A variety of materials may be used for noise wall panels and posts. This section provides details of some of the more common materials: including a description of the material, its features, examples of typical use, special considerations, typical quality verification, and regional considerations, where applicable. n addition, because the selection of a particular surface treatment texture can depend on a number of factors including aesthetic requirements of both sides of the barrier, constructability issues, maintenance concerns, and particularly the type of barrier material, this section also discusses barrier surface treatments. For example, selection of a form liner finish on both sides of a barrier could negate the ability to use horizontally cast precast barrier elements and require the use of either vertically cast precast elements or cast-in-place barriers.

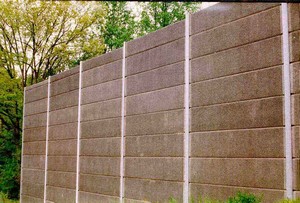

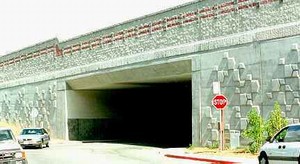

Concrete is one of the world's most common and versatile construction materials (see Figures 70 and 71). It is a mixture produced by combining Portland cement, coarse and fine aggregates, and water, and may also include specific additives to modify curing rate, air entrainment, strength, fluidity, and porosity. For cast-in-place operations, concrete is normally delivered on-site premixed by concrete truck, but for small quantities, it can be mixed on-site. For precast products, the plants usually have their own batch plants capable of providing sufficient quantities to match production.

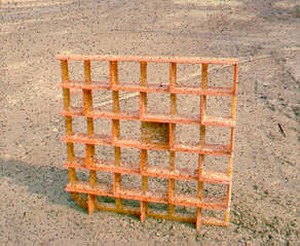

Figure 70. Concrete noise wall

photo #634

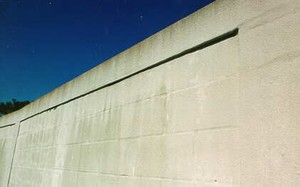

Figure 71. Concrete noise wall

photo #1239

Features - Almost half of the noise walls constructed in North America to date are made of concrete. The proliferation of the use of concrete is not without reason. Concrete, if formulated, cast (precast or cast-in-place), and cured properly, is considered to be one of the most durable materials currently used for many highway products, including noise barriers. It is rugged and able to withstand severe temperatures, intense sunlight, moisture, ice, and salt. It is a versatile material capable of being shaped, molded, and textured to take on the appearance of anything from weathered wooden boards to rock face to stone blocks to virtually any sculpted mural topic imaginable. Its mass, even at a thickness of only 12 mm (0.5 in.), is well within any Sound Transmission Class requirement (see Section 3.4.2).

Concrete products lend themselves well to coloring or tinting by either incorporating pigments into the concrete mix before pouring or afterwards by applying a stain onto the surface of the cured products. For more details, see Section 5.9.2.1

Typical Use - The versatility of concrete also extends to the shape and the size with which the panels can be produced (e.g., precast stacked panels, cast-in-place and precast full height panels, and precast concrete block). In addition, concrete allows for a complete range of installation techniques including post and panel, post integral with the panel, free standing, direct buried, and on top of spread footings, continuous footings, traffic barriers, and retaining walls. Cast-in-place concrete walls have been typically used on bridges and retaining walls because of their flexibility of design, high structural strength, and resistance to vehicle impact damage.

For all testing, it is important to select samples which are a true representation of the finished products or of the material(s) being used in the casting of the noise barrier components.

he following are standard tests, normally conducted at the casting plant, on concrete to verify overall quality and to confirm desired properties of the products. The tests discussed within this section are described in detail in Section 10. which discusses product evaluation of all types of barrier materials. Although most of these tests are suitable for both wet and dry cast concrete, some are more suitable for one type as compared with the other. Suitability of the test is noted where applicable.

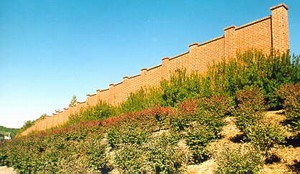

Brick (see Figure 72) is typically manufactured using a clay and sand mix which is fired in a kiln to increase the brick's strength and durability. Bricks can be produced in varying sizes but most commonly in 70 x 95 x 200 mm (2 x 3¾ x 8 in).

