U.S. Department of Transportation

Federal Highway Administration

1200 New Jersey Avenue, SE

Washington, DC 20590

202-366-4000

Federal Highway Administration Research and Technology

Coordinating, Developing, and Delivering Highway Transportation Innovations

| REPORT |

| This report is an archived publication and may contain dated technical, contact, and link information |

|

| Publication Number: FHWA-HRT-17-093 Date: February 2018 |

Publication Number: FHWA-HRT-17-093 Date: February 2018 |

The results from the thermal and cyclic loading are presented in this chapter. The prewetting and curing procedures adopted in this study prevented shrinkage cracking and debonding during and after construction of the connections. The specimens were kept inside the laboratory throughout the testing program, with each specimen first being subjected to the thermal cycling followed by the cyclic structural loading.

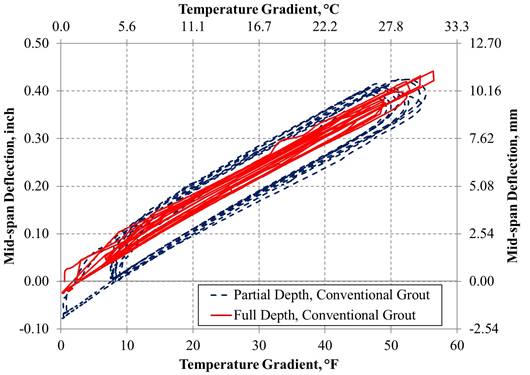

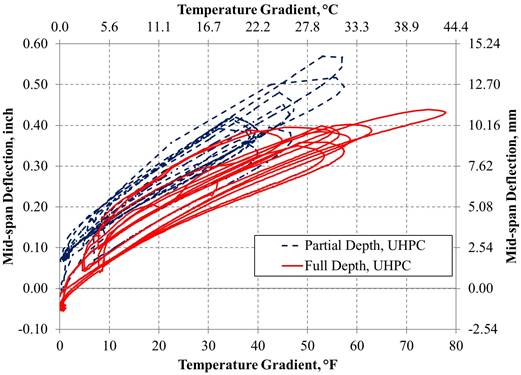

The specimens were thermally loaded to create a temperature gradient between the top and bottom flanges of approximately 50 °F (28 °C). A total of 10 thermal cycles were applied to each test specimen except for the full-depth connection specimens, which only underwent 8 cycles. The thermal loading generated an upward deflection at the mid-span of between 0.425 and 0.570 inch (10.8 and 14.5 mm). The deflection versus temperature gradient curves for the conventionally grouted connections in the study are presented in figure 50, and the curves for the UHPC connections are shown in figure 51.

Source: FHWA.

1 inch = 25.4 mm.

1 °F = 0.556 °C.

Figure 50. Graph. Relationship between upward deflection and temperature gradient in beams with conventionally grouted connections.

Source: FHWA.

1 inch = 25.4 mm.

1 °F = 0.556 °C.

Figure 51. Graph. Relationship between upward deflection and temperature gradient in beams with UHPC connections.

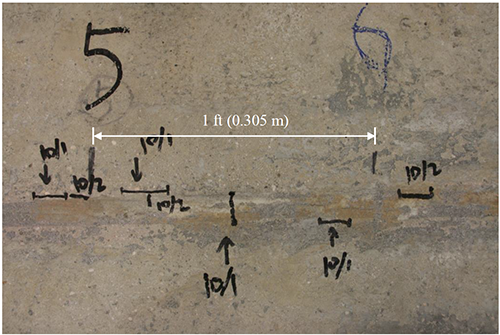

Table 10 summarizes the thermal loading and unloading data. The behavior of the beams used in the tests was generally the same. All of the tests had approximately the same deflection rate due to the thermal stress. The only exception was for the full-depth UHPC connection, which had a somewhat lower deflection rate. Despite reaching a gradient that was 20 °F (11 °C) higher than the other tests, the deflection was similar. The partial-depth UHPC connection had the greatest deflection, likely due to the largest heating rate. A visual inspection was conducted after the thermal loading. Only minor, non-structural cracking was observed in the partial-depth conventional grouted connection; the most severe is shown in figure 52. No debonding was caused by thermal loading for any of the connections.

1 inch = 25.4 mm.

1 °F = 0.556 °C.

1 inch/°F = 45.72 mm/°C.

Source: FHWA.

1 ft = 0.305 m.

Figure 52. Photo. Representative cracking observed in the partial-depth conventional grout connection after thermal loading.

The partial-depth conventional grout connection was first tested in this study, followed by the full-depth conventional grout connection, then the partial- and full-depth UHPC connections. The boundary conditions, loading range, and loading cycles used on each connection are presented in table 4 through table 7.

To effectively evaluate the connection performance and efficiency under different conditions, this study adopted three parameters to measure the performance of the connection. The first two are the proportion of moment factor for the loaded beam and longitudinal strains in the beams, respectively. These demonstrate the ability of the connection to transfer loads between beams. The third is Δδ, which provides an early indication of degradation of the connection. To be consistent between all tests, the longitudinal strain reported in graphs and used for proportion of moment are those from the embedded bottom strain gauges. The deflection measurements for proportion of moment are the average of both the vertical LVDTs on the beams, while Δδ is calculated using the method defined in chapter 3.

The proportion of moment carried by each beam and Δδ between the two beams was also assessed for each of the four connection details.

Partial-Depth Conventional Grout Connection

The full 100-kip (445-kN) transverse PT force was applied at each PT point 7 d after casting the shear key, generating PT distribution of 8 kip/ft (117 kN/m). The beams were then thermally loaded. The thermal loading did not initiate any local or global distress in the connection. Before the cyclic structural loading, the connection was checked, and only minor non-structural cracks were observed.

