The effective control of highway construction noise can be achieved in much the same manner as operational traffic noise is controlled by using a three-part approach. This consists of:

The three-part approach was taken in developing this portion of the manual.

This chapter presents various state-of-the-art methods and techniques of noise control that can be used to reduce noise impacts associated with highway construction. Most of the measures presented have been contained in either construction specifications, special provisions, or supplemental contract documents. The measures can be employed independently or in combination, depending on the scope of the project and the resultant effects that are desired. Section 4.1 outlines the factors necessary for identification and selection of an appropriate abatement measure to control construction noise. Section 4.2 details various methods that can be used. This section includes five subsections. Each subsection explains the methodology in general terms and then presents specific control strategies found under these broad methodologies. The control strategy is described, the dB reduction resulting from implementation is provided if known, the advantages and disadvantages are given, and a brief discussion is provided listing other characteristics of the specific control strategy. Sample specifications or examples are provided for each methodology. (Note: Values used in the specifications may not be practical or achievable. The manual user is encouraged to develop his own criteria.)

After the potential impacts resulting from the construction activities have been established, the final step in the process is the selection of appropriate control measures to be implemented on the project. This can be approached in two stages:

The first stage involves identification of control strategies that could be implemented that would bring about the desired reductions in noise impacts. Some of the factors that influence this identification process include:

On the basis of these and other factors, different noise mitigation strategies can be examined to determine what measures could be implemented for a specific project.

The last stage is the selection of a reasonable control strategy from the group examined in the identification stage. The measure or measures chosen should be weighed as to their benefits compared to their adverse effects. This weighing should take into consideration the monetary costs involved, problems with implementation of the measures, the sensitive receptors in the area, and the degree of noise reduction achievable.

Techniques for abating construction noise may vary from simple, inexpensive, easily implemented measures such as a requirement that all engines be equipped with a properly operating muffler, to more expensive, elaborate methods, such as equipment enclosures.

The control techniques outlined in this manual have been divided into five general categories. These categories have been further divided into different specific strategies. Figure 9 shows the breakdown and indicates how the remainder of this chapter is organized.

It should be noted that a measure that may be suitable in one situation may not be suitable in another. Care should be taken in selecting the appropriate mitigation measure.

Noise impacts to sensitive receptors can occur on any project involving the construction or reconstruction of a highway facility. While the magnitude of these impacts may not be known precisely early in the project development stages, certain measures can be implemented during the design phase that can reduce the anticipated noise impacts.

These measures fall into three categories:

The measure outlined are typically decided upon in the early stages of project development and included in the project plans and contract documents. Ideally, these strategies should be used in conjunction with other control methods.

Description:

During the early design stages of project development, the sensitive noise receptors can be established. By identification of these receptors, steps can be taken to lessen the construction noise impacts. During location studies, natural and artificial barriers such as ground elevation changes and existing buildings can be considered for use as shielding against construction noise. During design, waste material dump and storage sites can be designated in areas where they also serve as noise barriers. Haul roads can be designated in locations where the noise impacts caused by truck traffic will be reduced.

dB Reduction:

Undeterminable at the design stages of project development.

Advantages:

These techniques provide early consideration of the impacts caused by construction activities. A better understanding of potential problems can be obtained.

Disadvantages:

Design changes and modification to project layout are not always practical or feasible. The magnitude of the dB reduction is difficult to determine prior to construction.

Discussion:

The responsibility for development of these measures is born by the designer. The problem is analyzed prior to preparation of plans and other documents. The measures to be implemented are then placed in the contract documents at the appropriate time in the project development.

Description:

When planning for construction of a highway project, certain steps can be taken in scheduling work operations. Several noisy operations can be scheduled concurrently to take advantage of the fact that the noise levels produced will not be significantly greater than the level produced if the operations were performed separately. Noise barriers ultimately to be constructed as part of the project for traffic noise abatement can be constructed in the initial stages of construction to reduce the noise impacts of the construction.

dB Reduction:

Undeterminable at the design stages of project development.

Advantages:

These techniques tend to lessen the ongoing impacts as the project progresses.

Disadvantages:

The magnitude of reduction is difficult to determine in the early planning stages. These measures may not be feasible or practical to implement.

