"The project scoping process is a series of project-focused activities that develop key design parameters and other project requirements to a sufficient level of definition such that scope discovery is complete and a budget and project completion date can be accurately established to minimize the risk of significant change and project overruns"

- NCHRP Report 821 (Anderson et al, 2015)

The project development process for highways typically begins with the scoping process. Project scoping primarily focuses on identifying all necessary elements and potential risks that need to be considered in the delivery of a roadway project. The purpose of project scoping is to avoid any unintended consequences in the later phases of project development and ensure on-schedule and on-budget delivery of the project (ODOT, 1999). Highway agencies have extensive experience in conducting project scoping, and there is ample guidance available in the literature on conducting an effective scoping exercise.

The outcome of the project scoping process is a scoping document that typically includes, but is not limited to the following: (i) the context of the project, including location, project limits, background of the existing facility, and the role in the larger transportation network, (ii) the purpose and needs statement identifying the operational, asset condition and safety deficiencies in the existing system and the drivers of the proposed project, (iii) baseline scope for physical assets and operations, (iv) preliminary cost estimates (with contingencies) and schedules, including project development costs, (v) third-party requirements, such as right-of-way, utilities, railroads, permits, and requirements of other governmental entities, (vi) current and future operational factors, including current travel conditions, freight and transit, travel demand, crash history, etc., (vii) operational scenarios, potential alternatives, and preferred design solutions, (viii) design standards, design criteria and variances, (ix) potential stakeholders and their inputs, (x) proposed project/service delivery methods, and (xi) environmental impact summaries, including air quality, wetlands, wildlife, historic and archealogical resources etc.

While the project scoping process of highway owners has evolved into a comprehensive and effective exercise, the state-of-the practice is largely tailored to address the design and construction phases of a roadway project, including those delivered under D-B-B, D-B and D-B-F. For a P3 project, the project scoping process does not extend to include the post-construction asset lifecycle and operational performance of the roadway facility. However, note that much of the project scoping exercise is still valid as the general scope or the concept of the project described forms the basis for the environmental review process.

From the performance requirements perspective, the current project scoping process clearly identifies the purpose and needs statement as well as the base concept that form the basis for identifying user requirements and essential functions; however, the scoping process falls short of deriving performance requirements and performance criteria.

The agency's preparations for writing performance requirements begin with project scoping. Beginning in the scoping phase, the agency undertakes a thorough analysis of the requirements of the project and the facility from the perspective of the users and other stakeholders as well as the P3 private partner. The agency analyzes the user needs, the project-related (or facility-related) as well as exogenous constraints, and the primary factors for considering the P3 delivery method. The agency conducts an investigation of operational deficiencies with the existing highway facility or network, explore opportunities for improvement, and identify user needs. The findings of the investigations are summarized in the agency's scoping document. The scoping document describes how the facility will be operated and used, and further identifies the major features (e.g., physical and operational features) of the project.

Factors that may help identify the needs of a highway project:

Source: MnDOT Highway Project Development Process.

Based on the scoping document's findings, the agency generates a list of requirements for each major feature of the project, of which some requirements are absolute "needs" and others can be considered as "wants." The "needs" are those requirements that are truly necessary to ensure the "as-planned" project/service delivery and post-construction performance of the facility, otherwise referred to as "essential functions." When identifying the "essential functions" for a project, the agency should ask what the facility/project must do and what the needs are to achieve the objectives. Similarly, the project constraints, including cost, schedule, quality, performance and other technical factors, are identified for each feature of the project.

The agency then establishes performance requirements that define the essential functions as well as the associated performance criteria to measure them. They are typically written using concise and objective statements. Performance requirements describe what outputs need to be delivered to accomplish the objectives of the project, as summarized in the scoping document. Through the "what" part of the performance requirements, the agency allows the agency to open up for one or more solutions to meet a functional requirement, while the responsibility to determine the preferred solution, i.e., the "how" part, lies with the P3 private partner.

Performance criteria establish the rules by which the agency will evaluate the effectiveness of the design and construction as well as the facility performance downstream. Performance criteria set the baseline for desired performance as well as threshold or ceiling metrics for the agency's acceptance, and therefore, should be objective and measurable. Performance criteria are typically quantifiable; and wherever quantification is not feasible, performance criteria should at least be verifiable to avoid any likelihood of differences of opinion between the agency and the P3 private partner. When identifying the "performance criteria" for a project, the agency should ask how the performance criterion will help determine if the performance requirement was met.

