U.S. Department of Transportation

Federal Highway Administration

1200 New Jersey Avenue, SE

Washington, DC 20590

202-366-4000

Federal Highway Administration Research and Technology

Coordinating, Developing, and Delivering Highway Transportation Innovations

| REPORT |

| This report is an archived publication and may contain dated technical, contact, and link information |

|

| Publication Number: FHWA-HRT-12-023 Date: December 2012 |

Publication Number: FHWA-HRT-12-023 Date: December 2012 |

This chapter provides a practical example of how to apply the methodology resulting from this research to evaluate FWD load deflection data in network-level applications. At first, three large datasets were considered: the Illinois Tollway, the Maryland State Highway Administration (MDSHA), and Parks Highway in Alaska.

The majority of the Illinois Tollway system consists of composite pavements. Since no reliable model was found during this research for composite pavements due to the shortage of data, the analysis of the Illinois Tollway dataset was jeopardized. The effort to retrieve only sections for rigid and flexible pavements was significant and not efficient.

The Parks Highway in Alaska has a simple and straightforward dataset. The pavements were already managed using a statewide PMS. FWD data were available for use with the appropriate flexible pavement models. The State’s treatment decision matrix was based on roughness. However, there were significant limitations on the variety of available treatments. The Parks Highway, which is located between Anchorage and Fairbanks, AK, uses few alternative treatments, most of which consist of mill and fill or a thin overlay. The impact of introducing a decision matrix based on structural condition would have been minimal, since no alternative was available for preventive treatment in part due to the light traffic using the facility.

MDSHA has a pavement management system that is based on ride quality (i.e., IRI). It utilizes PMS software for network analysis, budget optimization, and pre- and post-processing. Deflection data are available at the project level. There are a variety of treatment options covering preventive M&R.

This chapter illustrates how to apply simplified deflection techniques for structural analysis in network-level applications. The example uses the available dataset retrieved from MDSHA's PMS.

The objective of a pavement design is to provide a structure that will exhibit adequate structural performance throughout its design life. It is expected that the structural condition affects the rate the pavement deteriorates over time. By definition, a given pavement structure has acceptable performance if distress levels do not exceed their threshold values during a period of time (e.g., fatigue cracking not to exceed 25 percent of the total area within the first 15 years of service).

Logistic models describe the probability of an event being acceptable or unacceptable as a function of a predictor variable. Therefore, they can be used to establish a link between performance and structural condition by modeling the probability of acceptable performance using measurements of deflections or parameters (techniques) computed from deflection basins. The goal of the proposed stochastic approach is to use the probability density function from the logistic model to obtain insightful information about the pavement structural condition required to achieve the desired performance during a desirable (design) period of time. This new PMS-based knowledge can then be used to define strategic treatments (maintenance or rehabilitation) to be used in the PMS optimization process.

A typical logistic model probability function is described in chapter 4 of this report (see figure 25). It describes the likelihood of the pavement section exhibiting acceptable performance of a particular distress as a function of a given deflection parameter, named "predictor variable X." In this example, the cutoff value was determined from the ROC curve and plotted.

In the stochastic approach, the probability density function is used to determine the thresholds that define structural condition. By definition, the cutoff value in a logistic model determines how to convert the continuous probability prediction as a dichotomous outcome (i.e., predicted probabilities above the threshold are defined as acceptable, while others are defined as unacceptable). In addition to the cutoff threshold, other values can be used to define further details about the structural condition. For example, figure 25 describes a second threshold created at the 0.4 probability level, and it is used to separate sections with fair structural condition from poor ones. (Note that this definition is arbitrary and can be adjusted to better fit an agency’s rehabilitation practices or network characteristics.)

Once thresholds and their respective deflection parameters are identified, a structural decision matrix (also referred to as a structural rehabilitation matrix) can be generated. Table 7 shows an example of structural decision matrix obtained from the probability density function in figure 25.

MDSHA is responsible for managing approximately 17,000 lane-mi (27,370 lane-km) of roadways (about 11,000 directional-mi (17,710 directional-km) or some 22,000 centerline-mi (35,420 centerline-km)). The budget for the Pavement System Preservation Program is between $150 million and $190 million per year, and it covers the maintenance and improvement of MDSHA’s pavement network. The network is divided into three regions: Mountain, Central, and Coastal. Among these, there are seven engineering districts, three rural districts, and four urban districts. The Pavement Management Division is responsible for the network-level data collection, analysis, and budget optimization through the PMS. The outcome of the budget optimization is typically the selection of sections for M&R. The Pavement and Geotechnical Division is responsible for project-level data collection, pavement design, and analysis after candidate projects are identified for M&R. These projects are assigned to the respective districts, and the districts are responsible for construction bids, quality control, and acceptance.