Discussion:

These measures are typically used in conjunction with other control measures and are contained in the project documents.

Description:

Certain phases of highway construction work such as pile driving may produce noise levels in excess of acceptable limits, even when feasible noise reduction methods are used. The impacts resulting from this type of situation may be lessened or avoided by using alternate methods of construction. Generally, piling is driven using an impact hammer. This operation often produces excessive noise levels. Some reduction can be attained by various dampening and shielding methods discussed later. However, such methods rarely reduce the noise level to an acceptable level for the sensitive receptors close to the site. As an alternative to driving piles, vibration or hydraulical insertion can be used. Drilled holes for cast in place piles are another alternative that may produce noise levels significantly lower than the traditional driving method.

dB Reduction:

Significant reductions may be realized by using less noisy construction methods.

Advantages:

New and innovative methods of construction may be evolved by considering alternate methods.

Disadvantages:

Alternate methods produce their own noise impacts and may produce other adverse effects that have to be weighed.

Discussion:

Great care should be exercised in choosing alternate construction methods. The choice should be weighed as to its desirability and feasibility. (The measures decided upon are placed in the contract documents.)

In devising construction noise control strategies, one important option is controlling the noise at the source. By specifying and/or using less noisy equipment, the noise impacts produced by construction of a highway facility can be greatly reduced or even eliminated. Source control requirements may have the added benefits of promoting technological advances in the development of quieter equipment.

Lessening the impacts from highway construction through source control techniques may be approached from three different ways:

These methods may be used separately or in combination in order to achieve the desired results.

Description:

Most construction noise originates from equipment powered by either gasoline or diesel engines. A large part of the noise emitted is due to the intake and exhaust portions of the engine cycle. A remedy for controlling much of the engine noise is the specification and use of adequate muffler systems.

dB Reduction:

Reductions of 10 dBA or more can be achieved with optimal muffler systems.6 (see references)

Advantages:

Muffler requirements can be easily written in contract specifications, complied with and enforced. Inspection and enforcement are simple and easily done. They are effective in reducing engine produced noise at a low cost to the user.

Disadvantages:

Only effective for machinery powered by internal combustion engines. Does not effect operational noises, i.e., the noise produced by doing the work.

Discussion:

This noise control strategy would lead to replacement of worn mufflers and to retrofitting where mufflers are not in use. The user of the equipment has the responsibility to comply with the specifications provided in the contract documents. Routine field inspection will be necessary by both the contractor and enforcement personnel to ensure compliance.

Example Specification:

Mitigation Group Two - Source Control

Mitigation Strategy One - Muffler Requirements

Sound Control Requirements: The Contractor shall comply with all Federal, State, and local sound control and noise level rules, regulations, and ordinances which apply to any work performed pursuant to the contract. In addition, each internal combustion engine, used for any purpose on the job or related to the job, shall be equipped with a properly operating muffler of a type recommended by the manufacturer. No internal combustion engine shall be operated on the project without said muffler.

This specification is provided for example purposes only. The contents do not necessarily reflect the official views or policy of the Department of Transportation.

Description:

Poor maintenance of equipment may cause very high noise levels. Faulty or damaged mufflers, loose engine parts, rattling screws, bolts, or metal plates all contribute to increasing the noise level of a machine. Careless or improper handling and operation of equipment can also increase construction noise levels. Poor loading, unloading, excavation and hauling techniques are some examples of how lack of adequate guidance may lead to increased noise levels. Specifications can be written to require that all equipment be regularly inspected for deficiencies in the maintenance area. Likewise, specifications can require that equipment users be properly trained in the use of construction equipment.

dB Reduction:

Significant reductions are achievable through correction of maintenance problems and adequate training in the use of equipment.

Advantages:

Proper maintenance can result in less down time for equipment, thereby shortening the time the equipment may be required in the area. Repair costs resulting from improper maintenance can be avoided.

Proper training increases the efficiency of the operation as well as reducing the equipment produced noise levels.

Disadvantages:

There is no procedure for determining the magnitude of noise level decreases prior to operation of the equipment. This type of specification is weak when used by itself.