Function Analysis System Technique can be used to analyze performance requirements of a project.

The products of the project scoping exercise, i.e., the list of essential functions, performance requirements and performance criteria, culminate in an agency's project requirements document that forms the basis for writing the Technical Provisions. An agency's project requirements typically includes project needs and goals, technical constraints (e.g. site, design, environmental), budget and schedule considerations, performance benchmarks and metrics, acceptable outcome-based codes and standards, warranty requirements, success criteria, and special directives and limitations. A good project requirements document describes the final output, and not how to do it.

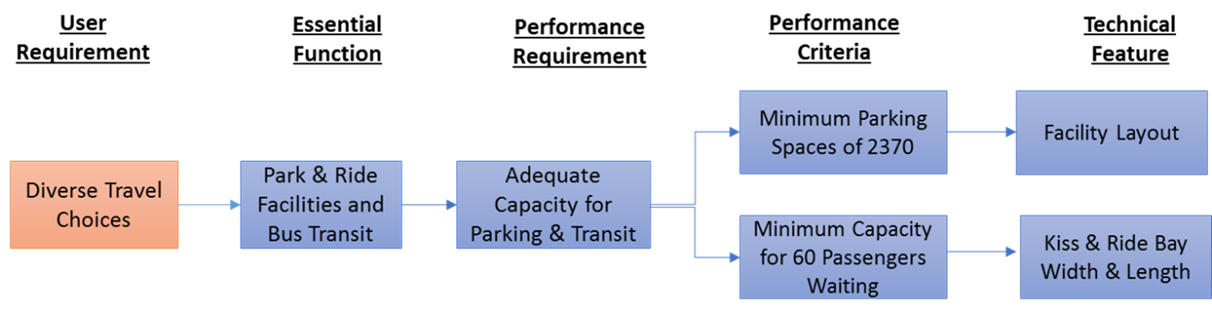

"Function Analysis System Technique (FAST)," a design tool, can be used to analyze the performance requirements of a project using "what" and "how" questions (Borza, 2011). Using the FAST tool, the agency can develop a graphical representation of the logical relationships between various functions of a project, and how to achieve them (Johnson, 2013). Figure 5 presents an illustration of the FAST tool with an example.

Figure 5. Sample Analysis of Performance Elements using Function Analysis System Technique

View larger version of Figure 5

| Ask "what is needed?" | Ask "how to achieve?" | |||

|---|---|---|---|---|

| User Requirement | Essential Function | Performance Requirement | Performance Criteria | Technical Feature |

| Improve Mobility | Reduce Travel Time | Adequate Capacity | LOS C or better | Number of Lanes |

| Design speed > 60 mph | Hor. Curves with x Radius | |||

| Free Turning Movements | Eliminate Left Turns | Interchanges and Ramps | ||

| Reduce Deceleration | Right Only Lanes | |||

Source: Adapted from Johnson, 2013.

The above-discussed process to be undertaken during the project-scoping phase is summarized in the following steps:

Note that the identification of performance requirements will begin in the project scoping phase but may not be finalized until the RFP is ready for release.

Figure 6. An Example with Virginia I-66 Outside the Beltway P3 Project

Purpose & Need:

Need:

Improvements are needed to address limited variety of

travel mode choices (i.e. transit, bicycling and pedestrian

facilities). As alternatives to single-occupant vehicle

(SOV) travel are limited, new infrastructure to support multimodal

opportunities are needed (VDOT, 2015).

Goal:

Improving multimodal mobility along the I-66 corridor by providing diverse travel choices through an efficient

network of Park-and-Ride, HOV, transit, and express lane opportunities

in a cost-effective and timely manner.

Project

Requirement: Design, construct, and transfer at Project

Completion of Transferred Project Assets, including Park-and-Ride

facilities, at strategic points along the corridor.

