Excluding Occupational, Safety and Health Administration (OSHA) requirements, noise measurements related to highway construction are generally made for only one purpose: to obtain information needed to identify, evaluate and mitigate highway construction noise impacts. Basically, three types of information may be needed:

Obviously, the amount of information needed will vary from project to project. In some environmental assessments, it may be possible to obtain all of the information needed without any measurements.

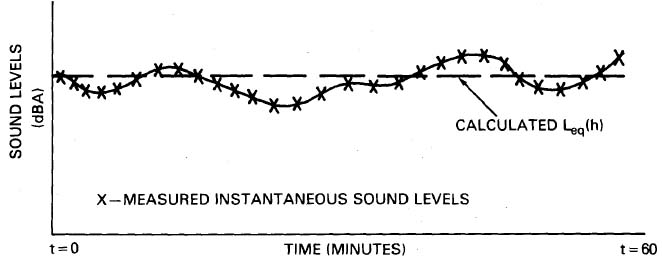

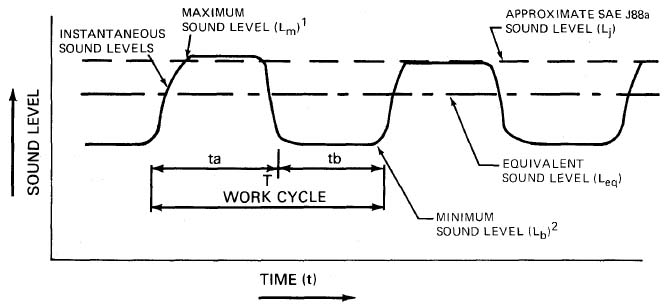

In this manual, all of the information needed to identify and evaluate highway construction noise impacts is expressed in terms of the hourly, A-weighted, equivalent sound level, Leq(h). Although equipment is available that will measure this metric directly, this manual assumes that only a hand-held sound level meter (SLM) is available. Therefore, it will be necessary to record the instantaneous sound levels measured by the SLM and compute the Leq(h). This is illustrated graphically in Figure 1.

This approach was chosen for two reasons. First, it was felt that the hand-held SLM was in more common use than the Leq meters among highway agencies. Secondly, standardized measurement procedures for construction noise are now under development by several national and international organizations. Unfortunately, these organizations have not adopted a standard metric to describe construction noise. Use of the Leq(h) permits the use of the measurement procedures that have been developed to date and allows data comparisons to be made using a common metric.

Figure 1: Sound Level Versus Time

The remainder of this chapter discusses measurement procedures that can be used to measure the existing sound levels (Section 2.1), the sound levels of individual construction equipment (Section 2.2), and the overall construction sound level (Section 2.3). Each section will define the sound level being discussed, indicate when the measurements are made, what uses are made of the sound levels, and how they are measured.

Existing sound levels describe the acoustical environment prior to modification of an existing highway or construction of a new one. The existing sound levels include all natural and manmade sounds present at the site.

Information on existing sound levels is routinely developed during the noise studies for a highway project. If the project involves the reconstruction of an existing highway, or if the new project is located near another highway, and if the existing sound levels are predominantly due to highway traffic, the Leq(h) can be computed. This can be done using the traffic noise prediction models. In other situations, sound level measurements are needed to quantify the existing acoustical environment. In either case, the information on existing sound levels is normally developed in the early stages of project development, often years before construction of the project is started. In some situations, it may be necessary to reevaluate the existing levels prior to the start of construction.

The existing sound levels serve as a reference where the magnitude of the increase in sound levels, due to some changed highway condition, is indicative of the degree of impact. Construction noise impacts can be expected whenever the expected sound levels significantly exceed the existing sound levels.

Chapter 3 of the text1 (see references). " The Fundamentals and Abatement of Highway Traffic Noise," discusses environmental or existing noise measurements. Information is provided on the use of sound level meters, the selection of measurement sites and when the measurements should be made. In addition, a detailed measurement procedure is provided for determining and recording the existing instantaneous sound levels. Based upon these sound level observations, a procedure and a criterion are given which insure computation of a statistically valid L10 for the time interval over which the measurements were made. Although this time interval is generally shorter than one hour, it is assumed that the sound levels are constant over one hour and the calculated L10 value is representative of an L10(h).

Once a statistically valid L10(h) has been obtained, the Leq(h) can be calculated as follows:

Leg(h) = 10log1/N NΣi=1n; 10Li/10 (2-1)

Where Leq(h) is the hourly, A-weighted, equivalent sound level,

N is the number of sound level readings taken to obtain a statistically valid L10

ni is the number of sound level readings in the ith class.

