U.S. Department of Transportation

Federal Highway Administration

1200 New Jersey Avenue, SE

Washington, DC 20590

202-366-4000

Federal Highway Administration Research and Technology

Coordinating, Developing, and Delivering Highway Transportation Innovations

| REPORT |

| This report is an archived publication and may contain dated technical, contact, and link information |

|

| Publication Number: FHWA-HRT-15-036 Date: December 2015 |

Publication Number: FHWA-HRT-15-036 Date: December 2015 |

This chapter provides a review of the procedures for post-processing the results and determining their accuracy as well as the CPTs used to store the backcalculated elastic layer moduli and other data.

As stated in chapter 4, the deflection data were obtained from SDR 27.0 and included data from all LTPP test sections and all days of deflection testing. The dataset contained both GPS and SPS experimental sections and represented all pavement design alternatives included in the LTPP database.

There were a total of 7,771 test days, of which 4,534 sections had an HMA surface, and 2,237 sections had a PCC surface. All LTPP sections were grouped by State code, Strategic Highway Research Program (SHRP) ID, and construction number to facilitate the pre-processing described in chapter 4.

The number of sections by each LTPP experiment included 1,744 sections with an HMA surface and 1,008 sections with a PCC surface. The surface type changed in 381 of the test sections. For example, a JPCP with a PCC surface that was eventually overlaid with HMA was counted in two categories or experiments. Therefore, there were a total of 3,133 unique sections in all States combined, as listed in table 9. Table 10 lists the total number of deflection basins and those basins falling within each of the four categories. As shown, the LTPP quality control processes have resulted in nearly 97 percent of the basins falling within the typical and type 2 categories, which the authors consider excellent. As such, 5,847,770 deflection basins (typical and type 2) were used in the backcalculation process.

The number of deflection basins analyzed and included in the backcalculation process are listed in table 11. The table also lists the percentage of deflection basins that were found to be acceptable after the initial evaluation with EVERCALC© using an expanded range of the upper and lower modulus limits and for the final results. As shown, about 75 percent of all deflection basins were considered acceptable after the second phase analysis and defined as accept or atypical, while about 85 percent of the deflection basins resulted in acceptable values from EVERCALC© and MODCOMP©.

Table 12 lists the percentage of deflection basins defined as acceptable on a State-by-State basis. The percentage of acceptable deflection basins increased to about 85 percent after the fourth phase analysis using MODCOMP© for those basins considered unacceptable from the second and third phase analyses. Table 13 summarizes the percentage of deflection basins defined as acceptable on a State-by-State basis for the PCC-surfaced pavements from the best fit method.

| HMA Surface | PCC Surface | ||

|---|---|---|---|

| LTPP Experiment | Number of Sections | LTPP Experiment | Number of Sections |

| GPS 1 | 233 | GPS 3 | 133 |

| GPS 2 | 145 | GPS 4 | 69 |

| GPS 6A | 63 | GPS 5 | 85 |

| GPS 6B | 131 | GPS 9 | 26 |

| GPS 6C | 31 | SPS 1 | 1 |

| GPS 6D | 24 | SPS 2 | 205 |

| GPS 6S | 162 | SPS 4 | 220 |

| GPS 7A | 35 | SPS 6 | 170 |

| GPS 7B | 56 | SPS 7 | 39 |

| GPS 7C | 18 | SPS 8 | 16 |

| GPS 7D | 3 | SPS 9C | 7 |

| GPS 7F | 3 | SPS 9J | 37 |

| GPS 7S | 27 | ||

| SPS 1 | 245 | ||

| SPS 2 | 2 | ||

| SPS 3 | 445 | ||

| SPS 5 | 204 | ||

| SPS 6 | 123 | ||

| SPS 7 | 1 | ||

| SPS 8 | 37 | ||

| SPS 9C | 7 | ||

| SPS 9J | 38 | ||

| SPS 9N | 50 | ||

| SPS 9O | 42 | ||

| Total GPS sections | 931 | Total GPS sections | 313 |

| Total SPS sections | 1,194 | Total SPS sections | 695 |

| Grand Total | 2,125 | Grand Total | 1,008 |

Note: Blank cells indicate no additional LTPP experiment within the pavement type.

| State/ Canadian Province/ Territory | Number of Drops | Percentage of Total Drops | Percentage of Typical and Type 2 | |||||||

|---|---|---|---|---|---|---|---|---|---|---|

| Type 1 | Type 2 | Type 3 | Typical | Total | Type 1 | Type 2 | Type 3 | Typical | ||

