U.S. Department of Transportation

Federal Highway Administration

1200 New Jersey Avenue, SE

Washington, DC 20590

202-366-4000

This chapter describes Federal guidelines for establishing and maintaining traffic monitoring programs. Detailed guidance is provided for traffic monitoring methodologies ranging from determining the number of data collection stations, to how to assign factor groups using cluster analysis as one of the tools.

This chapter is organized into the following sections:

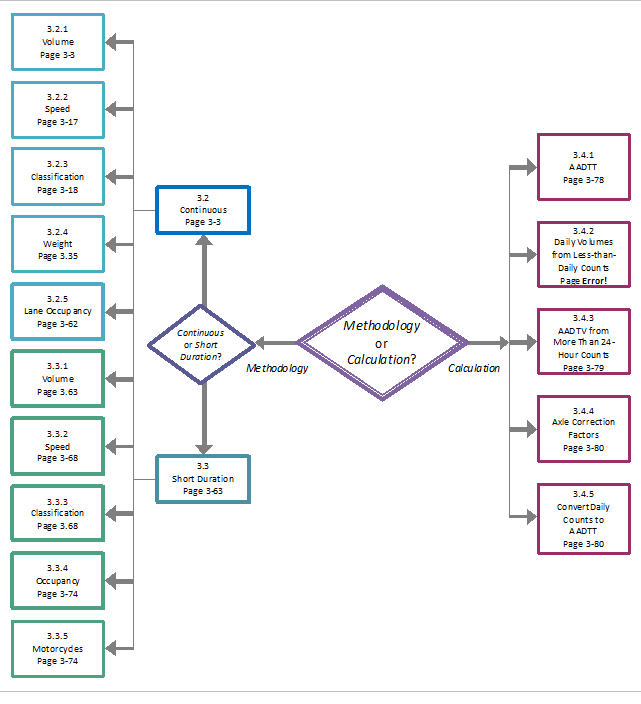

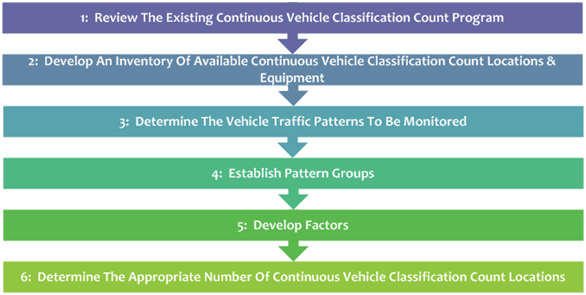

The Figure 3-1 is a chapter map showing how the sections relate to each other. Please note that some of the sections repeat certain information and guidance. This is to ensure all relevant points are made in every relevant section

Source: Federal Highway Administration

In most States, the continuous count stations form the basis for the overall traffic monitoring program. The definitions related to continuous count programs are included in Chapter 1. A continuous count is a volume count derived from permanently installed counters for a period of 24 hours each day over 365 days (except for leap year) for the data-reporting year. There is an attempt to collect 365 days of data per year, but sometimes data is not available for some of those days. In some States, this is referred to as the permanent count program. In the TMG, the program will be referred to as the continuous count program.

The objectives of continuous count programs are many and vary from State to State. Continuous count stations can be used to develop adjustment factors, track traffic volume trends on important roadway segments, and provide inputs to traffic management and traveler information systems. The number and location of the counters, type of equipment used, array, sensor technology, and the analysis procedures used to manipulate data supplied by these counters are functions of these objectives. As a result, it is of the utmost importance for each organization responsible for the implementation of the continuous count program to establish, refine, and document the objectives of the program. Only by thoroughly defining the objectives, and designing the program to meet those objectives, will it be possible to develop an effective and cost-efficient program.

Volume data is normally collected as part of a State’s continuous count program. The primary objective of the program is to develop hour of day (HOD), day of week (DOW), month of year (MOY) and yearly factors to expand short-duration counts to AADT. This objective is the basis for establishing the number and location of continuous count sites operated by the State highway agency. Secondary objectives of the continuous count program include the following:

Each agency develops its own balance between having larger numbers of continuous count stations (increasing the accuracy and reliability of analyses that depend on data supplied by those counters) and reducing the expenditures required to operate and maintain those counters. The TMG recommendations provide sufficient flexibility for each agency to find an appropriate compromise among objectives.