Example Specification:

Mitigation Group Two - Source Control

Mitigation Strategy Two - Maintenance and Operation of Equipment

Noise Abatement Measures

The Contractor shall take such noise abatement measures that are necessary to comply with the requirements of this contract, consisting of, but not limited to the following:

Proper maintenance of all equipment to insure that noise is kept to a minimum.

Conducting truck loading, unloading and hauling operations so that noise is kept to a minimum.

Routing of construction equipment and vehicles carrying spoil, concrete or other materials over streets that will cause the least disturbance to residents in the vicinity of the work. The Engineer shall be advised in writing of the proposed haul routes prior to the Contractor securing a permit from the local government.

This specification is provided for example purposes only. The contents do not necessarily reflect the official views or policy of the Department of Transportation.

Description:

One of the most effective methods of diminishing the noise impacts associated with individual pieces of construction equipment is to employ less noisy machinery. This may be accomplished by specifying the quietest available equipment. Specifications can be provided that set an upper noise level for equipment, or they may be worded so as to group certain pieces into a single category and then set upper limits for that category.

Modifications such as dampening of metal surfaces is quite effective in reducing noise due to vibration. Another possibility is the redesign of a particular piece of equipment to achieve quieter noise levels. These modifications can usually only be done by the manufacturer or with factory assistance and can be costly, time consuming, and possibly ineffective in reducing the overall noise levels.

Another method of source control is employing shields that are physically attached to the particular piece of equipment. For stationary equipment and in cases where considerable noise reduction is required, enclosures have proven to be effective.

dB Reduction:

The reduction is controlled by the imposed limits and on the technical capabilities of the manufacturer or the equipment user. Noise reductions of up to 5 dBA can be achieved using dampening materials.6 (see references)

Shields such as sound skins may achieve reductions of 20 dB at high frequencies and 10 dB in the middle frequency range. Sound aprons may achieve noise reductions up to 10 dBA.6 (see references)

Advantages:

Significant noise reductions are achievable through emission level requirements.

New equipment emission level standards provided by the Environmental Protection Agency (EPA) can be specified for use for various types of construction equipment.

Disadvantages:

Noise level limits may be relatively difficult to set. Enclosures are not practical if they interfere with the machines function or impede air circulation or servicing of the piece of equipment. Modifications or adjustments to the particular piece of equipment may not be feasible because of the costs involved or technical limitations.

Discussion:

The EPA is in the process of developing noise emission level standards for new equipment. Standards are currently set for portable air compressors. Work is progressing in setting standards for wheel and crawler tractors, mobil earth moving equipment, and pavement breakers and earth drills. Once identified as a potential noise source, other construction equipment may be regulated. Source control techniques may be limited to employing shields that are physically attached to the particular piece of equipment. This type of shield is used to reflect, contain or absorb the noise emitted from construction machinery. Sound aprons and sound skins are two examples of such shields.

Sound aprons generally take the form of sound absorptive mats hung like curtains from the piece of equipment or on a specially built frame physically attached to the equipment. The aprons can be constructed of rubber, lead-filled fabric, or PVC layers with sound absorptive material covering the side facing the machine. Additionally, quilted material is currently available. Sound aprons are useful when the shielding must be frequently removed or if only partial covering is possible.

Sound skins are similar to sound aprons but differ in that they should be close fitting and air tight. Allowance must be made, however, to let air in for cooling. Any openings should be equipped with mufflers or angled air ducts lined with sound absorptive materials.

Enclosures for stationary work may be constructed of wood or any other suitable material and should be lined with sound absorptive material to prevent an increase of sound levels within the structure. They should be designed for ease of erection and dismantling.

These source control methods are generally initiated or devised by the contractor in order to meet the noise emission level specifications or site noise levels. However, they may be actually specified in the contract documents.

1. Example Specification:

Mitigation Group Two - Source Control

Mitigation Strategy Three - Equipment Emission Level Requirements

Equipment Regulations:

Effective January 1, 19__, construction equipment on the project is prohibited from exceeding the prescribed limits shown in the following table, measured in dB(A) at a distance of 15m, in conformance with SAE Standard J 952 and SAE Recommended Practice J 184.