| AL | 593 | 56,826 | 3,326 | 150,435 | 211,180 | 0.28 | 26.91 | 1.57 | 71.24 | 98.14 |

| AK | 8 | 6703 | 20 | 17,856 | 24,587 | 0.03 | 27.26 | 0.08 | 72.62 | 99.89 |

| AZ | 982 | 117,565 | 5,720 | 253,549 | 377,816 | 0.26 | 31.12 | 1.51 | 67.11 | 98.23 |

| AR | 1,221 | 33,772 | 6,271 | 44,550 | 85,814 | 1.42 | 39.35 | 7.31 | 51.91 | 91.27 |

| CA | 2,566 | 72,207 | 5,384 | 129,688 | 209,845 | 1.22 | 34.41 | 2.57 | 61.80 | 96.21 |

| CO | 590 | 40,960 | 1,671 | 89,608 | 132,829 | 0.44 | 30.84 | 1.26 | 67.46 | 98.30 |

| CT | 87 | 13,727 | 1,350 | 43,544 | 58,708 | 0.15 | 23.38 | 2.30 | 74.17 | 97.55 |

| DE | 231 | 23,371 | 1,437 | 41,918 | 66,957 | 0.34 | 34.90 | 2.15 | 62.60 | 97.51 |

| DC | 0 | 311 | 2 | 711 | 1,024 | 0.00 | 30.37 | 0.20 | 69.43 | 99.80 |

| FL | 319 | 33,062 | 6,038 | 102,937 | 142,356 | 0.22 | 23.22 | 4.24 | 72.31 | 95.53 |

| GA | 813 | 53,464 | 7,195 | 99,894 | 161,366 | 0.50 | 33.13 | 4.46 | 61.91 | 95.04 |

| HI | 1 | 4,768 | 58 | 11,328 | 16,155 | 0.01 | 29.51 | 0.36 | 70.12 | 99.63 |

| ID | 2,104 | 35,038 | 1,321 | 45,974 | 84,437 | 2.49 | 41.50 | 1.56 | 54.45 | 95.94 |

| IL | 1,804 | 42,460 | 7,052 | 43,692 | 95,008 | 1.90 | 44.69 | 7.42 | 45.99 | 90.68 |

| IN | 1,384 | 56,244 | 13,013 | 54,283 | 124,924 | 1.11 | 45.02 | 10.42 | 43.45 | 88.48 |

| IA | 2,117 | 43,359 | 6,820 | 52,852 | 105,148 | 2.01 | 41.24 | 6.49 | 50.26 | 91.50 |

| KS | 2,122 | 47,191 | 3,343 | 80,159 | 132,815 | 1.60 | 35.53 | 2.52 | 60.35 | 95.89 |

| KY | 150 | 8,066 | 685 | 16,291 | 25,192 | 0.60 | 32.02 | 2.72 | 64.67 | 96.69 |

| LA | 242 | 7,165 | 1,241 | 10,932 | 19,580 | 1.24 | 36.59 | 6.34 | 55.83 | 92.43 |

| ME | 584 | 17,903 | 2,770 | 63,596 | 84,853 | 0.69 | 21.10 | 3.26 | 74.95 | 96.05 |

| MD | 300 | 44,640 | 2,009 | 61,514 | 108,463 | 0.28 | 41.16 | 1.85 | 56.71 | 97.87 |

| MA | 55 | 6,993 | 247 | 40,637 | 47,932 | 0.11 | 14.59 | 0.52 | 84.78 | 99.37 |

| MI | 775 | 27,481 | 3,224 | 66,084 | 97,564 | 0.79 | 28.17 | 3.30 | 67.73 | 95.90 |

| MN | 1,502 | 67,018 | 6,828 | 198,733 | 274,081 | 0.55 | 24.45 | 2.49 | 72.51 | 96.96 |

| MS | 615 | 42,521 | 1,112 | 101,452 | 145,700 | 0.42 | 29.18 | 0.76 | 69.63 | 98.81 |

| MO | 1,467 | 49,275 | 3,194 | 76,189 | 130,125 | 1.13 | 37.87 | 2.45 | 58.55 | 96.42 |

| MT | 455 | 38,957 | 2,782 | 139,478 | 181,672 | 0.25 | 21.44 | 1.53 | 76.77 | 98.22 |

| NE | 1,317 | 25,403 | 1,562 | 73,746 | 102,028 | 1.29 | 24.90 | 1.53 | 72.28 | 97.18 |

| NV | 1,403 | 27,078 | 894 | 75,115 | 104,490 | 1.34 | 25.91 | 0.86 | 71.89 | 97.80 |

| NH | 31 | 6,642 | 257 | 29,166 | 36,096 | 0.09 | 18.40 | 0.71 | 80.80 | 99.20 |

| NJ | 129 | 29,857 | 692 | 82,542 | 113,220 | 0.11 | 26.37 | 0.61 | 72.90 | 99.27 |

| NM | 39 | 17,194 | 551 | 90,288 | 108,072 | 0.04 | 15.91 | 0.51 | 83.54 | 99.45 |

| NY | 133 | 10,847 | 359 | 77,420 | 88,759 | 0.15 | 12.22 | 0.40 | 87.22 | 99.45 |

| NC | 1,067 | 40,461 | 2,584 | 91,811 | 135,923 | 0.79 | 29.77 | 1.90 | 67.55 | 97.31 |

| ND | 462 | 8,184 | 322 | 8,015 | 16,983 | 2.72 | 48.19 | 1.90 | 47.19 | 95.38 |

| OH | 2,072 | 40,984 | 4,895 | 62,117 | 110,068 | 1.88 | 37.24 | 4.45 | 56.44 | 93.67 |

| OK | 661 | 40,762 | 1,114 | 97,209 | 139,746 | 0.47 | 29.17 | 0.80 | 69.56 | 98.73 |

