Presentation

Presenter

Jagannath Mallela, Ph.D.

WSP | Parsons Brinckerhoff

Presentation Overview

- Why use performance requirements?

- Overview of performance requirements

- Writing performance requirements

- Role of Alternative Technical Concepts (ATC)

- Implementation Considerations

Why Performance Requirements?

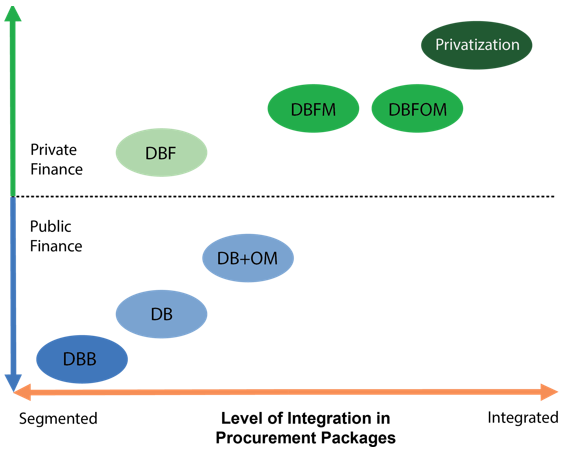

P3 Service Delivery

- Integrated delivery of assets and services

- Design, construction, finance, operations, maintenance

- P3 partner is singly responsible

- Both Design-Build (DB) and O&M contractors work for

P3 Partner

- Better value for money

- Cost certainty

- Potential cost minimization

- Potential for optimizing investment intervals

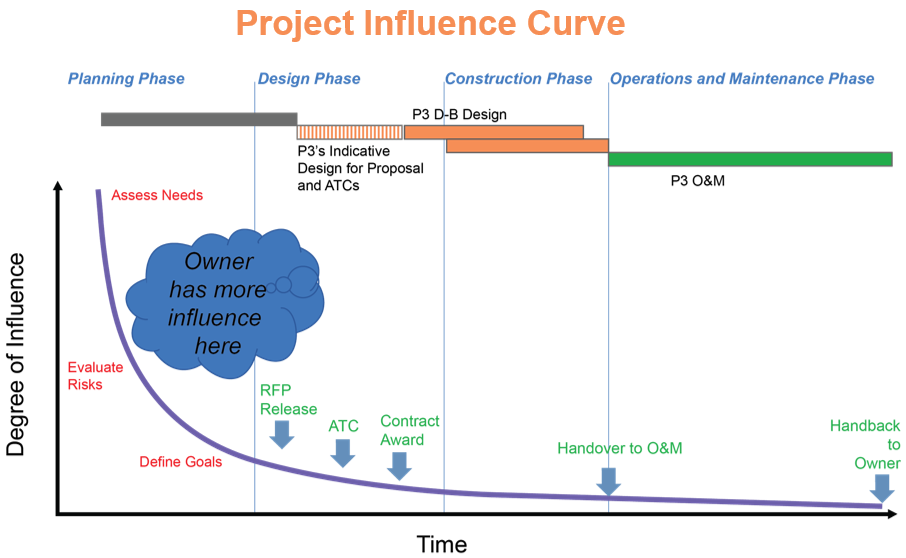

View

larger version of graph

Realizing P3 Opportunities

- Effective transfer of risks

- Majority of DB and O&M risks transferred to P3 Partner

- Asset and operational risks

- Design-build risks

- Risk retention with prescriptive requirements

- Potential for efficiency gains

- Level of integration - More than sum of its parts

- Larger contract size & increased coordination

- Design-build efficiencies

- Flexibility in making decisions

- Innovations to maximize asset lifecycle and operational

performance (e.g. safety, mobility, community impacts)

Concerns with Prescriptive Design Requirements in P3s

- Lost opportunities for efficiency gains

- Fewer opportunities are available when design decisions

are already made

- Limited potential for innovation and optimization due to

over-specificity of design details

- Risks are shifted back to the owner

An Example with Pavement Design

The P3 Developer shall use one of the following pavement types: hot

mix asphalt (HMA) or Portland cement concrete (PCC) pavement. The P3

developer shall use pavement designs that meet the following requirements.

| HMA Pavement |

PCC Pavement |

Minimum HMA Thickness = 10 inches. Use stone mastic asphalt

with PG 76-22 on the top two layers.

