U.S. Department of Transportation

Federal Highway Administration

1200 New Jersey Avenue, SE

Washington, DC 20590

202-366-4000

Federal Highway Administration Research and Technology

Coordinating, Developing, and Delivering Highway Transportation Innovations

| REPORT |

| This report is an archived publication and may contain dated technical, contact, and link information |

|

| Publication Number: FHWA-HRT-17-026 Date: March 2017 |

Publication Number: FHWA-HRT-17-026 Date: March 2017 |

The purpose of the current practices review was to identify rumble strip implementation criteria, design features, and special considerations followed by State transportation departments. The review also examined what issues departments have faced in implementing rumble strips and how they overcame them. The methodology followed included a review of States’ Web sites and follow-up interviews. The project team reviewed Web sites, published materials for all State transportation departments and for FHWA’s EFL, and conducted follow-up interviews with five departments and FHWA’s EFL to gain further insights into issues in which they have struggled and to identify practices that have helped them. Several departments have had success with systematic CLRS and SRS application, while others have struggled to find support for implementation on their rural two-lane highways. The needs for these departments are summarized as part of the department interviews. The results of this review guided the development of the rumble strips decision support guide.(1)

The current practices review focused on department policies related to rural two-lane highways and includes policies from other facility types that are applied to two-lane highways (e.g., a department SRS policy may apply to both rural undivided and divided roadways) or when a policy for rural two-lane highways could not be found. This chapter is organized as follows:

The objective of the follow-up interviews was to identify noteworthy practices and potential implementation issues with departments leading in CLRS and SRS applications on rural two-lane highways as well as departments struggling with rumble strip implementation. The project team was tasked with identifying five follow-up interview departments. Potential follow-up interview departments were to include three departments with notable practices and two departments struggling with implementation. Considering both perspectives allowed for the development of a rumble strip decision support guide that is useful for all agencies.

Prior to developing selection criteria for identifying candidate departments, FHWA identified MnDOT and the Texas Department of Transportation (TxDOT) as two candidate departments for interview. The following selection criteria were used to identify a set of candidate departments to be interviewed in addition to MnDOT and TxDOT:

Rumble strip mileage was not a consideration in order to include struggling departments; however, some installations on rural two-lane roads were required in order to measure the issues the department has been facing since installation.

Table 5 lists departments with successful rumble strip implementation, and table 6 lists those struggling with implementation obstacles recommended for follow-up interviews. The tables provide reasons why they were recommended for follow-up interviews. The candidate list was provided for FHWA to approve the final list of interview departments, with the research team conducting a total of five follow-up interviews. The research team indicated that they would follow up with potentially one or two successful departments and one or two struggling departments based on FHWA’s preference. FHWA selected MnDOT, TxDOT, the Louisiana Department of Transportation and Development (LaDOTD), the Montana Department of Transportation (MDT), and the Connecticut Department of Transportation (ConnDOT) for follow-up interviews. Additionally, FHWA requested that FHWA’s EFL be included in the follow-up interviews as a department struggling with rumble strip implementation.

Table 5. List of potential succeeding departments.

| Succeeding Departments |

|---|

California Department of Transportation (Caltrans)

|

Hawaii Department of Transportation (HDOT)

|

LaDOTD

|

MDT

|

Virginia Department of Transportation (VDOT)

|

Table 6. List of potential struggling departments.

| Struggling Departments |

|---|

EFL

|

ConnDOT

|

North Carolina Department of Transportation (NCDOT)

|

Rhode Island Department of Transportation (RIDOT)

|

Vermont Agency of Transportation (VTrans)

|

Appendix A provides a list of interview questions provided to each department in advance of the phone interview. The interview departments responded to the questions prior to the interview or during the phone interview. The follow-up interview notes are provided in appendix B. The takeaways from the interviews are included in the discussion in each section throughout the document. The interview information supplements that information found in the policies for each department and FHWA’s EFL.

Previous to this effort, FHWA conducted detailed in-person interviews and field inspections with the following departments:

FHWA provided the interview notes to the research team. The takeaways from these interviews are included in the discussion in each section throughout the document and supplements information found in the policies for each department as well.

Roadway departure crashes, which include ROR crashes and head-on crashes, are typically a systemic problem, meaning that they account for a high number of crashes, but their density is often low. Consequently, high-crash locations prove difficult to identify, although more success can be found in identifying high-crash corridors. As noted in Low-Cost Treatments for Horizontal Curve Safety 2016, the most effective safety improvement processes include both a systemic component and site analysis or, in this case, corridor analysis component.(54) Additionally, departments use an additional systematic component for installing rumble strips based on department-level policy.

Systemic and corridor analyses are most commonly used to identify corridors for retrofit installations. Retrofit installations are projects in which the objective is to install rumble strips where they did not previously exist. Systematic analyses are most commonly used for installing rumble strips on new, reconstructed, or resurfaced roadways (i.e., rumble strips are applied on corridors while workers are on site performing other activities). Each of these approaches is defined below and explained in further detail in terms of rumble strip safety.

Using the systemic safety approach, departments implement rumble strips on corridors based on risk features that are correlated with higher severity focus crash types (e.g., fatal and incapacitating injury severities on the fatal, incapacitating injury, nonincapacitating injury, possible injury, and no injury scale). In this approach, corridor crash history is not considered for identifying rumble strip treatment locations. Rather, crash data analyses are used to identify risk factors associated with fatal and severe injury ROR crashes, fatal and severe injury head-on crashes, or other focus crash outcomes. Severe crash types are typically addressed using a systemic approach because they are often less concentrated than total crashes but tend to be overrepresented at locations with more risk factors. Risk factors for severe ROR crashes often include characteristics such as lane width, shoulder width, and traffic volume, among others. Analyses are conducted across all corridors within a facility type (e.g., rural two-lane highways) to identify factors that contribute to increased risk of focus crash outcomes. Risk factors may be combined in a weighted manner to identify specific corridors for treatment.

For example, analysis of all rural two-lane highway corridors within a jurisdiction may identify risk factors for fatal and severe ROR crashes as being AADT greater than 400 and less than 2,000, lane width less than 12 ft, shoulder width less than 4 ft, curve density greater than 2 curves per mi, and roadside hazard rating greater than 3. The jurisdiction may prioritize corridors with all of these risk factors for rumble strip installation or may develop weights for each risk factor and prioritize segments with the highest combined ranking of risk factors within a given budget.

Departments have traditionally used crash frequency (e.g., locations with a high number of crashes or higher than expected number of crashes) to justify additional corridors for installing rumble strips on an as-needed basis. This approach may also be referred to as a “case-by-case” approach because installation must be considered for each corridor based on multiple factors, and the decision to install or not is made independently in each instance based on these factors. Departments often consider the crash rate in relation to the statewide average to determine whether a corridor should be examined further for rumble strip installation. Most often, they base installation recommendations on 3 to 5 years of historical crash data.

The Highway Safety Manual (HSM) defines the crash rate as “the number of crashes that occur at a given site during a certain time period in relation to a particular measure of exposure.”(55)(p. 3-13) This is commonly computed as the average crash frequency, or crashes per year, divided by the average traffic volume (expressed as AADT) for the same time period. At this point, the crash rate for a corridor is compared to the average crash rate for all corridors within the specific facility type (e.g., rural two-lane highways). Typically, the corridors with the highest crash rates or crash rates that are above average are selected for treatment. This methodology is simple to employ; however, it suffers from the following limitations:

SPFs provide the predicted number of crashes for corridors based on data from corridors with similar characteristics, and SPFs typically include the corridor’s AADT and length. SPFs account for the non-linear relationship between traffic volume and crash frequency, as well as potential differences in characteristics for short versus long corridors. As noted in the HSM, the SPF prediction can be used for several methods for identifying high-crash corridors that are more statistically valid than the crash rate method.(55) (See chapter 4 of the HSM for more details on performance measures and their strengths and limitations.(55))

While the systemic approach to safety focuses on identifying locations for rumble strip installation based on risk, the systematic approach to safety focuses on installing rumble strips system-wide, often while completing other construction activities, with exceptions for installations that are based on policy. Most departments have policies outlining criteria for systematic rumble strip installation. Criteria for installation are based on special considerations, including accommodating bicyclists, minimizing noise disturbance, and avoiding potential pavement quality issues. For CLRSs, the systematic approach is typically based on pavement condition, posted speed limit, and lane or pavement width. For SRSs, the systematic approach is typically based on pavement condition, posted speed limit, shoulder width, and presence of curb or guardrail. Posted speed limit is often used as a surrogate measure for built-up environments.