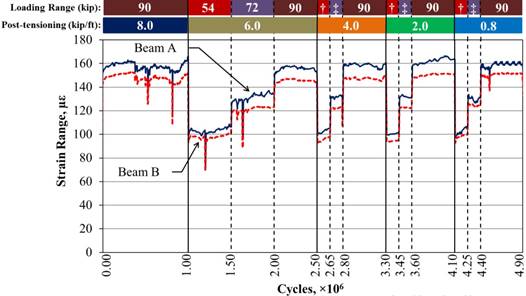

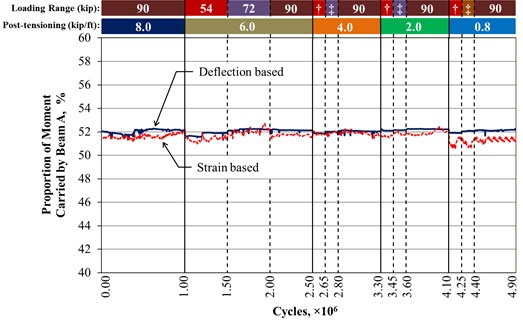

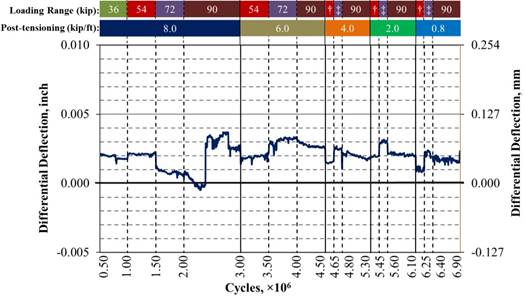

The beams were first tested in the unstiffened configuration. Loading ranges started at 18 kip (80 kN) and increased to 36, 54, 72, and 90 kip (160, 240, 320, and 400 kN). In total, 3 million cycles were performed; the existing cracks were not observed to propagate in the connection, and no new cracks formed. The transverse PT was then reduced from 8 to 6, 4, 2, and 0.8 kip/ft (117 to 87, 58, 29, and 12 kN/m). At each of these reduced transverse PT levels, the beams were cyclically loaded with the 54-, 72-, and 90-kip (240-, 320-, and 400-kN) loading ranges. An additional 3.9 million cycles were completed with no new cracks forming or existing cracks propagating. The longitudinal tensile strain at the mid-span, the loaded beam proportion of moment, and Δδ in these loading configurations are presented in figure 53 through figure 55, respectively. The tensile strain data were only available for the 90-kip (400-kN) loading range under the 8-kip/ft (117-kN/m) PT level.

Source: FHWA.

1 kip = 4.448 kN.

1 kip/ft = 14.59 kN/m.

† = 54-kip loading range.

‡ = 72-kip loading range.

Figure 53. Graph. Longitudinal tensile strain measured at the mid-span in unstiffened beams with a partial-depth uncracked conventionally grouted connection.

Source: FHWA.

1 kip = 4.448 kN.

1 kip/ft = 14.59 kN/m.

† = 54-kip loading range.

‡ = 72-kip loading range.

Figure 54. Graph. Proportion of moment based on the mid-span strain and deflection for unstiffened beams with a partial-depth uncracked conventionally grouted connection.

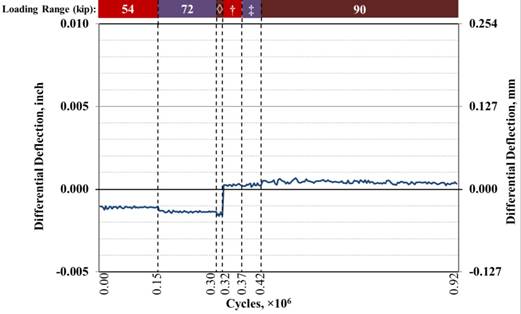

Source: FHWA.

1 kip = 4.448 kN.

1 kip/ft = 14.59 kN/m.

1 inch = 25.4 mm.

† = 54-kip loading range.

‡ = 72-kip loading range.

Note: Data for the first 500,000 cycles were not collected properly and therefore were not included.

Figure 55. Graph. Δδ measured at the mid-span in unstiffened beams with a partial-depth uncracked conventionally grouted connection.

The level of the three variables remained nearly constant within a particular loading range regardless of the level of transverse PT applied. Specifically, the longitudinal strain while in the 90-kip (400-kN) loading range remained 160 and 145 με for the loaded and unloaded beams, respectively. The proportion of moment on the loaded beam was consistently around 52 percent regardless of the loading range or the level of PT applied. Δδ was about 0.0025 inch (0.064 mm) in the largest loading range regardless of level of PT. These results indicate that the amount of transverse PT did not seem to have an effect on system performance when the connection was intact without any apparent cracking or debonding. Further discussion of the effect of transverse PT is provided in the Transverse PT section in chapter 5.

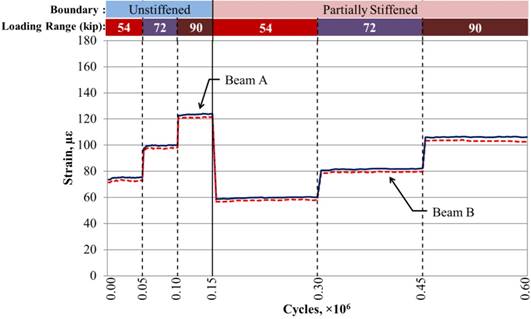

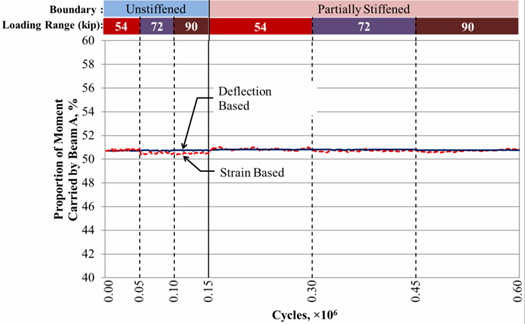

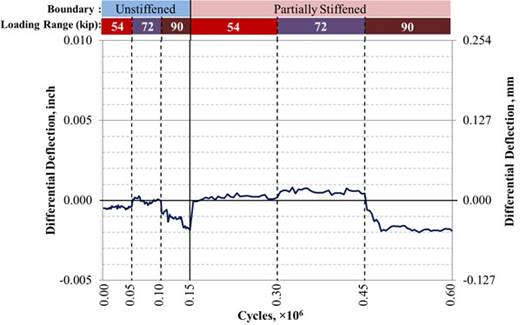

The specimen was stiffened using the two methods previously discussed, and 1.6 and 1.75 million cycles were performed with the partially and fully stiffened connections, respectively. The results for the partially stiffened boundary condition are shown in figure 56 through figure 58. Increasing the stiffness was found to decrease the longitudinal strain in the beams. When less PT force was used, strains were found to be lower, a more even load distribution was calculated, and lower Δδ was recorded. An error in an LVDT resulted in the deflection-based proportion of moment to be based solely on the exterior LVDT for the unloaded beam in this configuration.