Minimum Thickness for

Granular Base = 12 inches

The acceptance

of HMA shall be in accordance with XYDOT Standards & Specifications

|

Minimum PCC Thickness = 12 inches

Transverse Joints =

15 feet

The acceptance of PCC shall be

in accordance with XYDOT Standards & Specifications |

Any proposed changes to the above specified pavement sections requires

approval by the Department.

Where is scope for innovation and risk transfer?

Adopted from D.D. Gransberg, 2006

View larger version of Project Influence Curve graph

Business Case for Performance Requirements

- To ensure effective transfer of risks to P3 partner

- To maximize realization of efficiency gains

- Remove constraints to innovate

- Encourage lifecycle perspectives

- Provide continuity across phases

Questions?

Submit a question using the chat box

Overview of Performance Requirements

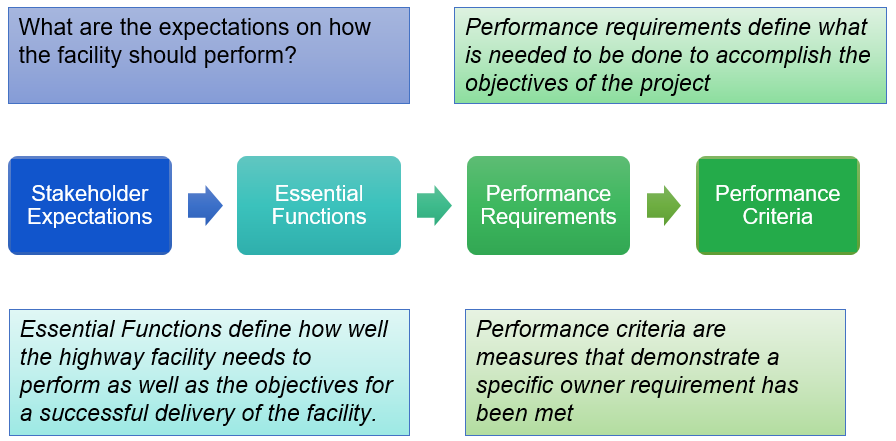

What are Performance Requirements?

View larger version of Performance Requirements chart

Text of Performance Requirements chart

| What are the expectations on how the

facility should perform? |

Performance requirements define what

is needed to be done to accomplish the objectives of

the project |

| Stakeholder Expectations » |

Essential Functions » |

Performance Requirements » |

Performance Criteria |

| Essential Functions define how well

the highway facility needs to perform as well as the

objectives for a successful delivery of the facility.