Most departments implement CLRSs and SRSs based on crash history and/or systematically. Many departments with a systematic approach note that installations are required for new construction, rehabilitation, or overlay projects. Several departments go on to specify that implementation may also take place on existing pavements that meet “good condition” requirements, have a specified surface depth, and have no scheduled pavement work for the next 2–3 years. Additionally, for segments that do not meet the systematic criteria, crash history is often used to recommend installations. Documentation is typically required, and, in most cases, consultation with a bicycle coordinator or committee is recommended to consider all factors before making a final decision. However, several interview departments, including FHWA’s EFL, noted that rumble strips can be a difficult to implement, even though they are shown to be effective. Engaging a committee, decisionmakers, and stakeholders may allow for flexibility in implementation and identification of alternative solutions or treatments.

TxDOT and LaDOTD are examples of State transportation departments that employ a systematic approach to rumble strip application in conjunction with a crash history/hot-spot approach. TxDOT generally requires a 2-ft shoulder width in order to maintain a 13-inch recovery area on the paved shoulder beyond the ELRS. However, if the crash data support installation, then the department will install rumble strips on narrower shoulders. TxDOT noted that if they demonstrate the historical crash reduction factors (CRFs) for rumble strip installations to the general public, then they have fewer complaints upon installation. LaDOTD implements SRSs on all rural two-lane highways with a paved surface width greater than 22 ft and employs a crash analysis for rural two-lane highways with a paved surface width of 22 ft or less. CLRSs are applied systematically when the paved surface width is greater than or equal to 28 ft, and shoulders are greater than or equal to 2 ft. If the paved surface width is 24 to 28 ft and the shoulder width is greater than or equal to 1 ft, then a crash analysis is required. If the crash analysis does not warrant CLRSs, then SRSs or ELRSs are to be used. The following section provides an overview of current department systematic policies. This is followed by current practices for rumble strip installation on high-crash corridors.

Departments use systematic policies to develop criteria that, if met, automatically qualify corridors for rumble strip installation. Systematic policies most often apply to new construction, reconstruction, or resurfacing. This work is performed while the contractor is already onsite performing other activities and ensures the pavement is in good condition and will not be resurfaced again in the near term. Alternatively, departments install rumble strips as a retrofit if the pavement quality is sufficient and there is no scheduled paving activity in the near term. The length of time varies by department.

Systematic policies provide criteria for installation and a standard specification for rumble strip dimension and layout. Criteria for installation are generally not crash- or risk-based; they are based on roadway geometry, roadway users, and traffic operations. The written policy specifies minimum (or maximum) values for which rumble strips may be considered. The SRS and CLRS sections provide examples of criteria that departments use for systematic policies. Standard drawings provide details on basic rumble strip dimensions, locations, and breaks. Rumble strips are typically broken for intersections and bridges; standard drawings may provide details on where the breaks occur and may address non-standard applications at locations such as tapers, auxiliary lanes, and driveways (if necessary). Additionally, the standard drawings may provide information on bicycle gaps.

Departments have found increased buy-in for rumble strips when stakeholders are included in developing the language for systematic policies. For example, MDT engaged the bicyclist community in developing their policy and received feedback on language such as “The ideal clear space between the shoulder rumble strip and the edge of the paved shoulder is 4 ft.”(56)(p. 3) MDT modified the design to allow for bicyclists and used quality control to try to ensure that the 4-ft gap was maintained. Engaging stakeholders also increases buy-in and leads to better solutions for high-crash corridor solutions when the corridor does not meet the criteria for systematic installation. If stakeholders feel that their voice is heard, then they will be more open to understanding the effectiveness of rumble strips and will be more willing to work toward a solution that includes more system-wide installation, even on roadways with bicycle activity.

The next two subsections provide an overview of systematic installation policies and standards for SRSs and CLRSs, respectively. These sections highlight the variability in current practices and the practices of the departments that have been more successful in obtaining buy-in for rumble strip installation for non-freeway applications. The discussion focuses on rural two-lane highways and applies to multilane highways.

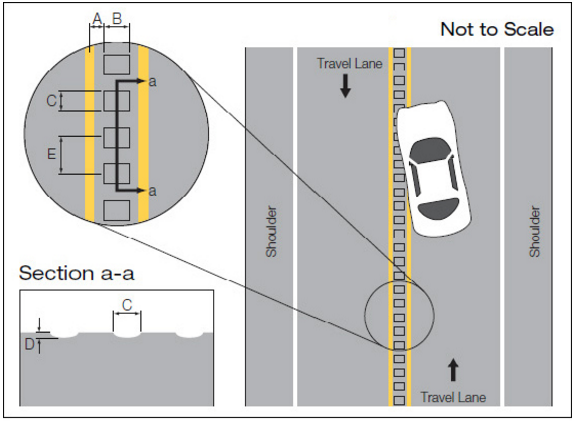

Table 7 provides key SRS and ELRS design dimensions and systematic installation criteria for all States and the FHWA Office of Federal Lands. Note that offset dimensions show the maximum under the department’s policy. The offset is zero for ELRSs. Figure 4 illustrates the dimensions used in table 7, which are consistent with those provided in the Rumble Strip Definitions section in chapter 1.

Table 7. Department systematic SRS design dimensions and installation criteria.

| State | A1 | B2 | C3 | D4 | E5 | Bike Gap—Run (ft) | Bike Gap—Gap (ft) | Posted Speed (mi/h) | Shoulder Width6 (ft) | Asphalt Condition | Use ELRS (Y/N) |