Source: FHWA.

1 kip = 4.448 kN.

1 kip/ft = 14.59 kN/m.

Figure 56. Graph. Longitudinal tensile strain measured at the mid-span in partially stiffened beams with a partial-depth uncracked conventionally grouted connection.

Source: FHWA.

1 kip = 4.448 kN.

1 kip/ft = 14.59 kN/m.

Figure 57. Graph. Loaded proportion of moment based on the mid-span strain and deflection for partially stiffened beams with a partial-depth uncracked conventionally grouted connection.

Source: FHWA.

1 kip = 4.448 kN.

1 kip/ft = 14.59 kN/m.

1 inch = 25.4 mm.

Figure 58. Graph. Δδ measured at the mid-span in partially stiffened beams with a partial-depth uncracked conventionally grouted connection.

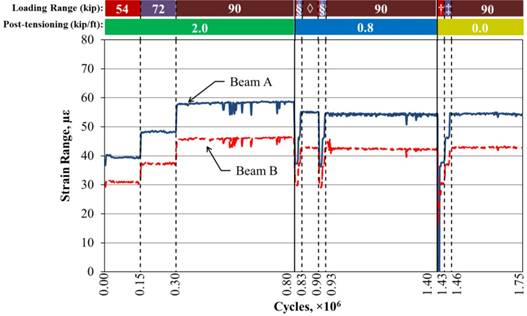

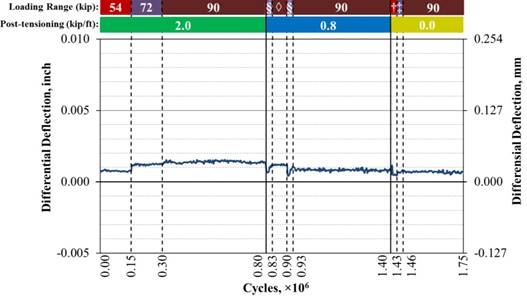

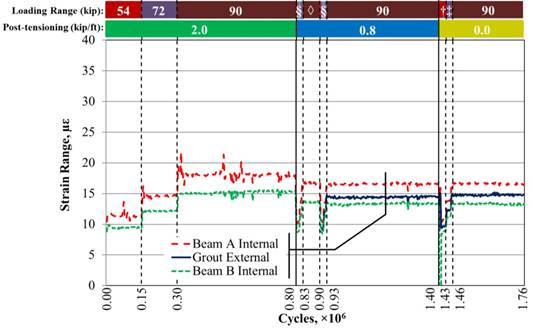

After the partially stiffened cycles were completed, the fully stiffened configuration was tested. The results for the fully stiffened boundary condition are shown in figure 59 and figure 60. The values reported were the strain range and deflection, as calculated from figure 41. For the final 360,000 cycles, the transverse PT force was eliminated. The fully stiffened boundary condition further lowered the longitudinal tensile strain experienced by the beams. Δδ was also lower—about 0.001 inch (0.025 mm)—compared to the simply supported case. The thermal cracks observed were not seen to propagate in the connection, indicating that the transverse PT force had a minimal impact on system performance as long as the connection remained in good condition.

Source: FHWA.

1 kip = 4.448 kN.

1 kip/ft = 14.59 kN/m.

§ = 15,000 cycles at both the 54- and 72-kip loading ranges.

◊ = 90-kip loading range.

† = 54-kip loading range.

‡ = 72-kip loading range.

Figure 59. Graph. Longitudinal tensile strain range measured at the mid-span in fully stiffened beams with a partial-depth uncracked conventionally grouted connection.

Source: FHWA.

1 kip = 4.448 kN.

1 kip/ft = 14.59 kN/m.

§ = 15,000 cycles at both the 54- and 72-kip loading ranges.

◊ = 90-kip loading range.

† = 54-kip loading range.

‡ = 72-kip loading range.

Figure 60. Graph. Δδ measured at the mid-span in fully stiffened beams with a partial-depth uncracked conventionally grouted connection.

More than 10 million cycles of structural loading were applied to the beams with a partial-depth conventional grout connection. At its most severe, the structural loading applied an Mequivalent of 478 kip-ft (646 kN-m) transferred through the connection. No distress was observed.

The connection was then mechanically cracked by applying a direct tensile force on top of the connection, as shown in figure 61. Cracks at the interface between the grout and box beam concrete were initiated and extended about 32 ft (9.8 m). The extent to which the cracks extended into the connection was checked by ponding water on the connection. Water was observed to penetrate the connection, indicating the connection had debonded along the length of the observed cracking.

Figure 61. Photos. Mechanical cracking of the partial-depth conventionally grouted connection, including the cracking setup and the cracked connection.

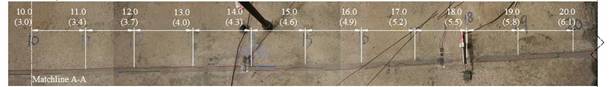

The beams were again cyclically loaded using the fully stiffened boundary condition. Transverse PT forces ranging from 8 to 0 kip/ft (117 to 0 kN/m) were tested, and 830,000 cycles were completed. The cracks were found to propagate along the connection regardless of the transverse PT force applied but propagated more quickly under lower levels of PT. After the 8- and 4-kip/ft (117- and 87-kN/m) PT cycles, the end of the crack was seen to extend about 9 inches (230 mm), and additional cracks propagated within the already cracked connection. The most extensive cracking occurred after the 0.8- and 0-kip/ft (12- and 0-kN/m) levels of PT cycles. After the 0.8-kip/ft (12-kN/m) cycles, the crack extended 4 ft (1.2 m) to a total cracked length of 37 ft (11.3 m). The cycles with no PT further extended the crack to 40 ft (12.2 m). The crack propagation can be seen in figure 62. Red marker indicates the extent of the mechanical cracking, while green, blue, and orange markers show propagation after the 4-, 0.8-, and 1-kip/ft (87-, 12-, and 0-kN/m) PT levels, respectively.

Source: FHWA.

B. Connection from the 10- to 20-ft (3.05- to 6.10-m) mark.

Source: FHWA.

C. Connection from the 28- to 36-ft (8.53- to 10.97-m) mark.

Source: FHWA.

D. Connection from the 36- to 46-ft (10.97- to 14.02-m) mark.

Note: Numbers in the photos reflect distance from the west end in feet where 1 ft = 0.305 m.