Li is the level of the ith sound level reading taken during the measurement period.

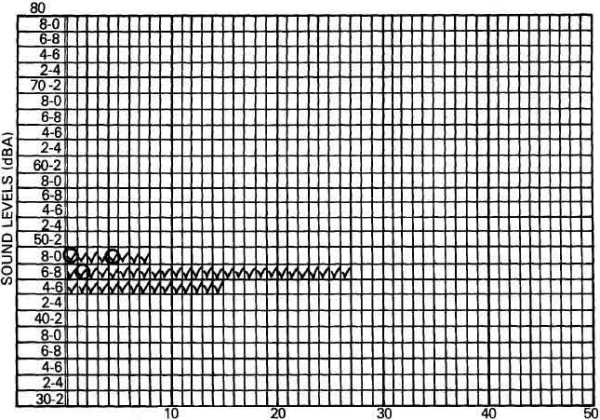

Problem No. 1: Compute the Leq(h) of the sound level readings shown in figure 2.

L10 = 49 +1-3dBA

L10 Criterion met after 50 samples

No. of Occurrences

Figure 2: Noise Level Readings

(Source: Sketch 3.4 page 3.9, Fundamentals and Abatement of Highway Traffic Noise

Leg(h) = 10log1/N NΣi=1n; 10Li/10

Leg(h) = 10log1/50 [Σ (8)(1049/10) + (27)(1047/10) + (15)(1045/10)]

= 10log2463010/50 = 10log49260

= 47 dBA

Alternately, the following procedure could be used.

| Measured Sound Level L | No. of Occurrences (N) | 10 log N | L + 10 log N | dB Sum (dB addition) |

|---|---|---|---|---|

| 49 | 8 | 9 | 58 | |

| 47 | 27 | 14 | 61 | 64 |

| 45 | 15 | 12 | 57 |

Leq(h) = dB Sum - 10 log N

= 64 - 17 = 47 dBA

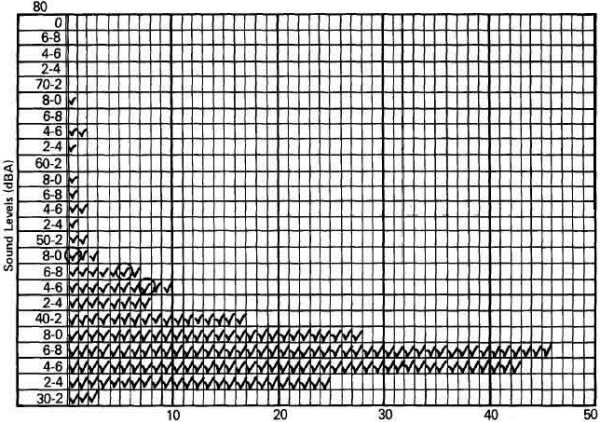

Problem No. 2: Compute the Leq(h) of the sound level readings shown in Figure 3.

L10 = 47 ± 3 dBA

L10 Criterion met after 200 samples

No. of Occurrences

Figure 3: Noise Level Readings

(Source: Figure 3.2, Fundamentals and Abatement of Highway Traffic Noise

Solution:

Leg(h) = 10log1/N NΣi=1n; 10Li/10

= 10log1/200 [Σ (1069/10) + (2)(1065/10) + (1063/10)

+ (1059/10) + (1057/10) + (2)(1055/10)

+ (1053/10) + (2)(1051/10) + (3)(1049/10)

+ (7)(1047/10) + (10)(1045/10) + (8)(1043/10)

+ (17)(1041/10) + (28)(1039/10) + (46)(1037/10)

+ (43)(1035/10) + (25)(1033/10) + (3)(1031/10)]

= 10log1/200 (20563972) = 10log102820

= 50.1 dBA (Note: L10 - Leq = -3.1 dBA)

In this manual, construction equipment sound levels are the sound levels emitted by the equipment under actual field operating conditions.