|---|---|---|---|---|---|---|---|---|---|---|---|

| Alabama | — | 8–12 | — | — | — | — | — | 45 | 2 | Good | Y |

| Alaska | 4 | 16 | 7 | 1/2 | 12 | 68 | 12 | 50 | 6 | Good, > 2 inches |

N |

| Arizona | 10 | 6–12 | 7 | 3/8 | 12 | 30 | 10 | — | 5 | Avoid joint | Y |

| Arkansas | 4 | 6–16 | 5 | 3/8 | 12 | 48 | 12 | 50 | 5-¼ | Good | Y |

| California | 6 | 6–12 | 5 | 5/16 | 14 | — | — | 40 | 5-½ | — | Y |

| Colorado | — | 12 | 7 | 3/8 | 12 | 48 | 12 | — | 5 | — | N |

| Connecticut7 | 6 | 16 | 7 | 1/2 | 12 | — | — | — | — | — | N |

| Delaware | 6 | 6 | 7 | 3/8 | 12 | 40 | 12 | 40 | 5 | New | Y |

| Florida7 | 12 | 16 | 7 | 1/2 | 12 | — | — | — | — | — | N |

| Georgia | 12 | 6–16 | 7 | 1/2 | 12 | 28 | 12 | 55 | 4 | — | Y |

| Hawaii | 2 | 6–12 | 5 | 3/8 | 12 | 47 | 13 | 40 | 4 | — | Y |

| Idaho | 12 | 6–16 | 6–7 | 3/8 | 12 | 48 | 12 | — | 2 | Good | Y |

| Illinois | — | 8–16 | 7 | 7/16 | 12 | 48 | 12 | — | — | — | Y |

| Indiana | — | 16 | 7 | 1/2 | 12 | 50 | 10 | — | — | — | Y |

| Iowa | 6 | 12 | 7 | 1/2 | 12 | 48 | 12 | 50 | 4 | — | N |

| Kansas | — | 12 | 7 | 1/2 | 12 | — | — | — | 2 | New, > 1 inch |

N |

| Kentucky | 12 | 8–16 | 7 | 3/8 | 12 | 50 | 10 | 50 | 1 | — | Y |

| Louisiana | — | 6–12 | 7 | 1/2 | 14 | 40 | 10 | 50 | — | Avoid joint | Y |

| Maine | 6 | 16 | 7 | 1/2 | 12 | 48 | 12 | 45 | 4 | < 5 years, > 3 inches |

Y |

| Maryland | 12 | 6–12 | 5–7 | 3/8 | 12 | 48 | 12 | 40 | 5 | Good | Y |

| Massachusetts | 4 | 16 | 6 | 3/8 | 12 | 64 | 16 | 40 | 8 | — | N |

| Michigan | 12 | 12 | 7 | 3/8 | 12 | 48 | 12 | 55 | 6 | — | N |

| Minnesota | 4 | 8–12 | 7 | 3/8 | 12 | 48 | 12 | 55 | < 4 | — | Y |

| Mississippi | — | 12 | 7 | 3/8 | 12 | — | — | — | 2 | — | Y |

| Missouri | — | 12 | 7 | 7/16 | 12 | — | — | 50 | 2 | > 1.75 inches | Y |

| Montana | 6 | 6–12 | 7–8 | 1/2 | 12 | 47 | 13 | 50 | 4 | — | Y |

| Nebraska | — | 8–16 | 6 | 5/8 | 12 | — | — | 50 | 2 | Good, > 2.5 inches |

Y |

| Nevada | — | 5-16 | 7 | 1/2 | 12 | 48 | 12 | — | 4 | — | Y |

| New Hampshire | — | 12 | 8 | 1/2 | 12 | 48 | 12 | 40 | 5 | — | Y |

| New Jersey7 | 4 | 16 | 7 | 1/2 | 12 | — | — | — | 6 | > 4 inches | N |

| New Mexico | 16 | 12 | 7 | 1/2 | 12 | 48 | 12 | — | < 6 | Good | Y |

| New York | 12 | 12 | 5–7 | 3/8 | 24 | 48 | 12 | 50 | 6 | Good, > 0.75 |

N |

| North Carolina | 6 | 8–16 | 7 | 1/2 | 12 | 30/50 | 6/12 | — | 4 | — | Y |

| North Dakota | 6 | 6–12 | 7 | 1/2 | 12 | 40 | 10 | 50 | < 2 | — | Y |

| Ohio | 10 | 6–16 | 5–7 | 3/8 | 12 | 48 | 12 | 50 | 2 | Pavement Condition Rating > 80 | Y |

| Oklahoma | 12 | 16 | 7 | 1/2 | 12 | 50 | 10 | 50 | 4 | — | N |

| Oregon | 12 | 6–16 | 7 | 3/8 | 12 | 30 | 10 | — | — | — | Y |

| Pennsylvania | 4 | 6–16 | 5 | 3/8 | 11 | 48 | 12 | <55 | 4 | Good | Y |

| Rhode Island | 4 | 12–16 | 7 | — | — | 48 | 12 | 40 | 6 | New, < 5 years |

Y |

| South Carolina | — | 4–12 | 7 | 3/8 | 12 | 48 | 12 | 45 | < 1 | Good | Y |

| South Dakota | 6 | 8–12 | 7 | 1/2 | 12 | 40 | 12 | 50 | 4 | — | Y |

| Tennessee | — | 4–16 | 5 | 7/16 | 12 | 60 | 15 | 40 | 0 | > 1.5 inches | Y |

| Texas | 4 | 8–16 | 7 | 1/2 | 12 | 40/60 | 10/12 | 50 | < 2 | < 3 years > 2 inches |

Y |

| Utah | 12 | 6 | 5 | 5/16 | 12 | 48 | 12 | — | 1 | — | Y |

| Vermont | — | — | — | — | — | — | — | — | — | — | N |

| Virginia | 6 | 12 | 7 | 1/2 | 12 | 48/52 | 12/16 | 45 | 4 | >2 inches | Y |

| Washington | 6 | 12–16 | 5 | 3/8 | 12 | 28/48 | 12 | 45 | 4 | Good | N |

| West Virginia | 6 | 12–16 | 7 | 3/8 | 12 | 48 | 12 | 45 | 4 | — | N |

| Wisconsin | 6 | 8 | 7 | 1/2 | 12 | 48 | 12 | 55 | 3 | Good | Y |

| Wyoming | 12 | 12–16 | 7 | 3/8 | 12 | 48 | 12 | 50 | 2 | — | N |

| Federal land | 12 | 8 | 5 | 1/2 | 12 | 48 | 12 | — | — | Good, > 2 inches |

Y |

|

1A represents dimension A (in inches) depicted in figure 4. 2B represents dimension B (in inches) depicted in figure 4. 3C represents dimension C (in inches) depicted in figure 4. 4D represents dimension D (in inches) depicted in figure 4. 5E represents dimension E (in inches) depicted in figure 4. 6Departments requiring a 4-ft shoulder typically require 5 ft if guardrail is present. 7Policy and criteria are not specific to rural two-lane highways (standards developed for freeways). —No information was available. |

|||||||||||

All State transportation departments except VTrans have a specific policy regarding SRSs and/or ELRSs. A few departments, such as the Florida Department of Transportation, do not have policies or standard drawings specific to rural two-lane highways, while other departments have combined guidance (e.g., rural non-freeway SRSs).

As shown in table 7, the typical SRS designs are 12 or 16 inches long, 7 inches wide, 0.5 inches deep, and spaced 12 inches apart. These typical SRS dimensions are similar to SRS recommendations from NCHRP Report 641, Guidance for the Design and Application of Shoulder and Centerline Rumble Strips.(8)

ELRSs have much more variety in applications of dimensions. ELRSs range from 4 to 16 inches long, with 6 inches being the most commonly specified length. However, 8- and 12-inch lengths are regularly specified. The most common width is 7 inches, but 5 inches is also used. Additionally, 0.375-inch depths are common for ELRSs, and 0.375 to 0.5 inch represent the majority of cases.

Many States allow rumble strips to be placed on the edge line or offset onto the shoulder. The decision is typically based on the paved shoulder width but may be influenced by the available pavement width between the rumble strip and the edge of the pavement. The most common reason for providing space between the SRS and the outside edge of the pavement is to provide adequate space for bicyclists (i.e., 4 ft of clear space, or 5 ft if curbing or guardrail is present); however, TxDOT noted the importance of providing recovery area on the shoulder. Their research indicates that a recovery area of at least 13 inches should be provided when possible.

Many States shown in table 7 have a standard rumble strip length based on a specified width of shoulder. As the shoulder width changes, the standard rumble strip dimension will changes correspondingly. For example, TxDOT specifies a minimum milled rumble strip length of 8 inches; therefore, in consideration of a 13-inch recovery area outside of the rumble strip, the minimum shoulder width for systemic installation is 2 ft. Typically, 2-ft shoulders are recommended for milled rumble strip implementation; however, as justified by crash need, ELRSs will be milled into roadways with narrower shoulders. Alternatively, raised pavement markers may be used, but milled rumble strips are preferred if the pavement thickness allows. If the shoulder is more than 2 ft but less than 4 ft wide, ELRSs with lengths of 8 to 16 inches may be used. However, rumble strips may be offset from the edge line if the paved shoulder width is wide enough to provide for a 13-inch recovery area. For shoulders equal to or greater than 4 ft, 16-inch rumble strips offset at least 4 inches from the pavement marking are typically recommended. The Tennessee Department of Transportation (TDOT) specifies that if the paved shoulder width is 0 to 4 ft, then 4-inch rumble strips are used in combination with the edge line pavement marking. If the paved shoulder is 2 ft or wider, then 8-inch rumble strips are used as an ELRS. If the paved shoulder width is 8 ft or wider, then 16-inch rumble strips are used with a 12-inch offset. These are two examples of departments that have adapted policies to allow rumble strips to be placed on nearly all two-lane roadways. Many departments have one rumble strip design that may be applied, and may apply minimum criteria (as defined in the minimum criteria section) for a roadway to be eligible for installation.