|

Performance criteria are measures that

demonstrate a specific owner requirement has been met

|

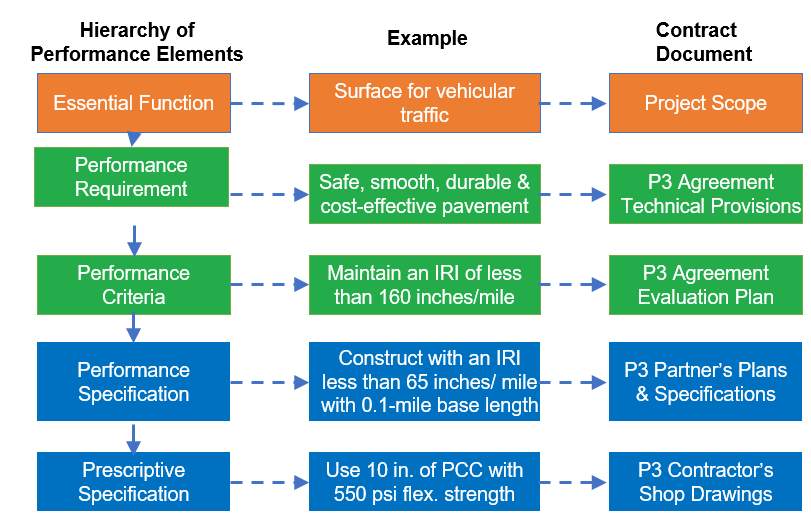

Hierarchy of Performance Elements

Adopted from D.D. Gransberg, 2006

View

larger version of Hierarchy of Performance Elements chart

Text of Hierarchy of Performance Elements chart

| Hierarchy of Performance Elements |

Example |

Contract Document |

| Essential Function → |

Surface for vehicular traffic → |

Project Scope |

| ↓ |

|

|

| Performance Requirement → |

Safe, smooth, durable & cost-effective pavement → |

P3 Agreement Technical Provisions |

| ↓ |

|

|

| Performance Criteria → |

Maintain an IRI of less than 160 inches/mile → |

P3 Agreement Evaluation Plan |

| ↓ |

|

|

| Performance Specification → |

Construct with an IRI less than 65 inches/ mile

with 0.1-mile base length → |

P3 Partner's Plans & Specifications |

| ↓ |

|

|

| Prescriptive Specification → |

Use 10 in. of PCC with 550 psi flex. strength → |

P3 Contractor's Shop Drawings |

Current Practice: Use of Performance Requirements in Various

Technical Areas

Technical areas where an agency is more likely to be flexible

in design requirements

- Geometric design

- Work zone management

- Ancillary assets

- Drainage/storm water management

- Landscaping and aesthetics

Technical areas where an agency is more likely to be prescriptive

in design details

- Pavements

- Bridges - types, structural elements & materials

Questions?

Submit a question using the chat box

Writing Performance Requirements

Writing Performance Requirements

- Beginning with project scoping, identify the needs:

- User and stakeholder needs

- P3 goals: Project delivery, operational and performance

management

- Prepare a list of functional requirements

- Must-haves, needs and project constraints

- Focus on project delivery as well as service delivery

- Project delivery: Target cost, quality and schedule outcomes

- Service delivery: Post-construction asset lifecycle and

operational performance needs (life-cycle costs and levels of

service targets)

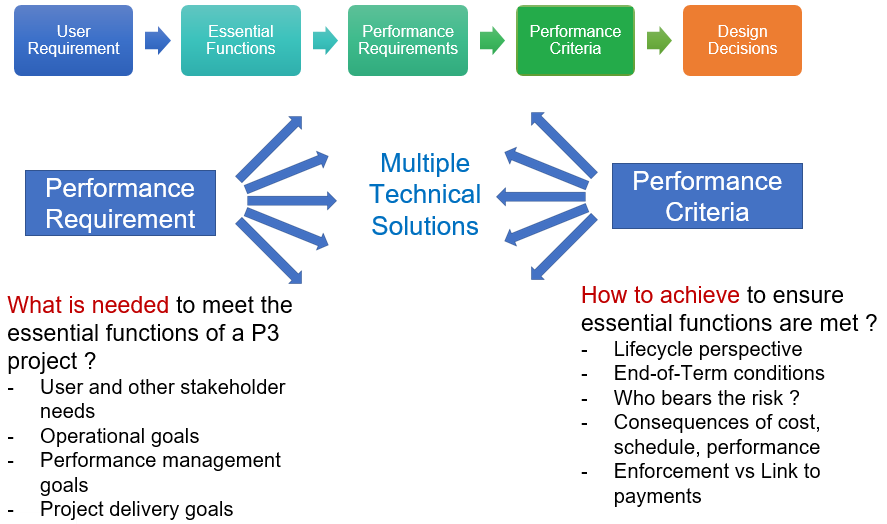

Identifying Performance Requirements/ Criteria

View

larger version of Performance Criteria flow chart

Text of Performance Criteria flow chart

User

Requirements → |

Essential Functions → |

Performance Requirements → |

Performance Criteria → |

Design Decisions |

| Performance Requirement → |

Multiple Technical Solutions |

← Performance Criteria |

What is needed to meet

the essential functions of a P3 project?