Flexible pavements correspond to 61 percent of MDSHA's network, rigid pavements correspond to 2 percent of the network, and the remaining 37 percent are composite pavements.

The MDSHA PMS is constructed on an Oracle® database platform, and it is supported by the RoadcareTM software. RoadcareTM is responsible for data management, inputs, analysis, and outputs. (31)

The performance of MDSHA's pavement network is monitored annually. Each year, pavement ride quality, rutting, and friction conditions are recorded in the outside lane of both directions of travel for the majority of mainline roadways in Maryland. A video record of the pavement surface and right-of-way is also captured every year. This information (with the exception of friction data) is collected at highway speeds using an Automatic Road Analyzer testing device. Friction condition is tested with the pavement friction tester. MDSHA collects IRI, cracking, and friction data on about 95 percent of the entire pavement network.

Data are collected at 0.1-mi (0.161-km) intervals. After data collection, quality control is performed, and data are processed and entered into the MDSHA’s PMS, along with traffic data and structure (mainly changes in structure due to annual M&R). The PMS uses homogenous segments based on region, traffic level, pavement type, M&R treatments, and pavement condition. The identification of homogeneous segments is the first step in the analysis process and precludes all budget optimizations. MDSHA uses the FHWA classification based on IRI to identify the pavement condition qualitatively, as described in table 40.

Table 40. MDSHA pavement classification based on IRI values

| Pavement Classification | IRI Values (inches/mi) |

|---|---|

Very good |

< 60 |

Good |

60-94 |

Fair |

95-170 |

Mediocre |

171-220 |

Poor |

> 220 |

| 1 inch = 25.4 mm 1 mi = 1.61 km |

|

MDSHA uses two preventive and four corrective treatment options for its flexible, concrete, and composite pavements. These treatments are currently assigned based on the age, pavement condition, and history of previously applied treatments. The 2-year maintenance and 4-year preventive maintenance strategies are labeled M2 and M4, respectively. The corrective treatments are classified as T5, T8, T12, and T15 based on the expected service life of the treatment-5, 8, 12, and 15 years, respectively.

Expected service life is assigned for every treatment. This is a crucial step in the development of the treatment decision matrix. It defines the years before any treatment can be applied to a specific road section after the M&R has been carried out. In addition, it also defines the years before the same treatment can be applied on the same section. The last caveat is important to prevent the optimization algorithm to be locked in just one treatment over long analysis periods.

The last step in the development of the decision matrix is the assignment of expected improvement in ride quality (i.e., IRI). MDSHA refers to this as "proposed consequences." The expected improvement in IRI is considered in the year immediately after the treatment is applied. LTPP's Results of Long-Term Pavement Performance SPS-3 Analysis: Preventive Maintenance of Flexible Pavements study, along with the analysis of historical data in the MDSHA PMS, provides guidance for defining the proposed consequences.(32)

The complete treatment decision matrix is depicted in table 41. The range for the decrease in IRI after treatment reflects the variation expected in ride quality improvement as a function of pavement surface condition prior to treatment. Pavements in worse condition than others are likely to have a higher percentage improvement in IRI.

Costs are associated with each treatment reported in table 41. These costs are calculated based on road class, pavement type, distress level (IRI), and the region/district the section is located. The budget optimization takes these costs into consideration and uses the expected decrease in IRI values as benefit. The expected span between treatments is used to estimate service life and to program future M&R measures.

The complete treatment decision matrix is depicted in table 41. The range for the decrease in IRI after treatment reflects the variation expected in ride quality improvement as a function of pavement surface condition prior to treatment. Pavements in worse condition than others are likely to have a higher percentage improvement in IRI.

Costs are associated with each treatment reported in table 41. These costs are calculated based on road class, pavement type, distress level (IRI), and the region/district the section is located. The budget optimization takes these costs into consideration and uses the expected decrease in IRI values as benefit. The expected span between treatments is used to estimate service life and to program future M&R measures.

