U.S. Department of Transportation

Federal Highway Administration

1200 New Jersey Avenue, SE

Washington, DC 20590

202-366-4000

Federal Highway Administration Research and Technology

Coordinating, Developing, and Delivering Highway Transportation Innovations

| REPORT |

| This report is an archived publication and may contain dated technical, contact, and link information |

| Publication Number: FHWA-HRT-14-039 Date: May 2014 |

Publication Number: FHWA-HRT-14-039 Date: May 2014 |

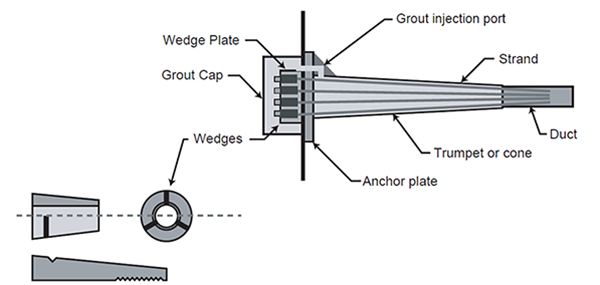

The number of prestressed concrete bridge structures utilizing high-strength seven-wire strands has steadily increased since the 1970s. The prestressing strands can be used in pre-tensioned and post-tensioned (PT) structures. The latter utilizes plastic or metal ducts that are initially empty tubes that allow for a bundle of the seven-wire strands to be fed through after the ducts are embedded in the concrete. The strands are fixed at both end anchorage points by a wedge plate and steel wedges that grip each strand. Ultimately, they are pulled to a pre-determined level of stress using a specialized hydraulic jack. The assembly of the prestressed seven-wire strands and the duct is called a PT tendon. In this report, a prestressed seven-wire strand will be simply referred to as a “PT strand.” Figure 1 shows schematic of a typical PT tendon system.(1)

Figure 1. Illustration. Typical PT anchorage hardware for strand tendons.(1)

The PT tendon is divided into two types: (1) unbonded tendons typically filled with grease or wax and (2) bonded tendons filled with cementitious material called grout. For bonded PT tendons and cables, the grout functions as the last layer of corrosion protection for the highly stressed PT strands by providing a high pH environment to form a protective oxide film on the strand surface and acting as a physical barrier to water and oxygen. Corrosion of strands initiates when the protective oxide film is compromised due to chloride attack or carbonation of the surrounding grout upon exposure to water and air. Once corrosion initiates, corrosion propagates at a certain rate controlled by many factors such as oxygen availability, moisture content, electrical resistance, grout pH, and chloride concentration.

The literature review for this study has shown that among several causes in earlier tendon corrosion failures, any one or a combination of some of the following deficiencies can trigger active corrosion with presence of moisture and oxygen: voids, micro-cracks, sedimentation leading to variable water-cement ratio, bleed water, and contamination with chloride or sulfate ions.(2,3) Uneven grout cover ranging from very thick to virtually no cover within a typical duct system can also result in corrosion in the thin and no cover sections where PT strands in a tendon have a greater chance of getting exposed to water and oxygen if the tendon fails to maintain its water/air tightness. Some examples caused by this type of corrosion in the field tendons are provided in appendix A. The prestressing strand is less tolerant to corrosive environments than ordinary reinforcing steel because of its much higher load-bearing requirement per unit area. While some tendon corrosion problems were observed in the grout defects filled with water and oxygen, various amounts of chloride ions were found in other incidents. A couple of investigative reports claimed that sulfate ions could be responsible for tendon corrosion as well.(2,4) In particular, a laboratory study conducted by the Florida Department of Transportation (FDOT) demonstrated that aggressive nature of free sulfate ions can result in intensive corrosion.(4) Excessive free sulfate ions found in segregated grout were also a suspect of corrosion failure of some tendon specimens employed in the present study. Recognizing the importance of having high-quality grout in the PT system concrete bridges and cable stayed bridges, commercially available pre-packaged grouts were introduced to the construction market to minimize quality variations that may occur in the construction sites. In addition, enhanced grout installation guidelines and training certification programs were developed. These changes have been beneficial and improved the quality of in-place grouts.

