U.S. Department of Transportation

Federal Highway Administration

1200 New Jersey Avenue, SE

Washington, DC 20590

202-366-4000

Federal Highway Administration Research and Technology

Coordinating, Developing, and Delivering Highway Transportation Innovations

| REPORT |

| This report is an archived publication and may contain dated technical, contact, and link information |

|

| Publication Number: FHWA-HRT-14-093 Date: December 2014 |

Publication Number: FHWA-HRT-14-093 Date: December 2014 |

The Specimen Preparation section of this report indicated that each lab participating in the variability study received 20 test plates for each coating series. The intent was to test five specimens, and an extra five plates were available if the situation arose where one of the primary plates was untestable for any reason. At the end of the variability study, each participating lab sent all their extra plates back to lab 1. Lab 1 then matched the extra plates from each coating series together based on DFT similarities to form additional specimens. The intent of the extra specimens was two-fold: to see if additional curing time would change the slip coefficient and to assess an alternate way to measure slip displacements.

The question regarding aging effects was posed midway through the project and not addressed as part of developing the main variability study. In bridge fabrication, sometimes it is the case that the fabricated steel will sit in the primed condition for many months before slip-critical connections are ever assembled. Since the slip coefficient is based on recommended manufacturer cure time, it was thought that organic zinc-rich primers may continue to cure and harden beyond this period. If the primer continues to harden, then it is possible the slip coefficient could decrease (i.e., harder surfaces would tend to not stick together as easily).

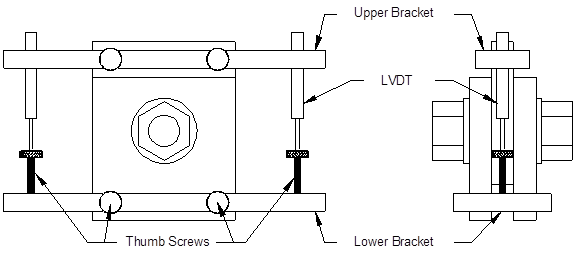

The alternate slip displacement measuring technique was conceived in the middle of the variability study, but it was not explored to avoid introducing additional variables during the variability study. Since each lab was effectively measuring the slip as the displacement between the loading platens, all labs observed a soft slip response as the loading systems settled into each specimen. The notion was to get the LVDTs to measure slip displacement within the specimen, not between the loading platens as illustrated in figure 53. Close-up views of individual pieces are shown in figure 54 and figure 55.

The number of specimens that were tested for aging effects varied between one and six specimens depending on the coating series. This occurred because for some coating series, either the labs used the extra plates as part of the variability study or the DFTs on them could not be matched with others available to make a viable specimen.

The aging study began after RCSC had begun to digest the preliminary results from the interlaboratory variability study. As such, RCSC had formed a task group to make recommendations to modify their testing specification, and the aging study was used to test some of the preliminary ideas. Mostly, the aging specimens were tested according to the existing RCSC specification except for two modifications. First, after clamping, the specimens were preloaded with 5 kip of vertical load and then unloaded to 0 kip of vertical load to set the specimen against the platens. Second, the test began from a state of 0 kip of vertical load, whereas in the variability study, it was implied that testing should begin from 1 kip of vertical load. The preload step was ignored when testing the five specimens of coating A2 to test if that step was necessary with the modified displacement measuring device.

Figure 53. Illustration. Overall view of modified slip measuring device mounted to a specimen.

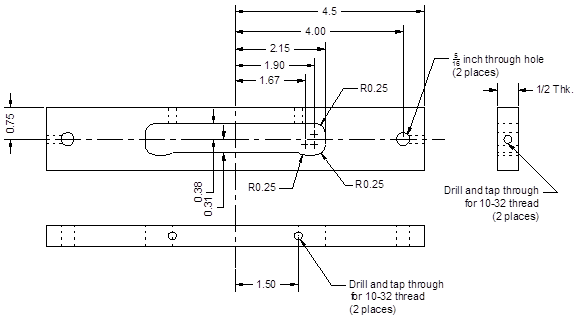

Note: Units are shown in inches.

Figure 54. Illustration. Upper bracket detailing of modified slip measuring device.