When determining the balance point, the objectives of the continuous count program should be statewide in nature, and the focus should reflect this statewide perspective (see Appendix D, Case Studies #1 and #2). As a result, the continuous count program should be developed to meet the minimum requirements of the State highway agency for ensuring statistical validity. Sub-area and roadway-specific data collection needs should be secondary considerations in the design of the continuous count program as desired by the appropriate agency.

Consequently, the TMG recommends that the division responsible for factor development operate at least the minimum number of continuous count locations needed to meet the accuracy and reliability requirements of the factoring program. Expansion of the data available through the program should come from other available count programs. That is, data available through other count programs such as intelligent transportation systems (ITS), MPOs, cities, counties and WIM programs (if separate), where the funding for the installation and operation of the counters comes from other sources, should be considered to supplement and expand the continuous count database (See Chapter 5, Case Studies #1 through #5). However, while the cost of equipment installation and operation of these supplemental continuous count programs is the responsibility of those other programs, the statewide traffic monitoring division should be responsible for ensuring its accuracy and making this data available to users. Determining how best to obtain, summarize, and report this data is an issue best addressed at the State level. Data management best practices can be learned from advanced travel monitoring programs. These examples are provided in Appendices D, E, and L.

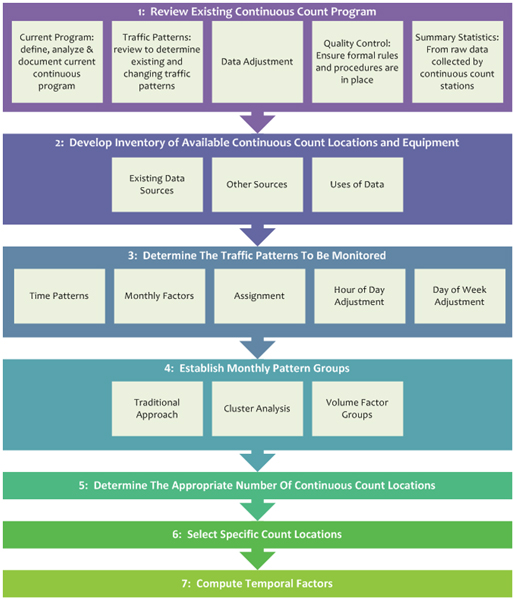

Several steps should be followed in establishing and evaluating a continuous count program for statewide traffic monitoring. The results of those steps will allow for benchmarking and improving the monitoring program. The lists were designed for 1) developing a new program; 2) checking to ensure compatibility with the guidance; and 3) evaluating a program.

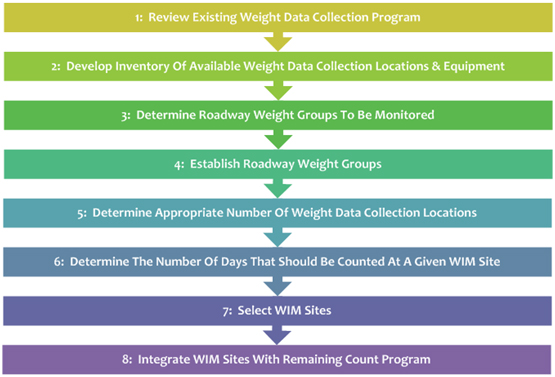

The following figure shows the steps to be followed in establishing a volume program.

VOLUMES

Source: Federal Highway Administration

A. Current Program – The first step in refining the continuous count system is to define, analyze, and document the current continuous count program. A clear understanding of the current program will increase confidence in later decisions to modify the program. The review should explore the historical design, procedures, equipment, personnel, objectives, and uses of the information. This review should start with an inventory of the continuously operating traffic data collection equipment available (this would include features, limitations, age, and repair/failure rates). It should then progress to determining how the data is being used, who is using it, and how it would be used if tools for using it in new ways were available

B. Traffic Patterns – Next, the data should be reviewed to determine hourly, daily, and monthly traffic patterns that exist in the State and whether previous patterns have changed in order to establish whether the monitoring process should also change.