Flexibility is important in department policy, especially if the policy specifies parties that are involved in the decisionmaking process. For example, the MnDOT policy allows districts to use discretion for lateral placement to abate noise concerns and accommodate bicyclists.(57) Additionally, the policy provides flexibility in rumble strip length based on pavement width, flexibility in offset to accommodate bicyclists with input from the State Bicycle Coordinator, and flexibility to gap rumble strips on the inside of horizontal curves with nearby residences if a Safety EdgeSM or wider shoulder is installed. The Safety EdgeSM provides a recoverable 30-degree pavement edge rather than a vertical drop-off at the pavement edge.

Table 8 lists CLRS design dimensions and systematic installation criteria for each State transportation department and FHWA Office of Federal Lands. Note that the spacing is listed as 12/24 inches for several departments, which indicates that the spacing is 12 inches between rumbles followed by a 24-inch gap. Figure 8 illustrates the dimensions used in table 8, which are consistent with those provided in the Key Definitions section.

Table 8. Department systematic CLRS design dimension and installation criteria.

| State | B1 | C2 | D3 | E4 | Minimum Width—Pave (ft) | Minimum Width— Lane (ft) | Posted Speed (mi/h) | Asphalt Condition | Used in Pass Zone (Y/N) |

|---|---|---|---|---|---|---|---|---|---|

| Alabama | 8–12 | — | — | — | — | 11 | — | Good | Y |

| Alaska | 12 | 7 | 3/8 | 12 | 28 | — | 45 | Good, > 2 inches |

Y |

| Arizona | 6 | 7 | 3/8 | 12 | — | 11 | 45 | — | Y |

| Arkansas | 16 | 5 | 3/8 | 12 | 28 | 10 | 45 | Good | N |

| California | 6–12 | 5 | 5/8 | 12 | — | — | 40 | — | Y |

| Colorado | 12 | 7 | 3/8 | 12 | — | — | — | — | Y |

| Connecticut | 12 | 7 | 3/8 | 24 | 26 | — | 40 | Good | N |

| Delaware | 16 | 7 | 3/8 | 12 | — | 10 | 40 | New | — |

| Florida | — | — | — | — | — | — | — | — | — |

| Georgia | 16 | 7 | 1/2 | 12 | — | — | — | — | — |

| Hawaii | 16–20 | 6–9 | 1/2 | 12 | — | — | 40 | — | — |

| Idaho | 12 | 7 | 1/2 | 12 | 24 | — | — | Good | N5 |

| Illinois | — | — | — | — | — | — | — | — | — |

| Indiana | 16 | 7 | 1/2 | 12/24 | — | — | — | — | — |

| Iowa | 16 | 7 | 1/2 | 12/24 | — | 11 | 50 | < 5 years | — |

| Kansas | 12 | 7 | 1/2 | 12 | — | — | — | New, > 1.5 inches |

— |

| Kentucky | 8–12 | 7 | 3/8 | 12 | — | 11 | 50 | — | — |

| Louisiana | 6–12 | 7 | 1/2 | 14 | 24 | 11 | 50 | Avoid joint | — |

| Maine | 12 | 7 | 1/2 | 24 | — | 11 | 45 | < 5 years, > 1.5 inches |

Y |

| Maryland | 16 | 7 | 1/2 | 24/36 | — | 10 | 40 | Good | Y |

| Massachusetts | — | — | — | — | — | — | — | — | — |

| Michigan | 16 | 7 | 3/8 | 12/24 | 26 | — | 55 | — | Y |

| Minnesota | 16 | 7 | 3/8 | 12 | — | 11 | 55 | — | Y |

| Mississippi | — | — | — | — | — | — | — | — | — |

| Missouri | 12 | 7 | 7/16 | 12/24 | — | 10 | 50 | > 1.75 inches | Y |

| Montana | 6–12 | 7–8 | 1/2 | 12/24 | — | — | 50 | — | — |

| Nebraska | — | — | — | — | — | 11 | 50 | Good, > 2.5 inches |

— |

| Nevada | 12 | 7 | 1/2 | 12 | — | — | — | — | Y |

| New Hampshire | 12 | 7 | 1/2 | 12 | 28 | — | 40 | Good, >1.25 inches |

Y |

| New Jersey | 16 | 7 | 1/2 | 12 | — | 10 | 35 | Good, Surface Distress Index > 3 | Y |

| New Mexico | 16 | 7 | 1/2 | 12/24 | 26 | 12 | 50 | Good | Y |

| New York | 12 | 7 | 3/8 | 24 | 26 | — | 45 | Good, > 0.75 |

Y |

| North Carolina | — | — | — | — | — | — | — | — | — |

| North Dakota | 6–12 | 7 | 1/2 | 12/24 | — | — | 50 | — | — |

| Ohio | 16 | 5 | 3/8 | 12/24 | — | — | — | — | — |

| Oklahoma | — | — | — | — | — | — | — | — | — |

| Oregon | 16 | 7 | 1/2 | 24/48 | — | — | — | — | Y |

| Pennsylvania | 14–18 | 7 | 1/2 | 24/48 | — | 10 | — | Good, > 2.5 inches |

Y |

| Rhode Island | 12 | 7 | — | 12 | — | 11 | 40 | New, < 5 years |

Y |

| South Carolina | 12 | 7 | 3/8 | 14 | — | 10 | 45 | Good | — |

| South Dakota | 12 | 5 | 3/8 | 12 | — | — | 50 | — | — |

| Tennessee | 12 | 7 | 7/16 | 24 | — | 12 | 40 | Avoid joint | Y |

| Texas | 16 | 7 | 1/2 | 24 | — | 11 | 50 | < 3 years > 2 inches |

Y |

| Utah | 6 | 8 | 5/8 | 12 | — | — | — | — | Y |

| Vermont | 12–18 | 7 | 3/8 | 12/24 | 28 | — | 45 | Good | Y |

| Virginia | 14 | 7 | 1/2 | 12 | — | 11 | 45 | > 4 inches | Y |

| Washington | 12 | 7 | 1/2 | 12 | 24 | — | — | Good | Y |

| West Virginia | — | — | — | — | — | 11 | 45 | — | — |

| Wisconsin | 8 | 7 | 3/8 | 12/24 | — | 12 | 55 | Good | — |

| Wyoming | 12 | 7 | 1/2 | 12 | — | — | 50 | — | — |

|

1B represents dimension B (in inches) depicted in figure 4. 2C represents dimension C (in inches) depicted in figure 4 3D represents dimension D (in inches) depicted in figure 4. 4E represents dimension E (in inches) depicted in figure 4. 5Policy being reviewed currently. —No information was available. |

|||||||||

Figure 8. Illustration. CLRS dimensions.(7)

A total of 46 State departments, including the Federal Lands Highway Division Safety Team, currently have CLRS design standards, which were collected and compiled into a matrix. Of the five departments that did not have identifiable standards, NCDOT noted that CLRSs could be considered on a case-by-case basis dictated by crash history; however, no design policy was found for NCDOT.

