Safety Evaluation of the Safety Edge Treatment

Chapter 5. Estimated Cost of the Safety Edge Treatment

This chapter presents the analysis results for the cost of

the safety edge treatment. Section 5.1 discusses an analysis of costs for both

treatment and comparison resurfacing contracts, and section 5.2 presents

another method for determining the cost of the safety edge.

5.1 Comparison of Overall Costs of Resurfacing Projects

Since the safety edge treatment adds a wedge of asphalt to each edge of

the roadway, it is expected to add

cost to a resurfacing project. Costs of resurfacing both treatment and

comparison sites were obtained

from each of the participating States after the resurfacing project was

completed and project accounts were finalized. The cost items obtained for each

project included the engineer's estimate, the contract cost or price bid for

the project by the winning bidder, and the cost per ton of the hot-mix asphalt (HMA) concrete used to resurface the roadway and

form the safety edge.

The Georgia data set included 28

resurfacing projects (15 treatment and 13 comparison sites) and 345 mi of roadway. A summary of the project

costs for Georgia is shown in table

29. Costs per mile of safety edge resurfacing versus

non-safety edge resurfacing were found to be $110,000 versus $140,000.

Table 29. Summary of Georgia resurfacing project costs (2005).

Cost item |

Weighted average

cost |

Nonweighted

average cost |

Safety edge sites |

Comparison sites |

Safety edge sites |

Comparison

sites |

Engineer's

estimate

($ million/mi) |

$2.650 |

$1.353 |

$3.222 |

$1.272 |

Contract

cost

($ million/mi) |

$1.306 |

$1.353 |

$1.183 |

$1.268 |

HMA

resurfacing cost ($/ton) |

$45.730 |

$43.050 |

$49.210 |

$42.970 |

HMA

resurfacing cost

($ million/mi) |

- |

- |

$0.110 |

$0.140 |

- Not applicable.

The Indiana data set included 16

resurfacing projects (8 treatment and 8 comparison sites) and 165 mi of roadway. A summary of the project costs

for Indiana is shown in table

30. Costs per mile of safety edge resurfacing versus non-safety edge resurfacing were found

to be $140,000 versus $150,000.

Table 30. Summary of Indiana resurfacing project costs (2005).

Cost

item |

Weighted average

cost |

Nonweighted

average cost |

Safety edge sites |

Comparison sites |

Safety edge sites |

Comparison sites |

Engineer's

estimate

($ million/mi) |

$1.878 |

$1.766 |

$1.748 |

$1.691 |

Contract

cost

($ million/mi) |

$1.505 |

$1.419 |

$1.407 |

$1.388 |

HMA

resurfacing cost ($/ton) |

$38.200 |

$35.510 |

$38.600 |

$35.650 |

HMA

resurfacing cost

($ million/mi) |

- |

- |

$0.140 |

$0.150 |

- Not applicable.

The New York data set included six resurfacing projects (three

treatment and three comparison sites) and 25 mi of roadway. A summary of

the project costs for New York is shown in table 31. Costs per mile of safety edge resurfacing versus non-safety

edge resurfacing were found to be $30,000 versus $40,000. Costs for New York projects are substantially less

than Indiana and Georgia. The HMA costs were generally higher in Indiana

and Georgia than in New York, but it is also possible that the New York

projects differed in scope from those in Indiana and Georgia.

Table 31. Summary of New York resurfacing project costs (2005).

Cost item |

Weighted average

cost |

Nonweighted

average cost |

Safety edge sites |

Comparison sites |

Safety edge sites |

Comparison sites |

Engineer's

estimate

($ million/mi) |

$0.368 |

$0.881 |

$0.354 |

$0.737 |

Contract

cost

($ million/mi) |

$0.106 |

$0.145 |

$0.108 |

$0.143 |

HMA

resurfacing cost ($/ton) |

$40.290 |

$49.180 |

$40.670 |

$51.710 |

HMA

resurfacing cost

($ million/mi) |

- |

- |

$0.030 |

$0.040 |

- Not applicable.