| OR | 1,257 | 10,349 | 2,505 | 9,067 | 23,178 | 5.42 | 44.65 | 10.81 | 39.12 | 83.77 |

| PA | 1,446 | 37,136 | 5,584 | 49,688 | 93,854 | 1.54 | 39.57 | 5.95 | 52.94 | 92.51 |

| RI | 1 | 4,035 | 295 | 1,701 | 6,032 | 0.02 | 66.89 | 4.89 | 28.20 | 95.09 |

| SC | 21 | 8,906 | 522 | 6,623 | 16,072 | 0.13 | 55.41 | 3.25 | 41.21 | 96.62 |

| SD | 704 | 33,400 | 2,553 | 100,325 | 136,982 | 0.51 | 24.38 | 1.86 | 73.24 | 97.62 |

| TN | 78 | 26,402 | 1,137 | 54,864 | 82,481 | 0.09 | 32.01 | 1.38 | 66.52 | 98.53 |

| TX | 1,381 | 113,126 | 8,176 | 425,696 | 548,379 | 0.25 | 20.63 | 1.49 | 77.63 | 98.26 |

| UT | 599 | 22,078 | 725 | 64,515 | 87,917 | 0.68 | 25.11 | 0.82 | 73.38 | 98.49 |

| VT | 310 | 13,392 | 1,314 | 53,877 | 68,893 | 0.45 | 19.44 | 1.91 | 78.20 | 97.64 |

| VA | 156 | 26,417 | 923 | 126,862 | 154,358 | 0.10 | 17.11 | 0.60 | 82.19 | 99.30 |

| WA | 635 | 22,207 | 1,348 | 60,124 | 84,314 | 0.75 | 26.34 | 1.60 | 71.31 | 97.65 |

| WV | 144 | 7,307 | 410 | 6,347 | 14,208 | 1.01 | 51.43 | 2.89 | 44.67 | 96.10 |

| WI | 1,237 | 37,348 | 6,628 | 46,604 | 91,817 | 1.35 | 40.68 | 7.22 | 50.76 | 91.43 |

| WY | 295 | 35,151 | 772 | 54,942 | 91,160 | 0.32 | 38.56 | 0.85 | 60.27 | 98.83 |

| PR | 31 | 2,384 | 10 | 4,942 | 7,367 | 0.42 | 32.36 | 0.14 | 67.08 | 99.44 |

| AB | 1 | 8,119 | 51 | 44,672 | 52,843 | 0.00 | 15.36 | 0.10 | 84.54 | 99.90 |

| BC | 0 | 1,228 | 2 | 16,096 | 17,326 | 0.00 | 7.09 | 0.01 | 92.90 | 99.99 |

| MB | 504 | 27,998 | 8,294 | 98,541 | 135,337 | 0.37 | 20.69 | 6.13 | 72.81 | 93.50 |

| NB | 0 | 2,771 | 154 | 10,640 | 13,565 | 0.00 | 20.43 | 1.14 | 78.44 | 98.86 |

| NF | 0 | 697 | 34 | 8,010 | 8,741 | 0.00 | 7.97 | 0.39 | 91.64 | 99.61 |

| NS | 0 | 109 | 1 | 3,761 | 3,871 | 0.00 | 2.82 | 0.03 | 97.16 | 99.97 |

| ON | 175 | 9,415 | 1,184 | 56,362 | 67,136 | 0.26 | 14.02 | 1.76 | 83.95 | 97.98 |

| PE | 0 | 1,235 | 0 | 9,597 | 10,832 | 0.00 | 11.40 | 0.00 | 88.60 | 100.00 |

| QB | 265 | 10,933 | 508 | 34,926 | 46,632 | 0.57 | 23.45 | 1.09 | 74.90 | 98.34 |

| SA | 125 | 17,359 | 5,470 | 55,714 | 78,668 | 0.16 | 22.07 | 6.95 | 70.82 | 92.89 |

| Total | 39,766 | 1,717,961 | 155,943 | 4,129,809 | 6,043,479 | 0.66 | 28.43 | 2.58 | 68.33 | 96.76 |

PR = Puerto Rico; AB = Alberta; BC = British Columbia; MB = Manitoba; NB = New Brunswick; NF = Newfoundland; NS = Nova Scotia; ON = Ontario;

PE = Prince Edward Island; QB = Quebec; and SA = Saskatchewan.

| EVERCALC© Analysis | Total Drops Analyzeda | Accept Results | Atypical Results | Atypical and Accept Results | Error Drops | Percentage Atypical and Accept Results |

|---|---|---|---|---|---|---|

| Run 1 using typical material-specific ranges for each layer | 5,694,207 | 2,573,025 | 1,327,896a | 3,900,921 | 1,793,286 | 68.5 |

| Run 2 using wider range for cases where more than 25 percent of the run 1 results hit the limits | 5,611,563 | 1,853,484 | 2,377,648b | 4,390,049 | 1,380,431 | 75.4 |

| Final Results (EVERCALC© and MODCOMP©) | 5,662,494 | 1,817,186 | 2,494,628 | 4,311,814 | 1,350,680 | 76.1 |

Note: Different values are reported for the total number of basins analyzed because the total number accounts for basins that may have been dropped or added for the individual runs for basins that were borderline between typical and type 2 versus types 1 and 3.