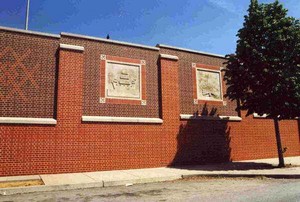

Figure 72. Brick noise barrier

photo #6511

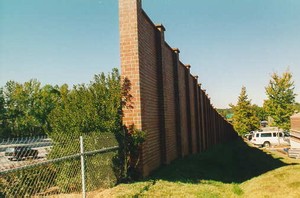

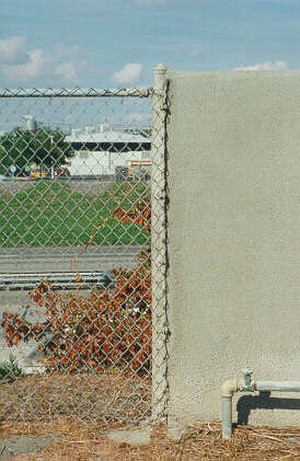

Masonry block (see Figure 73) is manufactured using a dry-cast concrete mix. These blocks can be produced in any size but with the most common in the range of 200 to 300 mm (8 to 12 in) thick by 200 to 250 mm (8 to 10 in) high and 355 to 460 mm (14 to 18 in) long.

Figure 73. Masonry block noise barrier

photo #2456

Features - Both brick and masonry block walls can be either hand-laid or preassembled by machine. Hand-laid walls have greater versatility in their ability to conform to the variety of ground contours encountered in the roadway environment and in their layout than do the preassembled panels with their fixed panel sizes and heavy equipment requirements. Preassembled panels have an advantage in speed of erection, provided that the site environment allows for easy maneuvering of the necessary cranes and transport vehicles. In addition, brick and masonry block walls can be constructed satisfactorily with no special leveling courses on grades of up to 6 percent. In some cases, brick is used as a facing or veneer on masonry block or cast-in-place walls.

All brick and masonry walls, whether they are hand or machine laid, require a continuous concrete foundation (see Figure 74). The wall must be anchored to the foundation with reinforcing bars. Vertical and horizontal reinforcing bars are also needed in the wall itself to provide structural strength. Preassembled panels usually must be braced while the supporting concrete gains its strength.

Figure 74. Barrier concrete foundation

photo #568

Figure 75. Scaffolding for barrier installation

photo #2455

The tests discussed within this section are described in detail in Section 10 which discusses product evaluation of all types of barrier materials.

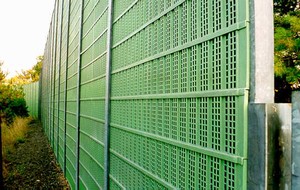

Figure 76. Metal noise barrier

photo #158

Figure 77. Metal noise barrier

photo #5692

Three type of metals are most commonly used: (1) steel; (2) aluminum; and (3) stainless steel.

Steel - Steel is the least expensive and most common of all metals used in construction (see Figure 76). It is composed of a mixture, in varying proportions, of iron ore, carbon, and small amounts of other metals depending on the physical characteristics desired.

Most steel panels, posts, and girts are either: (1) coated with plastisols, bonded powders, enamel paints, or galvanizing material; or (2) manufactured as a self protecting weathering steel.

Aluminum - Aluminum is a lightweight alloy commonly made from bauxite and is typically coated with a bonded powder, enamel paints or anodized (see Figure 77). It is not compatible with galvanized coatings.

Stainless Steel - Stainless steel is a highly durable and corrosion resistant metal alloy. It is a mixture of steel carbon, nickel, and chrome (in varying proportions). Since this material is virtually corrosion resistant, the surface does not need to be coated.

Features - Metal panels have a weight advantage which makes them particularly useful for vertical extensions of existing sound walls, for mounting on existing retaining walls which have limited residual strength, or on bridge structures, because of their light weight.

Typical Use - This type of material can be used anywhere. However, bridges and retaining walls are ideal locations for the use of these light-weight type of panels.

Figure 78. Metal barrier: climbability

photo #157

The tests discussed within this section are described in detail in Section 10 which discusses product evaluation of all types of barrier materials.

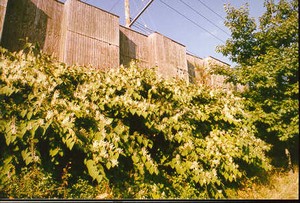

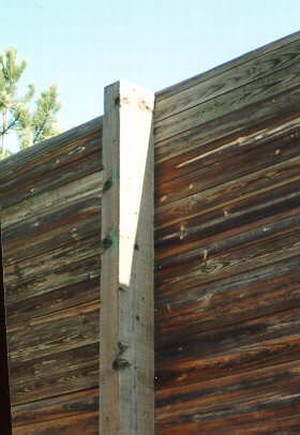

Most wood noise barrier walls are constructed of pressure preservative treated lumber, plywoods (see Figure 79), and glue laminated products (see Figure 80).