Figure 62. Photos. Propagation of the end of the connection crack induced by cyclic structural loading.

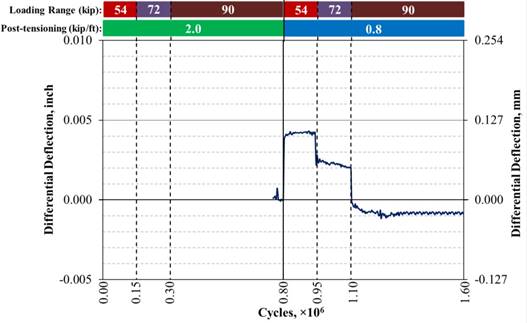

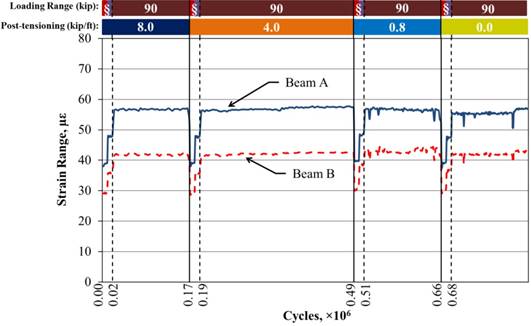

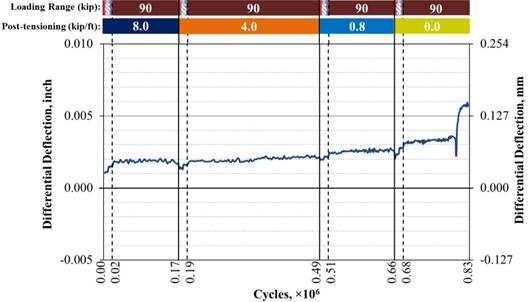

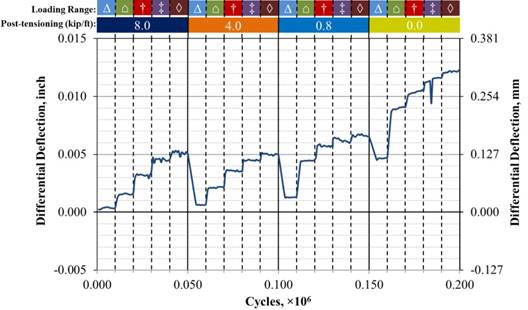

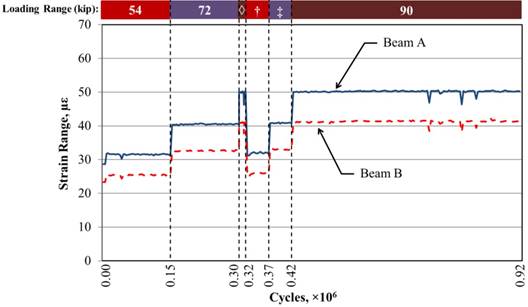

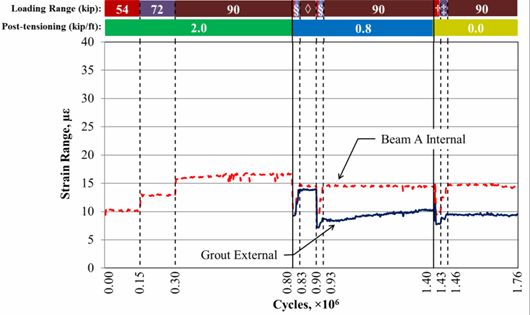

The longitudinal tensile strain range and Δδ between the two adjacent beams at the mid-span for the partially cracked connections are presented in figure 63 and figure 64. The partially cracked connection could still effectively transfer the load from one beam to the other, likely through friction between the grout and the box beam concrete; however, a slightly larger Δδ was observed. A jump can be seen during the 90-kip (400-kN) range of the cycles without PT around 800,000 cycles. This may correspond to the propagation of the crack seen in figure 62.

Source: FHWA.

1 kip = 4.448 kN.

1 kip/ft = 14.59 kN/m.

§ = 10,000 cycles at both the 54- and 72-kip loading ranges.

Figure 63. Graph. Longitudinal tensile strain range measured at the mid-span in fully stiffened beams with a partial-depth partially cracked conventionally grouted connection.

Source: FHWA.

1 kip = 4.448 kN.

1 kip/ft = 14.59 kN/m.

1 inch = 25.4 mm.

§ = 10,000 cycles at both the 54- and 72-kip loading ranges.

Figure 64. Graph. Δδ measured at the mid-span in fully stiffened beams with a partial-depth partially cracked conventionally grouted connection.

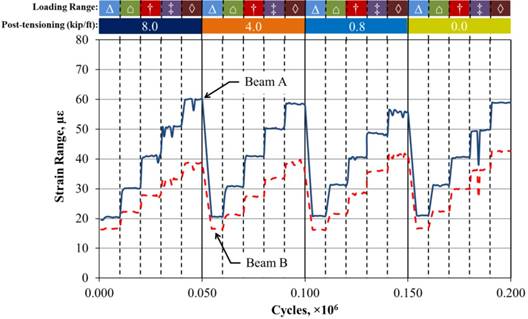

The connection was then mechanically cracked so the full length of the connection was cracked. The beams were then subjected to further cyclic loading with the stiffest boundary condition. A total of 200,000 cycles were performed with the transverse PT forces ranging from 8 to 0 kip/ft (117 to 0 kN/m).

The longitudinal tensile strain range and Δδ between the two adjacent beams at the mid-span for the fully-cracked connection are presented in figure 65 and figure 66. Larger Δδ and longitudinal strains were observed in the fully cracked connection.

Source: FHWA.

1 kip = 4.448 kN.

1 kip/ft = 14.59 kN/m.

△ = 18-kip loading range.

⌂ = 36-kip loading range.

† = 54-kip loading range.

‡ = 72-kip loading range.

◊ = 90-kip loading range.

Figure 65. Graph. Longitudinal tensile strain range measured at the mid-span in fully stiffened beams with a partial-depth fully cracked conventionally grouted connection.

Source: FHWA.

1 kip = 4.448 kN.

1 kip/ft = 14.59 kN/m.

△ = 18-kip loading range.

⌂ = 36-kip loading range.

† = 54-kip loading range.

‡ = 72-kip loading range.

◊ = 90-kip loading range.

Figure 66. Graph. Δδ measured at the mid-span in fully stiffened beams with a partial-depth fully cracked conventionally grouted connection.