C. Data Adjustment – The next step is to review how the data is being adjusted, and whether those data adjustment steps can be improved or otherwise made more efficient. Of considerable interest in this review is how the quality of the data being collected and reported is maintained. Establishing the quality of the traffic data reported by the system and the outputs of the analysis process is a prerequisite for future improvements. Continuous traffic data is subject to discontinuities due to equipment malfunctions and errors. The way a State identifies and handles errors or anomalies (i.e., due to weather, construction, special events, etc.) in the data stream is a key component of the program. Data adjustment should be made according to ASTM E27-59 Standard Practice for Highway Traffic Monitoring Truth-In-Data. The emphasis is on documenting the process and implementing of the documented process.

D. Quality Control – Each State highway agency should have formal rules and procedures for these important quality control efforts. Truth-in-data implies that agencies maintain a record of how data is adjusted, and that each adjustment has a strong basis in statistically rigorous analysis. Data should not be discarded or replaced simply because they appear atypical. Instead, each State should establish systematic procedures that provide the checks and balances needed to identify invalid data, control how those invalid data are handled in the analysis process, and identify when those quality control steps have been performed

E. Finally, the State highway agency should periodically review whether these procedures are performed as intended or need to be revised. For States that currently do not have formal quality control procedures, Appendix E provides several examples of how States use data quality control procedures.

F. Summary Statistics – The last portion of the review process should entail the steps for creating summary statistics from the raw data collected by continuous counters. These procedures should be consistent from year to year, be replicable, and should accurately account for the limitations (such as gaps in data) that are often present in continuous count data.

A. Existing Data Sources – The inventory of existing (and planned) continuous count sites ensures that the State’s traffic monitoring effort obtains all of the continuous count data that are available. As noted earlier, the key to the inventory process is for the agency to identify not just the traditional continuous count sites but also other data collection devices that can supply continuous volume data. These secondary sites include, but are not limited to:

Other Sources – Posing more challenges are devices operated by other divisions within the State highway agency. Obtaining this data can be difficult, particularly when internal cooperation within the agency is limited. However, the current emphasis on improved cost-efficiency in government means that in most States there is strong upper management support for full utilization of data resources, wherever they exist. The key to taking advantage of this support is to make the transfer of the data as automated as possible, so that little or no staff time need be expended outside of the continuous count data collection group to obtain the data.

The State highway agency should also look for data outside of its own agency. While it may not be possible to obtain this data at the level provided by standard continuous count devices (i.e., hourly records by lane for all days of the year), it is often possible to obtain useful summary statistics such as AADT and seasonal volume patterns from these locations. These summary data can be used to supplement the State’s data at those locations and geographic areas. The accessibility of data from supplemental locations reduces the cost of collecting and increases access to useful data. Local data can also be provided to FHWA. To obtain this data, the State highway agency may have to acquire software that automatically collects and reports this data. The intent is to reduce the operating agency’s staff time needed to collect and transmit the data. The easier this task is for the agency collecting the data, the more likely that this data can be obtained and integrated.

B. Uses of Data – This step involves determining how the continuous count data is currently being used, who the customers are for those data, and which data products (raw data? summary statistics? factors?) are being produced. Data should be collected for a purpose, and the users and uses of those data should be prioritized. Data has benefit when it answers important questions. Understanding by whom and how the data is being used creates a clear understanding of what value the data collection effort has to the organization. Understanding this value, and being able to describe it, is crucial to defending the data collection budget when budget decisions are made.

Several State DOTs find the use of a data business plan to be a useful tool for documenting the business needs for data and information (Chapter 2). Data business plans help to document how data systems support current business operations, identify data gaps (i.e., where new data and information are needed to support current needs), and provide a structured plan for the development of enhanced data systems to meet future needs and include life cycle costs to make best use of limited resources.