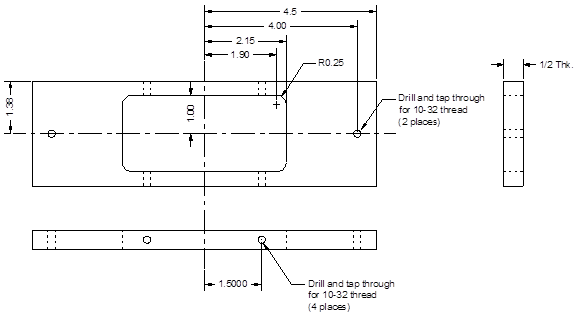

Note: Units are shown in inches.

Figure 55. Illustration. Lower bracket detailing of modified slip measuring device.

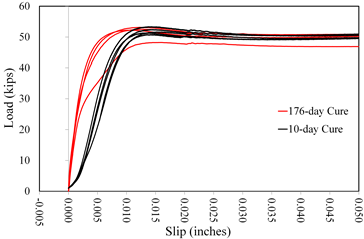

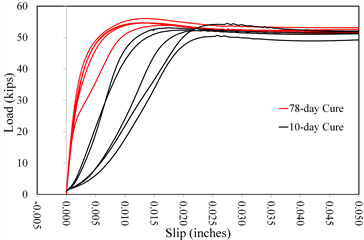

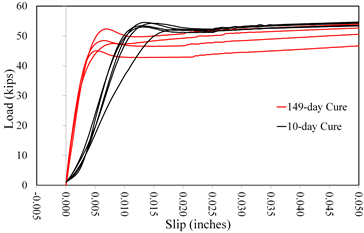

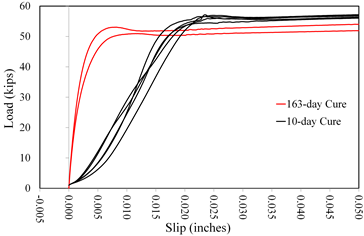

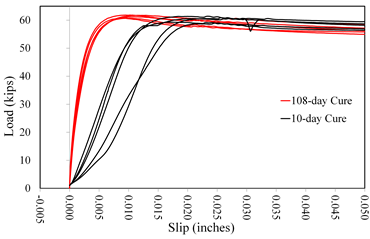

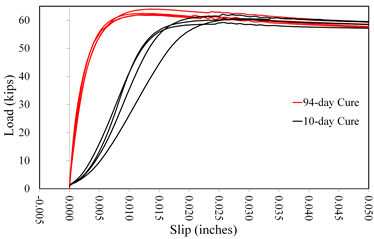

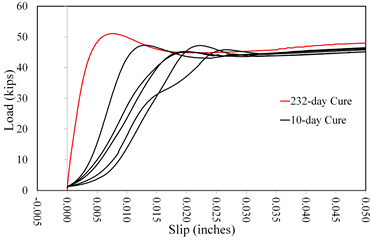

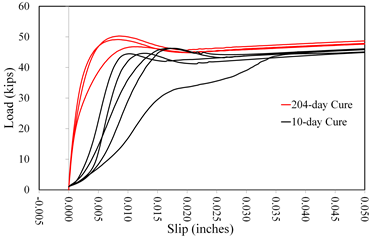

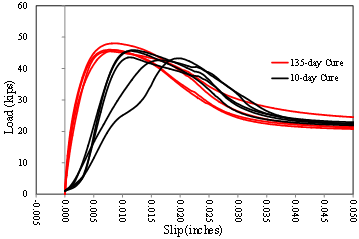

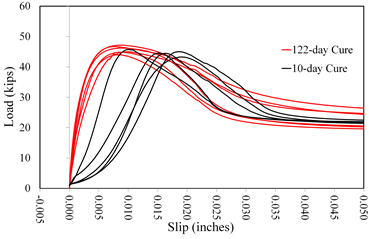

The results of the aging study are presented in table 11 in terms of the slip coefficient for each specimen. The total cure time for each coating is also shown. The load versus slip displacement plots comparing the aged (i.e., extended cure) specimens to those tested at lab 1 as part of the interlaboratory study are shown in figure 56 through figure 65 for each of the 10 coating series. The graphs clearly indicate a stark contrast in the initial loading behavior between the 10-day and extended cure specimens. That is, the 10-day cure specimens with LVDT referencing platen motion demonstrate a soft initial nonlinear response indicative of shakedown of the specimens into the loading platens, whereas the extended cure specimens with modified LVDT holder all showed initially linear behavior with no shakedown response. This was observed for all 10 coating series, including A2 that did not preload the specimen to 5 kip before testing.