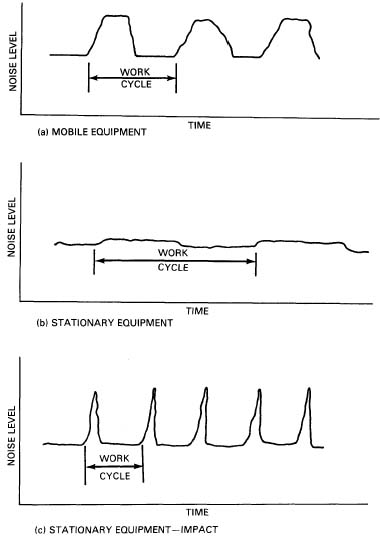

Construction equipment operates under two primary modes - mobile and stationary. Mobile equipment such as dozers, scrapers, graders, etc., operate in a cyclic fashion in which a period of full power is followed by a period of reduced power. Stationary equipment can be subdivided into two groups. One group contains such items as pumps, generators, compressors, etc., and generally operates at a fixed power and produces a fairly constant sound level under normal operation. The other group contains impact equipment such as pile drivers, jackhammers, pavement breakers, etc. Figure 4 shows typical idealized graphs of instantaneous sound levels as a function of time under field operating conditions for each group. This figure also indicates that the variations in sound levels are actually a function of the work cycle.

Data on equipment sound levels can be obtained by two methods: review of current technical publication and by measurements. Information on equipment sound levels being published in technical publications should be used with caution. These values are often peak values and must be adjusted to account for the variations in sound levels over the work cycle. Appendix A presents information on peak sound levels developed by the American Road Builders Association (ARBA). These values, once they are converted to Leq(h), are suitable for use in the environmental assessments conducted in project development. Appendix A also provides Leq values for air compressors developed by EPA. Accurate equipment sound levels can best be developed by measurement. These values can be measured at any time, and if the equipment is well maintained, need only be measured once. Detailed evaluation of mitigation strategies generally require accurate equipment sound levels.

Equipment sound levels have two basic uses:

To maximize their usefulness in these functions, the sound level must be in terms of the A-weighted, equivalent sound level measured over the equipment's work cycle. This requires a different measurement procedure for each of the three groups of equipment shown in Figure 4.Unfortunately, standardized measurement procedures have not yet been developed. Until they are standardized, the following procedures can be used:

Figure 4: Sound Level Versus Time for Construction Equipment

Mobile EquipmentThe Society of Automotive Engineers (SAE) test, J88a, " Exterior Sound Level Measurement Procedure for Powered Mobile Construction Equipment," sets forth a procedure for measuring the exterior noise level for the certification of construction equipment. The sound levels obtained during these tests " ...are repeatable and are representative of the higher ranges of noise levels generated by the machinery under actual field conditions, but do not necessarily represent the average sound level over a field use cycle,," Figure 5 illustrates the differences between the SAE J88a sound level, the instantaneous sound levels produced by the equipment, and the equivalent sound level. Thus, the first steps in determining the equivalent sound level of the equipment is to measure the sound level using the SAE J88a test procedure. A copy of this procedure is included in Appendix B.

Figure 5: Sound Level Versus Time at 15.2m

The maximum sound level (Lm) measured during the duty cycle is assumed to be approximately equal to the SAE J88a Sound level (Lj) when Lm is measured at 15.2 meters.

The minimum sound level (Lh) is measured during the duty cycle at the same distance as Lm. In this figure, it is at 15.2 meters.

To convert the SAE J88a sound level, Lj, to an Leq, the time spent at the various sound levels must be accounted for. Since mobile equipment produces an instantaneous sound level curve that is rectangular in form, an approximate Leq(h) can be calculated as follows (see Figure 5):

Leq(h) = 10log[(ta10Lm/10 + tb10Lb/10)/(ta + tb)] (2-2)

Since Lm ≈ Lj equation 2-2 reduces to

Leq(h) = Lj + 10log ta/T +10log[1 + tb/ta10-(Lm - Lb)/10]

Where: Leq(h) is the A-weighted equivalent sound level assuming that the work cycle is repeated continuously over a one-hour period.

Lj is the sound level measured using the SAE J88a test procedure.

ta is the time spent at the maximum level (Lm) during the work cycle.

Lm is the maximum sound level (approximately=to Lj).

Lb is the reduced sound level of the work cycle.

tb is the time spent at the reduced sound level.

T is equal to ta + tb and represents the work cycle time.

In this manual the expression

10log ta/T +10log[1 + tb/ta10-(Lm - Lb)/10] (2-3)

will be called the equivalency factor (E.F.).

