U.S. Department of Transportation

Federal Highway Administration

1200 New Jersey Avenue, SE

Washington, DC 20590

202-366-4000

Federal Highway Administration Research and Technology

Coordinating, Developing, and Delivering Highway Transportation Innovations

| REPORT |

| This report is an archived publication and may contain dated technical, contact, and link information |

|

| Publication Number: FHWA-HRT-14-064 Date: August 2014 |

Publication Number: FHWA-HRT-14-064 Date: August 2014 |

The physical flume modeling is described in this chapter. Particle image velocimetry (PIV) and acoustic Doppler velocimetry (ADV) are employed to achieve detailed representation of the flow field within the experimental apparatus. In addition to traditional PIV, stereoscopic particle image velocimetry (SPIV) is applied as a tool to characterize the 3D velocity field.

The Cartesian coordinate system for all analyses is defined by the x-axis representing the longitudinal (flow) direction. Looking downstream, the vertical direction (depth) is represented by the y-axis, and the horizontal direction (width) is represented by the z-axis.

The physical experiments were carried out in a rectangular cross-section tilting flume at Turner-Fairbank Highway Research Center in McLean, VA. The flume is 30 ft long and 4 ft wide and is shown in figure 4. The culvert test section is 16.2 ft long and 1.5 ft wide. The flume can be tilted up to 3 degrees. A honeycomb was placed in the trumpet-shaped inlet to channel the water to ensure flow homogeneity. Uniform steady-state flow conditions were controlled with screw jacks (to raise the upstream end of the flume while lowering the downstream end) and a bottom-hinged flap gate in the exit section. Fifteen ultrasonic sensors measured the water surface profile. A 4 ft3/s pump was used for circulating water into the flume. The flume was mounted by a two-dimensional (2D) robot to facilitate measurement of the velocity field.

Figure 4. Photo. Fish passage culvert experimental flume

A 16 MHz microADV from SonTek™ was used to collect velocity measurements. It was mounted on a robot, as shown in figure 5, and controlled with a LabView™ program. These measurements were used to evaluate the accuracy and efficiency of other velocity measurement techniques and the CFD modeling. Fifteen hundred sample points were collected for each velocity measurement to precisely average fluctuating streamlines. For more information on ADV, see appendix B of this report.(21)

Figure 5. Photo. SonTek™ ADV mounted on the data collection robot

PIV and SPIV were used in these experiments to collect more comprehensive and detailed representations of the velocity field than is achievable using ADV. These methods are non-intrusive whole flow field techniques for assessment of the mean and instantaneous velocity vectors within a single plane of interest.

In SPIV, two coupled cameras capture the same plane at the same time but with different off-axis view angles. A double-pulsed Solo 120 PIV New Wave Research™ Nd:YAG laser along with a pair of Megaplus™ ES 1.0 digital cameras from Roper Scientific MASD Inc. were configured in LabView™ to operate in a synchronized manner. The SPIV setup is shown in figure 6, and a close-up of the laser is shown in figure 7.

Figure 6. Photo. SPIV configuration

The spatial resolution was limited to 960 (horizontal) by 960 (vertical) pixels, which was implemented in the charge coupled device (CCD) array. The camera was connected through a 68-pin small computer system interface cable to the frame grabber card and could capture up to 30 images per s. It also featured a built-in electronic shutter with exposure times as short as 127 ms for maximum flexibility and performance when imaging fast moving objects. CCD cameras were equipped with two Sigma zoom lenses with a focal length ranging from 1.1 to 2.8 inches and an 8-level f-number from 2.8 to 32.

Silver-coated hollow glass spheres (AGSL150-16TRD from the Potters Industries Inc., Carlstadt, NJ) were introduced into the flow with an average diameter of 69 m, density of 0.93 g/cm3, and 17.7-percent weight of silver coated on their surfaces. For further information, see appendix B of this report.(22)

Symmetrical half sections of corrugated metal pipe (CMP) were used to maximize the size of culvert that would fit into the flume with one of the flume walls serving as the culvert centerline. Flume runs were conducted for the conditions listed in table 1. All runs were based on a 3-ft diameter corrugated metal pipe with 3- by 1-inch corrugations. Two velocities (discharges) were tested at each embedment level and flow depth. Flow depths of 4.5, 6, and 9 inches represented 12, 16, and 25 percent of the culvert diameter, respectively. The flume runs are labeled as FpqrrVsDt where: 1) p represents the diameter of the culvert in feet, 2) q designates whether the run is a symmetrical half section (H) or full section (F), 3) rr represents the embedment level (in percent of the culvert diameter), 4) s represents velocity from lowest to highest in the matrix, and 5) t represents the depth from lowest to highest in the matrix. For example, F3H15V2D3 is a 3-ft diameter half-section run with the embedment at 15 percent of the diameter.

Table 1 . Test matrix for the experimental flume.