aThe atypical results in run 1 represent basins with backcalculated moduli that converge to the lower or upper limits of the specified typical range. These may include sections that may produce results outside the atypical range if the range is expanded. Therefore, these basins may include basins that can be categorized as errors if the range is expanded.

bThe atypical results in run 2 represent basins with backcalculated moduli that converge within the lower or upper limits of the specified atypical range (i.e., these basins may not be categorized as errors).

| STATE_ CODE | TOTAL_DROPS | ERROR_DROPS | ATYPICAL_DROPS | ACCEPT_DROPS | Percent Acceptable |

|---|---|---|---|---|---|

| 1 | 199,465 | 28,341 | 99,850 | 71,274 | 85.8 |

| 2 | 24,559 | 6,188 | 6,018 | 12,353 | 74.8 |

| 4 | 367,159 | 116,309 | 162,913 | 87,937 | 68.3 |

| 5 | 77,904 | 14,206 | 30,161 | 33,537 | 81.8 |

| 6 | 193,500 | 60,991 | 75,684 | 56,825 | 68.5 |

| 8 | 130,421 | 49,733 | 47,512 | 33,176 | 61.9 |

| 9 | 57,271 | 6,129 | 17,565 | 33,577 | 89.3 |

| 10 | 65,289 | 9,282 | 36,820 | 19,187 | 85.8 |

| 11 | 1,022 | 160 | 319 | 543 | 84.3 |

| 12 | 135,999 | 50,662 | 48,522 | 36,815 | 62.7 |

| 13 | 153,065 | 16,886 | 69,767 | 66,412 | 89.0 |

| 15 | 16,096 | 3,727 | 6,307 | 6,062 | 76.8 |

| 16 | 80,804 | 28,423 | 33,432 | 18,949 | 64.8 |

| 17 | 86,152 | 22,671 | 34,200 | 29,281 | 73.7 |

| 18 | 93,376 | 24,438 | 39,795 | 29,143 | 73.8 |

| 19 | 95,867 | 28,030 | 40,923 | 26,914 | 70.8 |

| 20 | 126,318 | 38,013 | 46,290 | 42,015 | 69.9 |

| 21 | 24,357 | 8,725 | 9,355 | 6,277 | 64.2 |

| 22 | 18,097 | 1,324 | 4,621 | 12,152 | 92.7 |

| 23 | 81,499 | 6,151 | 33,610 | 41,738 | 92.5 |

| 24 | 106,138 | 27,664 | 49,703 | 28,771 | 73.9 |

| 25 | 44,976 | 4,671 | 21,745 | 18,560 | 89.6 |

| 26 | 93,392 | 15,832 | 34,056 | 43,504 | 83.0 |

| 27 | 264,185 | 54,432 | 112,931 | 96,822 | 79.4 |

| 28 | 143,797 | 31,183 | 72,221 | 40,393 | 78.3 |

| 29 | 117,624 | 44,556 | 51,913 | 21,155 | 62.1 |

| 30 | 178,393 | 39,040 | 91,324 | 48,029 | 78.1 |

| 31 | 98,629 | 18,671 | 40,554 | 39,404 | 81.1 |

| 32 | 101,504 | 17,931 | 56,182 | 27,391 | 82.3 |

| 33 | 35,808 | 2,775 | 12,998 | 20,035 | 92.3 |

| 34 | 112,399 | 12,285 | 65,259 | 34,855 | 89.1 |

| 35 | 107,482 | 20,493 | 45,650 | 41,339 | 80.9 |

| 36 | 88,267 | 8,243 | 58,641 | 21,383 | 90.7 |

| 37 | 132,159 | 32,663 | 56,570 | 42,926 | 75.3 |

| 38 | 16,199 | 4,218 | 6,972 | 5,009 | 74.0 |

| 39 | 103,092 | 24,359 | 37,449 | 41,284 | 76.4 |

| 40 | 136,754 | 25,706 | 56,493 | 54,555 | 81.2 |

| 41 | 19,416 | 5,817 | 8,703 | 4,896 | 70.0 |

| 42 | 86,759 | 28,033 | 47,666 | 11,060 | 67.7 |

| 44 | 5,736 | 1,488 | 3,825 | 423 | 74.1 |

| 45 | 15,529 | 7,544 | 5,710 | 2,275 | 51.4 |

| 46 | 130,246 | 21,574 | 48,238 | 60,434 | 83.4 |

| 47 | 81,234 | 31,811 | 32,462 | 16,961 | 60.8 |

| 48 | 534,862 | 134,664 | 219,904 | 180,294 | 74.8 |

| 49 | 86,480 | 29,619 | 48,924 | 7,937 | 65.8 |

| 50 | 67,199 | 4,830 | 34,503 | 27,866 | 92.8 |

| 51 | 153,279 | 32,257 | 89,569 | 31,453 | 79.0 |

| 53 | 81,825 | 23,132 | 37,514 | 21,179 | 71.7 |

| 54 | 12,316 | 6,630 | 3,970 | 1,716 | 46.2 |

| 55 | 82,468 | 20,558 | 40,304 | 21,606 | 75.1 |

| 56 | 90,093 | 29,562 | 42,538 | 17,993 | 67.2 |