The transverse PT force did not have much effect on the longitudinal strain at the mid-span. The transverse PT force varied from 8 to 0 kip/ft (117 to 0 kN/m) in the partially and fully cracked connections. The transverse PT affected Δδ. When it was removed from the fully cracked connection, Δδ was noted to increase within the 50,000 cycles conducted in this study.

Full-Depth Conventional Grout Connection

The same construction procedure used for partial-depth conventionally grouted connection was adopted for the full-depth conventionally grouted connection. Approximately two-thirds of the length of the connection cracked when the wrench-tight PT force was removed. The transverse curvature (i.e., sweep) of the beams with the full-depth connection may have varied enough to cause cracking to develop, as illustrated in figure 67. When the PT forces were applied, the beams aligned from the applied force. After the grout was cast and the transverse force was removed, the beams tried to return to their original shape. This introduced a tensile force across the connection and could lead to connection cracking if the bond strength between the grout and the box beams were not sufficiently large. This would imply that the differential transverse curvature on the beams with the full-depth shear keys was larger than that on the beams with the partial-depth shear keys. This caused the full-depth shear key to crack upon release of the PT force, while the partial-depth shear key did not.

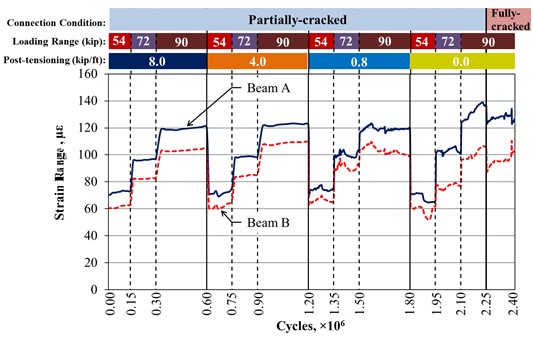

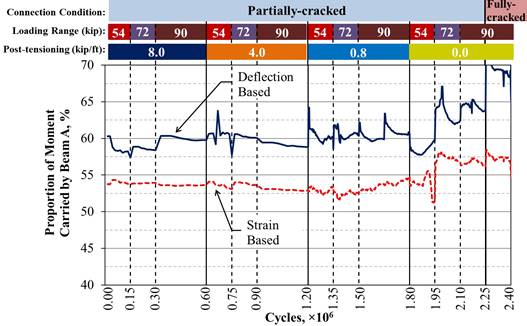

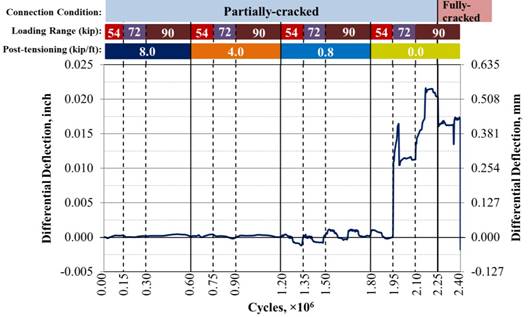

Cyclic loading was applied to the specimen with the partially cracked connection using the unstiffened configuration and varying levels of transverse PT. A total of 2.25 million cycles were completed, and the existing cracking in the connection was observed to propagate. However, the crack did not extend the entire length of the beam. The connection was further cracked with the same method used for the partial-depth connection so that the connection interface cracks extended the entire length of the specimen. The beams were then loaded for another 150,000 cycles. The longitudinal tensile strain at the mid-span and the proportion of moment carried by the loaded beam are presented in figure 68 and figure 69, respectively. Δδ between the two beams is presented in figure 70. With transverse PT forces of 8, 4, and 0.8 kip/ft (117, 58, and 12 kN/m), the partially cracked connection could still effectively transfer the moment, having a proportion of moment factor of about 54 percent. When the transverse PT was removed, the proportion of moment factor remained about 54 percent under the 54-kip (240-kN) loading range but increased to over 57 percent when the loading range increased to 72 and 90 kip (320 and 400 kN).

Similar observations were noted with Δδ. As shown in figure 70, Δδ was constantly within 0.001 inch (0.025 mm) for all loading ranges while having any level of transverse PT. It jumped to around 0.015 inch (0.381 mm) for the partially cracked connection under the 72-kip (320-kN) loading range. Both the partially and fully cracked connections had Δδ of around 0.018 inch (0.457 mm) in the 90-kip (400-kN) loading range.

Source: FHWA.

1 kip = 4.448 kN.

1 kip/ft = 14.59 kN/m.

Figure 68. Graph. Tensile strain at the mid-span showing full-depth connection, conventional grout, unstiffened boundary, and partially and fully cracked conditions.

Source: FHWA.

1 kip = 4.448 kN.

1 kip/ft = 14.59 kN/m.

Figure 69. Graph. Proportion of moment carried by the loaded beam based on the mid-span strain and deflection for the full-depth partially and fully cracked conventionally grouted connections.

Source: FHWA.

1 kip = 4.448 kN.

1 kip/ft = 14.59 kN/m.

1 inch = 25.4 mm.

Figure 70. Graph. Δδ measured at the mid-span in the full-depth partially and fully cracked conventionally grouted connections.

Partial-Depth UHPC Connection

After the conventional grout connections were tested, the pair of beams were separated and repositioned to construct the UHPC connections. Both UHPC connections were constructed successfully, and no cracks were observed before the cyclic structural loading.