As shown in table 8, the typical CLRS design standard is 12 or 16 inches long, 7 inches in wide, approximately 0.5 to 0.625 inch deep, and 12 inches in spacing. These typical CLRS dimensions are similar to recommendations from the NCHRP Report 641, Guidance for the Design and Application of Shoulder and Centerline Rumble Strips.(8)

While 12- and 16-inch CLRSs were the most prevalent of those identified in the department policies, the practices were not universal. Department policies included a minimum of 6 inches for rumble strip length and 16 inches as the maximum. A few departments (e.g., LaDOTD) specify rumble strip length based on roadway characteristics. In Louisiana, 6-inch rumble strips are used if the pavement width is 24 to 28 ft, with at least 1 ft of paved shoulder, while 12-inch rumble strips are used if the paved surface width is 28 or more ft. The most common application is a 12- or 16-inch milled rumble strip centered on the center line joint with pavement markings applied over the rumble strip. Other departments, (e.g., TDOT and the Nebraska Department of Roads (NDOR)) do not allow milled rumble strips on the center line joint. TDOT specifies 6-inch milled rumble strips, with each straddling a 4-inch gap for the center line joint, while NDOR places two 8-inch rumble strips with a 4-inch gap between them on either side of the center line joint. The double-yellow pavement markings are placed directly on top of the milled rumble strips, and the rumble strips are discontinued when the pavement markings are discontinued.

Departments are nearly universally specifying a rumble strip width of 7 inches for CLRSs and have policies for rumble strip depth that allow for some tolerances. Most commonly, 0.5 inch is specified for rumble strip depth, and tolerances range from 0.25 to 0.063 inch.

Departments commonly specify continuous CLRS spacing or may require a skip pattern for CLRS spacing. The skip pattern is used to allow for raised pavement markers or to provide a differentiation from SRSs/ELRSs. The idea is that the difference in sound will alert the driver as to which side he or she is drifting, since drivers most commonly assume they have drifted to the right and will correct to the left. The majority of departments specify 12-inch center-to-center CLRS spacing, but several departments specify 24-inch center-to-center continuous spacing. For skip patterns, it is most common to skip every third rumble, creating a 12-inch center-to-center run with a 24-inch center-to-center skip.

Departments provide gaps, or breaks, in the continuous patterns at many locations. Bicycle gaps are discussed separately in the Bicyclists section in chapter 3 and are not characterized here. Gaps for noise reduction are also discussed separately in the Noise Impacts section in chapter 3. Policies for gaps are commonly similar for CLRS and SRS/ELRS policy within a department. Profile rumble strips and raised rumble strips do not require gaps at bridges and overpasses and may be placed instead of milled rumble strips.

Gaps in milled rumble strips are commonly provided at intersections, auxiliary lanes, bridges and approach slabs, private and commercial driveways, locations with curbs and gutters or guardrails in combination with narrow shoulders, and railroad crossings. There is large variation in department policies for distance prior to bridge decks and intersections to break the continuous rumble strips. The most common practice is to provide a break 50 ft prior to bridge decks; however, some departments provide breaks 25 ft prior to bridge decks. VTrans allows CLRSs on bridges if there is at least 2.5 inches of bituminous overlay.

There is variation on providing gaps for intersections. Several departments define the break as a distance prior to the intersection, while other departments define the break by the location of the point of curvature for intersections. There is too much variation to characterize common practices in terms of distance before an intersection or point of curvature for an intersection; however, the range covers 25 to more than 100 ft. CLRSs are commonly broken where the center line pavement marking is broken for intersections and major commercial driveways.

Caltrans only breaks CLRSs at public street intersections and commercial driveways with at least 500 vehicles/d. Engineering judgment is recommended for ELRSs. LaDOTD only breaks CLRSs at major roadways because they feel safety is more important than the noise the rumble strips would generate for low-volume public streets and driveways. Department policies differ on providing gaps at passing zones for CLRSs. Several departments discontinue CLRSs at passing zones, while others, such as Caltrans and LaDOTD, provide CLRSs within passing zones. The Arizona Department of Transportation (ADOT) recommends that CLRSs be installed in rural areas with passing zones unless there will be a likelihood of significant noise generation in the vicinity of occupied residences.

This section describes the selection criteria for determining eligibility of roadways for systematic installation of rumble strips. The selection criteria are often exclusionary, meaning that rumble strips are eligible at locations unless the selection criteria indicate that they should be excluded from a location.

ADT is a measure of the total volume of vehicle traffic for a roadway for a day. Rumble strips are installed to alert drivers when they drift from their lane and are effective at reducing accidents; however, a certain amount of traffic volume may be necessary to make them

cost effective.

Most departments have no specific ADT specifications for the installation of CLRSs or SRSs. A few departments do specify ADT requirements, such as ConnDOT, where the ADT must be greater than 2,000 to install CLRSs. NDOR and VTrans also have CLRS ADT requirements of 1,500 or greater. The Maine Department of Transportation (MaineDOT) requires all roadways with 3,000 ADT regardless of a crash history to have CLRS and SRS installations.

For SRSs, only three State transportation departments other than MaineDOT have ADT requirements. The Georgia Department of Transportation requires 400 ADT for ELRSs, NDOR requires 500 ADT or greater for SRSs/ELRSs on non-interstate roadways, and SCDOT generally installs SRSs/ELRSs if the ADT is greater than 500.

MnDOT, in its follow-up interview, mentioned that their ongoing research has shown that, based on fatal crashes, both CLRSs and SRSs should be installed on all roadways with ADT greater than 4,700.

Departments typically consider pavement condition when determining whether to implement rumble strips because of the potential for increasing pavement deterioration. This criterion can include anything from pavement depth, pavement condition index, pavement type (e.g., new or reconstructed), or a time-based consideration. Most departments require that the pavement be in good condition, which is usually determined by a maintenance department or a specified group (e.g., district offices) at their State transportation department. Departments vary in their definition of good pavement condition, as shown in the following examples:

Additionally, a few departments, such as the Arkansas State Highway and Transportation Department (AHTD) and the Maryland State Highway Administration, note that future pavement preservation is a consideration in rumble strip installation. These departments note that installation may take place if no asphalt overlay is expected in the next 2 to 3 years.

While departments are consistent with developing policies requiring minimum pavement depth and/or condition for rumble strip implementation, their policies vary on the placement location of rumble strips in relation to the longitudinal joints. Some departments, such as MnDOT, have concerns regarding center line joint degradation, particularly for concrete pavements. TDOT and NDOR do not allow CLRSs to be milled onto the center line joint, instead opting for a pattern that straddles the longitudinal joint. However, most departments are allowing CLRSs to be milled over the center line joint, with the rumble strip centered on the longitudinal joint. CLRSs are being milled that are 12 to 16 inches long, with no departments reporting any issue with accelerated degradation when the pavement is in good condition. For SRSs and ELRSs, ADOT notes that the longitudinal joint should be avoided where practical, AHTD notes that the offset for SRSs may be increased to avoid longitudinal joints, and LaDOTD specifies that the longitudinal joint should be avoided for SRSs/ELRSs.

Additional considerations for rumble strip implementation include future pavement maintenance treatments on roads with rumble strips. These pavement maintenance treatments generally include thin treatments such as thin HMA overlays, chip seals, and microsurfacing. In a July 2010 New Hampshire Department of Transportation (NHDOT) report, Preparation of Rumble Strips Prior to Overlayment, the author initially recommended that existing rumble strips could simply be tacked and overlaid with a thin HMA overlay.(58) However, early implementation revealed several issues with this practice, including cracking of the new pavement and reflection of the original rumbles in the pavement surface. NHDOT ultimately elected to require that all rumble strips be milled and inlaid prior to placement of the overlay. Guidance from Donnell et al., developed for PennDOT, notes that existing rumble strips should be milled for HMA overlays, a second seal coat, or some forms of microsurfacing.(33) Separate guidance applies to CLRSs, SRSs, or their combination. The MDOT guidelines recommend that for HMA overlays (including surface milling with non-structural HMA overlay) and microsurfacing the overlay material should be used to fill in existing rumble strips.(59) Rumble strips should be reestablished after the HMA or microsurfacing overlay. However, the guidelines state that chip seals should be placed over existing rumble strips. If new rumble strips are desired for roadways to be chip sealed, then they should be milled into the pavement prior to the chip seal. Similarly, WSDOT’s guidance states that chip seal surfacing should have a total thickness (including HMA applications) of at least 3 inches for milled rumble strip application.(60) The guidance notes that insufficient depth and exposure to freezing and thawing of moisture can lead to delamination. Further guidance states that chip seals can be placed over existing rumble strips once and still be effective. Roadways receiving subsequent chip seals are to be evaluated to determine whether the depth of the remaining rumble strips is adequate for an additional chip seal.