A recent discovery of grout with elevated levels of chloride used in a PT concrete straddle cap located in Corpus Christi, TX, led to a full investigation to better understand the extent of the potential corrosion problem that may be caused by the use of chloride-contaminated grout.(5) The grout in question was a commercially available pre-packaged product. According to an investigative report, the reported chloride concentration was as high as 5.27 percent (52,700 ppm) by weight of cement, and the chloride concentration in the retained bags was as high as 0.5 percent by weight of cement.(5,6) Figure 2 shows a 4-month-old segregated grout in question, and table 1 shows its corresponding chloride concentration data. Label A indicates normally hardened grout, and label B indicates defective grout that contained numerous air voids.

Figure 2. Photo. Chloride-contaminated grout in the straddle caps for Carbon Plant Road bridge.(5)

Table 1. Chemical analysis results.(5)

| Sample | Instrument | Chloride Percent by Weight* | ppm |

|---|---|---|---|

| Tendon 1A inlet “A” | Scanning electron microscope (SEM)/energy dispersive spectroscopy (EDS) | N/A | N/A |

| X-ray fluorescence | 5.27 | 52,700 | |

| Ion chromatography | 2.13 | 21,330 | |

| Tendon 1A, outlet “B” | SEM/EDS | 0.54 | 5,400 |

| Tendon 1B, inlet “B” | SEM/EDS | 0.41 | 4,100 |

| Tendon 2B, inlet “A” | SEM/EDS | 0.57 | 5,700 |

| Tendon 2B, inlet “B” | SEM/EDS | 0.22 | 2,200 |

*Chloride percent by weight reported using SEM/EDS is for total chlorides.

N/A = Not available.

It is apparent that the confirmed chloride concentrations exceeded the past and current limits set by all of the domestic and international regulatory committees such as American Concrete Institute (ACI) 201, 318, 222R, and British Code CP 110. Because the existing limits are based on either weight percent of cement or weight percent of grout, a conversion between the two units has to be made with certain assumptions regarding the fraction of cement in a given weight or volume of a grout sample. According to the current chloride limit by ACI committees, maximum water-soluble chloride content by weight of cement of 0.06 percent (600 ppm) is allowed for the prestressed concrete. The specified limit for the acid-soluble by weight of cement is 0.08 percent (800 ppm). (See references 7–10.) The former indicates chloride ions currently available for corrosion, while the latter indicates total amount of chloride ions potentially available for future corrosion. The Virginia Department of Transportation (VDOT) also limits total (acid-soluble) chloride ions by weight of cementitious material to a maximum 0.08 percent (800 ppm), whereas FDOT Standard Specification Section 934 limits chloride content to a maximum of 0.40 lb/yd3.(11) As noted in the ACI 222R-01 committee report, other international codes have different specified chloride limits for pre-hydrated grouts despite lack of rationale for the established values.(10) The same report also introduces a dimensionless ratio of [Cl-]/[OH-], which can be used as a chloride threshold in relation to corrosion initiation of reinforcing steel. More information can be found in the literature review report.(3)

Dr. David Whiting stated in his article,

Origins of Chloride Limits for Reinforced Concrete, that:

“ ... “limits” refers to the amounts of chloride which are permitted in fresh concrete by code authorities. This is not necessarily equal to the so-called “threshold” limit for corrosion, which is the actual amount of chloride needed to initiate corrosion under a given set of conditions. The former term “limits” is thus an artificial criterion set by man; the “threshold” is set by nature. Thus, while the “limits” must be set, the “threshold” must be investigated.”(pg. 3)(12)

This statement points out that even though the code specifications have built in a factor of safety, the allowable chloride limits are not adequate to predict corrosion behavior of the PT concrete bridges subjected to corrosive environments. Corrosion process of the PT strands and cables consists of two steps: (1) corrosion initiation and (2) corrosion propagation. Corrosion initiates when a protective oxide film is compromised due to chloride attack or carbonation (lowing pH) of the surrounding grout. An FDOT study demonstrated that corrosion can initiate on the unstressed strands exposed to fresh water mixed with a chloride concentration of 500 ppm in a simulated corrosion study.(13) Once corrosion begins, the corrosion propagation stage follows a kinetic process in the given condition. The rate of corrosion is influenced by many factors including electrical resistance, temperature, and dissolved oxygen. In addition, a limited laboratory experiment performed at the Federal Highway Administration’s (FHWA) Turner-Fairbank Highway Research Center for the internal San Francisco-Oakland Bay Bridge tendon corrosion study suggested that the corrosion rate of the prestressing wires may be related to chloride concentration, pH, and stress level. Therefore, it is imperative to take into account stress level, concentration of actual chloride in the grout, and pH at the strand/grout interface to determine a single chloride threshold or a range of chloride threshold values for any PT tendons and cables.