View larger version of flow chart

| User Requirement | Essential Function | Performance Requirement | Performance Criteria | Technical Feature |

|---|---|---|---|---|

| Diverse Travel Choices | Park & Ride Faciliites and Bus Transit | Adequate Capacity for Parking & Transit | Minimum Parking Spacing of 2370 | Facility Layout |

| Minimum Capacity for 60 Passengers Waiting | Kiss & Ride Bay Width & Length |

Source: VDOT and WSP | Parsons Brinckerhoff

Figuratively referred as the three-legged stool, the key elements of highway project/service delivery are (i) cost, (ii) schedule, and (iii) design details. In a P3 arrangement, another leg or element, "lifecycle performance," is added to this stool. While the cost, schedule, and performance elements typically remain as constraints, the only variable element is design details. In other words, the P3 private partner attempts to develop design details to the constraints of cost, schedule, and performance. Similarly, the agency has the responsibility to ensure that the performance requirements define what is needed from a successful project.

In a typical set of Technical Provisions, there are four essential types of performance requirements, which include, but are not limited to, the following examples:

Performance requirements place an emphasis on the outcomes rather than inputs. Further, as laid down in a P3 agreement, the measured performance outcomes are contractually binding and form the basis for payment and incentive mechanisms. Hence, it is critical to write performance requirements/criteria in a clear, definite and consistent manner to avoid any ambiguities and misinterpretations.

It is a generally agreed principle that performance requirements/criteria should be written using an abductive reasoning approach. Under this approach, the agency specifies "rule" and "result" in the Technical Provisions, while leaving the task of identifying the "case" that produces the "result" within the constraints of the "rule" to the P3 private partner. In addition, the agency can ensure the effectiveness of the proposed performance requirement/criteria by evaluating them using the "SMART" model.

The "SMART" model presents a systematic way to evaluate the effectiveness of the proposed performance requirement/criteria using five measures, as presented in Figure 7: Specific, Measurable, Achievable, Relevant and Time-bound (CDC, 2011). Using the "SMART" criteria, the agency can ensure that the proposed performance requirement/criteria will be directly tied to the intended result and can be measured or verified.

Figure 7. Description of SMART Criteria for Evaluating Performance Requirements

View larger version of Figure 7

Specific - Are the criteria clear on what should be done?

Measurable - Are the criteria quantifiable and how can the results be measured?

Achievable - Are the criteria realistic, practical and achievable?

Relevant - Are the criteria relevant to the goals and strategies of the project?

Time-Bound - Are the criteria achievable within a reasonable time frame?

Source: WSP | Parsons Brinckerhoff.

Every technical requirement specified by the agency, irrespective of whether it is performance criteria, design preferences or prescriptive requirements, will have consequences on cost, schedule and performance. The agency should consider conducting a risk evaluation using a "round table" type exercise to assess the consequences of the agency's technical requirements. The agency must ensure that the representatives from all technical disciplines, particularly operations and asset managers, are brought in for the risk evaluation exercise.

The focus of the risk evaluation exercise would be to understand the interrelationships between the agency's proposed technical requirements and their implications on cost, schedule, asset lifecycle and operational performance within the context of project-specific and programmatic constraints, and how the agency's decisions affect the risk landscape of the project. The risk evaluation ensures that the dependence on mandatory technical requirements is only as much as necessary, while the emphasis on performance criteria is only to the extent practicable. Similarly, all mandatory technical requirements are evaluated to avoid unintentional assumption of design liability. Some examples are provided in Table 3.

| Technical Requirement Examples | Potential Impacts | Notes | |||||

|---|---|---|---|---|---|---|---|

| Cost | Schedule | Asset Performance | Mobility | Safety | Community | ||

| Provide an interchange with pedestrian crossing | ↔ | ↔ | ↔ | ↓ | ↓ | ↓ | Though not prescriptive, the requirement is too open. Limiting the pedestrian-vehicle conflict points to a specific number will control potential operational risks. For instance, by limiting the conflict points to 8, a diverging diamond design with center walkway may be proposed, otherwise, a conventional diamond interchange with 12 conflict points for pedestrian crossing may be proposed. |

| Place a hot mix asphalt overlay of 5 inches over the existing concrete pavement. Maintain an IRI of 120 or less at all times | ↓ | ↔ | ↓ | ↓ | ↓ | ↔ | Reflective cracking will be an issue for the agency prescribed design solution. To meet the performance requirement, the P3 private partner will have perform frequent rehabilitation treatments, which increases the cost, affects lifecycle performance, and increases the risks of work zone disruption and safety. |

| Remove and replace the existing soil with the select fill by 3 ft. wherever expansive clays are present | ↓ | ↓ | ↔ | ↔ | ↔ | ↔ | There is no clear definition of severity of expansive clays to be replaced. Most clays may have some expansive minerals but not all clay minerals are detrimental. Providing flexibility to deal with expansive soils, such as the use of stabilization techniques, may provide better solutions than the prescribed method. The agency retains the risks of means and methods, if the removal and replacement does not produce the intended result. |

Key: ↔ indicates no or little impact; ↓ indicates negative impact; ↑ indicates positive impact.