In the noteworthy practice department interviews, the Atlanta District of TxDOT mentioned through its interview that it uses preformed raised rumble strip bars. After roadway resurfacing over the existing preformed rumble bars with a thin HMA overlay, TxDOT found from field visits that the vibration and audible noise level from the rumble strips was still at an acceptable level with one overlay. Upon applying two thin HMA overlays the vibration and noise level of the rumble strips was lost.

If milled into pavements in good or better condition, there is no documented evidence that rumble strips themselves require maintenance. Several departments have used and continue to use fog seals (spray applications of diluted asphalt emulsion) with the expectation that it will reduce the risk of premature deterioration. Some departments have stopped using fog seals because they did not experience a benefit. Additionally, as noted by FHWA, fog seals are incompatible with thermoplastic pavement marking applications.(32)

Additionally, some States have expressed concern about the potential for water to collect in the depression made by milling rumble strips. TxDOT, along with other departments, had no mention of issues such as hydroplaning or debris build up due to rumble strips. Weather conditions, such as snow removal, have not been discussed within departments outside of the fact that most northern States do not use raised rumble strips due to snowplowing operations. However, northern State departments have noted that plow drivers use rumble strips for assistance in lane keeping when visibility is low, which is a maintenance benefit.

Speed limits set the maximum and occasionally minimum speeds along particular roadways stretches in which it is legal for vehicles to travel. Speed limits are representative of the level of urbanization along a roadway. Across the United States, maximum speed limits on rural two-lane highways can vary from a low of 45 to a high of 75 mi/h. Speed limit restrictions do not transpose well across the United States because the demographics, geography, and urbanization varies greatly. Some States, such as Rhode Island or Hawaii, have limited rural undivided roadways with speeds over 45 mi/h, unlike Texas or other midwestern or western States where speed limits on rural two-lane highways are commonly 70 or 75 mi/h. This implies that a one-size-fits-all speed limit surrogate for urbanization is not appropriate. However, commonly used maximum speed limits for rumble strip implementation are provided.

CLRSs and SRSs are generally installed on roadways with a speed of 45 mi/h or greater. California, Connecticut, Hawaii, and New Jersey allow mainly CLRSs be installed on roadways with 35 mi/h or greater, while Delaware, Maryland, New Hampshire, and Rhode Island allow 40 mi/h for two-way conventional CLRSs and SRSs.

It is important to understand the interaction of design elements, especially minimum lane width, when implementing rumble strips along roadways. Operational and safety performance can be impacted by vehicles attempting to avoid unnecessary contact with rumble strips when lane widths are too narrow. Vehicles tend to shift away from rumble strips, potentially into adjacent lanes or the shoulder affecting the safety of other drivers, as well as non-motorized users such as bicyclists who may be using the adjacent lane or shoulder.

Across departments, minimum widths vary in relation to the type of rumble strip being implemented. CLRSs are often specified as requiring a minimum total pavement width and minimum lane width. SRSs and ELRSs are often specified as requiring a minimum total pavement width and minimum shoulder width. Most commonly, an 11-ft minimum lane width is required for CLRS and/or SRS installation, with 9 ft of effective lane width being the minimum and 12 ft as the maximum.

MDT is experimenting with the current standards by allowing lane narrowing by 6 inches and using ELRSs to make the shoulder as wide as possible without having to place the rumble strips on the outside edge of the mat. The goal is to provide at least a 4-ft clear space for bicyclists.

Bicyclist advocacy groups have expressed their concerns regarding rumble strip installation, particularly SRSs and ELRSs, due to inadequate shoulder width for bicyclists. Many departments have included these organizations into their advisory committees before determining design standards or include their input when proposing to install SRSs. Additionally, the paved shoulder width is important for providing a separation between the edge of pavement to the rumble strip for maintenance concerns and for providing adequate recovery areas for vehicles, especially where there is a narrow clear zone outside of the paved shoulder. TxDOT noted that their research has shown that at least 13 inches of recovery area should be provided outside of rumble strips on the paved shoulder.

TxDOT has a Bicycle Advisory Committee and Motorcycle Safety Coalition. These groups both have input into TxDOT policies, and, by involving these representatives of the public, TxDOT helps ensure effective communication with the bicyclist community. The bicyclists’ perspectives are considered in the development of departmental policies affecting bicycle use, including the design, construction, and maintenance of highways. Additional bicycle information is discussed in the Bicyclists section in chapter 3.

Due to these organizations and advisory committees assisting with department designs, the majority of departments require a minimum shoulder width of 4 ft or greater for installing SRSs and ELRSs, especially in high bicycle traffic areas. WSDOT requires at least 4 ft of available width between the rumble strip and the edge of the pavement, except in rare cases, and 5 ft if there is barrier at the pavement edge. When a roadway does not have high bicycle traffic, some departments are using a smaller shoulder width of 2 ft. According to the data collected from departments, the minimum required shoulder width is 2 ft, and maximum required shoulder width is 6 ft. MDOT requires 6 ft of paved shoulder for systematic installation to accommodate bicyclists with trailers. If crash problems are identified on sections with less than 6 ft of paved shoulder, then they typically recommend adding 2 ft of shoulder in conjunction with installing the rumble strips. PennDOT does not install rumble strips if less than 4 ft of shoulder will remain. They consider bicyclists’ needs a top priority, and, if there is a high departure crash rate, then they recommend using Highway Safety Improvement Program funds to widen the shoulder and add rumble strips.

These varying shoulder widths dictate dimensions and placement of rumble strips for many departments. For example, TxDOT allows for narrower rumble strips or ELRSs for narrower shoulders in comparison to their standard design. VDOT and NYSDOT allow for ELRSs if the specific area has a documented history of ROR crashes.

Since rumble strips are a low-cost, proven safety countermeasure, few departments discuss shoulder widening as a potential alternative when narrow shoulders are a concern. HDOT notes that paved shoulder widening should be considered if necessary to accommodate installation of SRSs/ELRSs.

It should be noted that these policies refer to systematic installation of SRSs and ELRSs. The interview departments noted that they will place ELRSs on narrower shoulders, so long as the crash data justify the need. These locations are typically identified using a hot spot approach to safety.

Departments mainly specify a minimum total pavement width for CLRSs, although LaDOTD does specify a minimum of 22-ft pavement width for ELRS installation. The required minimum pavement width varies between departments from 22 to 28 ft, with the most commonly required minimum pavement width being 28 ft.

Additionally, ConnDOT is concerned about CLRS installation, with the concern coming from the bicyclist/pedestrian community, who note that vehicles may shift away from the roadway center line and encroach on the shoulder. ConnDOT has decided that due to this concern, it is best to install CLRSs on roads with a satisfactory shoulder for pedestrian use, and, based on feedback provided by the bicyclist and pedestrian communities, their advisory committee determined that a minimum width of 26 ft is needed to install CLRS.

Many high-risk locations may not qualify for systematic installation but may benefit from rumble strip installation based on crash history. For example, highway corridors with narrow shoulders may not provide adequate clear space for bicyclists with rumble strip implementation but may have a history of high ROR crash counts. Practitioners can use the methods provided in the Rumble Strips and Safety Management section of the decision support guide to identify the need for and potential benefits of rumble strips in these corridors.(1) Most departments reviewed do not provide specific guidelines for how and when to install rumble strips in these cases. Additionally, these corridors have the greatest potential for installation issues due to special considerations. Consideration of the potential benefits and trade-offs is paramount, and the departments with the most success installing rumble strips have written processes or requirements, including who is involved in the final decisionmaking. Successful policies include relevant stakeholders in the decisionmaking process once the need is identified.