One of the tasks integral to the existence of the continuous counter program is the monitoring of traffic volume trends. Foremost among these trends is the monitoring of AADT at specific highway locations, and the tracking of seasonal and DOW patterns around the State. The Traffic Monitoring Analysis System (TMAS) is a good way to evaluate volume trends over time. The inventory process should document how the continuous count program is being used to create and apply adjustment factors to short duration traffic counts to estimate AADT, as well as which highway locations require continuous counters simply because of the importance of tracking volume with a high degree of confidence.

The collection of continuous data to determine AADT should only be necessary at a limited number of locations.

A. Time Pattern Variations – Monthly and DOW patterns are of much greater concern in the refinement of the continuous count program, since the effectiveness of the seasonal factoring process (and consequently the accuracy of most AADT counts) is a function of the seasonal patterns observed around the State. Understanding what patterns exist, how those patterns are distributed, and how they can be cost-effectively monitored is a major portion of the factor review process. Obtaining data from other sources (both volumes and speeds) and integrating the data with existing sources can be beneficial for monitoring traffic and congestion patterns for factoring.

The review of monthly patterns can be undertaken using one of a number of analytical tools. Two of the most useful are cluster analysis (that can be performed using any one of several major statistical software packages such as SAS or SPSS) and graphic examination (that uses GIS tools) of seasonal pattern data from individual sites.

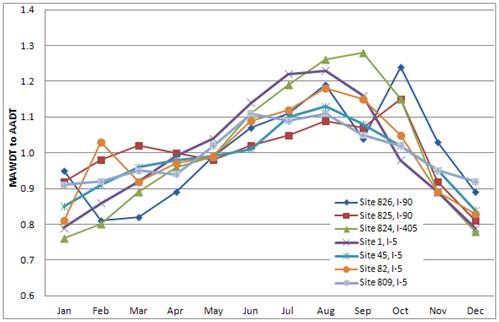

The intent of the MOY pattern review is to assess the degree of seasonal (monthly) variation that exists in the State as measured by the existing continuous count data and to examine the validity of the existing factor grouping procedures that produces the seasonal factors. The review consists of examining the monthly variation (attributed to seasonality) in traffic volume at the existing continuous count locations, followed by a review of how roads are grouped into common patterns of variation. The goal of this review is to determine whether the State’s procedures successfully group roads with similar seasonal patterns, and whether individual road segments can be correctly assigned to those groups.

B. Monthly Factors – The review process begins by computing the monthly average daily traffic (MADT) and the monthly factors at each continuous count location. The monthly factors are then used as input to a computerized cluster analysis procedure. The patterns for individual sites can also be plotted on paper or electronically so that patterns from different sites can be overlaid to visually test for similarities and/or differences. If the groups of roads reported by the cluster analysis are similar to the groups of roads already in use, or if the visual patterns of all continuous counts in each factor group are similar, then it can be concluded that the factor groups are reasonably homogeneous. Specifically, all of the continuous counts that make up each factor group have the same or reasonably similar MOY pattern

Factor groups are not necessary to be identical to the cluster analysis output for two reasons. For any given year, the cluster output is likely to be slightly different, as minor variations in traffic patterns are likely to be reflected in minor changes in the cluster analysis output. In addition, the cluster analysis output will require adjustment to create identifiable groups of roads.

C. Assignment – The remaining review step is to make sure that the groups are defined by an easily identifiable characteristic that allows complete assignment of all short duration counts to a factor group. The definition of each group must be complete so that analysts can correctly select the appropriate factor for every applicable roadway section.