Run ID |

Flow Depth (inches) |

Embedment (inches) |

Flow Velocity (ft/s) |

|---|---|---|---|

F3H00V1D1 |

4.5 |

0 |

0.71 |

F3H00V1D2 |

6 |

||

F3H00V1D3 |

9 |

||

F3H00V2D1 |

4.5 |

0 |

1.1 |

F3H00V2D2 |

6 |

||

F3H00V2D3 |

9 |

||

F3H15V1D1 |

4.5 |

5.4 |

0.71 |

F3H15V1D2 |

6 |

||

F3H15V1D3 |

9 |

||

F3H15V2D1 |

4.5 |

5.4 |

1.1 |

F3H15V2D2 |

6 |

||

F3H15V2D3 |

9 |

||

F3H30V1D1 |

4.5 |

10.8 |

0.71 |

F3H30V1D2 |

6 |

||

F3H30V1D3 |

9 |

||

F3H30V2D1 |

4.5 |

10.8 |

1.1 |

F3H30V2D2 |

6 |

||

F3H30V2D3 |

9 |

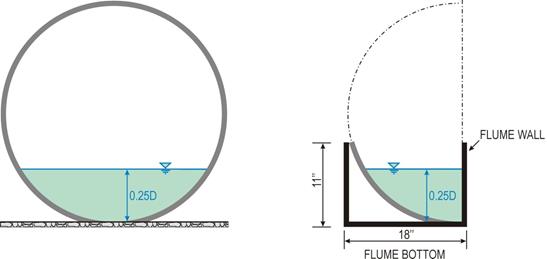

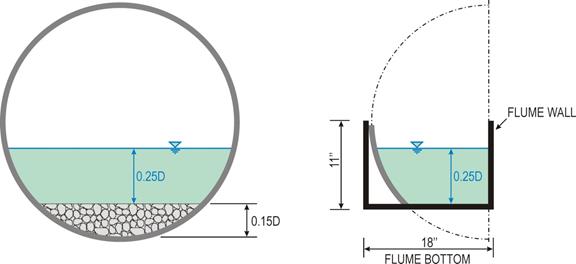

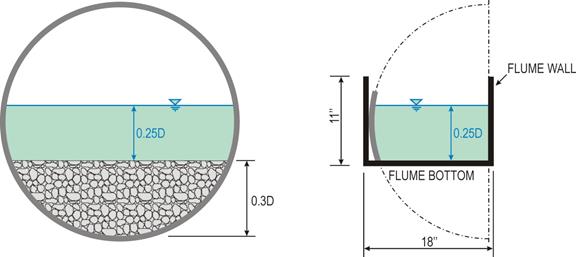

An embedment of zero inches represents the case with no embedment as shown in figure 8. Similarly, embedment representing 15 percent of the culvert diameter (5.4 inches) and 30 percent of the culvert diameter (10.8 inches) are illustrated in figure 9 and figure 10, respectively.

For the 15- and 30-percent embedment runs, the culvert bed material is coarse gravel with a mean particle diameter, D50, equal to 0.472 inches. Bed roughness was achieved by gluing one layer of the gravel on the bottom of the flume. Flow depth is defined from the top of the bed.

Figure 8. Illustration. Culvert with no embedment

Figure 9. Illustration. Culvert with 15-percent embedment

Figure 10. Illustration. Culvert with 30-percent embedment

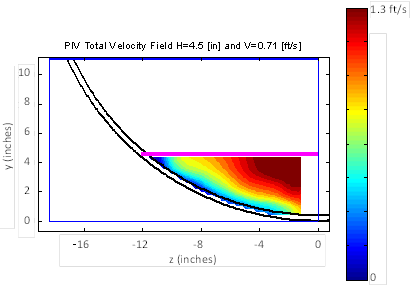

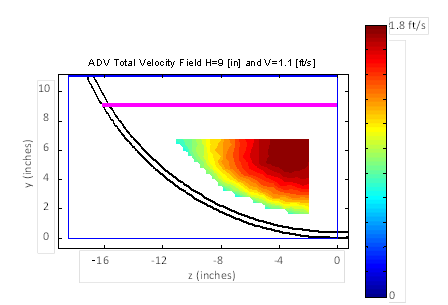

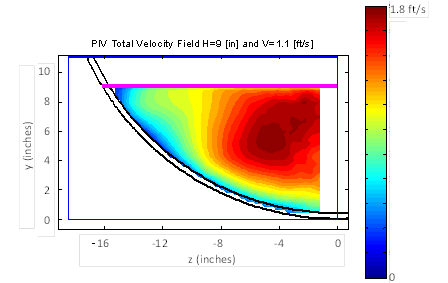

COMPARISON OF ADV AND PIV MEASUREMENTS

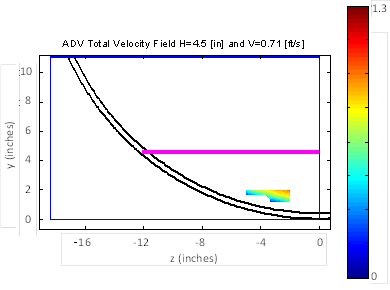

ADV and PIV results were compared to evaluate the robustness of the PIV results. Test runs used for this purpose had zero embedment and included three different flow depths and two different velocities. Figure 11 and figure 12 show a representative result for the case with a depth of 4.5 inches and velocity of 0.71 inches (run F3H00V1D1). The ADV results demonstrate that ADV is limited in its ability to collect data near fixed and water surface boundaries. Figure 13 and figure 14 summarize the flow fields for the case where depth is 9 inches and velocity is 1.1ft/s (run F3H00V2D3). ADV data in the area where the probe provides good readings are an important cross-reference for PIV data.

Figure 11. Graph. Run F3H00V1D1 velocity field using ADV

Figure 12. Graph. Run F3H00V1D1 velocity field using PIV

Figure 13. Graph. Run F3H00V2D3 velocity field using ADV

Figure 14. Graph. Run F3H00V2D3 velocity field using PIV