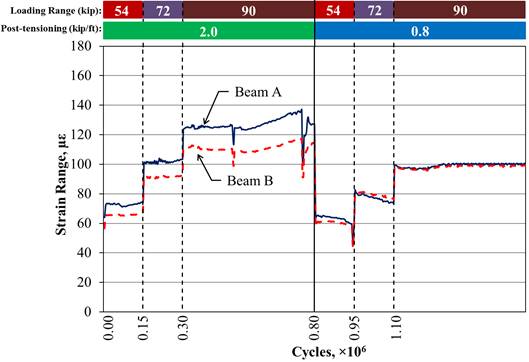

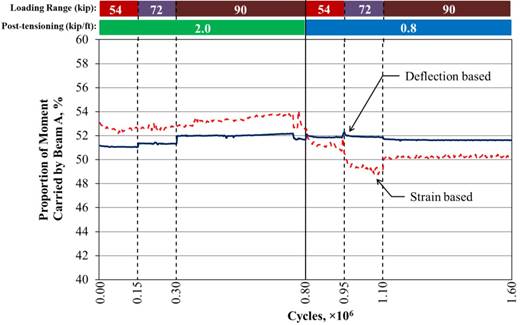

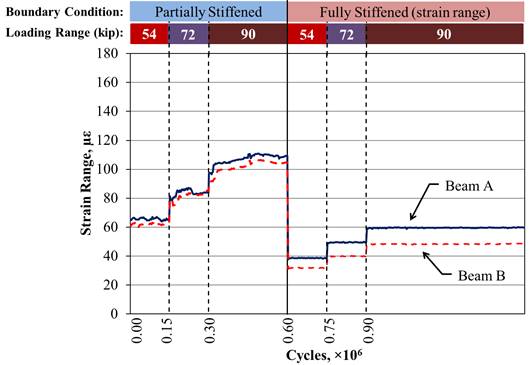

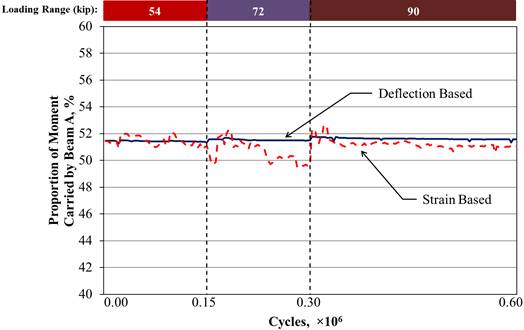

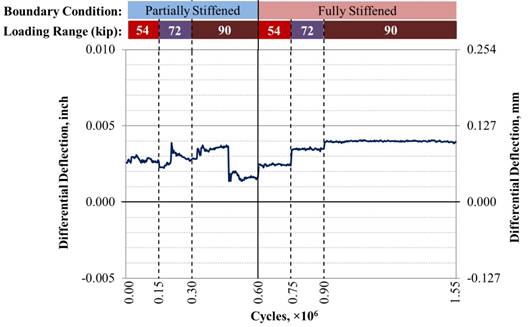

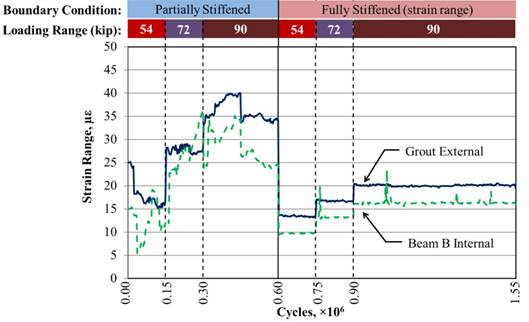

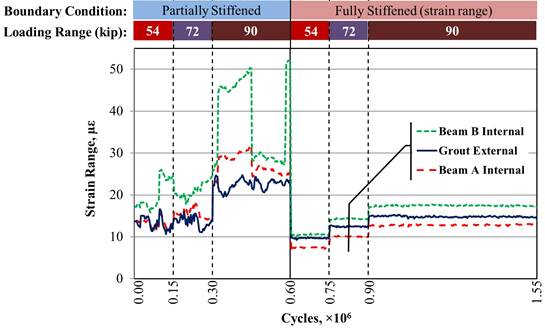

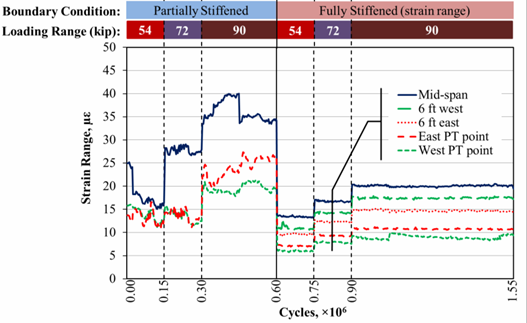

The beams with the partial-depth UHPC connection were loaded with the partially stiffened and fully stiffened boundary conditions. A total of 1.55 million cycles were performed, and no cracking was observed in the specimen. The longitudinal tensile strain at the mid-span for beams with partial-depth UHPC connection is presented in figure 71. Values for the tensile strain for the fully stiffened portion of the plot are the range of longitudinal strains. Proportion of moment on the loaded beam for the partially stiffened connection is presented in figure 72. Δδ for the connection is presented in figure 73. Under the 54-, 72-, and 90-kip (240-, 320-, and 400-kN) loading ranges, the loaded beam had a proportion of moment around 50 percent with the partially stiffened boundary, and Δδ was limited to within 0.005 inch (0.127 mm).

Source: FHWA.

1 kip = 4.448 kN.

Figure 71. Graph. Longitudinal tensile strain measured at the mid-span in partially and fully stiffened beams with a partial-depth UHPC connection.

Source: FHWA.

1 kip = 4.448 kN.

Figure 72. Graph. Proportion of moment carried by the loaded beam based on the mid-span strain and deflection for partially stiffened beams with a partial-depth UHPC connection.

Source: FHWA.

1 inch = 25.4 mm.

1 kip = 4.448 kN.

Figure 73. Graph. Δδ measured at the mid-span in partially and fully stiffened beams with a partial-depth UHPC connection.

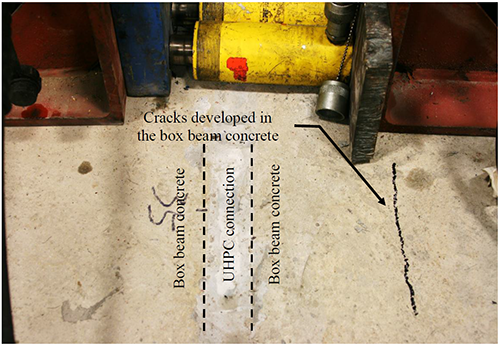

An attempt to induce cracking in the connection with the same method as the conventional grout specimens was performed. When the transverse tensile force was applied across the connection, cracks developed in the box beam rather than in the UHPC or the connection interface, as shown in figure 74. This suggests that the interface bond strength between the UHPC and EA interface concrete was similar to or greater than the tensile strength of the box beam concrete. This behavior demonstrates that UHPC can create a connection whose behavior is comparable to or exceeds the tensile cracking strength of monolithically cast concrete box beams due to the tensile strength, interface bond strength, and reinforcement development ability of the UHPC.

Source: FHWA.

Figure 74. Photo. Crack development in the box beam during an attempt to mechanically induce a crack in the UHPC connection.