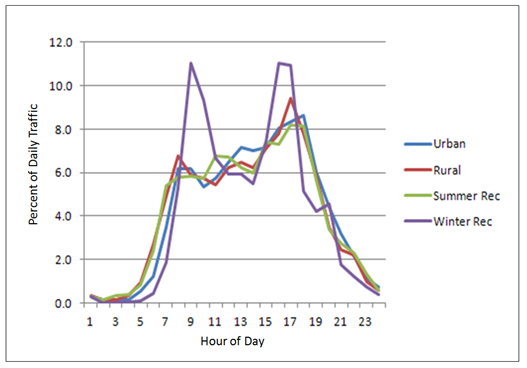

D. HOD Distribution – The repeatability of hourly variability is of great importance. Typical hourly variation in traffic volume on the traffic monitoring sites from Arizona DOT is shown in the figure below. The typical morning and evening peak hours are evident for urban routes on weekdays. The evening peak generally has somewhat higher volumes than the morning peak. Rural routes do not show two prominent peaks, while recreational routes shows a single daily peak (as travelers go to their recreational destination). Figure 3-3 shows an example of the HOD distribution.

Source: Federal Highway Administration.

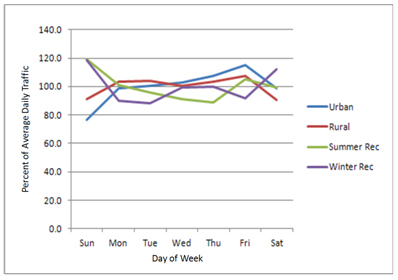

E. DOW distribution – Volume variation by day of the week is also related to site location (urban or rural) and the type of highway on which observations are made. Typical DOW variation in traffic volume on the traffic monitoring sites from Arizona DOT is shown in the figure below. Monday to Thursday traffic is similar and close to an average while the weekend traffic is generally lower than weekday traffic on urban routes. Friday traffic is generally higher than the rest of the days. States are allowed flexibility in how they design their DOW adjustment factor process to account most effectively for their own traffic patterns and data analysis process. At a minimum, weekday and weekend factors should be developed. However, individual DOW factors may be more appropriate in many cases due to the variability in traffic volumes from Friday through Monday on many roads.

Source: Federal Highway Administration.

If the factor groups are not reasonably homogeneous, the definition of the groups is not clear, or new traffic patterns are emerging, it may be necessary to re-form the monthly factor groups.

The basic statistic used to create factor groups can be either the ratio of AADT to MADT, or the ratio of AADT to MAWDT. In many States there are patterns of variation related to rural roads, urban roads, and recreational areas. However, in some States, significant geographic differences in travel need to be accounted for in the seasonal factoring process. For example, rural roads in the northern half of the State may have different travel patterns than rural roads in the southern half of the State. In addition, in some States clear patterns have failed to emerge.

The three prominent types of analysis are described as follows:

A. Traditional Approach – The more subjective traditional approach to grouping roads and identifying like patterns is based on a general knowledge of the road system combined with visual interpretation of the monthly graphs. The advantage of the traditional approach is that it allows the creation of groups that are easier for agency staff to identify and explain to users. This happens because the grouping process starts by defining road groups that are expected to behave similarly. The hypothesis is then tested by examining the variation of the seasonal patterns that occur within these expected groups.

The initial groups of roads that behave similarly could consist of roads of the same functional classification, or a combination of functional classifications. The groups should be further modified by the State highway agency to account for the specific characteristics of the State. Note that these are simply examples; there are other ways to accomplish this. Expected revisions include the creation of specific groups of roads that have travel patterns driven by large recreational activities, or that exhibit strong regional differences.

Deciding on the appropriate number of factor groups should be based on the actual data analysis results and the analyst’s knowledge of specific, relevant conditions. As a general guideline, a minimum of three to six groups is usually needed. More groups may be appropriate if a number of recreational patterns need to be monitored or if significant regional differences exist.

B.Cluster Analysis – The cluster procedure is illustrated by an example in Appendix G where the monthly factors (ratio of AADT to MADT) at the continuous count stations are used as the basic input to the statistical procedures. An understanding of the computer programs used for statistical clustering procedures is helpful but not required to interpret the program results

The cluster analysis procedures have two major weaknesses. One is the lack of theoretical guidelines for establishing the optimal number of groups. Determining how many groups should be formed is difficult. The cluster analysis process starts with all continuous counts in a single group, and proceeds until each continuous count is in an individual group. The difficulty is in determining at what point to stop this sequential clustering process. Unfortunately, the optimal number of groups cannot be determined mathematically.