- User and other stakeholder needs

- Operational goals

- Performance management goals

- Project delivery goals

|

How to achieve to ensure

essential functions are met?

- Lifecycle perspective

- End-of-Term conditions

- Who bears the risk?

- Consequences of cost, schedule, performance

- Enforcement vs Link to payments

|

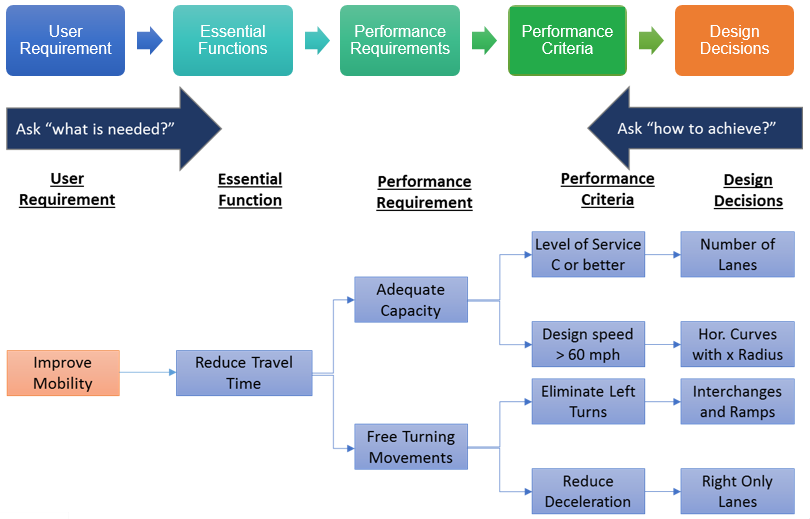

Identifying Performance Requirements/ Criteria: "Improve Mobility"

Example

View larger version of the Improve Mobility Example flow chart

Text of Improve Mobility Example flow chart

User

Requirements → |

Essential Functions → |

Performance Requirements → |

Performance Criteria → |

Design Decisions |

| Ask "what is needed?" → |

|

← Ask "how to achieve?" |

| Improve Mobility → |

Reduce Travel Time → |

Adequate Capacity → |

Level of Service C or better → |

Number of Lanes |

| Design speed > 60 mph → |

Hor. Curves with x Radius |

| Free Turning Movements → |

Eliminate Left Turns → |

Interchanges and Ramps |

| Reduce Deceleration → |

Right Only Lanes |

Function Analysis System Technique is suggested

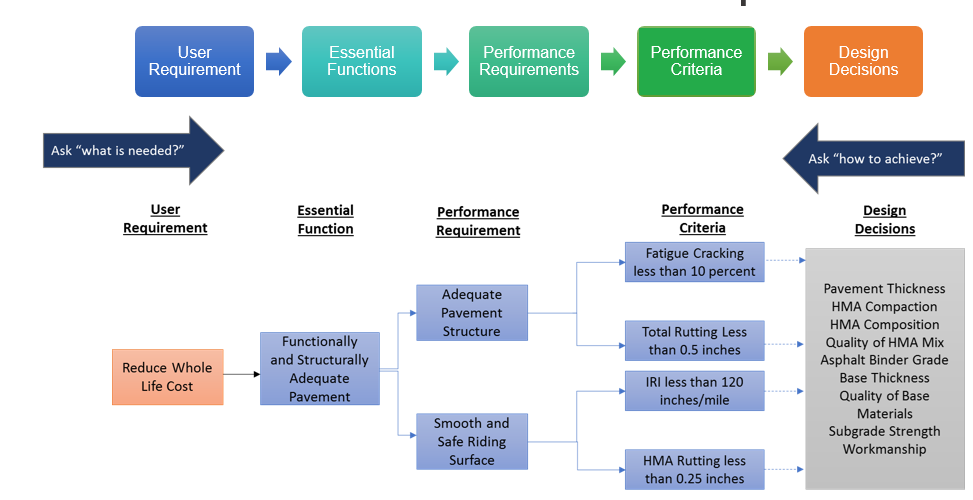

Identifying Performance Requirements/ Criteria: "Reduce Cost"