1 JAN. __

| Equipment | (dB(A) measured at 15 m) |

|---|---|

| Earthmoving Equipment | |

| Frontloader | 75 |

| Backhoes | 75 |

| Dozers | 75 |

| Tractors | 75 |

| Scrapers | 80 |

| Graders | 75 |

| Trucks | 75 |

| Pavers | 80 |

| Materials Handling Equipment | |

| Concrete Mixer | 75 |

| Concrete Pumps | 75 |

| Crane | 75 |

| Derrick | 75 |

| Stationary Equipment | |

| Pumps | 75 |

| Generators | 75 |

| Compressors | 75 |

| Impact Equipment | |

| Pile Drivers | 95 |

| Jack Hammers | 75 |

| Rock Drills | 80 |

| Pneumatic Tools | 80 |

| Other Equipment | |

| Saws | 75 |

| Vibrator | 75 |

This specification is provided for example purposes only. The contents do not necessarily reflect the official views or policy of the Department of Transportation.

The values given may not be practical or achievable.

2. Example Specification:

Mitigation Group Two - Source Control

Mitigation Strategy Three - Equipment Emission Level Requirements

Construction Equipment Noise

Powered equipment, truck or power hand tools that produces a maximum sound level exceeding the following limits shall not be used during construction operations. The sound level limits specified are referenced to a distance of 50 feet from the equipment. Sound levels shall be measured in substantial conformity with Standards and Recommended Practices established by the Society of Automotive Engineers, Inc., including the latest revisions to SAE J366a and SAE J952b.

Where required by agencies having jurisdiction, certain noise producing work may have to be performed during other than regular working hours or only at specified periods.

| Type of Equipment | Sound Level Limits |

|---|---|

| (a) Construction and Industrial machinery, such as crawler-tractors dozers, rotary drills and augers, loaders, power shovels, cranes, derricks, motor graders, paving machines, off-highway trucks, ditchers, trenchers, compactors, scrapers, wagons, pavement breakers, compressors, and pneumatic power equipment. | 90 dBA |

| (b) Highway Trucks | 88 dBA |

This specification is provided for example purposes only. The contents do not necessarily reflect the official views or policy of the Department of Transportation.

The values given may not be practical or achievable.

3. Example Specification:

Mitigation Group Two - Source Control

Mitigation Strategy Three - Equipment Emission Level Requirements

Noise Abatement Measures

The Contractor shall provide such equipment, sound-deadening devices, and take such noise abatement measures that are necessary to comply with the requirements of this contract, consisting of, but not limited to the following:

This specification is provided for example purposes only. The contents do not necessarily reflect the official views or policy of the Department of Transportation.

The ultimate purpose of construction noise control is to reduce the impacts on the sensitive receptors. In order to achieve this goal, another abatement technique is to specify and employ site noise limits and noise control measures. Site noise control typically involves limiting the amount of noise reaching the sensitive receptors. Specifications may be written that set certain limits at the receptors, thus allowing the equipment user to devise his own methods for meeting the requirements or they may directly specify certain actions that may be taken to achieve a noise reduction at the receptors.

Description:

In order to meet site or receptor limits, various methods to reduce noise impacts have proven successful. The methods described are normally used in conjunction with other mitigation strategies to achieve an overall noise level reduction at identified locations.

One way to reduce the noise impacts at sensitive receptors is to operate stationary equipment such as air compressors, generators, etc. as far away from the sensitive receptors as practical. Pit areas or excavate portions on the job site may provide suitable locations for stationary construction activities and at the same time serve as noise barriers.

In some cases, activities such as form building, bridge and culvert construction, or other work involving stationary activities can effectively be accomplished inside an enclosure in order to reduce the noise impacts. In all cases where enclosures and excavation are involved, proper ventilation, access, egress and safety for the construction worker must be considered and maintained.

In some situations, such as in urban areas or on isolated sections of a project, it may be beneficial and indeed necessary to construct barriers adjacent to the work area.

dB Reduction:

The reduction in noise levels will vary with the method employed. Measurements are necessary to determine the exact levels.

Advantages:

Site noise limits are useful and advantageous because they tend to allow the contractor more freedom in developing means to reduce the noise impacts to the surrounding areas.

If properly designed and erected, barriers can not only be very effective in reducing sound propagation from the work area, but can also serve as physical, safety barriers to the site.