Table 11 . Slip coefficient results of aging study.

Specimen |

Coating |

|||||||||

|---|---|---|---|---|---|---|---|---|---|---|

A1 |

A2 |

B1 |

B2 |

C1 |

C2 |

D1 |

D2 |

E1 |

E2 |

|

1 |

0.54 |

0.56 |

0.50 |

0.54 |

0.63 |

0.65 |

0.52 |

0.51 |

0.47 |

0.46 |

2 |

0.49 |

0.56 |

0.53 |

0.52 |

0.62 |

0.64 |

|

0.50 |

0.47 |

0.48 |

3 |

0.54 |

0.55 |

0.46 |

|

0.62 |

0.63 |

|

0.48 |

0.49 |

0.48 |

4 |

0.53 |

0.56 |

0.48 |

|

0.63 |

0.63 |

|

|

0.47 |

0.45 |

5 |

|

0.57 |

|

|

0.63 |

|

|

|

|

0.47 |

6 |

|

|

|

|

|

|

|

|

|

0.46 |

Cure (days) |

176 |

78 |

149 |

163 |

108 |

94 |

232 |

204 |

135 |

122 |

Note: Blank cells indicate that there were not enough spare plates to make more specimens.

Figure 56. Graph. Comparison of slip behavior with cure time for coating A1.

Figure 57. Graph. Comparison of slip behavior with cure time for coating A2.

Figure 58. Graph. Comparison of slip behavior with cure time for coating B1.

Figure 59. Graph. Comparison of slip behavior with cure time for coating B2.

Figure 60. Graph. Comparison of slip behavior with cure time for coating C1.

Figure 61. Graph. Comparison of slip behavior with cure time for coating C2.

Figure 62. Graph. Comparison of slip behavior with cure time for coating D1.

Figure 63. Graph. Comparison of slip behavior with cure time for coating D2.

Figure 64. Graph. Comparison of slip behavior with cure time for coating E1.

Figure 65. Graph. Comparison of slip behavior with cure time for coating E2.

Table 12 compares the average slip coefficients attained from the aging study to those from the interlaboratory variability study using the peak load ignoring the 0.02-inch criteria. When using the modified measuring device, none of the specimens ever came close to being controlled by the 0.02-inch displacement criteria. COV is not presented in table 12 since each coating series had different numbers of specimens, many not even having enough specimens to make a viable COV calculation. The final row in the table presents the difference in slip coefficients between the aging and variability portions of the overall study. Mostly, the average slip coefficient increased with the extended cure time. The one noted exception is coating B, which exhibited more variability and overall reduced average slip coefficient with an extended cure at both the +1- and +2-mil thicknesses.

Table 12 . Comparison of slip coefficients between 10-day and extended cure.

Coating |

Extended Cure Average |

10-Day Cure Average |

Difference |

|---|---|---|---|

A1 |

0.53 |

0.53 |

0.00 |

A2 |

0.56 |

0.53 |

0.03 |

B1 |

0.50 |

0.55 |

-0.05 |

B2 |

0.53 |

0.56 |

-0.03 |

C1 |

0.63 |

0.62 |

0.01 |

C2 |

0.64 |

0.62 |

0.02 |

D1 |

|

0.47 |

|

D2 |

0.50 |

0.45 |

0.05 |

E1 |

0.47 |

0.45 |

0.02 |

E2 |

0.47 |

0.45 |

0.02 |

Note: Blank cells indicate that only one specimen could be tested for coating D1 with the extended cure, and an average could not be calculated. Because an average could not be calculated for the extended cure, the difference relative to the 10-day cure could not be calculated either.