Example

View larger version of Reduce Cost Example flow chart

Text of Reduce Cost Example flow chart

User

Requirements → |

Essential Functions → |

Performance Requirements → |

Performance Criteria → |

Design Decisions |

| Ask "what is needed?" → |

|

← Ask "how to achieve?" |

| User Requirement |

Essential Function |

Performance Requirement |

Performance Criteria |

Design Decisions |

| Reduce Whole Life Cost → |

Functionally and Structurally Adequate

Pavement → |

Adequate Pavement Structure → |

Fatigue Cracking less than 10 percent → |

Pavement Thickness

HMA Compaction

HMA Composition

Quality of HMA

Mix

Asphalt Binder Grade

Base Thickness

Quality

of Base Materials

Subgrade Strength

Workmanship |

| Total Rutting Less than 0.5 inches → |

| Smooth and Safe Riding

Surface → |

IRI less than 120 inches/mile → |

| HMA Rutting less than 0.25 inches → |

Writing Performance Requirements: Some Considerations

- Optimal risk allocation between contracting parties

- Whole life perspective

- Use of performance analysis

- Need for re-evaluating environmental commitments

- Enforcement through non-compliance points and disincentives

- Use of performance specifications to relate construction quality

with performance

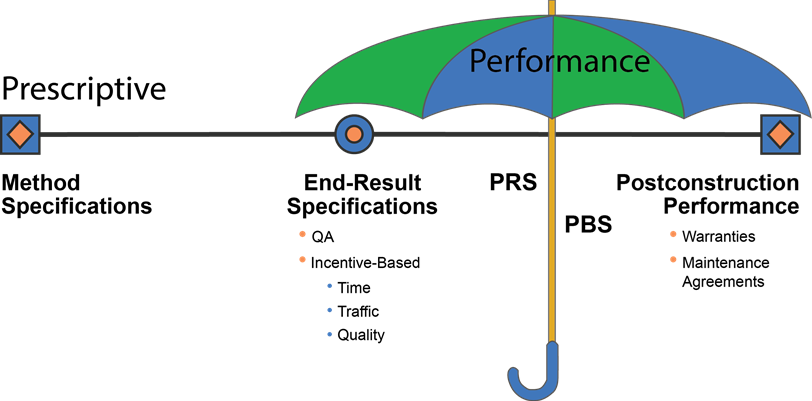

Performance Specifications

View larger version of Performance Specifications chart

Performance specifications provide the vital link between construction

quality characteristics and performance

Source: SHRP2 R07, Scott et al, 2014

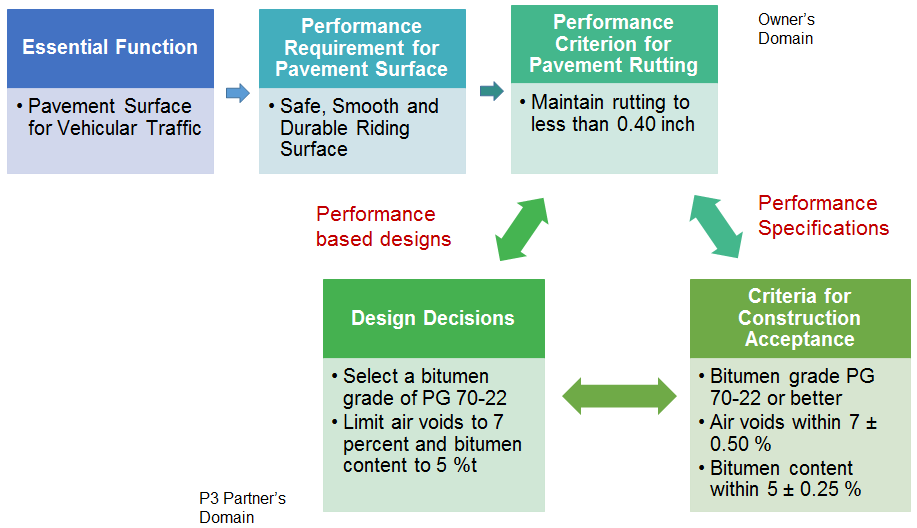

Linking Construction Quality to Performance: An Example

View larger version of flow chart

Text of flow chart

Essential Function

- Pavement Surface for Vehicular Traffic

|

→ Performance Requirement for Pavement

Surface

- Safe, Smooth and Durable Riding Surface

|

→ Performance Criterion

for Pavement Rutting

- Maintain rutting to less than 0.40 inch

|

Owner's Domain |

| |

|

↕

Performance based designs |

↕

Performance Specifications |

|

| P3 Partner's Domain |

|

↔

Design Decisions

- Select a bitumen grade of PG 70-22

- Limit air voids to 7 percent and bitumen content

to 5 %t

|

↔

Criteria for Construction Acceptance

- Bitumen grade PG 70-22 or better

- Air voids within 7 ± 0.50 %

- Bitumen content within 5 ± 0.25 %

|

|

Implementing Performance Specifications

- Degree of readiness depends on technical areas:

- Pavements & work zone management - more mature

- Bridges & geotechnical - yet to mature

- Known challenges with performance specifications

- Understanding factors influencing performance

- Robustness of performance predictions - Need long-term data

- Standardization - repeatability and reproducibility