Disadvantages:

It may become very complex to set reasonable yet effective limits. Limits can not be set so low as to make the specification impossible or impractical to meet. Limits should not be set so high as to make the specification meaningless.

This type of control is extremely difficult to enforce, particularly when the noise metric involves long term averaging, i.e., Leq (24).

In employing some site control methods, the noise levels in certain areas within the construction area boundaries may be increased which will in turn affect project personnel working in the area.

Some measures may be costly and not easily implemented. Care must be taken to insure that if some type of barrier is used it will not create a hazard for the traveling public or the project personnel.

Discussion:

Special prefabricated panels are currently manufactured that can be relatively easily moved and erected. These may be ideally suited for controlling overall site noise in some situations.

Example Specification:

Mitigation Group Three - Site Control

Mitigation Strategy One - Site Control

The noise level from the Contractor's operation shall not exceed:

This requirement in no way relieves the Contractor from responsibility for complying with local ordinances regulating noise level.

The Contractor shall purchase, modify, and operate equipment; erect barriers; attach aprons and skins; etc., and take any other measures necessary to meet the specified site noise limits.

Said noise level requirement shall apply to all equipment on the job or related to the job, including but not limited to trucks, transit mixers or transient equipment that may or may not be owned by the Contractor. The use of loud sound signals shall be avoided in favor of light warnings except those required by safety laws for the protection of personnel.

Full compensation for conforming to the requirements of this section shall be considered as included in the prices paid for the various contract items of work involved and additional compensation will be allowed therefore.

This specification is provided for example purposes only. The contents do not necessarily reflect the official views or policy of the Department of Transportation.

Construction activity and the associated noise can be quite annoying and disruptive during leisure hours, during the hours of sleep, and, any time where loud continuous noises may effect certain special activities. Time constraints and use of equipment regulations can be very effective in reducing the impacts caused during these hours of the day.

Description:

During leisure hours and during periods of sleep, disturbance from equipment use can be kept to a minimum. The basis for the noise control strategy is to limit the times that certain noise construction activities may be prosecuted. Generally, this can be accomplished by requiring the contractors to perform such work during daylight hours when the majority of individuals who would ordinarily be affected by the noise are either not present or are engaged in less noise sensitive activities or limit nighttime work to that which is less than certain specified values.

Loud continuous noises around such critical noise receptors as schools, hospitals, etc., are disturbing at all times. Time constraints that restrict the construction activity to limited time periods can be effective in lessening these impacts.

dB Reduction:

During hours that the activity is restricted there is no impact associated with the particular activity.

Advantages:

Time constraints are effective in reducing noise impacts during critical periods of the day.

Disadvantages:

Time limitations may increase the overall length of time necessary to complete the project.

1. Example Specification:

Mitigation Group Four - Time Constraints

Mitigation Strategy One - Time Constraints

Noise Control - The Contractor's construction operations shall be performed in such a manner that noise levels established for designated land use activities and time periods, when measured at designated distances from the Right-of-Way, will not exceed those shown in Table 1-1. However, this provision is not applicable if the ambient noise (noise caused by sources other than construction operations) at the doing of reception is in excess of the construction noise level at that point.

The Department reserves the right to monitor construction operations as deemed necessary. In the event construction noise level (s) exceeds those levels shown in Table 1-1, the Contractor shall take such action as necessary to conform with this provision prior to proceeding with his operation. The Contractor shall be responsible for all costs arising from delay of operation(s) due to non-compliance with this noise control provision.

| LAND USE ACTIVITY | MAXIMUM ALLOWABLE EXTERIOR NOISE LEVELS dB (A) | APPLICABLE TIME PERIOD |

|---|---|---|

| residential, hospitals, nursing homes, schools, churches, libraries, offices, parks, picnic areas, recreational areas, play ground | 88 | 6 a.m. - 8 p.m. |

| active sport areas | 67 | 8 p.m. - 6 a.m. |

This specification is provided for example purposes only. The contents do not necessarily reflect the official views or policy of the Department of Transportation.