Full-Depth UHPC Connection

The partial-depth UHPC connection exhibited performance that could be expected to be comparable to a monolithic bridge system. Given the similarities between the partial- and full-depth UHPC connections, it was anticipated that the full-depth UHPC connection would exhibit similar performance.

The longitudinal tensile strain for the unstiffened and partially stiffened cases is presented in figure 75, the loaded beam proportion of moment for these cases is given in figure 76, and Δδ is presented in figure 77. The partially stiffened boundary condition caused the strains measured at mid-span to decrease. The proportion of moment on the loaded beam stayed constant around 51 percent. Δδ between the beams were minor, between -0.002 and 0.001 inch (-0.051 and 0.025 mm), across both boundary conditions and all loading ranges.

Source: FHWA.

1 kip = 4.448 kN.

Figure 75. Graph. Longitudinal tensile strain measured at the mid-span in unstiffened and partially stiffened beams with a full-depth UHPC connection.

Source: FHWA.

1 kip = 4.448 kN.

Figure 76. Graph. Proportion of the moment carried by the loaded beam based on the mid-span strain and deflection for unstiffened and partially stiffened beams with a full-depth UHPC connection.

Source: FHWA.

1 kip = 4.448 kN.

1 inch = 25.4 mm.

Figure 77. Graph. Δδ measured at the mid-span in unstiffened and partially stiffened beams with a full-depth UHPC connection.

The longitudinal tensile strain range and Δδ for the uncracked full-depth UHPC connection with the fully stiffened boundary condition are presented in figure 78 and figure 79, respectively, and a total of 915,000 cycles were conducted. No cracks were initiated. The connection limited Δδ to within ±0.0015 inch (±0.038 mm).

Source: FHWA.

1 kip = 4.448 kN.

◊ = 90-kip loading range.

† = 54-kip loading range.

‡ = 72-kip loading range.

Figure 78. Graph. Longitudinal tensile strain range measured at the mid-span in fully stiffened beams with a full-depth UHPC connection.

Source: FHWA.

1 kip = 4.448 kN.

1 inch = 25.4 mm.

◊ = 90-kip loading range.

† = 54-kip loading range.

‡ = 72-kip loading range.

Figure 79. Graph. Δδ measured at the mid-span in fully stiffened beams with a full-depth UHPC connection.

Connections mainly transfer a load from one beam to another through transverse shear, which drives adjacent beams to effectively have the same deflection. The connections also need to provide transverse flexural rigidity to resist transverse tensile forces due to eccentrically placed wheel loads and superimposed dead loads. The results of the transverse strain due to structural loading are presented here.

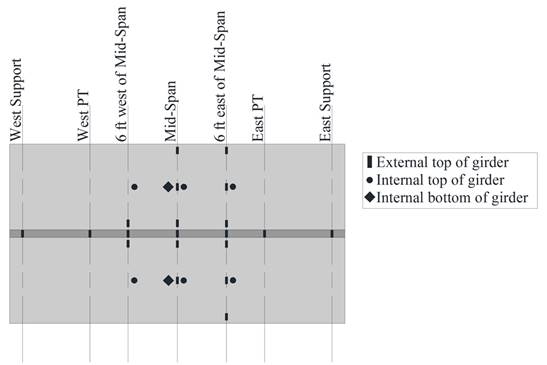

Figure 80 presents a reference for the transverse strain gauges used in this section. The simulated structural loading was intentionally placed 6 inches (152 mm) off the centerline of the beams (refer to figure 22 for the test setup) to increase the transverse tensile stress.

Source: FHWA.

1 ft = 0.305 m.

Figure 80. Illustration. Location of all possible transverse strain gauges in this study.

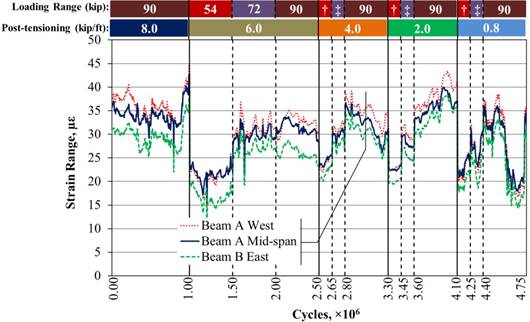

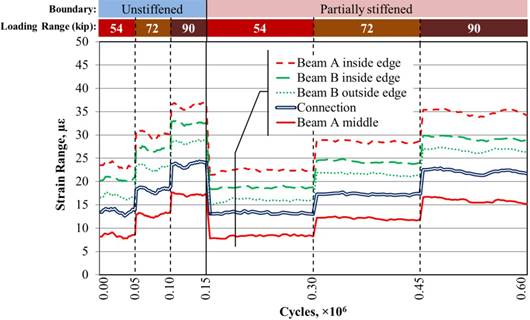

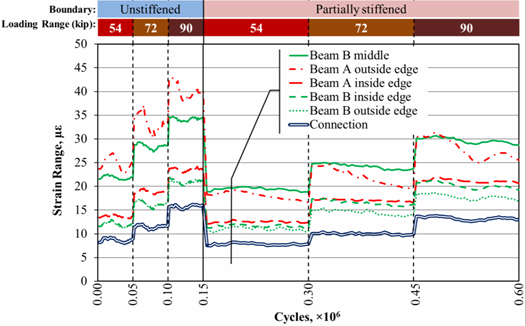

Figure 81 through figure 90 present the recorded transverse tensile strains for the uncracked partial-depth conventional grout and the partial- and full-depth UHPC connections. Specifically, figure 81 shows transverse strains measured by the embedded gauges for the simply supported partial-depth conventional grout connections. Some of the embedded strain gauges did not function properly during the tests; therefore, only those with valid data were reported. A transverse strain between 30 and 42 με was measured in beam A, while beam B had a transverse strain between 25 and 35 με in the 90-kip (400-kN) loading range. The beams were then loaded with the fully stiffened boundary condition. The transverse strain range is reported in figure 82 and figure 83. The stiffer boundary condition reduced the transverse tensile strain in the embedded strain gauges with values between 10 and 20 με in the 90-kip (400-kN) loading range. Surface tensile strain on the connection surface was similar to the embedded gauges in the beams.

Source: FHWA.

1 kip = 4.448 kN.

1 kip/ft = 14.59 kN/m.

† = 54-kip loading range.