- Availability of technology and skills

Questions?

Submit a question using the chat box

Alternative Technical Concepts

Alternative Technical Concepts

ATCs are suggested changes submitted by proposing

teams to the contracting agency's supplied basic configurations, project

scope, design or construction criteria.

An ATC is a request by a proposer to modify a contract requirement,

specifically for that proposer's use in gaining competitive benefit

during the bidding or proposal process. An ATC must provide

a solution that is equal to or better than the requirements in

the Invitation for Bid (IFB)/RFP document.

ATCs to Foster Innovation

- Contract tool to attract innovative and alternative ideas from

bidders

- Proven & time-tested process

- Risk transfer to P3 partner

- Rare need for ATCs when using performance requirements

- For P3s, ATCs contribute:

- To evaluate bidders' ideas on case-by-case basis (both control

and opportunity)

- Re-evaluate agency's mandatory requirements and constraints

ATCs - an Intermediate or Alternative Step to Performance Requirements

What qualifies as an ATC?

- Value: Must generate a cost, schedule or life cycle benefit

- Deviations with RFP requirements and agency standards (design

criteria, specifications, etc.)

- Design Exceptions vs Design Variances Approval

- "Cardinal Change" doctrine - Are the changes within

the contract scope?

- Handling permitting and NEPA commitments

Source: NCHRP 44-09

Interpreting "equal or better than" criteria

- Compare against the baseline concept (3-step process)

- Similar methodologies

- Caltrans value analysis methodology

- Performance-based practical design

- Other considerations

- Unintentional NEPA/Permitting commitments

- Divesting ownership rights

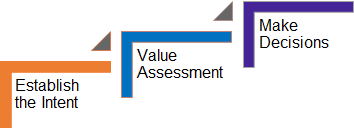

Three Step Process for ATC Review & Decision-Making

Questions?

Submit a question using the chat box

Implementation Considerations

Drafting Performance Requirements

- Involve interdisciplinary teams in drafting requirements

- e.g., environmental, maintenance, operations team

- Link performance standards to proposal evaluation criteria

- Determine the methodology and frequency of monitoring

- Consider future changes to service requirements and end-of-term

conditions

- Allow sufficient time for drafting

- Consider involving independent advisors

Organizational Cultural Change

- New demands, new skills and new perspectives

- Understanding performance consequences of design decisions

- Training needs, particularly on legal issues, dispute resolution,

and risk management

- Audit approach to oversight and quality acceptance

- Potential role of an independent engineer

- Sharing the benefits of "duty of care"

