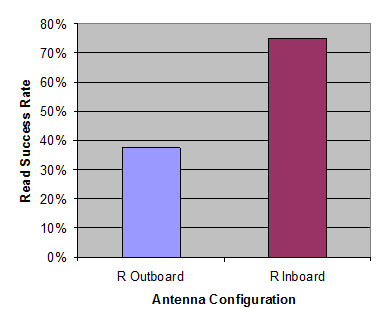

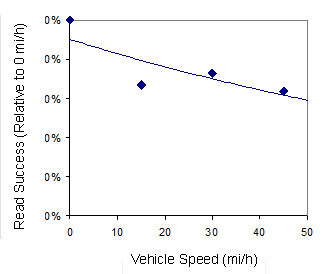

The vehicle-mounted read system (figure 34) was again used to scan the tags immediately after construction. The antenna configurations were similar to those in the November 2007 trials except that only the lower 3-inch (75-mm) antenna height was used, and the influence of antenna orientation (receive sides inbound/outbound) was evaluated. Three passes (edge, centerline, and edge of lane) were performed at each of several vehicle speeds. Additional passes were made over the southbound travel lane containing the tags placed during the November 2007 paving to ascertain whether they were still functioning and readable.

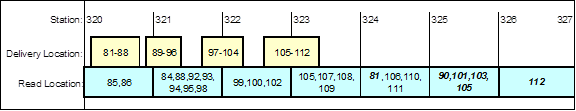

The delivery and read locations for all tags that could be read are summarized in figure 39. Overall, 78 percent of the Alien® 2x2 tags placed in the upper base lift could be found by the reader; this is a slightly higher percentage than for the lower base lift paved the preceding November. GPS coordinates were not recorded during this field trial, so instead, all position information is referenced to station. The station at which the haul truck began unloading into the MTV defines the beginning of the delivery range, and the station at which the unloaded haul truck pulled away from the MTV defines the end. Read locations are recorded only within a station (100 ft (30 m)) interval, although many of the tag locations could be pinpointed more precisely. The data in figure 39 indicate that most of the tags were found in roughly the correct sequence in the completed mat. The fact that the MTV itself is more than 50 ft (15 m) long and that it can carry (and potentially mix) more than one truckload of HMA means that there will inevitably be a spatial lag of unknown length between the truck unloading range and the final location of the tags in the mat. Tag IDs in bold italics in figure 39 indicate tags that were offset more than one station interval from the delivery range; 80 percent of the tags were found within one station interval of their delivery, with the longest offset of the remaining 20 percent between four to five stations (tags 81, 90).

Note: Bold italics identify tag IDs that are displaced more than one station (100 ft (30 m)) from their delivery location.

Figure 39. Chart. Delivery and read locations for RFID tags paved into the upper base lift at the Hampstead Bypass (April 2008).

Note that even without the MTV, there will always be a significant spatial distribution of tags from a given truckload along the alignment. One truckload of HMA for a 4-inch (100-mm)-thick lift corresponds to approximately 70 lane-ft (21 lane-m) of paving; tags in the truckload can end up anywhere along this length. This lack of spatial resolution-even when magnified by use of an MTV-is not significant in practical terms because the material properties from the sampled truckload are intended to represent an entire lot of material (e.g., 1,000 T (907 t), corresponding to about 0.5 lane-mi (0.8 lane-km) of paving).

Some of the tags in figure 39 are in the incorrect sequence. For example, tag 81 from the first truckload was found in the same interval of pavement as tags 106, 110, and 111 from the fourth truck. Similarly, tag 90 from the second truck and tags 101 and 103 from the third truck appear in the same interval as tag 105 from the fourth truck. This may be due to the variable nature of the spatial lag between delivery and read location, or it may be a consequence of mixing of HMA from different loads in the MTV. Regardless of the cause, this incorrect sequencing would not be an issue for production use when only random (as opposed to sequential) truckloads would be tagged.

Additional key observations drawn from the read trials in April 2008 include the following:

R = receive

Figure 40. Chart. Influence of antennae orientation on read success rate.

1 mi/h = 1.6 km/h

Figure 41. Graph. Influence of vehicle speed on read success rate.

Field trials at several projects confirmed the very high survival rate of the encapsulated tags. Read success rates varied significantly with tag size and less significantly on other details such antenna configuration and vehicle speed. Nonetheless, the field trials consistently demonstrated that post-construction read success rates of 60 to 80 percent or higher are achievable from a bumper-mounted antenna array, even on a vehicle moving at traffic speeds. A major secondary advantage of the approach is its minimal intrusion in the usual paving construction sequence. The only potential drawback observed was the occasional surfacing of tags at the top of the compacted mat. All surfaced tags were aligned parallel to the mat surface; no tags were observed in an upright orientation protruding above the mat in any of the trials.