The outcomes of the risk evaluation exercise will help allocate the risks between the public agency and the P3 private partner in a balanced and effective manner. The general principle is that risks should be allocated to the party that is in the best position to manage or mitigate them. While the private sector generally has good appetite for risks, the agency will realize good value only for those that the private sector can manage or mitigate effectively; otherwise, the risk will be priced as contingency in the bids. There are some risks for which the agency is best placed to provide more data to reduce the overall risk regardless of allocation, such as the impact of differing site conditions.

Alternative Technical Concepts (ATCs) are a valuable contracting mechanism used by highway agencies to allow for innovation and input during the procurement process. ATCs appear to be a natural fit for P3 procurement: the ATC process allows the proposers to propose alternative and innovative solutions to create cost, schedule and work zone management efficiencies during the project delivery phase, and maximize asset life-cycle and operational performance during the facility use phase.

ATCs are defined as the suggested changes proposed by bidders in response to the agency's base technical requirements. As described by the FHWA, an ATC is "a request by a proposer to modify a contract requirement, specifically for that proposer's use in gaining competitive benefit during the bidding or proposal process... [and] must provide a solution that is equal to or better than the owner's base design requirements in the invitation for bid (IFB for D-B-B) or request for proposal (RFP for D-B) document."

The use of ATCs is well established in the P3 and D-B procurement processes. More than half of the states in the U.S. have experience with ATCs in D-B contracting, and many projects have demonstrated value increases and/or cost savings with ATCs (FHWA, 2014). State agencies, including Florida, Minnesota and Washington, have institutionalized the ATC process in their D-B programs. ATCs are being used in a growing number in P3 projects, including the I-595 Corridor Improvements Project in Florida, the North Tarrant Express Project in Texas, and the Downtown Tunnel/Midtown Tunnel/ MLK Extension Project in Virginia.

Handling geotechnical risks contractually has always been

challenging, particularly in D-B and P3 projects, since the

contract is awarded before a geotechnical investigation is complete.

Some agencies have demonstrated the use of ATCs as an effective

risk management tool to handle geotechnical risks.

Gransberg

and Pereira (2016) presents three case-study projects that demonstrate

the successful application of ATCs in mitigating geotechnical

risks. First, on the New Mississippi River Bridge Project delivered

using Design-Bid-Build, the Missouri DOT saved about $7.5 million

in costs for installation of drilled shafts for bridge foundations

through ATCs. Second, on the TH61 Hastings River Bridge Design-Build

Project in Minnesota, the embankment settlement risks were effectively

handled using the ATC process resulting in significant cost

savings of about $ 80 to 100 million. Third, on the Tuttle Creek

Dam stabilization project, delivered using the Construction

Manager/General Contracting method, the Army Corps of Engineers

successfully mitigated the liquefaction potential of an earthen

dam foundation using the ATC process. This project was completed

two years ahead of the planned schedule with costs about 30

percent below the original estimate.

There is a rare need for ATCs with performance requirements, since proposers would have the required flexibility in making decisions to achieve the desired level of performance. When performance requirements are not used, the ATC process can be effective in validating the need for the agency's prescriptive design requirements or the agency's understanding of design constraints. Through this process, not only can the agency re-evaluate its mandatory requirements and constraints, but it also gets an opportunity to maximize value at the proposer's risk.

Furthermore, an agency is likely to undergo an organizational change management process and various implementation stages before successfully transitioning to the use of performance requirements in procurement. Until the use of performance requirements is in place, the agency can use a robust ATC process to attract alternative ideas from the proposers. The ATC process gives the agency both opportunity and control to evaluate each proposal carefully in the procurement stage of P3 delivery. Not only does the ATC process enable the agency to attract alternative concepts, but it also serves as a "sandbox" testing environment during the agency's transition to performance requirements, when effectively utilized with no undue burden to proposers. Implementing an effective ATC program is an essential step for an agency transitioning to performance requirements and will make the transition more practicable.