Figure 79. Plywood noise barrier

photo #657

Figure 80. Glue laminated post and plank noise barrier

photo #736

A number of different species of wood have the potential for being used as a noise barrier product, but this does not mean that all perform equally. Some species, such as the pines, are well suited for pressure treatment. Whereas, it may be difficult to obtain a deep, uniform penetration of the preservative in spruces. Some of the more common species used are as follows:

Features - Panels can be either installed piece by piece in the field or partially assembled in a plant or on the ground prior to attachment to the post. Power nailers, which are commonly used in the plant as well as in the field, make quick work of assembly. Some wood barriers can also be easily dismantled if future highway changes are needed. This material blends well with natural or residential background and does not conduct electricity.

Figure 81. Wood barrier:tongue and groove planking

photo #411

| ACC |

Acid Copper Chromate. |

|---|---|

| ACA | (Ammoniacal Copper Arsenate) is a bright greenish colored waterborne preservative. |

| CCA | (Chromated Copper Arsenate) is a mild green colored waterborne preservative. This cannot be used on fir wood. |

| Penta | (Pentachlorophenol) comes in either a gas or oil borne formula. Colors vary, with the gas borne generally being lighter in color. This product has a distinct odor for a season and tends to draw out natural pitch leaving deposits and streaks on the wall facing. |

| Creosote | is a Coal Tar based oil borne preservative, usually dark brown in color. |

The tests discussed within this section are described in detail in Section 10 which discusses product evaluation of all types of barrier materials.

The typical transparent noise barrier (see Figure 82) may use panel material made of either glass or a clear plastic product such as Plexiglas, Butacite, Surlyn, Lexan, or Acrylic. Glass panels are commonly made of single tempered or laminated tempered glass sheets. Both plastics and glass can be tinted and can also be etched or given a frosty appearance.

Tempering of the glass is a heat treating process which strengthens the glass, producing a much more shatter resistant product. When it does shatter, the shards are small and granular in appearance, with pieces typically not larger than 12 mm (½ in). These are much safer than the long knife-like shards produced from shattering common non-heat treated glass. In addition to the tempering, the glass panels can also be laminated. This type of glass panel is produced by adhering two sheets of tempered glass sheets to both sides of a clear rubbery type flexible sheeting. When this type of glass panel is shattered, the glass will break into small granular-like pieces, where the pieces will remain adhered to the sheeting.

Figure 82. Transparent panel noise barrier

photo #1981

Features - The transparent panel materials are an ideal way of reducing or virtually eliminating the visual impact of a noise barrier.

Typical Use - Transparent barriers are normally only built for 3 reasons:

Since transparent noise barriers costs can be as much as 20 times that of common concrete or steel panels, the decision to use transparent noise barriers should not be made lightly. Possibly, the only other reasons for their use would be to improve safety, where opaque noise barrier walls may have an adverse affect on stopping sight distance, visibility in merge areas, lighting, and shading.

Transparent noise barriers come with their own unique set of engineering, safety, and environmental considerations which are significantly different than most other types of material normally used for noise barrier panels.

Figure 83. Transparent panel barrier: vandalism

photo #1947

The tests discussed within this section are described in detail in Section 10 which discusses product evaluation of all types of barrier materials.

There are several types of plastic materials available for use as a barrier material, including Polyethylene, PVC, and fiberglass (see Figure 84).

Figure 84. Plastic noise barrier

photo #782

There are countless standard test methods published to assist in the verification of plastic products. Each of these test methods are normally only relevant to very specific plastic formulations. The tests discussed within this section are described in detail in Section 10 which discusses product evaluation of all types of barrier materials. This handbook will not attempt to list or describe these and suggests current testing information be obtained from other sources.