| 72 | 7,326 | 4,178 | 2,912 | 236 | 43.0 |

| 81 | 52,791 | 21,534 | 26,103 | 5,154 | 59.2 |

| 82 | 17,324 | 1,682 | 4,952 | 10,690 | 90.3 |

| 83 | 126,539 | 21,726 | 44,798 | 60,015 | 82.8 |

| 84 | 13,411 | 4,480 | 8,562 | 369 | 66.6 |

| 85 | 8,164 | 1,871 | 2,147 | 4,146 | 77.1 |

| 86 | 3,870 | 180 | 1,176 | 2,514 | 95.3 |

| 87 | 65,777 | 7,945 | 20,217 | 37,615 | 87.9 |

| 88 | 10,832 | 4,454 | 5,606 | 772 | 58.9 |

| 89 | 45,250 | 13,087 | 19,373 | 12,790 | 71.1 |

| 90 | 73,073 | 27,001 | 32,359 | 13,713 | 63.0 |

Note: Not all agencies are included within this table because of missing data that were needed for the backcalculation process for the LTPP sections, or there were no LTPP test sections within that agency.

| STATE_CODE | TOTAL_DROPS | ERROR_DROPS | ATYPICAL_DROPS | ACCEPT_DROPS | Percent Acceptable |

|---|---|---|---|---|---|

| 1 | 7,246 | 1,076 | 580 | 5,590 | 85.2 |

| 4 | 23,495 | 1,950 | 1,913 | 19,632 | 91.7 |

| 5 | 20,167 | 2,242 | 1,976 | 15,949 | 88.9 |

| 6 | 22,712 | 3,455 | 5,539 | 13,718 | 84.8 |

| 8 | 15,798 | 733 | 4,040 | 11,025 | 95.4 |

| 9 | 960 | 4 | 44 | 912 | 99.6 |

| 10 | 11,698 | 449 | 1,248 | 10,001 | 96.2 |

| 12 | 6,793 | 1,707 | 777 | 4,309 | 74.9 |

| 13 | 14,018 | 1,985 | 6,400 | 5,633 | 85.8 |

| 16 | 6,103 | 256 | 1,357 | 4,490 | 95.8 |

| 17 | 8,646 | 438 | 211 | 7,997 | 94.9 |

| 18 | 11,663 | 406 | 6,296 | 4,961 | 96.5 |

| 19 | 16,935 | 482 | 4,399 | 12,054 | 97.2 |

| 20 | 24,563 | 1,942 | 3,348 | 19,273 | 92.1 |

| 21 | 1,788 | 229 | 89 | 1,470 | 87.2 |

| 22 | 655 | 12 | 174 | 469 | 98.2 |

| 23 | 1,603 | 8 | 822 | 773 | 99.5 |

| 26 | 15,148 | 955 | 2,388 | 11,805 | 93.7 |

| 27 | 19,250 | 1,110 | 4,494 | 13,646 | 94.2 |

| 28 | 4,922 | 892 | 2,210 | 1,820 | 81.9 |

| 29 | 20,662 | 2,192 | 1,818 | 16,652 | 89.4 |

| 31 | 11,970 | 576 | 6,561 | 4,833 | 95.2 |

| 32 | 8,772 | 2,101 | 2,946 | 3,725 | 76.0 |

| 34 | 337 | 0 | 0 | 337 | 100.0 |

| 35 | 953 | 131 | 89 | 733 | 86.3 |

| 36 | 5,265 | 330 | 426 | 4,509 | 93.7 |

| 37 | 17,420 | 1,202 | 4,440 | 11,778 | 93.1 |

| 38 | 13,673 | 241 | 1,200 | 12,232 | 98.2 |

| 39 | 21,524 | 991 | 4,701 | 15,832 | 95.4 |

| 40 | 8,077 | 565 | 4,508 | 3,004 | 93.0 |

| 42 | 16,876 | 4,409 | 1,865 | 10,602 | 73.9 |

| 45 | 1,161 | 12 | 0 | 1,149 | 99.0 |

| 46 | 12,766 | 771 | 3,272 | 8,723 | 94.0 |

| 47 | 4,146 | 59 | 579 | 3,508 | 98.6 |

| 48 | 18,083 | 2,384 | 11,062 | 4,637 | 86.8 |

| 49 | 12,253 | 1,173 | 5,004 | 6,076 | 90.4 |

| 50 | 433 | 24 | 0 | 409 | 94.5 |

| 51 | 156 | 47 | 8 | 101 | 69.9 |

| 53 | 21,151 | 1,937 | 5,909 | 13,305 | 90.8 |

| 54 | 1,489 | 312 | 61 | 1,116 | 79.0 |

| 55 | 22,021 | 2,701 | 5,139 | 14,181 | 87.7 |

| 56 | 1,110 | 1 | 331 | 778 | 99.9 |

| 72 | 1,892 | 1,126 | 154 | 612 | 40.5 |

| 83 | 4,096 | 485 | 34 | 3,577 | 88.2 |

| 84 | 564 | 1 | 21 | 542 | 99.8 |

| 89 | 8,103 | 361 | 681 | 7,061 | 95.5 |

Note: Not all agencies are included within this table because some of the agencies did not have any LTPP rigid pavement test sections.

The following subsection provides a summary of the hardware used to backcalculate the results as well as an estimate of the length or amount of computational time to execute the first phase analysis using EVERCALC©.