The foundational principle for qualifying an ATC is that the alternate concept must generate equal or better value to the project, agency and/or stakeholders than the base concept. The term "value" is defined using cost, schedule, performance and risks, and can be related to minimizing costs, expediting schedule, minimizing environmental impacts or right of way needs, improving service quality (i.e., capacity, accessibility, mobility, safety, etc.), and lifecycle performance of assets. Highway agencies do not typically allow any alternate concepts that lead to scope reduction.

The highway agency has the discretion to establish criteria on what specific areas of the P3 delivery it would like to allow or disallow; a good rule of thumb is to select, using an internal assessment during the preliminary design and RFP technical requirements drafting stage, those aspects of the project scope for which the agency wants to encourage ATCs to generate value. There is additional guidance available in federal statutes and literature on what would or would not qualify as an ATC.

The federal statute 23 Code of Federal Regulations (CFR) 636.209(b), which allows ATCs in two-phased design-build solicitations, essentially states (USGPO, 2016a):

"At your discretion, you may allow proposers to submit alternate technical concepts in their proposals as long as these alternate concepts do not conflict with criteria agreed upon in the environmental decision making process."

While providing flexibility to the procuring agency on the ATCs, the federal statute makes two stipulations:

The NCHRP Synthesis Report 455: Alternative Technical Concepts for Contract Delivery Methods conducted a national survey on what respondent agencies perceived as a qualifying ATC (Gransberg et al, 2014). Per the survey, the key benchmark that agencies use to qualify an ATC is that the concept must generate a cost, time, or life cycle benefit to the agency. The survey indicated that highway agencies are open to qualifying a concept that requires a design variation from agency approved standards, policies and standard specifications, or a simple variation from a contract requirement unrelated to design.

Highway agencies are generally not receptive to allowing a concept that violates any of the ten controlling criteria in the AASHTO Green Book, since a formal approval is necessary from the FHWA for design exceptions. The agency has final discretion to opt for undertaking a formal design exception process, if it is convinced that the ATC generates significant value and the potential safety risks relating to the design exception can be mitigated. However, when allowing a concept that conflicts with the existing contract requirements, the agency should make sure that all bidders are aware of this variance through a global addendum without affecting the confidentiality of the proposed ATCs.

Similarly, given the schedule risks with permits and environmental approvals, the agency may decide not to entertain the proposed concept as an ATC, if it does not comply with existing permits or the footprint approved in the NEPA process. In some instances, the agency may provide conditional approval to a concept, while allowing the P3 private partner hold the risk in obtaining any additional approvals within a stipulated time frame and bearing any cost and schedule consequences. To accommodate potential ATCs the agency can, in the NEPA process, choose to obtain approval for a footprint that is reasonably broad enough to cover ATCs.

As discussed earlier, an ATC, to be valid, must provide an alternate solution that is functionally "equal to or better than" the requirements in the RFP. The outcome of the interpretation of the clause is a decision by the agency to fully approve an alternate concept, approve with conditions or reject in favor of the base concept. Interpreting the clause correctly can be challenging, as there is potential for making inconsistent decisions.

Many highway agencies require bidders to describe in their ATC submittals how their proposed alternate concept is equal to or better than the base concept, including the anticipated cost savings, and schedule and performance benefits. Except for concepts relating to innovations, a significant number of ATCs involving design variances or design exceptions are dependent on trade-off analysis among costs, schedule and performance. Before making a decision, the agency has a responsibility to validate the proposer's projected benefits by either undertaking value analyses on its own or requiring the proposer to substantiate the benefits using widely accepted or approved methods, standards, data and references. In accordance with the Federal regulation, Title 23 CFR Part 627, the FHWA no longer requires value engineering analysis for projects delivered using the design/build method of construction (USGPO, 2016b).

Given the number of ATCs typically handled on P3 projects in a short period, there is little opportunity for back and forth communications between the agency and proposers to clarify any disagreements over the design details, methodology and expected benefits. In cases involving innovative and emerging materials or techniques, there may not be adequate performance history to support the proposer's claims.

To ensure consistency in interpretations, there is a need for the agency to make an "informed" decision on whether the alternate concept provides equal or better value than the base concept based on its comparative "value." This entails establishing the intent of both base and alternate concepts, evaluating them to quantify their comparative value, and ensuring that the original intent is fully achieved with no compromise. In making decisions, the agency must take into consideration the risk profile of a P3 contractual arrangement when interpreting the clause.