Table 41. MDSHA PMS treatment decision matrix

| Treatment Type | Treatment Code | Typical Treatment | Expected Span Between Treatments (years) | Decrease in IRI After Treatment (percent) | |

|---|---|---|---|---|---|

| Preventive | Corrective | ||||

Preventive |

M2 |

Fog seal |

2 |

2 |

2 |

Crack sealing |

|||||

M4 |

Slurry seal |

2 |

4 |

5 |

|

Microsurfacing |

|||||

Preventive/ |

T5 |

In-place recycling |

4 |

5 |

8-14 |

Thin overlay |

|||||

Corrective |

T8 |

Thin overlay |

5 |

8 |

16-23 |

Mill/level and recycled |

|||||

Asphalt pavement overlay |

|||||

T12 |

Thin overlay |

6 |

10 |

17-27 |

|

Mill/level and recycled |

|||||

Asphalt pavement overlay |

|||||

T15 |

Mill/level and asphalt overlay |

7 |

12 |

33-55 |

|

The MDHSHA PMS does not currently use deflection data for performance analysis or budget optimization. Network-level deflection surveys were not available. The alternative was to select sections that have been identified as targets for rehabilitation projects but where construction has not begun. In these cases, a complete project-level survey is conducted with FWD deflection testing performed at 0.1-mi (0.161-km) intervals.

In total, 50 sections were selected for this example where sufficient data were available, and the average length was 1.8 mi (2.90 km). The total lane-miles only corresponded to around 1 percent of the entire network. Additionally, 10 different districts were represented, and only flexible pavements were considered. Detailed descriptions of each site are provided in appendix F, including location, road class, thickness, traffic, and deflections. A summary of the sample statistics is provided in table 42 and table 43.

Table 42. Summary statistics of MDSHA sections used in the example.

| Statistics | Average | Standard Deviation | Minimum | Maximum |

|---|---|---|---|---|

AC thickness (inches) |

7.6 |

3.96 |

1.0 |

18.5 |

Total thickness (inches) |

15.8 |

3.83 |

10.0 |

25.5 |

AADTT |

1,322.4 |

1,562.51 |

12.5 |

6,373.5 |

Volume of class 5 (number of vehicles) |

439 |

423 |

7 |

1,748 |

Volume of class 9 (number of vehicles) |

425 |

700 |

1 |

2,520 |

| 1 inch = 25.4 mm | ||||

| Road Class | Distribution (percent) |

|---|---|

Rural interstate |

10 |

Urban interstate |

6 |

Rural principal |

8 |

Urban principal |

6 |

Rural collector |

72 |

Incorporation of Structural Analysis on MDSHA PMS

For this example, a new subset of the PMS database was created containing only sections identified in the sample. Since the sample size was only 1 percent of the total lane-miles in the State, the PMS simulation was carried out on 1 percent of the annual cost allocation for MDSHA pavement M&R program. In 2010, this value was $177 million. Therefore, the budget scenario for this example was assumed to be $1.7 million per year.

The analysis period was defined as 25 years, which is a typical period of time for an MDSHA optimization and budget study. 2007 was set as the initial year for this analysis, the earliest in which deflection data were available.

The analysis process consisted of performing the typical functional evaluation and budget optimization process, considering the functional decision matrix already in use and based on IRI performance alone. After the selection of treatments was generated, the structural analysis was incorporated as an extra data element. The following steps were taken as part of the incorporation of structural analysis on MDSHA PMS as an example to this project:

Two logistic models were used; one was based on roughness performance and one was based on rutting. These two models are shown in table 21 and figure 30 for roughness and table 22 and figure 34 for rutting. Table 44 describes the structural decision matrix adopted for this example. Each section was evaluated, and the structural condition was assessed based on the model constants shown in table 45.

Table 44. Structural decision matrix based on roughness and rutting performance.

| Structural Condition | Probability of Acceptable Performance | |

|---|---|---|

| Roughness | Rutting | |

Good |

> 0.812 |

> 0.792 |

Fair |

0.812-0.406 |

0.792-0.396 |

Poor |

< 0.406 |

< 0.396 |

The next step is the comparison between the usual solution generated by the functional analysis only and the need for structural improvement. To simplify this comparison, table 45 was created to help identify where there was disagreement between the solution proposed based on functional analysis and the structural need of the pavement. For purposes of this example, table 45 was created based on engineering best judgment and adaptation to MDSHA current treatment options.

|

Table 45. Adjustment of MDSHA treatment option based on structural analysis

| |||||||||||||||||||||||||||||||||||

Results of the Analysis Without Structural Component

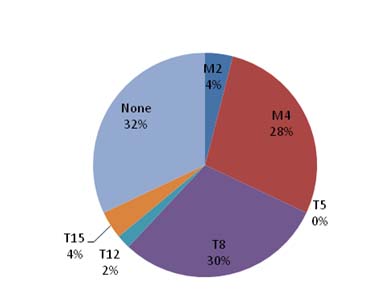

The results of the analysis without a structural component were provided at the end of step 3 mentioned above. The majority of sections were identified as in need of some type of treatment within the 25-year analysis period. Figure 64 illustrates the distribution of sections by prescribed treatment. Only the first treatment for each section in the analysis period was considered. The average year for the first treatment was 2011 (4 years after the initial year).