Therefore, equation 2-2 reduces to

Leq(h) = Lj + E.F. (2-4)

Table 2 contains E.F.'s based on the difference between the maximum and minimum sound level, Lm and Lb, and the percent of time spent at the maximum level. Lm and Lb can be measured at any distance, but both values must be measured at the same distance. Note that Lm is approximately equal to Lj when Lm is measured at 15.2 meters. This procedure was chosen because it allows the calculation of Lj by a standardized procedure that is readily available. The measurements of the absolute levels for Lm and Lb are not critical since the maximum difference (Lm - Lb) is the parameter needed.

| Lm-Lb (dBA) | .1 | .2 | .3 | .4 | .5 | .6 | .7 | .8 | .9 | .10 |

|---|---|---|---|---|---|---|---|---|---|---|

| 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 |

| 1 | -1 | -1 | -1 | -1 | 0 | 0 | 0 | 0 | 0 | 0 |

| 2 | -2 | -2 | -1 | -1 | -1 | -1 | -1 | 0 | 0 | 0 |

| 3 | -3 | -2 | -2 | -2 | -1 | -1 | -1 | 0 | 0 | 0 |

| 4 | -3 | -3 | -2 | -2 | -2 | -1 | -1 | -1 | 0 | 0 |

| 5 | -4 | -3 | -3 | -2 | -2 | -1 | -1 | -1 | 0 | 0 |

| 6 | -5 | -4 | -3 | -3 | -2 | -2 | -1 | -1 | 0 | 0 |

| 7 | -6 | -4 | -4 | -3 | -2 | -2 | -1 | -1 | 0 | 0 |

| 8 | -6 | -5 | -4 | -3 | -2 | -2 | -1 | -1 | 0 | 0 |

| 9 | -7 | -5 | -4 | -3 | -2 | -2 | -1 | -1 | 0 | 0 |

| 10 | -7 | -6 | -4 | -3 | -3 | -2 | -1 | -1 | 0 | 0 |

| 11 | -8 | -6 | -4 | -3 | -3 | -2 | -1 | -1 | 0 | 0 |

| 12 | -8 | -6 | -5 | -4 | -3 | -2 | -1 | -1 | 0 | 0 |

| 13 | -8 | -7 | -5 | -4 | -3 | -2 | -1 | -1 | 0 | 0 |

| 14 | -9 | -7 | -5 | -4 | -3 | -2 | -1 | -1 | 0 | 0 |

| 15 | -9 | -7 | -5 | -4 | -3 | -2 | -2 | -1 | 0 | 0 |

Thus, to obtain an Leq(h), the following steps can be used:

Problem No. 3: Compute the Lb(h) for a D-8 dozer which has an Lj of 92 dBA. Under a normal work cycle, the dozer operates at a maximum sound level of 81 dBA for 30 seconds. This is followed by a reduced level of 70 dBA for 20 seconds.

Solution:

Stationary Equipment

The procedure used to determine the Leq(h) for all stationary equipment, except impact equipment, is identical to that used for mobile equipment with one exception. For stationary equipment, Lj is measured using SAE J952b, " Sound Levels for Engine Powered Equipment." A copy of this procedure is included in Appendix B.

Stationary Equipment - Impact

There are no current procedures for measuring the Leq(h) for impact equipment. The measurement of sound levels for this type of equipment will require an impulse sound level meter. It is suggested that the instantaneous sound levels be determined over an extended period with particular attention given to peak values and that Leq(h) be computed from this curve. The measurement setup should conform to that used in SAE J952b. Additional information in this area will be developed by the Federal Highway Administration (FHWA) and furnished at a later date.

Overall or boundary noise levels are the resultant sound levels produced by a particular construction operation at some point outside the construction site boundary. These values represent the sound levels heard by the community.

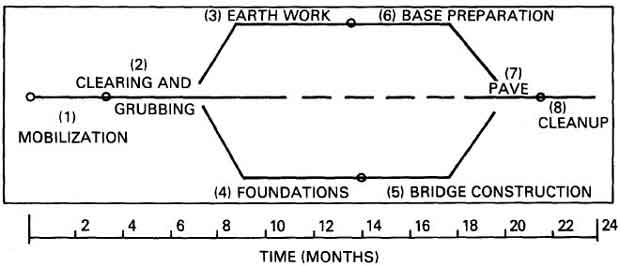

The construction of a highway is accomplished in several different phases. These phases can usually be characterized by the following:

Each of these operations occurs over some period of time. A simplified construction schedule using the above phases is presented in Figure 6.

Figure 6: Simplified Construction Schedule

Each phase will have its own noise level. Thus, the expression "construction noise" is rather meaningless unless it is expressed as the noise level during some phase of the construction operation.

Obviously, overall or construction noise measurements can only be made after construction starts. These values can be used for the following purposes:

Draft No.7, "SAE Recommended Practice: Measurement Procedure for Determining a Representative Sound Level at a Construction Site Boundary Location", can be used to compute and approximate Leq. A copy of this procedure is included in Appendix B. Users of this manual should recognize that this is a draft procedure.