Establishing Intent: Understanding the expressed intent of both base and alternate concepts, which is a cardinal rule in contract interpretation, is the critical step in the ATC review. The highway agency must establish the intent of a given concept in the context of the purpose and need of the project and the "essential functions" without which the facility will not perform satisfactorily or will not be delivered as planned.

The intent is typically captured using measurable performance attributes, which can be further defined in terms of service quality, asset maintenance, constructability, safety, and environmental, community and social impacts. The relative importance of these performance attributes must be established, and may change depending on the concept type and the project needs.

Value Assessment: To enable comparative evaluation of the concepts, the agency must identify value metrics that would typically include cost, schedule, risks and performance. Construing the term "value" in a narrow sense or using a single metric, say cost, schedule, a technical parameter or performance objective, must be discouraged; rather, the value should be interpreted holistically given the trade-offs between these metrics.

For example, to interpret the "equal to or better than" clause with regard to two pavement design alternatives, the value cannot be established using initial cost, schedule, structural number or thickness, or future predicted pavement distress. Such comparison may not ensure an "apples to apples" comparison, since each alternative would have different investment needs and service potential. To truly capture value, the two pavement design alternatives should be evaluated based on life-cycle costs that would be incurred to provide a desired level of service over a reasonably long period.

Title 23 USC Section 106A requires value engineering analyses on all NHS projects with project costs exceeding $50 million, and all NHS bridge projects with costs exceeding $40 million. Caltrans has taken this requirement a step further to implement value analysis at key milestones of project development, and as early as in the project initiation stage where value analysis would be most effective. Chapter 19 (Value Analysis) of the Caltrans Project Development Procedure Manual presents the policies and procedures for applying value analysis to highway construction projects (Caltrans, 2013). The purpose of a value analysis study is to identify a best proposal from a pool of alternatives with a goal of maximizing performance, minimizing costs, and ensuring that the selected alternative aligns with the project scope, purpose and need.

Caltran's value analysis process adopts a decision analysis methodology that evaluates feasible alternatives against predefined performance criteria to select an alternative with best value (i.e., performance/cost). Performance criteria include a set of performance attributes that are essential to achieve the project objectives, with each attribute assigned with a numerical weighting to indicate its relative importance to the project. Performance attributes may include traffic operations, construction impacts, project schedule, environmental impacts, phasing ability, land-use, and maintainability. Each alternative is evaluated, scored and weighted against the performance attributes and aggregated to produce a performance score. The value potential of each alternative is evaluated using value metrics (i.e., performance score, cost and schedule) to select the best one.

Gransberg et al (2013) recommends that the adoption of a similar approach in the ATC process would reflect the agency objectives and project needs in making ATC related decisions.

Making Decisions: In the end, the agency's decision to accept or reject the alternate concept will largely depend on the perception of risk that the proposed concept will entail. Taking into account the P3 contractual risk allocation arrangement associated with the concept, the agency may have to apply a stricter interpretation of the clause and follow a more rigorous evaluation when it shares or holds the risk. Note that the agency cannot disregard some aspects of performance, such as safety, user needs, and long-term needs or costs, and has to ensure mitigation of any conflicts with the purpose and need of the project.

A value-based comparison of base and alternate concepts will guide the agency to make more consistent interpretations and informed decisions in the ATC review process. Decision support methodologies, such as the Kepner Tregoe Decision Analysis, Analytical Hierarchy Process, and Risk Management tools, provide a generic but robust framework to facilitate an objective comparison of different alternatives.

The typical two-phased ATC process under a P3 or D-B procurement, as illustrated in Figure 8, is summarized as follows:

Figure 8. Typical Process with Alternative Technical Concepts

View larger version of Figure 8

Source: FHWA, 2014.

To make the agency's ATC process more effective, some of the best practices are summarized as follows:

The agency should consider using the ATCs from unsuccessful bidders, if needed, with any restrictions or limitations, especially given the fact that stipends are paid to most bidders for proposal development. The agency can include specific clauses in the stipend agreement to ensure vesting of the full ownership rights to the information presented in the ATC submittal. Some states have legal provisions in-place that essentially transfer the ownership rights of any information contained in proposal submittals, as a matter of public records and governmental property, to the public agency.