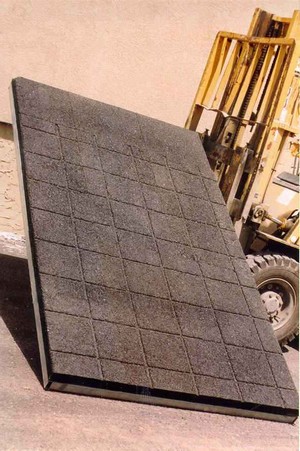

The issue of using recycled rubber from tires in products used for roadway construction has been under investigation for many years by numerous government agencies, world wide. The results of their efforts indicate widely varying success in trying to adapt this type of material into a usable product (see Figure 85).

Figure 85. Recycled rubber noise barrier

photo #3124

Recycled rubber can refer to a wide range of products, made from an equally wide range of rubber compounds. In practice, however, the rubber waste stream is dominated by scrap tires. There are two other significant sources: (1) tire trim and off-spec tires from tire production and (2) buffings from rubber product manufacturers.

The tests discussed within this section are described in detail in Section 10 which discusses product evaluation of all types of barrier materials.

Composite noise barrier materials, in general terms, can be defined as any product composed of two or more primary materials, such as plywood with a fiberglass skin (see Figure 86), or wood mixed with concrete and then layered onto concrete (see Figure 87). Since the possibilities are almost endless, this section will mainly focus on the special considerations which should be used in evaluating their safety, durability, and performance.

Figure 86. Composite noise barrier

photo #132

Figure 87. Composite noise barrier

photo #707

The combining of basic materials has a tendency to change the performance, durability, and, in some cases, the safety characteristics of the final product. These changes should be investigated thoroughly before the composite materials are used in an actual installation.

Some combinations may not have sufficient in-field performance history to be able to determine the long term durability, safety, and performance of specific composites. Therefore testing is much more critical for these types of materials than most others used for noise barrier panels. There are countless standard test methods published to assist in the verification of various materials. Each of which are normally only relevant to very specific material formulations. This handbook will not attempt to list or describe these and suggests current testing information be obtained from other sources. The tests discussed within this section are described in detail in Section 10 which discusses product evaluation of all types of barrier materials. However, the following fundamental tests should be considered for all of these types of materials.

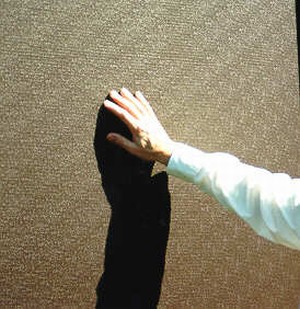

This section describes various surface treatments, including textures, colors, and coatings which may be applied to a noise wall.

A vast majority of surface textures are available to the noise barrier designer (see Figure 88). In many cases, such treatments can be applied to several elements of the barrier systems (e.g., posts, panels, caps, etc.). Different barrier surface treatments can be obtained by having different combinations of treatments on these separate barrier elements. The intent of the following discussion is not to address all possible combinations of treatment, but rather, to discuss the more common surface texture types available. The following discussion of texture types is categorized by material type.

Figure 88. barrier surface treatment textures

photo #512

Figure 89. Concret:smooth surface

photo #996

Figure 90. Concrete: exposed aggregate

photo #1180

Figure 91. Concrete: form liner

photo #1180

Figure 92. Concrete: form liner

photo #498

Figure 93. Concrete: form liner

photo #698

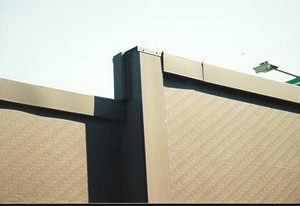

Figure 94. Concrete: form liner panel joints

photo #7029

Figure 95. concrete: raked finish

photo #508

Figure 96. Concrete: stamped finish

photo #6512

Figure 97. Concrete: stamped finish

photo #6514

Figure 98. Concrete: inserts

photo #8014

Figure 99. Concrete: inserts

photo #8015

Figure 100. Masonry block: stucco

photo #1066

Figure 101. Masonry block: fractured fin

photo #948

Figure 102. Masonry block: stucco

photo #1061

Figure 103. Brick: surface texture

photo #560

Figure 104. Brick: surface texture

photo #6518

Figure 105. Metal: surface texture

photo #1708

Figure 106. Wood: horizontal plank

photo #745

Figure 107. Wood: vertical plank

photo #730

Figure 108. Wood: patterns on battens attached to panels

photo #471

Figure 109. Wood: pattern on laminated panels

photo #663

Figure 110. Wood: circular post type

photo #744

Figure 111. Wood: square post type

photo #435

Surface texture treatments are limited to aesthetic type designs (stencils) applied to such barriers (see Figure 112).