The first and second phase analyses were performed in two modes using the interface for the cases with a bedrock layer and by running the executable from an MS-DOS prompt for the cases without a bedrock layer. The runs were executed in a batch mode for both cases.

For cases with the bedrock layer, three virtual machines were used, each with 2 GB of random access memory, and running the Windows XP® operating system. These machines had 2.4 Ghz dual core processors. The runs took about 2 weeks of computational time (336 h), with the programmer or user having to monitor the progress of the software’s status. In some cases, the program had to be restarted twice each day.

For cases without the bedrock layer, three virtual machines were used, and they had the same specifications as those described. The analyses took about 1 week of computational time (168 h). These analyses were more stable, but the programmer still had to monitor the program’s status when processing data for States with large data sets (e.g., Arizona, Colorado, and Texas).

The two parameters used to determine whether the results were acceptable were also used as a measure to judge the success of the backcalculation process: (1) the average error or difference between the measured and calculated deflection basin and (2) the percentage of points with acceptable modulus values for all layers. The criteria for determining acceptable and unacceptable backcalculated layer modulus values were discussed earlier. The following list provides a generic definition of success:

For sites with anomalies or high RMSE, the resulting elastic layer moduli were identified as such. MODCOMP© was used to determine a probable reason for the results. These sites or days of testing were flagged for investigation, if still available. If forensics have not been completed and a site has been taken out of service, these were simply identified along with some potential causes for the differences encountered.

Table 14 lists the LTPP test sections and the areas within the test section for which the results were eliminated from the CPT because most of the results were found to be outside one or both of the acceptance criteria. Table 15 lists the error flags and their description used in the CPTs and included in the feedback reports.

| Test Section | Area Excluded Station | Type of Structure |

|---|---|---|

| 01-4127 | 110+ | Conventional flexible pavement structure |

| 01-4129 | -40 | Conventional flexible pavement structure with a thin surface |

| 04-1006 | 140+ | Conventional flexible pavement structure |

| 02-9035 | 80+ | Conventional flexible pavement structure with a thin overlay |

| 04-1022 | -50 | Conventional flexible pavement structure |

| 04-1015 | 120+ | Conventional flexible pavement structure with overlay |

| 06-8534 | 130+ | Conventional flexible pavement structure with a thin surface |

| 30-7088 | 70+ | Conventional flexible pavement structure with overlay |

| 37-2824 | -60 | Semi-rigid pavement |

| 38-2001 | 80+ | Semi-rigid pavement |

| 40-4088 | 50+ | Semi-rigid pavement |

| 42-1618 | -35 | Conventional flexible pavement structure with overlay |

| 48-9005 | -50 | Conventional flexible pavement structure with overlay |

| 53-1002 | -40 | Conventional flexible pavement structure |

| Report No. | Flag | Subject | Situation | Recommended Action |

|---|---|---|---|---|

| 1 | MISSING_DEFL | Missing deflection data | Deflection data is missing in the MON_DEFL_DROP_ DATA for this STATE_CODE, SHRP_ID, TEST_ DATE, TEST_TIME, POINT_ LOC, and DROP_NO. |

None. The basin was not used in backcalculation analysis. |

| 2 | LAYER_THK_ UNAVAILABLE |

Missing thickness data | Layer thickness data is missing in the TST_L05B table for this STATE_CODE, SHRP_ID, TEST_DATE, and CONSTRUCTION_NO | None. The basin was not used in backcalculation analysis. |

| 3 | BLACKLISTED_ BASINTYPE |

Non-decreasing deflection basin | Invalid deflection data for the basin in the MON_DEFL_ DROP_DATA table. The test location has a non-decreasing deflection basin and was characterized as either a type I or a type III basin. |

None. The basin was not used in backcalculation analysis. |

| 4 | MISSING_TEMP | Missing temperature data and depth of temperature measurement | Temperature measurement and depth of measurement is missing in the MON_DEFL_TEMP_ DEPTHS and MON_DEFL_ TEMP_VALUES for this SHRP_ID, test_date, and Point_LOC. |

None. The basin was used in backcalculation analysis. |

| 5 | MISSING_DEPTH_ THKCOR |

Missing depth of temperature measurement | Missing layer depth Information in the MON_DEFL_TEMP_ DEPTHS table LAYER_TEMP_ DEPTH from the Supplementary Temperature Table). |

None. The basin was used in backcalculation analysis. |

| 6 | TEMPERATURE_ DEPTH_MISMATCH |

Temperature depth mismatch | The data for the layer thicknesses from TST_L05B and depth of temperature measurements do not align | None. The basin was used in backcalculation analysis. |

| 7 | MISSING TEMP_ DEPTH |

Missing temperature within the surface layer | For the STATE_CODE, SHRP_ID, and TEST_DATE, the temperature within surface layer could not be determined using the temperature depth and temperature values reported in MON_DEFL_TEMP_DEPTHS and MON_DEFL_TEMP_ VALUES tables. |

None. The basin was used in backcalculation analysis. |

| 8 | INVALID_LTE | Invalid LTE | Deflection measurement was considered invalid because of missing deflection or sensor spacing. | None. The LTE was not reported in the summary tables. |

| 9 | LTE_NON_DEC | LTE non decreasing | Invalid deflection data for the basin in the MON_DEFL_ DROP_DATA table. The test location has a non-decreasing deflection basin. |