In total, 32 percent of the sections were prescribed preventive treatment, 36 percent were prescribed corrective treatment, and 32 percent did not require any treatment. Improvements on the network sample were calculated in terms of improvement in service life and ride quality (i.e., a decrease in IRI). The expected increase in interval between treatments averaged 2.4 years. Additionally, the IRI values were expected to decrease by 6.9 percent between the first and second predicted intervention times.

Figure 64. Graph. Distribution of prescribed treatment for the first intervention.

Results of the Simulation With Structural Component

The decision of when to apply a treatment in a pavement section is part of the budget optimization process. In this analysis with a structural component, it was assumed for simplicity that the year the alternative is recommended remained as defined by the previous functional analysis (based on IRI) alone. In other words, the structural analysis did not define or modify when M&R is planned. Therefore, the new analysis could be carried out without the need to modify the PMS algorithm.

Two logistic structural models were used in this example: roughness and rutting. The models were used to compute the probabilities of acceptable performance based on FWD load deflection parameters. Table 44 was used to qualitatively assess pavement structural condition. Based on this assessment and in conjunction with the prescribed treatment already defined based on the previous functional analysis, table 45 was used to adjust the treatments to incorporate the expected structural needs of each candidate pavement section.

After the conclusion of the analysis, improvements to the network were recomputed to reflect the new selection of treatments. Table 46 combines the results from the optimization with a structural analysis component and the previous results from the optimization without a structural analysis (labeled MDSHA).

The incorporation of the new structural analysis changed the outcome of prescribed treatments in about 60 percent of the sections. The majority of changes happened to sections that initially did not have any prescribed treatment. In these cases, the majority received preventive treatments. The percentage of corrective cases remained the same when the structural analysis was associated with roughness performance. In the cases association with rutting performance, there was a drop in corrective cases. These results agree with the expected outcome. Pavements in MDSHA’s network are more likely to fail due to roughness. Rutting is not a major problem in most of the State’s highways. The structural analysis reflected this particular characteristic of MDSHA's network.

The new allocation of treatments obtained from the structural analysis provided greater improvement in ride quality. On average, about 10 percent improvement in IRI was expected when the optimization was done with a structural analysis for roughness, compared with 6.9 percent when it was only a functional optimization and 7.4 percent for when it was with structural analysis for rutting.

The interval between treatments also increased. The previous functional analysis had an expected increase of 2.1 years in the period between treatments. The incorporation of a structural analysis in the optimization results expanded this period by some 60 percent to a total of 3.4 years (structural analysis based on roughness) and by 33.7 percent to a total of 2.9 years (structural analysis based on rutting).

Table 46. Results from the PMS optimization considering the structural analysis.

| Results | MDSHA | Optimization with Structural Analysis | |

|---|---|---|---|

| Roughness | Rutting | ||

Preventive cases (percent) |

32.0 |

64.0 |

78.0 |

Corrective cases (percent) |

36.0 |

36.0 |

14.0 |

Solutions modified by structural analysis (percent) |

N/A |

60.0 |

68.0 |

Improvement in IRI (percent) |

6.9 |

10.0 |

7.4 |

Expected average increase in interval between treatments (years) |

2.1 |

3.4 |

2.9 |

Improvement in expected average increase in interval between treatments, compared to MDSHA (percent) |

N/A |

60.6 |

33.7 |

| N/A = not available. | |||

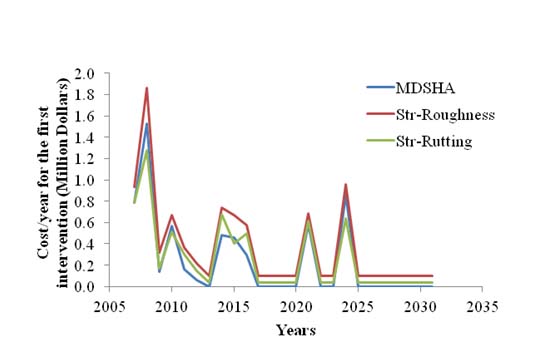

Cost Implications

The incorporation of structural analysis on the PMS optimization had an impact on the budget. Since the objective was not to perform a comprehensive budget analysis, some assumptions were made to simplify the process shown in this example.

There was no change in year allocated for treatments. Optimization prior to the structural analysis provided the year for any given treatment. In other words, the analysis considering the structural condition did not change the year associated with the first prescribed treatment in the analysis period.

