U.S. Department of Transportation

Federal Highway Administration

1200 New Jersey Avenue, SE

Washington, DC 20590

202-366-4000

Federal Highway Administration Research and Technology

Coordinating, Developing, and Delivering Highway Transportation Innovations

| REPORT |

| This report is an archived publication and may contain dated technical, contact, and link information |

|

| Publication Number: FHWA-HRT-17-093 Date: February 2018 |

Publication Number: FHWA-HRT-17-093 Date: February 2018 |

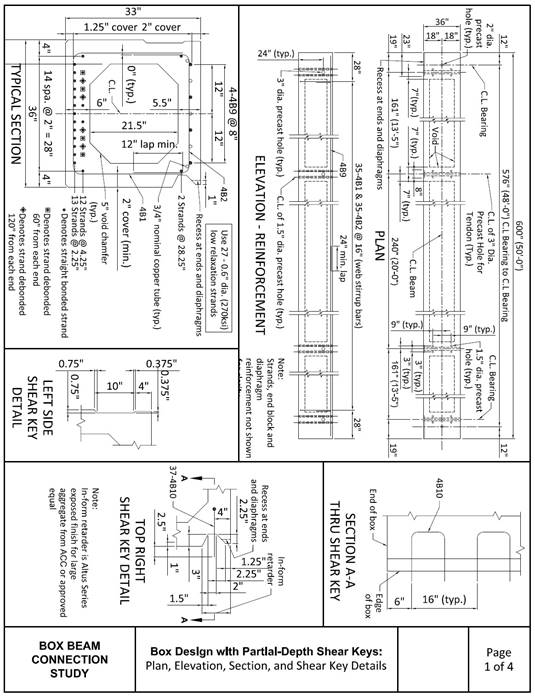

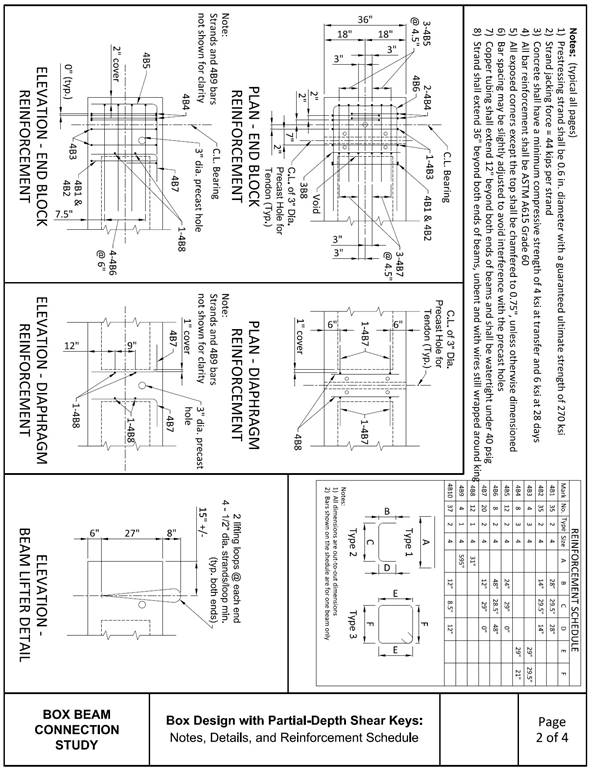

Drawings associated with the fabrication of the box beams are found in this appendix.

Source: FHWA.

1 inch = 25.4 mm.

Figure 113. Drawing. Box design with partial-depth shear keys showing plan, elevation, section, and shear key details.

Source: FHWA.

1 inch = 25.4 mm.

Figure 114. Drawing. Box design with partial-depth shear keys showing notes, details, and reinforcement schedule.