Several departments have identified key personnel involved with decisionmaking or have identified personnel who are typically included in a rumble strip decisionmaking committee. Examples of personnel who may be involved in the decisionmaking process include the following (note that departments differ in the titles of individuals and names of key offices):

Each of these personnel may be considered at the local/county, regional/district, or State/central office level of the organization, and concurrence among personnel is paramount. Additionally, stakeholders may be included in the process or notified as early as possible to allow time for feedback. Potential stakeholders include municipalities, local bicyclist groups, and adjacent roadway property owners and residents. Their feedback is critical and should be considered in combination with potential safety benefits. This also gives the department an opportunity to provide stakeholders with information on the safety benefits, including specific performance measures calculated in the safety analyses. This may help the department promote rumble strips to stakeholders.

A few departments also note the importance of project decision documentation. Due to the potential safety impact of decisions, it is important to document the need and the decision whether or not to install rumble strips and the reasoning for the decision. Documentation is also important for explaining the benefits to stakeholders and others who may perceive a disbenefit for their installation. TxDOT noted that if they demonstrate the historical CRFs for rumble strip installations to the general public, they have fewer complaints after installation. MDOT requires documentation when the decision not to use SRSs is made for special cases where a crash history does not exist, such as locations where horse-drawn buggies use the roadway or the driveway density exceeds 30 access points within 0.5 mi.

MDT has a specific process for new construction, reconstruction, rehabilitation, and overlay corridors where the shoulder width is greater than 1 ft but less than 4 ft. The procedure includes the following steps:(56)

This subsection describes the issues that departments encounter that alter their standard practice of rumble strip installation.

As mentioned previously, the typical design standards that were collected from department standards and policies are similar to those found in NCHRP Report 641, Guidance for the Design and Application of Shoulder and Centerline Rumble Strips.(8) Some departments alter their design for a variety of reasons, such as the results of peer exchanges, influence from public organizations, or legislation. For example, MnDOT had some legislative and public pushback when installing rumble strips. It forced the department to change its practices, ultimately leading MnDOT to work with sinusoidal rumble strips. The goal was to allow for continued rumble strip implementation in consideration of the pushback on exterior noise generated by rumble strips. ConnDOT learned that the barriers were more perceived then actual because CLRSs and SRSs are still new concepts that people are not familiar with in Connecticut.

The three major influences that cause departments to adjust their standard practices include bicyclists, external noise impacts, and research. These subsections are described in detail in the following subsections.

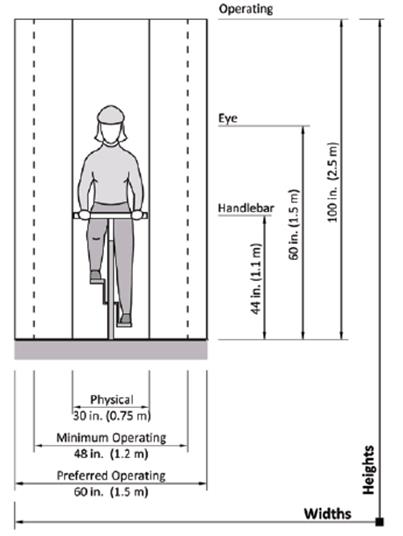

Bicyclists have a variety of basic requirements that need to be accommodated for their safe navigation on shared roadways with vehicles. As the AASHTO Guide for the Development of Bicycle Facilities shows in figure 9, the minimum operating width is 4 ft.(61) The CROW Design Manual for Bicycle Traffic additionally notes the need for 13 to 25 inches of clearance from fixed obstacles.(62) This distance provides for the width of the bicyclist as well as the necessary width to operate or maneuver the bicycle. Additional factors that affect bicyclists on roadways with rumble strips are clean pavements and the ability to cross rumble strips safely.

©AASHTO.

Figure 9. Illustration. Bicycle roadway requirement dimensions.(61)

Caltrans has conducted field testing and determined that the strip depths (0.313 ± 0.063 inch) are traversable by bicycles. Other departments such as the AHTD changed the depth of their rumble strips to 0.375 inch because this depth is less disruptive to bicyclists. For installation of CLRSs, ConnDOT generally requires that roadways be at least 26 ft wide. On roadways with high bicyclist activity, TxDOT gives consideration to bicyclists before the installation of ELRSs. Factors considered include the size of rumble strips, rumble strip material, and location of rumble strips on the shoulder. If the TxDOT designer determines that gaps are needed in the rumble strips due to bicyclist use of the road, the requirements provided in the FHWA Technical Advisory T5040.39 or the latest version detail of the spacing are included in the plans.(63)

Some departments have approached bicycle accommodations with rumble strips with an absolute consideration. Caltrans, the Delaware Department of Transportation, and HDOT require a 5-ft minimum shoulder if bicycles are permitted; however, if a 5-ft shoulder is unattainable, then ELRSs are recommended. Other State transportation departments, such as LaDOTD and MnDOT, use a case-by-case approach that vets their bicycle accommodations through multiple advisory committees before recommending SRSs. These advisory committees may include FHWA representatives, upper management within the department (e.g., State pedestrian and bicycle coordinators), senior citizen advocacy group members, bicyclist groups, non-motorized vehicle committee members, and/or Complete Street policy advocates. In recent years, bicyclist organizations/associations have taken a much more vocal role in designing safer roadways that accommodate non-motorized vehicles. Departments have made a concerted effort to involve these organizations/associations into their roadway designs. For example, MnDOT has a Non-Motorized Advisory Committee that assists with the design and comments on where rumble strips are installed. Departments such as MaineDOT also specify that the concurrence of the Safety Office in consultation with the bicyclist/pedestrian coordinator is required if a 4-ft clear space cannot be maintained or if a 5-ft clear space in the presence of curbing or guardrail cannot be maintained. Departments are recognizing the need for clear space for bicyclists and may break the rumble strip pattern for a length if the clear space cannot be maintained (e.g., along a section of guardrail).

Rumble strip gaps are another strategy for helping with roadway rideability rather than omitting rumble strips on roadways with bicyclist activity. Gaps in the continuous rumble strip pattern allow the bicyclists to enter or cross the travel lane as necessary to make a turn or avoid an object ahead on the paved shoulder. Departments vary regarding bicycle gap design; however, the most common trend is a 12-ft gap every 60 ft. This implies that there is 48 ft of continuous rumble strips followed by a 12-ft gap. It is also common practice for departments to provide a 10-ft gap in rumble strips with a 30- to 40-ft run of continuous rumble strips. A few departments, such as NCDOT and VDOT, have lengthened the gap distance somewhat in the presence of steeper downgrades, recognizing the increased speeds of bicycles.

Some departments also involve the public at large when designing roadways with bicyclist accommodations. During the roadway design process, ConnDOT submits a bicyclist and pedestrian assessment form to the Office of Intermodal Planning for their consideration. From there, a letter is sent to all chief elected officials to explain the project and allow them to request a public meeting. MDOT has worked with the League of Michigan Bicyclists to survey bicyclists on several design related issues, including video and documentation of motorist vehicle placement when passing bicyclists. MDOT worked with the group during the design and implementation of the rumble program to help create a “Share the Road” public service announcement to help drivers understand how to pass bicyclists where CLRSs exist due to a concern that CLRSs would discourage motorists from crossing the center line while passing a bicyclist. WSDOT conducts outreach to bicyclist groups near proposed projects, involved a Bicycle and Pedestrian Advisory Committee during the development of the SRS policy for undivided highways, and has discontinued rumble strips on roadways that host annual bicycle races. SCDOT initiates discussions with bicyclist advocacy groups to obtain feedback when proposing installations on South Carolina bicycle routes. Recommendations for installations come from crash analyses, and SCDOT is proactive about gaining support from the bicyclist community in order to apply rumble strips on designated bicycle routes.