None. The LTE was not reported in the summary tables. |

| 10 | F_OUTPUT_IDD_ MISMATCH |

Failure to obtain results for all basins for an identification descriptor designation | Results were generated for a subset of the drops for the IDD. The results are written to the drops starting from the first drop; however a mismatch might exist. | None. The results are reported for the IDD. |

| 11 | F_NO_IDD_MATCH | No results were obtained for this IDD | No output data are found for an IDD (i.e., POINT_LOC, TEST_DATE, TEST_TIME, SHRP_ID, and STATE (likely that the input data were not fully processed by EVERCALC©). | No results reported for IDD. |

| 12 | EXCLUDED_FROM_ SUMMARY |

Subsection excluded from results summary | Subsection of the SHRP_ID showed high variability in calculated modulus values relative to the majority of the section. Subsection had higher error rate. | Results excluded from summary. |

Note: “Report No.” refers to an integer that defines a specific error flag.

The individual test sections with error numbers 1 through 9 in table 15 were included in unpublished data feedback reports and were submitted to FHWA because these pertain to the data themselves. Error numbers 10–12 were excluded from the unpublished data feedback reports, which were prepared and submitted to LTPP to document and report errors or anomalies found in the database, because these errors only pertain to the results from the backcalculation programs. In addition, error numbers 1–3 were excluded in the datasets for the individual results because of missing critical data such that the backcalculation process could not be performed.

The first level review of results was the post-processing of the backcalculated results. The post-processor groups and determines the number of deflection basins that are found to be acceptable and unacceptable based on the two parameters previously discussed. If the majority of the results were found to be acceptable, that test section and test date were accepted, and the averages, standard deviation, and other information were determined in the post-processing of the data. If a significant amount of the results are unacceptable, the test section and test date went through a second and possibly third level review.

The second level review was a more exhaustive review to identify possible causes for the unacceptable results. This included an indepth review of the post-evaluation factors and other LTPP data and layer properties to try to identify the reasons for the high error term or modulus values that fell outside the range of typical values. If the results were still considered unacceptable after the second level review, the test section and test date moved to a

third level review.

The third level review included making additional runs with MODCOMP© based on all available information. If this third level did not result in acceptance, a feedback report was prepared for the test section and test dates. As part of this review level, a decision was made regarding the probable cause for the unaccepted results and the results flagged. The probable cause and recommended resolution were included in the feedback reports. Appendix B lists the test sections that exhibited a high percentage of moderate to high RMSE values and did not meet all of the acceptance criteria.

Many factors can lead to erroneous results in the backcalculation process because they impact the measured deflection basin. Some evaluation factors include the following:

Another evaluation criterion was to compare the backcalculated elastic modulus values with those values measured in the laboratory for PCC, HMA, and unbound materials and soils. LTPP sponsored other projects to determine the dynamic and resilient modulus values that are consistent with the MEPDG methodology and inputs.(1) Dynamic moduli were calculated for the different HMA mixtures from volumetric and component properties and are included in the LTPP database, which represent an undamaged and unaged condition. The backcalculated modulus values, however, represented an in-place composite elastic modulus and were not discrete values, as measured in the laboratory. In addition, the backcalculated modulus values represented any in-place damage and aged conditions. As such, one-to-one correspondence was not expected between the backcalculated elastic modulus values and those calculated from volumetric properties (laboratory-derived dynamic modulus values).

The layer- or mixture-specific dynamic modulus values were combined to determine a composite modulus value using the equivalent modulus concept and compared to the backcalculated composite values. The equivalent modulus concept was used in the FHWA-sponsored study to compare backcalculated values to laboratory-derived values.(45) Use of the equivalent modulus concept to determine the composite laboratory-derived dynamic modulus was found to be of little value in explaining the difference between the laboratory-derived and field-derived values.

Compensating Layer Effects

Identifying compensating layer effects is an important step in the backcalculation process. Compensating layer effects occurs when one layer consistently increases in stiffness while an adjacent layer decreases in stiffness. Compensating layer effects can result in layer modulus values that are inappropriate for the pavement structure, even when the error between the measured and predicted deflection basins is considered acceptable. Characterizing the deflection basins can assist in identifying LTPP test sections that are prone to compensating layer effects. The deflection basins were categorized in the first backcalculation study to identify the sites where this characteristic is likely to occur.(4) The same process was used in this project to reduce the possibility for compensating layer effects on the calculated elastic modulus values. When compensating errors identified for a specific test section, MODOMP was used or the pavement structure was revised.

Discontinuities

Discontinuities in the pavement structure (i.e., cracks, joints, segregation, etc.) have an impact on selected deflection basins, especially if the discontinuity is supporting a sensor platform or located between two sensors near the loading plate. The sensor bar and loading plate are usually located in intact areas, but that is not always possible or the condition noted by the operator. The shape of the deflection basin can distinguish some of these conditions.

As part of the backcalculation process, the distress data were extracted for each site for review when selected areas along the LTPP site continually do not meet the acceptance criteria to explain the high RMSE or surface layer modulus values that deviate significantly from typical laboratory-derived values. These results were flagged as having extensive cracking or distress along the section as part of the post-processing of results.