2. Example Specification:

Mitigation Group Four - Time Constraints

Mitigation Strategy One - Time Constraints

| Area | Hours | Sound Level |

|---|---|---|

| Residential Areas | Daily, except Sundays & Legal Holidays 7:00 a.m. to 7:00 p.m. | 85 dBA |

| Daily, except Sundays & Legal Holidays 7:00 p.m. to 7:00 a.m. | 65 dBA | |

| 7:00 p.m. Saturday to 7:00 a.m. Monday & Legal Holidays | 65 dBA | |

| Business - Commercial Area | Daily, including Sunday & Legal Holidays, all hours | a maximum of 90 dBA |

| Area | Hours | Sound Level |

|---|---|---|

| Residential Areas | Daily, except Sundays & Legal Holidays 7:00 a.m. to 7:00 p.m. | 70 dBA |

| Daily, except Sundays & Legal Holidays 7:00 p.m. to 7:00 a.m. | 55 dBA | |

| 7:00 p.m. Saturday to 7:00 a.m. Monday & Legal Holidays | 55 dBA | |

| Business - Commercial Area | Daily, including Sunday & Legal Holidays, all hours | a maximum of 75 dBA |

This specification is provided for example purposes only. The contents do not necessarily reflect the official views or policy of the Department of Transportation.

The values given may not be practical or achievable.

Although not a physical method of noise abatement, public relations and community awareness is a positive method of lessening the impacts of construction-related noise and disturbances. There are numerous instances during the various phases of activity where noise reduction is not feasible or warranted. In these cases, it is especially helpful for the impacted property owners to be made aware of the upcoming activity. It is also possible to forestall a great deal of adverse community reaction by implementing early public involvement into the project.

Description:

There are various techniques that may be employed to inform the public of upcoming noise impacts related to the construction activity. Depending on the scope of the project, the lengths of time involved in a particular phase of work, and the degree of unavoidable impact, the methods used can be as simple as distributing flyers to the adjacent property owners or may be as complex as conducting public informational meetings. The most important consideration in any method chosen is early communication. The scope of the proposed work and when possible, the time span of the activity should be spelled out in order to allow residents to plan their activities accordingly.

Advantages:

This method promotes better relations between the public, the contracting agency and the contractor.

Disadvantages:

This method may not physically reduce the construction noise impacts.

Discussion:

The contracting agency should also take an active role in insuring that the communication lines are open and the public is properly informed of upcoming construction activity. This may be accomplished by seeing to it that all questions and inquiries from the general public are courteously and reasonably responded to.

The highway agency may require the contractor to alert the public in a timely manner in the contract documents or the agency may take on the public relations function itself.

Example:

Mitigation Group Five - Community Awareness

Mitigation Strategy One - Public Relations

TO THE PUBLIC

Our purpose in distributing this circular is to keep you informed concerning the Metro Construction in your neighborhood. As is METRO policy, it is our aim to cooperate with property owners, tenants, businessmen, businesswomen and ordinary citizens who are directly affected or inconvenienced by the work. In turn, we would appreciate your indulgence during the construction period. Inquires should be directed to Resident Engineer.

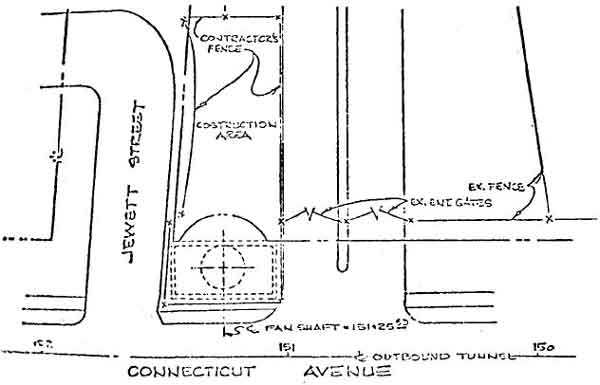

Zoo park fan shaft

Description of Work: Drill and blast 20' diameter shaft 150' deep through rock. Blasting will be monitored by instruments to insure against any damages to adjacent buildings.

Duration of Work: April 1 to February 1.

Days of Operation: Monday through Friday 7:00 a.m. to 10:00 p.m.

This is provided for example purposes only. The contents do not necessarily reflect the official views or policy of the Department of Transportation.