U.S. Department of Transportation

Federal Highway Administration

1200 New Jersey Avenue, SE

Washington, DC 20590

202-366-4000

Federal Highway Administration Research and Technology

Coordinating, Developing, and Delivering Highway Transportation Innovations

| REPORT |

| This report is an archived publication and may contain dated technical, contact, and link information |

|

| Publication Number: FHWA-HRT-14-088 Date: March 2015 |

Publication Number: FHWA-HRT-14-088 Date: March 2015 |

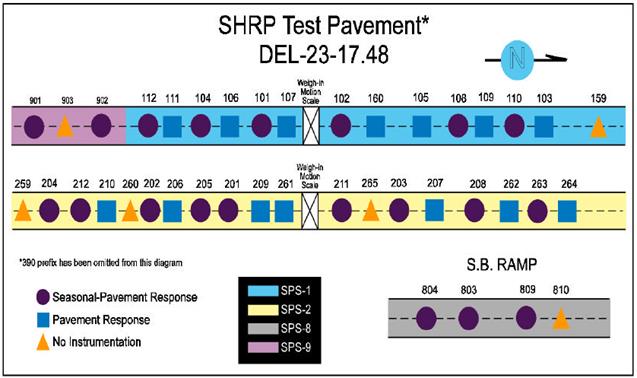

The Long-Term Pavement Performance (LTPP) program conducted an internal review of the dynamic load response (DLR) data collected in 1996-1997 from Route US-23 in Delaware County north of Columbus, OH. Figure 1 shows the layout of the Strategic Highway Research Program (SHRP) test pavement for Specific Pavement Studies (SPS).(7) Forty test sections were constructed by the Ohio Department of Transportation on 3.5 mi of US-23. The test sections encompassed the SPS-1, SPS-2, SPS-8, and SPS-9 experiments. This study focused on the DLR data collected on Ohio SPS-1 (asphalt concrete (AC)) and SPS-2 (portland cement concrete (PCC)) test sections.

Figure 1. Illustration. SHRP test pavement layout (7)

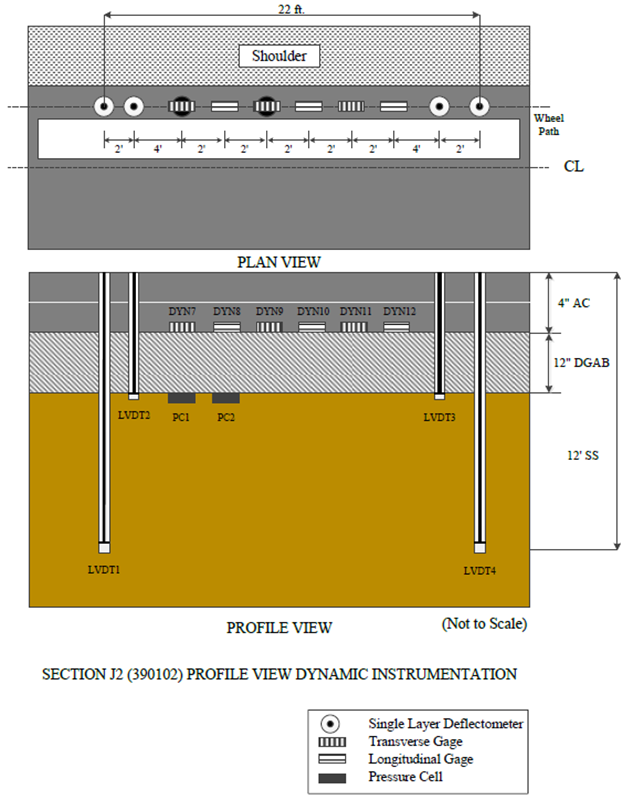

Figure 2 shows the instrumentation layout in plan and profile views as well as the pavement layer structure in profile view for Ohio SPS-1 test section 390102. The instrumentation consisted of strain gauges (transverse and longitudinal), linear variable differential transformers (LVDTs), and pressure cell (PC) sensors. In the plan view, the LVDTs are capped with a single-layer deflectometer. The sensors were deployed on the defined right wheelpath, which was 30 inches from the right pavement edge. A total of 12 sensors were deployed on test section 390102: 4 LVDTs (LVDT1 through LVDT4), 2 PCs (PC1 and PC2), and 6 strain gauges (Dyn7 through Dyn12).

Figure 2. Illustration. Ohio SPS-1 test section 390102 sensor layout

Each of the other SPS-1 test sections (390104, 390108, and 390110) had a total of nine strain gauge sensors, Dyn10 through Dyn18 (see appendix A). The number of LVDTs and PCs for those sections were the same as for test section 390102.