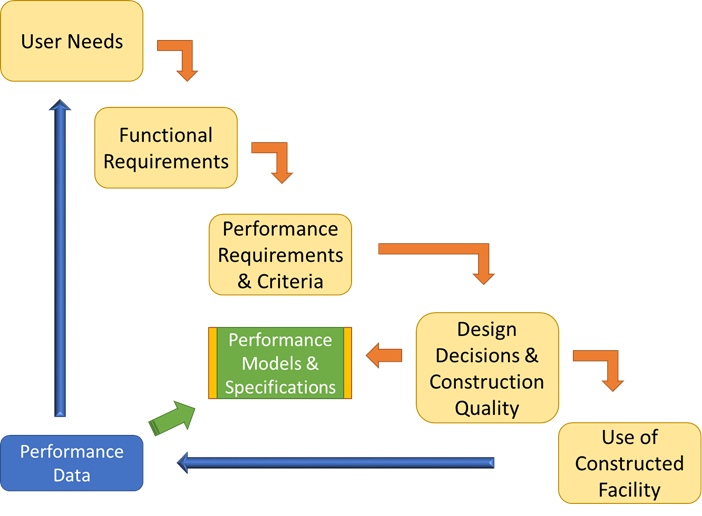

Performance-Based Decision Making

- Need for performance-based decision making

- Long-term performance data is foundational

- Performance prediction models

- Performance specifications

- Parallel FHWA study to capture performance metrics of P3 and

non-P3 cohorts

- Need for more robust and integrated asset management systems

View larger version of Decision Making flow chart

Text of Decision Making flow chart

Performance Data → User Needs → Functional Requirements →

Performance Requirements & Criteria → Design Decisions &

Construction Quality → Use of Constructed Facility and

Performance Models & Specifications

Best Practices

- Capacity building and knowledge management

- Involving multi-disciplinary teams in drafting performance requirements

- Robust contract administration and support process

- Re-engaging advisors who drafted performance requirements

- Reducing propensity to micromanage

- Hiring third-party consultants/specialists to support the

delivery

- Enforcement mechanisms

- Detection of early deficiencies

- Linking performance to payments

- Robust asset and operational management process

- Need for performance data

- Continual update to performance models

Legal Perspectives

- Spearin Doctrine: Who is responsible for defects in the plan,

design, or specifications provided to the contractor?

- Developed for D-B-B

- Less certain on contractor-provided designs

- Basic principles apply - prescriptive requirement, differing

site conditions, inaccurate information

- Prescriptive vs Performance Requirements

- Focus NOT on words "design" and "performance"

- Evaluates whether "instructive" or "outcome"

based

- Differing site conditions

- Provide an opportunity to P3 proposers to conduct their

own investigations

- Shared risks - use risk "allowance"

- Order of precedence

- Likelihood of disputes when technical proposal is directly

incorporated into P3 agreement

- "Brand name or equal" clause

- Will be treated as a performance requirement

- Should be a reasonable number of vendors

Questions?

Submit a question using the chat box

Upcoming P3 Webinar

- February 16 P3 Projects in the

U.S.

To register for the webinar, please visit:

/ipd/p3/p3_training/webinars.aspx

FHWA P3 Toolkit: https://www.fhwa.dot.gov/ipd/p3/toolkit/

| Fact Sheets |

- Ten concise single-sheet discussions of key P3 concepts

for a non-technical audience

|

| Primers |

- P3 Concessions for Highway Projects

- Risk Assessment

- Value for Money

- Financial Structuring and Assessment

- Establishing a P3 Program

|

| Guides |

- How FHWA Reviews P3s

- Model Toll Concession Contracts

- Model Availability Payment Contracts

- P3 Project Financing

- Risk Assessment

- Value for Money

- Benefit-Cost Analysis

|

| Discussion Papers |

- Revenue Risk Sharing

- Performance Requirements for Design and Construction

in P3s

|

| Analytical Tools |

|

| Informational Reports |

- Successful Practices for P3s

- Highway P3 Projects in the U.S

|

Contact Information

Jagannath Mallela

Director, Research & Innovation

Solutions

WSP Parsons Brinckerhoff

mallelaj@pbworld.com

Patrick DeCorla-Souza

P3 Program Manager

USDOT Build America Bureau

& FHWA Center for

Innovative Finance Support

(202) 366-4076

Patrick.DeCorla-Souza@dot.gov