Figure 112. Transparent: surface stencil design

photo #1954

Surface textures of plastic panels are generally limited to shapes and textures which can be accomplished via the panel component molding process (see Figure 113).

Figure 113. Plastic: surface texture

photo #792

Similarly, barriers constructed of recycled rubber materials are limited to shapes obtainable through molding of their components. The surface texture of such panels is also influenced to some degree by the density and porosity of the rubber (see Figures 114 and 115).

Figure 114. Rubber: surface texture

photo #2948

Figure 115. Rubber: surface texture

photo #2949

Composite panel texture treatment opportunities reflect the availabilities and constraints of the particular components used to form the outside barrier face (see Figures 116 and 117).

Figure 116. Composite: surface texture

photo #136

Figure 117. Composite: surface texture

photo #708

Figure 118. Gunite: surface texture

photo #2243

As discussed briefly in the introduction of Section 5, the selection of a particular surface treatment texture depends on a number of factors including aesthetic requirements of both sides of the barrier, constructability issues, maintenance concerns, and the type of barrier material. The selection of a form liner finish on both sides of a barrier requires specialized equipment, could negate the ability to use horizontally cast precast barrier elements and could require the use of either vertically cast precast elements or cast-in-place barriers. The inability to use full height precast panels (in a situation where placing such panels is restricted due to overhead wires or other factors) could limit the barrier type, material, and therefore the surface texture options. Texture treatments used with stacked panels should be coordinated so that the joints are either concealed by the pattern or become a part of the pattern (see Figures 119 and 120).

Figure 119.

photo #902

Figure 120.

photo #533

The desired color of noise barriers is provided by one of the following two general techniques or a combination thereof:

Options related to colors of noise barriers are discussed below for various types of barrier materials.

These types of materials are quite versatile in their ability to be colored (see Figures 121 to 123). The color of their natural elements (sand, stone, and cement) can be varied to obtain different earth tone colors. Addition of a pigment to such a coating can provide a uniform color to a plain concrete surface wall. Pigments can also be added to the mix prior to the forming of barrier components. Quality control and consistency are critical in the production of pigmented concrete since unevenness and blotchiness can become apparent, particularly on smooth surfaces. A consistent color from panel to panel is an important aesthetic factor in achieving a successful barrier system. To ensure a panel-to-panel color consistency, a surface-applied stain may be more effective than the use of integral colors or pigments in the oncrete mix. Natural and pigmented barriers have the advantage of not showing damaged areas (from chips, scrapes, etc.) as much as painted or stained surfaces. The maximum protection against the visual effects of such damage can be provided by use of a pigmented panel with a surface stain of a matching color. This reduces any unevenness in the pigmenting process while providing for consistent color throughout the panel. The added cost of such a dual treatment may, however, not be warranted in many cases.

Figure 121. Concrete: color

photo #2337

Figure 122. Concrete: color

photo #1218

Figure 123. Masonry block: color

photo #2373

While many variations in color are available with these types of materials, the color is limited to the that of the material itself (see Figure 124).

Figure 124. Brick color

photo #2655

Except in cases where a natural (e.g., aluminum, stainless steel, etc.) or rusted look (e.g., weathering steel) appearance is desired, color on metal panels is usually obtained by painting or application of some bonded type of surface coating (see Figure 125). In many cases, barrier elements (particularly posts) are designed with their protective galvanized finish as the ultimate color. This process protects the post while negating any maintenance requirements associated with paint. When colors are desired on metal barriers they may be either applied at the origin of manufacture or in the field. If applied where the barriers are manufactured, such coatings may be applied using a variety of techniques such as a baked enamel finish, a sprayed-on finish, by using a plastisol (a poured-on PVC emulsion), or via a bonded powder coating applied via an electrostatic process. In any coating application process, surface preparation is critical. Such preparation needs to consider the initial, intermediate, and final coats in terms of their undercoating and surface preparation requirements. Manufacturers' requirements (related to both coating and material coated) such as extent of sand blasting (white blast, grey blast, etc.), cleaning materials, temperature and moisture controls, etc. need to be adhered to closely. Certain coatings may also allow for easier removal of graffiti without any detrimental effects to panel aesthetics.