The cost of treating sections without an assigned year was evenly spread across the 25-year analysis period. This reflects directly on sections that did not have any treatment assigned by the functional analysis, most likely due to budget constraints and cost/benefit analysis. However, during the structural analysis, some of these sections needed structural improvement. Without an assigned year, the extra cost of maintaining these sections was evenly distributed over the analysis period.

The cost analysis only reflected the first treatment prescribed to the section during the analysis period. Preventive treatments are common practice at MDSHA. Its PMS reflects this characteristic by incorporating preventive treatments to extend the service life of the pavement. Subsequent maintenance alternatives (M2 and M4 in table 41) were often predicted throughout the analysis period. The costs of subsequent maintenance efforts were not incorporated in this example’s cost analysis. The monetary values were not correct by any rate during the analysis period. Figure 65 provides an overview of cost allocation for the first treatment throughout the analysis period.

Figure 65. Graph. Cost distribution over the analysis period.

Table 47 provides a summary of differences observed in the budget. The total cost of all first interventions was $5.9 million for the optimization without structural analysis. The incorporation of structural analysis increased the budget by 59 percent to a total of $9.4 million (roughness model) and by 10.6 percent to a total of $6.5 million (rutting model). While these numbers may seem surprising, there is a considerable amount of new mileage being treated. Only 53.6 mi (86.3 kg) from the original 88.7 mi (142.8 kg) in the sample network were prescribed treatment when the current MDSHA PMS was used. Some treatment was prescribed to all sections when the structural model based on roughness was incorporated and to 79.5 mi (127.9 km) if the model was based on rutting.

Table 47. Impact on costs from the PMS optimization considering the structural analysis.

| Results | MDSHA | Optimization with Structural Analysis | |

|---|---|---|---|

Roughness |

Rutting |

||

Total cost ($ in millions) |

5.9 |

9.4 |

6.5 |

Cost difference (percent) |

69.5 |

59.4 |

10.6 |

Mileage treated |

53.6 |

88.7 |

79.5 |

Cost/mile ($ in thousands) |

110.4 |

106.3 |

82.3 |

The benefit of including the structural component in the PMS can be observed when cost per mile is compared between all three alternatives (see table 47). The cost/mile for the MDSHA PMS was $110,000/1 mi (1.61 km). After incorporating the structural component, the cost/mile reduced by 4 percent to $106,000/1 mi (1.61 km) (roughness model) and 25 percent to $82,000/1 mi (1.61 km) (rutting model). The association of these numbers with the improvements in service life and ride quality and the overall impact of including the structural analysis in the PMS is encouraging.

The incorporation of structural analysis provided a new dimension in the prediction of performance and prescribed treatments to mitigate ride quality and structural deterioration of the pavement network. The process is simple and can be easily incorporated in existing PMS. An algorithm can be written to include the structural analysis as part of the optimization routine, or it can be done externally, like in the example based on the sample from MDSHA PMS.

Two structural models were tested. In this particular example, the scenario in which the structural model was based on roughness was the critical example. Roughness is the most common performance indicator driving the need for M&R in MDSHA's network.

The incorporation of the new structural analysis changed the outcome of prescribed treatments on about 60 percent of the sections. Sections that initially did not have any prescribed treatment received preventive treatments. Preventive maintenance is key to an effective level of service in any pavement network. The identification of segments where early structural failure is likely to happen helps mitigate them through early preventive maintenance. As a consequence, more M&R can be done with the same budget level and the backlog of pavement repairs can be reduced.

The new allocation of treatments obtained from the structural analysis provided greater improvement in ride quality. On average, about 10 percent improvement in IRI was expected when the optimization was done with a structural analysis for roughness, compared with 6.9 percent when it was only a functional optimization.

The interval between treatments also increased. The previous functional analysis had an expected increase of 2.1 years in the period between treatments. The incorporation of a structural analysis in the optimization results expanded this period by some 60 percent to a total of 3.4 years (structural analysis based on roughness) and by 33.7 percent to a total of 2.9 years (structural analysis based on rutting).

There was a clear impact on budget allocation, which could be better adjusted if the optimization process was repeated with the new treatments. However, even without a new optimization, the benefits outlast the costs. There was a nominal increase in cost of 50 percent, considering the critical scenario. At the same time, there was a significant change in the improvements expected from the new M&R scenario based on the structural analysis. A 44 percent increase in expected ride quality performance and a 60 percent increase are expected in interval between treatments. Overall, the consideration of structural condition in the network-level analysis improved performance, minimized maintenance, and reduced the M&R costs per mile.