The profile view in figure 2 shows that Dyn7, Dyn9, and Dyn11 were buried in the transverse direction, whereas Dyn8, Dyn10, and Dyn12 were buried in the longitudinal direction. The trace pattern for a strain gauge sensor is contingent on the direction in which the sensor is laid. If a strain gauge is buried in the transverse direction, then the sensor would only display peaks (compressive strains) but not valleys (tensile strains) in a raw trace. In contrast, if a strain gauge is buried in the longitudinal direction, it would display both peaks and valleys in a raw trace.

In terms of sensor locations, the metrics for the SPS-1 (AC) test sections are as follows: X_AC is the distance along the direction of traffic as referenced from the start of the southernmost first LVDT gauge in the section; Y_AC is the distance from the shoulder joint as referenced from the start of the southernmost first LVDT gauge in the section; and Z is the distance from the pavement surface to the measurement point of the sensor. (Sensor layouts of Ohio SPS-1 test sections 390102, 390104, 390108, and 390110 are shown in figure 2 and figure 25 through figure 27.)

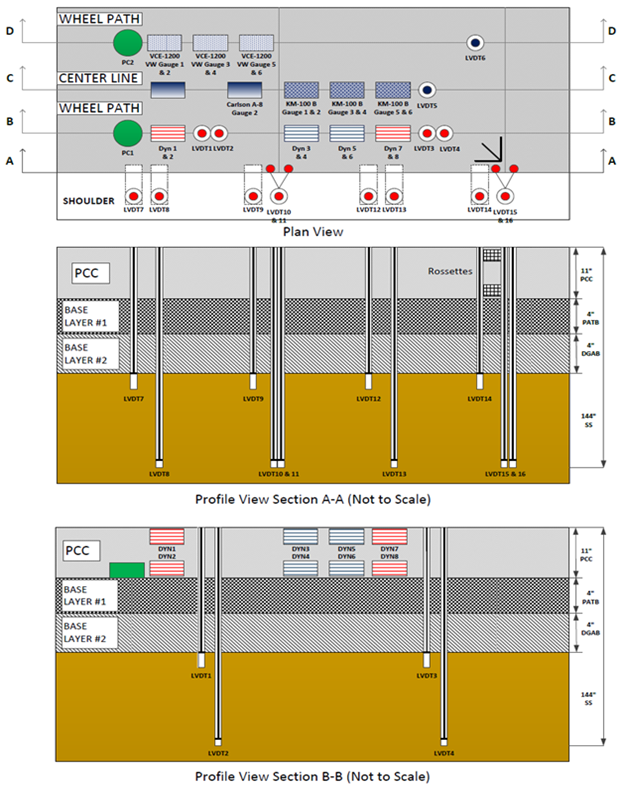

Figure 3 shows the instrumentation layout in plan and profile view as well as the pavement layer structure in profile view for Ohio SPS-2 test section 390212. The instrumentation consisted of strain gauges (Dynatest®), LVDTs, PCs, rossettes PMR-60, KM-100B gauges, Carlson A-8 gauges, and VCE-1200 VW gauges. The raw DLR traces for Ohio SPS-2 test jobs show time history data only for strain gauge and LVDT sensors; recorded time history data do not exist for the other sensors. A total of 16 LVDTs (LVDT1 through LVDT16) and 8 strain gauges (Dyn1 through Dyn8) were deployed on SPS-2 test sections. Test sections 390201, 390205, and 390208 had similar sensor instrumentation to that of test section 390212.

In terms of sensor locations, the metrics for the SPS-2 (PCC) test sections are as follows: X is the distance in millimeters along the direction of traffic as referenced from the entry slab corner; Y is the distance in millimeters from the shoulder joint as referenced from the entry slab corner; and Z is the distance in millimeters from the pavement surface to the measurement point of the sensor. (Sensor layouts of Ohio SPS-2 test sections 390201, 390205, 390208, and 390212 are shown in figure 50, figure 53, figure 60, and figure 67 in appendix C.)

Figure 3. Illustration. Ohio SPS-2 test section 390212 sensor layout

Since the completion of the Ohio SHRP test site in 1996, nine series of controlled vehicle tests have been conducted to monitor DLR under known vehicle parameters and environmental conditions. For the SPS-1 test sections, a series II test truck with a single or tandem rear axle was used in different tests (i.e., one rear axle configuration with load parameters was used in each test job). For the SPS-2 (PCC) test sections, series II and IV test trucks (each of which had a single or tandem rear axle configuration) were used in different test runs (i.e., within one test job, one test run used a single rear axle test truck, while the other test run used a tandem rear axle test truck).

Appendices A through E in this report show the sensor layouts in the Ohio SPS-1 and SPS-2 DLR test sections as well as the results, both numerically and in color-coded graphic form, of the 23 Ohio SPS-1 DLR test jobs and the 24 Ohio SPS-2 DLR test jobs.