Figure 125. Metal: color

photo #1720

A wide variety of natural colors is available in wood products (see Figure 126). The selection of a particular wood species for its color attributes must also consider other factors of the wood. While a particular wood species may have the exact natural color desired, its qualities related to other areas of concern (durability, warping, rot resistence, etc.) may be unacceptable. Most woods can be stained or painted to obtain a desired color. Clear and pigmented preservative treatments are also available. The type of treatment, stain, or paint must be compatible with the type of wood, nails, and other fasteners used in the barrier assembly, and with the environment in which the barrier will be placed. Chemical reactions between steel nails and certain wood preservative treatments have caused these nails to corrode, requiring their replacement with stainless steel fasteners. Moisture content at the time of paint or stain application is also critical. It is essential that a wood barrier be properly seasoned before application of any paint or stain, and that no such protective materials are applied when the barrier is damp. Specific requirements will vary for each coating material, necessitating strict compliance with the specifications of the coating manufacturer.

Figure 126. Wood: color

photo #464

Color of these materials is most often obtained through the pigmentation of the emulsifiers used in the molding process of barrier elements (see Figure 127). A scratch coat may also be added for protective purposes.

Figure 127. Plastic: color

photo #1728

Recycled rubber material generally cannot be pigmented. Rubber can be coated (usually with a more expensive polyurethane coating) to obtain a desired color.

Composite panel color treatment opportunities reflect the availabilities and constraints of the particular components used to form the outside barrier face (see Figure 128). Particular concern should be paid to ensure compatibility between the barrier materials (including any glues, attaching devices, etc.) and the applied coating to negate any potential for damaging chemical reactions.

Figure 128. Composites: color

photo #2533

Color in such walls can be obtained by the selection of the appropriate plants. Different colors and patterns can be obtained with changes in season.

The discussion in this section is limited to coatings on concrete and masonry barriers, since coatings on other types of barriers are inherently addressed within the discussions of color found in Section 5.9.2.

Coatings are typically applied to concrete or masonry barriers for protective and/or aesthetic reasons. Protection against the elements (wind, rain, salt spray, ultraviolet light, etc.) and potential vandalism (anti-graffiti) are common reasons for application of such coatings. While coatings can significantly enhance the appearance of a barrier or be its primary aesthetic element, care should be taken in application to assure positive results. Addition of a clear protective coating can have positive benefits in terms of enhancing the color and brilliance of a concrete exposed aggregate surface. Conversely, application of the same clear protective coating on a plain concrete barrier can have a negative impact by making the barrier surface look wet and enhancing any unevenness or blotchiness.

A number of products are on the market which can provide varying degrees of protection against graffiti. Few, if any, barriers can be made graffiti-proof. Quick removal (within 24 hours) of the graffiti may discourage "artists" who try to return to embellish upon the previous night's work. Rougher surfaced and darker colored barriers and barriers covered with vegetation or vines may also provide more resistence to being "hit" by graffiti artists as compared to light colored, non-planted, and/or smooth-surfaced barrier surfaces. However, there is no guarantee that a barrier will not be susceptible to graffiti. Once hit with graffiti, an unprotected concrete or masonry surface can be marred for life due to staining and penetration of the graffiti paint into the concrete substrate, even if the graffiti is "removed." Anti-graffiti coatings are meant to prevent such penetration and to make the removal of the graffiti somewhat easier. Anti graffiti coatings may be clear or pigmented. Clear coatings are usually applied to architectural surfaces such as exposed aggregate or brick (see Figure 129), where the source of the barrier's color is in the natural barrier material itself. In some instances, such coatings applied to exposed-aggregate surfaces tended to enhance its appearance by deepening the aggregate colors. Pigmented coatings are typically applied to natural (unpainted, unstained, un-pigmented) concrete surfaces. Application of coatings is usually done by spraying, although rolling and brushing may occasionally be performed, especially in areas where over-spray is a concern. Anti-graffiti coatings may be of either the permanent or sacrificial variety as described below:

Figure 129. Anti-graffiti coating

photo #5332

In addition to providing the desired color in a noise barrier, a concrete stain can provide a degree of protection against the elements as well as be reapplied to areas "tagged" with graffiti. Stains can be either oil-based or water-based, with the latter being more widely used for concrete applications.

Coating of precast barrier elements may be performed at the point of their manufacture (normally a precast plant) prior to their erection or in the field after their erection. Only on rare occasions would coating of precast barrier elements be performed in the field prior to the erection of the barrier. Coating of cast-in-place noise barriers must occur in the field. If coating is done at the plant, conditions may be better controlled, but barrier elements must be stored during drying or between coats at a location free of dust and potential damage from plant operations. Additional care must also be taken during transport of coated panels to the job site and during their erection process to protect them against possible damage. It is for these reasons that the majority of coating is performed in the field following the erection of the barrier. Even in this situation, coating must be done when conditions (rain, temperature, wind) are acceptable.