‡ = 72-kip loading range.

Figure 81. Graph. Top transverse strain ranges recorded by internal strain gauges in two beams for unstiffened beams with a partial-depth uncracked conventionally grouted connection.

Source: FHWA.

1 kip = 4.448 kN.

1 kip/ft = 14.59 kN/m.

§ = 15,000 cycles at both the 54- and 72-kip loading ranges.

◊ = 90 kip loading range.

† = 54 kip loading range.

‡ = 72 kip loading range.

Figure 82. Graph. Top transverse strain ranges recorded at the mid-span for fully stiffened beams with a partial-depth uncracked conventionally grouted connection.

Source: FHWA.

1 kip = 4.448 kN.

1 kip/ft = 14.59 kN/m.

§ = 15,000 cycles at both the 54- and 72-kip loading ranges.

◊ = 90 kip loading range.

† = 54 kip loading range.

‡ = 72 kip loading range.

Figure 83. Graph. Top transverse strain ranges recorded 6 ft (1.8 m) east of the mid-span for fully stiffened beams with a partial-depth uncracked conventionally grouted connection.

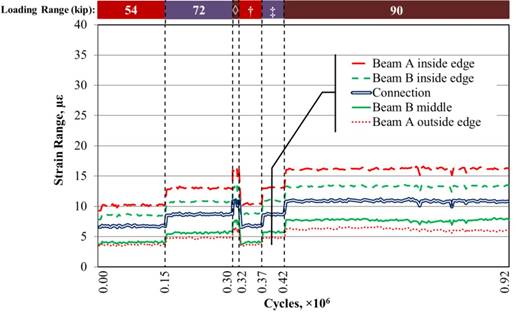

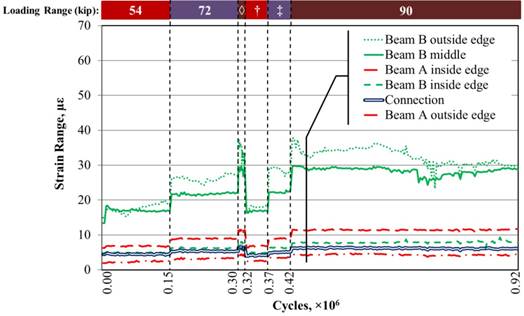

For the partial-depth UHPC connections, surface strain gauges were installed on the connection and the box beam surfaces at the mid-span and 6 ft (1.8 m) from the mid-span. More surface strain gauges were installed on the connection at transverse PT locations. The transverse tensile strain in the UHPC was generally less than or equal to 20 με, which was the same as with the conventional grouted connection. The results are presented in figure 84 through figure 86.

Source: FHWA.

1 kip = 4.448 kN.

Figure 84. Graph. Top transverse strain ranges recorded at the mid-span for partially and fully stiffened beams with a partial-depth uncracked UHPC connection.

Source: FHWA.

1 kip = 4.448 kN.

Figure 85. Graph. Top transverse strain ranges recorded 6 ft (1.8 m) east of the mid-span for partially and fully stiffened beams with a partial-depth uncracked UHPC connection.

Source: FHWA.

1 kip = 4.448 kN.

1 ft = 0.305 m.

Figure 86. Graph. Top transverse strain ranges recorded along the length of the connection for partially and fully stiffened beams with a partial-depth uncracked UHPC connection.

When the full-depth UHPC connection was tested, additional surface strain gauges were installed along the cross section at the same longitudinal locations on the beam. Not all of the strain gauges functioned properly; only those with valid data were reported in figure 87 through figure 90. The simply supported case showed the highest transverse tensile strain of all the cases studied. The strain gauges placed next to the connection usually had more transverse strain. The only exception was for the strain gauge located on the outside edge of the loaded beam 6 ft (1.8 m) from the mid-span, as shown in figure 88.

Source: FHWA.

1 kip = 4.448 kN.

Figure 87. Graph. Distribution of top transverse strain ranges recorded along the top of the unstiffened and partially stiffened beams with a full-depth uncracked UHPC connection at the mid-span.

Source: FHWA.

1 kip = 4.448 kN.

Figure 88. Graph. Top transverse strain ranges recorded along the top of unstiffened and partially stiffened beams with a full-depth uncracked UHPC connection 6 ft (1.8 m) from the mid-span.

Source: FHWA.

1 kip = 4.448 kN.

◊ = 90-kip loading range.

† = 54-kip loading range.

‡ = 72-kip loading range.

Figure 89. Graph. Top transverse strain ranges recorded along the top of fully stiffened beams with a full-depth uncracked UHPC connection at the mid-span.

Source: FHWA.

1 kip = 4.448 kN.

◊ = 90-kip loading range.

† = 54-kip loading range.

‡ = 72-kip loading range.

Figure 90. Graph. Top transverse strain ranges recorded along the top of fully stiffened beams with a full-depth uncracked UHPC connection 6 ft (1.8 m) east of the mid-span.

Independent of the connection design and boundary conditions, the transverse tensile strain generated by the structural loading was observed to be less than 40 με. If a maximum transverse tensile strain of 40 με in the box beam concrete close to the connection is assumed, the interface bond between the grout and box beam concrete should have enough strength to resist this strain. A 40-με deformation in a 6,000-psi (41-MPa) concrete produces a stress of approximately 150 psi (1 MPa).

Proper selection of a grout, a connection surface preparation technique, and curing methodology can mitigate interface cracking by ensuring that the tensile resistance of the connection is at least as strong as the precast concrete. It must be recognized that the early age dimensional stability of the grout is also important as shrinkage strains can be large, potentially resulting in cracking of the grout and interface debonding.

When a direct tensile force was applied to the UHPC connections, as demonstrated in figure 74, the box beam concrete cracked rather than the connection interface or the UHPC itself. This indicates that the interface bond between the UHPC and the box beam with an EA surface preparation and rebar in a non-contact lap splice is of similar or greater tensile strength as compared to the tensile strength of the box beam concrete. This was also observed in a study by De la Varga et al. where interface bond between different grout materials and concrete was investigated.(17) They found that, for connections with UHPC and EA, the failure primarily occurs in the concrete rather than at the interface or within UHPC itself. This is not true for conventional grout connections, as the interface often fails under the same conditions. Note that the discrete steel reinforcement that is distributed along the length of the UHPC connections provides further advantages in terms of increasing local shear and tensile strengths and limiting the crack width if any cracks should develop at the interface.