The cost analyses for resurfacing with the safety edge

treatment as compared to resurfacing projects on similar roads without the

safety edge treatment were reviewed collectively and individually. A summary of

the resurfacing costs for all three States combined is shown in table

32. Collectively, the cost of resurfacing with the

safety edge treatment was found to be slightly less than without the safety

edge treatment. Earlier analysis of the yield of coverage

on safety edge and non-safety edge sites in Georgia found only a very small difference

in the amount of area covered per ton of asphalt.

Table 32. Summary of combined Georgia, Indiana, and New York resurfacing project costs (2005).

Cost item |

Weighted average

cost |

Nonweighted average

cost |

Safety edge sites |

Comparison sites |

Safety edge sites |

Comparison sites |

Engineer's

estimate

($ million/mi) |

$1.632 |

$1.333 |

$1.775 |

$1.233 |

Contract

cost

($ million/mi) |

$0.973 |

$0.973 |

$0.899 |

$0.933 |

HMA

resurfacing cost ($/ton) |

$41.407 |

$42.578 |

$42.830 |

$43.445 |

HMA

resurfacing cost

($ million/mi) |

- |

- |

$0.096 |

$0.110 |

- Not applicable.

Some advocates of the

safety edge treatment maintain that incorporating the treatment in resurfacing

projects has little, if any, added cost

because the asphalt used is merely reformed to create the safety edge

treatment. The results summarized in table

32 can be interpreted as consistent with this

hypothesis. However, construction practices vary between contractors and highway agencies, and while the amount of asphalt

used for the safety edge treatment may be very small, it is unrealistic

to assume there is no additional cost to implement this treatment. The next

section presents an alternative approach to estimating the additional cost per

mile of the safety edge treatment.

5.2 Cost of Safety Edge Treatment Based on Amount of Asphalt Used

An alternative method to determine

the cost of the safety edge treatment is to compute the amount of

asphalt used to provide the treatment and multiply this quantity by a typical bid

cost per ton of HMA for that specific project.

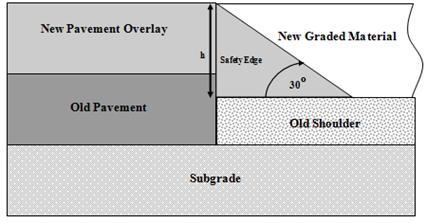

Figure 5 shows a typical triangular cross section for the

safety edge treatment. The safety edge treatment is shown with a cross slope of

30 degrees, which is consistent with current practice. The cost per mile

for the safety edge treatment on both sides of the road based on the cross

section shown in figure 5 can be estimated using equation 5.

Figure 5. Diagram. Typical cross section for the safety edge treatment on one side of the road.

(5) (5)

Where:

CCSE = cost for

application of the safety edge treatment ($ per mi)

A = area of the safety edge

treatment cross section (ft2)

h = height of safety edge

treatment (inches)

L = length of safety edge

treatment (ft)

D = HMA density (1b/ft3)

C = HMA cost ($/ton)

The height of the safety edge treatment (h) is estimated to range from 1.5 to 3.0 inches, based on the assumption that a 1.5-inch overlay will be

placed and that the shoulder will be leveled between 0 and 1.5 inches

below the elevation of the pavement existing before resurfacing.

The length of the safety edge treatment for a 1.0-mi road

section would be 2.0 mi or 10,560 ft for both sides of the road combined.

The density of the HMA for the safety edge treatment is

estimated to be 100 1b/ft3. This is less than the maximum density of

compacted asphalt because the safety edge treatment is not compacted as an

overlay course would be.

The cost of HMA has increased since the 2005 costs shown in table

29 through table

32. HMA costs vary substantially between regions of the

United States. Based on discussions with several highway agencies, a

representative current price for HMA is $75 per ton.

Applying equation 5 to the

values discussed above, the cost for a safety edge treatment 1.5 inches

high would be $536 per mi. The cost for a

safety edge treatment 3.0 inches high would be $2,145 per mi. Thus, a

reasonable range of costs for the safety edge treatment is $536-2,145 per

mi.

|