Anti-graffiti coatings should only be applied if the responsible organization has a policy which dictates the removal of graffiti from barriers. If the standard operating procedure related to the treatment of graffiti is to paint over it, then anti-graffiti coating is not only a waste of money, but also creates a surface to which the "paint over" paint will not easily adhere. With this maintenance philosophy, the use of stains appears to be more consistent and cost-effective.

In addition to the factors listed above, it is essential that the coating be compatible with the intended acoustical performance of the barrier. If the barrier is designed to be sound reflective (see Section 3.5.4), then any type of coating may be applied without affecting its acoustical erformance. However, if the barrier is to perform a sound absorptive function, any coating used must not interfere with the barrier's sound absorptive characteristics. For instance, coating a sound absorptive, porous surface with a paint or a urethane-based anti-graffiti coating could seal up the voids which provide the barrier's sound absorptive characteristics. A water-based penetrating stain may be an appropriate coating in this instance. Before applying any coating to a sound-absorptive surface, research and coordination with both the barrier manufacturer and the coating supplier is strongly recommended.

While significant benefits in several areas can be realized by the use of coatings, there are health and environmental issues which need to be addressed in association with their use. As a general rule, products should be stored, applied, and disposed of in strict compliance with the recommendations of the manufacturer and in accordance with all applicable federal, state, and local regulations. Urethane-based coatings require particular attention due to their higher content of volatile organic compounds (VOC) and their more potent odors. Water-based and other more recently developed coatings will have little or no VOCs and less of an odor problem. They also have less toxicity. Over spray is still a factor requiring careful consideration where barriers are in close proximity to either residences or vehicles or where coating application is being performed near water courses or swales leading to such sources of water. Adequate covering of the ground with tarpaulins can help to minimize ground and water contamination.

|

Noise Wall Materials. |

||||

|---|---|---|---|---|

| Item# | Main Topic | Sub-Topic | Consideration | See Also Section |

| 5-1 | Concrete | Aesthetic | For cast-in-place: form liners and architectural inserts must be placed on vertical surfaces of the form work which can increase the chance of imperfections in the wall surface. | 5.1 |

| For cast-in-place: application of concrete retarding chemicals to the vertical form work surfaces for the purposes of obtaining an exposed aggregate finish is difficult. | 5.1 | |||

| For cast-in-place: other surface textures obtained through raking, brushing, or stamping of concrete are not possible. | 5.1 | |||

Surface textures:

|

5.9.1.1 | |||

| Quality control and consistency is critical in the production of pigmented concrete since unevenness and blotchiness can become apparent, particularly on smooth surfaces. The maximum protection against the visual effects of damage can be provided by use of a pigmented panel with a surface stain of a matching color. The added cost of such a dual treatment may, however, not be warranted in many cases. | 5.9.2.1 5.9.3 |

|||

| Drainage and Utility | Application of concrete retarding chemicals to the vertical form work surfaces for the purposes of obtaining an exposed aggregate finish is difficult. | 5.1 | ||

| Safety | Consider on-site material testing and inspection during construction. | 5.1 | ||

| Installation | For precast , consider size limitations, shipping requirements, traffic implications, reusability of precast panels, quality assurance process | 4.1.2.3.1 5.1 |

||

| For cast-in-place, consider on-site material testing and inspection procedures during construction, and weather concerns for on-site casting and curing. | 4.1.2.6 5.1 |

|||

| Maintenance | For free-standing noise walls, consider access for landscaping. | 4.1.2.6 | ||

| 5-2 | Brick and Masonry Block | Aesthetic | Surface textures: Exposed Aggregate - Consider limited use due to mass production constraints. Form Liners - While some molds may be applied to the production of concrete blocks, their use is rare and limited. Veneers - Ensure an adequate attachment bond. Stucco - The cleanliness and roughness of the noise barrier surface is critical in order to ensure an adequate bonding surface for the stucco. |