As noted earlier, when MDT was developing its Rumble Strip Guidance, it sent out modified guidance and received pushback on the initial language.(56) MDT engaged the bicyclist community to receive feedback on the language, and one relevant change was the statement that “The ideal clear space between the shoulder rumble strip and the edge of the paved shoulder is 4 ft.”(56)(p. 3) For narrower pavements, the text specifies that the lane width can be reduced by 6 inches or an ELRS can be used to try to obtain a 4-ft clear space. Additionally, MDT has implemented quality control measures as an effort to ensure that a 4-ft clear space is maintained through the installation process. MDT is stressing to construction departments the importance for quality in this case. MDT also identifies high-priority bicycle routes by engaging the pedestrian and bicyclist coordinator who interacts with the pedestrian and bicyclist groups to determine the protected routes. Additionally, they use tools such as online heat maps to identify high-usage bicycle routes. Heat maps are generated by fitness devices worn by bicyclists, identifying an exposure level for each route. Departments are being cognizant of designated routes and highly traveled bicycle routes and are using bicycle heat maps and State and local bicycle route maps as they update and construct new roadways.

Rumble strip effectiveness comes from the external noise and vibrations that are generated when a vehicle drives over them. The external noise level has been shown to be a function of the design characteristics of the rumble strip. MnDOT conducted a rumble strip noise study in May 2014 after they received complaints from residents expressing their concern regarding rumble strip noise.(64) After concluding this research, a moratorium was placed on rumble strips as MnDOT continued researching quieter options. The Kansas Department of Transportation also conducted research on different types of rumble strip designs to decrease the noise impact.(65) This study compared football-shaped rumble strips with rectangular rumble strips and concluded that there was no significant difference between the two designs. There is a current lack of research and information that addresses how to accommodate both safety and noise complaints especially in residential or similar areas.

Noise complaints from the public seem to generally occur in locations where the speed is low, the roadways are rural, and there is a certain degree of development. Most departments have a minimum speed limit threshold of 45 mi/h as a surrogate for urbanization. However, MDOT noted that most rural highways are posted at 55 mi/h, and including 45 mi/h roadways would only add about 70 mi of additional highway. Departments such as the AHTD and ADOT normally do not install rumble strips in urban areas because of higher population and lower speed limits; however, if an engineering study determines that rumble strips are needed to reduce roadway departure crashes, then it is deemed acceptable. The policy of TxDOT (which has a roadway criterion of 45 mi/h or greater for rumble strips) states that consideration should be given to noise levels when ELRSs are installed near residential areas, schools, churches, etc., and allows for a minimum of 0.375-inch depth in these areas. MDOT studied locations with noise complaints and changed their policy to allow rumble strip omission where the driveway density exceeds 30 driveways per 0.5 mi. MoDOT found that most noise complaints from new installations subside within a year. When complaints continue beyond a year, MoDOT has found that an evaluation is needed because there is a greater likelihood there is a problem at the location. In some cases, they have removed rumble strips in the stretch where the noise concern is concentrated.

ConnDOT, who uses a 35-mi/h or greater criteria for installing rumble strips, installed CLRSs in 1999 at high-crash locations yet removed the installations within a year due to the large number of noise complaints. It was not until 2014 that ConnDOT began installing CLRSs again. Due to the level of pushback, and subsequent moratorium, ConnDOT does not have a policy for installation of CLRSs. LaDOTD, which only installs rumble strips on roadways with speeds of greater than 50 mi/h and not in residential areas, reported not having any pushback or issues with the noise impact from rumble strips.

Several departments have criteria on when to discontinue rumble strips before residential areas that range from 130 ft (MnDOT) prior to residential/commercial areas to 1,000 ft (Nevada Department of Transportation (NDOT)) or 2,000 ft (ADOT). Practical constraints show that policies in rural Arizona and Nevada cannot be applied well in more urbanized States, such as those in the northeast. In general, most departments have a more blanket approach to noise impacts, such as the Alabama Department of Transportation (ALDOT), whose policy states that noise should be considered when determining whether to install CLRSs near residential or other sensitive receptors, but this guidance is secondary to safety.

Noise complaints are handled differently by every department due to differing levels of pushback. While TxDOT has removed rumble strips due to noise complaints, they noted that this has been a very rare circumstance. TxDOT and LaDOTD both noted that noise complaints have been minimal. MoDOT found that a widespread implementation program may have helped to reduce noise concerns. There is a perception that if only a few roads had rumble strips installed, or if the program had been over a much longer time period, then residents would have complained more about the noise because it would not have been fair. However, the program affected everyone equally and was associated with an improved roadway surface, and many drivers experienced the benefits of the warning firsthand. Alternatively, FHWA’s EFL struggles with a variety of pushback from sign installation to rumble strip installation; moreover, FHWA’s EFL noted that wildlife and environmental issues are typically a larger concern due to rumble strip noise, which impacts the surrounding wilderness. It is difficult for these departments to gain public approval of rumble strips, and FHWA’s EFL noted that any additional information they can provide to emphasize their effectiveness would help achieve this objective.

Passing zones are another area where noise impacts are frequently found and where department policies vary substantially. Caltrans installs CLRSs continuously through passing and no-passing zones. ALDOT, AHTD, and NDOT policy states that CLRSs should be installed continuously through no-passing zones, while no CLRSs should be installed at passing zones. ConnDOT does not install CLRSs in passing zones and requires them to be discontinued 25 ft before the passing zone begins, with the main reason being noise created by vehicles hitting CLRSs legally/purposefully (as opposed to accidentally hitting them in a non-passing zone). RIDOT requires CLRSs to be installed consistently with the passing zone striping (8-ft strip and 32-ft gap), while VDOT requires the CLRSs be 0.375 inch deep in the passing zone areas with the possibility of increasing the spacing to 24 inches.

Additionally, PennDOT and WSDOT have discontinued ELRSs on the inside of horizontal curves due to nuisance strikes or off-tracking from heavy vehicles. Alternatively, the West Virginia Department of Transportation and MoDOT increase the offset to SRSs in locations where external noise may be a factor. MDOT uses a skip pattern on the center line and a 12-inch offset on the shoulder to help reduce noise generated by vehicle contact.

Departments noted that using several different cross section and rumble strip designs based on the following special considerations:

Although most departments have their own standard design for CLRSs, SRSs and ELRSs, they do allow some flexibility to design standards, especially with sites that have a history of ROR crashes and bicyclist concerns. Most departments have policies for systematic rumble strip installation on reconstructed, resurfaced, or newer pavements, often specifying a minimum pavement width for CLRSs and minimum shoulder width for SRSs. However, most departments specify that high-crash locations can be identified through crash data and will choose to install rumble strips at these locations even if the systematic criteria are not met. However, it is important for the department to show the effectiveness of the rumble strip design because the installation may impact the usability of the roadway for bicyclists or may burden nearby residents with increased noise or perceived noise activity. While rumble strips are an effective systemic safety solution, systemic installation is not discussed in department policies, and the systematic approach is used instead.

Many departments struggle with these considerations, which is where a tool or guide can be most useful. In the context of transportation safety, a tool implies decisionmaking based on a series of inputs and a computer routine that arrives at a series of recommendations. For rumble strips, a blanket solution for all departments may not be feasible because each State already has a set of selection criteria and design policies in place. There is insufficient information for developing a tool that provides a recommended rumble strip design that may differ from a department’s policy. However, the results of this effort can be used to help struggling departments shape their current policies, provide guidance based on how other departments handle the same decisions, and provide assistance in the decisionmaking process.

As a result of the current practices review, the project team recommended developing a rumble strip decision support guide, which was selected by the FHWA. The next chapter discusses the development of the decision support guide, the development of a model decisionmaking framework, and the vetting process used for departments to provide feedback on the guide.