HMA Stripping and Other Material Defects

Stripping can have a softening effect on HMA mixtures. Some of the forensic investigations that have been completed on the SPS-1 and SPS-2 supplemental sites have identified HMA mixtures that exhibit stripping in selected layers. This softening effect can result in low elastic modulus values backcalculated for that structure. The first LTPP backcalculation study recognized this behavior, and all layers that were found to exhibit stripping were simulated as a separate layer. The error term using this approach was lower in comparison to combining all HMA layers into a composite layer.

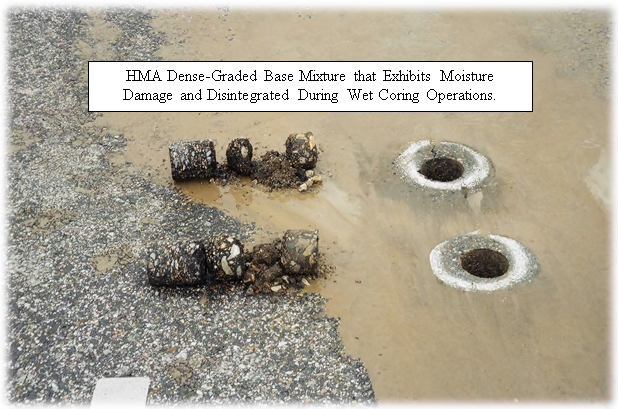

Figure 34 illustrates this point for an LTPP site where deflection testing was done prior to any forensic investigation. The pavement structure was an HMA overlay of an existing HMA pavement. The backcalculated modulus reported for the in-place dense-graded base mixture beneath the HMA overlay was similar to that of a good quality aggregate base material. That modulus value was believed to be incorrect and rejected. After coring operations, the low modulus value was found to be representative of moisture-induced damage or stripping. Similar examples are applicable for the unbound layers (e.g., high water content resulting in very low modulus values to base layers with an excessive amount of fines or low water content (a dry condition) resulting in very high modulus values representative of a bound layer).

Figure 34. Photo. Cores recovered where moisture damage occurred, decreasing the in-place modulus of the layer/mixture (Texas SPS-5 project).

Loss of Bond between Layers

Most backcalculation studies and software packages assume adjacent layers are fully bonded. However, forensic investigations have shown that there were SPS-1 and -5 test sections where bond was lost with time. Some of these sections have been reconstructed or taken out of the LTPP monitoring cycle because the distress increased significantly.

The bond between adjacent bound layers can affect the deflection basin, but the effect is usually considered minor. Based purely on the deflection basins, it is difficult to determine if bonded or full slip between layers should be assumed. If adjacent layers become debonded, the distresses usually increase at a significant rate. Simulating this condition becomes difficult because of the limit on the number of layers that can be backcalculated, and most of the commonly used programs have the bond between layers fixed to full bond. If this condition is expected from the results of the backcalculation process through low modulus values, the results are flagged as such.

Variable or Perched Water Table Depth

The water content of unbound materials has a significant effect on the elastic properties of that layer. This was recognized during the first backcalculation study, so boring logs and water content were used to determine if this condition was exhibited at each LTPP site. Where this condition was found, two runs were made—one where the subgrade was combined as one layer and another where the subgrade was divided into two layers where the water table or nearly saturated conditions existed. The error between the measured and calculated deflection basins was almost always lower by simulating the depth of saturation. In most cases, the backcalculated elastic modulus values were also higher for the layer above the water table depth than the values below the water table depth. In some cases, these depths were seasonal.

Variable Depth of an Apparent Rigid Layer

The depth to bedrock can be determined from the shoulder borings that were drilled at all (or nearly all) of the LTPP test sections. However, a saturated or soft (weak) layer overlying a dry, overconsolidated clay layer can behave as a very stiff layer; all of the energy is being absorbed in the soft, weak layer. Similar to the comments relative to saturated layers, the boring logs and physical properties were used to identify these conditions. Where these conditions were found, two runs were made, one with and one without a rigid layer at the interface between the wet and dry layers. In most cases, the error between the measured and calculated deflection basins was less by simulating a rigid or stiff layer at that location or dividing the subgrade into two layers at that depth.

Warping and Curling of PCC Slabs

Curling of JPCP slabs can occur over a day’s test program and significantly impact the measured deflection basin. It this condition is not recognized, it will result in lower PCC elastic modulus values not representative of the in-place material.

The CPTs were designed to store the results from the backcalculation process and assist in interpreting the results. One set of tables stores the EVERCALC© and MODCOMP© results, while a second set of tables stores the best fit results. The data in these sets of tables include the following:

The data included in the CPTs are similar to those designed and prepared from the first round of backcalculation results in 2002 and include, as a minimum, the following:(4)

A user’s manual and source code, Backcalculation Procedures and User Guide for Software Programs and Utility Tools, was prepared for all software packages and tools that were modified, revised, or developed as a part of this study.(56) In addition, source codes were prepared for each of the pre- and post-processing utility tools used in this round of backcalculation. Source codes were not prepared for any program that was already available in the public domain and was not changed in any manner.

Note: Bolding indicates the critical value.