5.2 5.9.1.2 |

| Quality control and consistency is critical in the production of pigmented blocks since unevenness and blotchiness can become apparent, particularly on smooth surfaces. | 5.2 5.9.2.1 5.9.3 |

|||

| Structural | Consider the need for a continuous concrete foundation. | 5.2 8.4 |

||

| Consider the compressive strength of the concrete materials. | 5.2 | |||

| Installation | Hand-laid versus preassembled panels: Consider each type's versatility to conform to ground contours. Consider each type's speed of erection. Consider special leveling courses on grades of up to 6 percent. Consider the scaffolding requirements for hand-laid panels. |

5.2 11.1 |

||

| 5-3 | Metal | Acoustical | Consider the Sound Transmission Class requirements. | 5.3 |

| Aesthetic | Consider the possible "industrial" appearance of metal walls. | 5.3 | ||

| Consider weathering steel concerns because unpainted rusting panels can stain adjacent concrete. | 5.3 | |||

| Manufacturers' requirements (related to both coating and material coated) such as extent of sand blasting, cleaning materials, temperature and moisture controls, etc. need to be adhered to closely. | 5.9.2.3 5.9.3 |

|||

| Structural | Consider the non-compatibility of various metal combinations. | 5.3 | ||

| Ensure corrosion resistance. | 5.3 | |||

| Consider the metal's structural strength. | 5.3 | |||

| Safety | Consider the possible glare due to on-coming vehicles. | 5.3 | ||

| Consider implementing a deterrent for climbing on barrier girts. | 5.3 | |||

| Maintenance | Debris and errant vehicles easily causes noticeable damage. | 5.3 | ||

| 5-4 | Wood | Acoustical | Consider possible shrinkage and warping causing noise leakage through gaps. | 5.4 |

| Ensure a tight fit for tongue and groove planking to avoid noise leakage. | 5.4 | |||

| Aesthetic | Selection of a wood species for its color attributes must also consider durability, warping, rot resistence, etc. The type of treatment, stain, or paint must be compatible with the type of wood, nails, etc. used in the barrier assembly, and with the environment in which the barrier will be placed. Chemical reactions between steel nails and wood preservative treatments may corrode nails. Moisture content at the time of paint or stain application is also critical. | 5.9.2.4 5.9.3 |

||

| Safety | Consider the wood's burning characteristics when choosing a wood. | 5.4 | ||

| Consideration should be given to a wood's shatter resistance. | 5.4 | |||

| 5-5 | Transparent Panels | Structural | Consider the various methods of mounting. | 5.5 |

| Consider edge conditioning the panels. | 5.5 | |||

| Safety | Consideration should be given to shatter resistance. | 5.5 | ||

| Consider the possible glare due to on-coming vehicles. | 5.5 | |||

| Maintenance | Consider the methods of cleaning the panels. | 5.5 | ||

| Consider the maintenance concerns related to vandalism and scratches. | 5.5 | |||

| Consider the need for ultraviolet light protection. | 5.5 | |||

| Debris and errant vehicles easily causes noticeable damage. | 5.5 | |||

| Cost | Transparent noise barriers costs can be more costly than common concrete or steel panels. | 5.5 | ||

| 5-6 | Plastics | Acoustical | Consider the possible shrinkage in plastic materials. | 5.6 |

| Safety | Consideration should be given to the material's shatter resistance. | 5.6 | ||

| Consider the possible glare due to on-coming vehicles. | 5.6 | |||

| Consider the burning characteristics of the materials. | 5.6 | |||

| Maintenance | Consider the need for ultraviolet light protection. | 5.6 | ||

| Consider the maintenance concerns related to vandalism and scratches. | 5.6 | |||

| 5-7 | Recycled Rubber | Acoustical | Consider possible coating interference with the material's Noise Reduction Coefficient. | 5.7 |

| Ensure an adequate Sound Transmission Class. | 5.7 | |||

| Recycled rubber material generally cannot be pigmented. Rubber can be coated (usually with a more expensive polyurethane coating) to obtain a desired color. | 5.9.2.6 5.9.3 |

|||

| Structural | Consider the panel's structural strength requirements. | 5.7 | ||

| Consider the material's bonding requirements. | 5.7 | |||

| Safety | Consider the need for flame retardants. | 5.7 | ||

| Consider the material's possible toxicity concerns. | 5.7 | |||

| 5-8 | Composites | N/A | (Refer also to concerns for individual materials within composites) Particular concern must be paid to ensure compatibility between the barrier materials (including any glues, attaching devices, etc.) and the applied coating to negate any potential for damaging chemical reactions. | 5.8 5.9.3 |