The second weakness in the cluster analysis approach is that the groups that are formed often cannot be adequately defined, since the cluster procedure considers only variability at the continuous counts, not applicability to the short counts. Plotting the sites that fall within a specific cluster group on a map is sometimes helpful when attempting to define a given group output by the cluster process, but in some cases, the purely mathematical nature of the cluster process simply does not lend itself to easily identifiable groups.

Two advantages of cluster analysis are that it allows for independent determination of similarity between groups, therefore making the groups less subject to bias, and it can identify travel patterns that may not be intuitively obvious to the analyst. Accordingly, it helps agency staff investigate road groupings that might not otherwise be examined, which can lead to more efficient and accurate factor groups and provide new insights into the State’s travel patterns.

C. Volume Factor Groups – Because of the importance and unique inter-regional nature of travel on the interstate system, States should consider maintaining separate volume factor groups for the interstate functional categories. When interstate intrusive continuous count stations are not fiscally or logistically feasible, agencies utilize non-intrusive technologies to collect data. The interstate system will always be subject to higher data constraints because of its national emphasis and high usage levels. Most States maintain many continuous counts on the interstate system; therefore, separate interstate groups are easily created.

The following table shows the advantages and disadvantages of seasonal factor

| Type | Advantages | Disadvantages |

|---|---|---|

| Traditional | 1 – Creation of groups is easier 2 – Application for factoring can be explained 3 – Easier to assign short-term count to a group |

1 – May not stand statistical scrutiny |

| Cluster Analysis | 1 – Independent determination of similarity of groups without bias 2 – Traffic pattern can be found which may not be intuitively obvious 3 – Efficient and accurate factor groups |

1 – Lack of guidelines for establishing optimal number of groups 2 – Groups that are formed often cannot be adequately defined 3 – Difficult to assign short-term count to a group |

| Volume Factor Group | 1 – Consistent national framework for comparison among the State 2 – The precision of the seasonal factors can be calculated 3 – Easier to assign short-term count to a group |

1 – Functional or road classification may not be based on travel characteristics 2 – May not stand statistical scrutiny |

The TMG recommends the groups illustrated in Table 3-2 as a minimum

| Recommended Group | HPMS Functional Code |

|---|---|

| Interstate Rural | 1 |

| Other Rural | 2, 3, 4, 5, 6,7 |

| Interstate Urban | 1 |

| Other Urban | 2, 3, 4, 5, 6, 7 |

| Recreational | Any |

The first four groups are self-explanatory. The recreational group relies on subjective judgment and knowledge of the travel characteristics of the State. Usually, recreational patterns are identifiable from an examination of the continuous count data. The existence of a recreational pattern should be verified by knowledge of the specific locations and the presence of a recreational travel generator. A roadway is likely a recreational road when the difference between the ratio of the highest hourly volume to AADT and the ratio of the thirtieth highest hourly volume to AADT is greater than one. No single method exists for determining recreational patterns. A typical commuter pattern roadway can operate as a recreational pattern on weekends or a weekday depending on events, etc. The best way to determine trip purpose absolutely is to conduct intercept surveys.

Distinct recreational patterns cannot be defined based simply on functional class or area boundaries. Recreational patterns are obvious for roads at some locations but non-existent for other, almost adjacent, road locations. The boundaries of the recreational groups should be defined based on subjective knowledge. The existence of different patterns, such as for summer and winter, further complicates the situation. Therefore, the recommendation is to use a strategic approach to determine subjectively the routes or general areas where a given recreational pattern is clearly identifiable, establish a set of locations, and subjectively allocate factors to short counts based on the judgment and knowledge of the analyst. The road segments where these recreational patterns have been assigned should be carefully documented so that these recreational factors can be accurately applied and periodically reviewed

While this may appear to be a capitulation to ad hoc procedures, it is a realistic acknowledgment that statistical procedures are not directly applicable in all cases. However, recreational areas or patterns are usually confined to limited areas of the State and, in terms of total vehicle distance traveled (VDT), are small in most cases. The direct statistical approach will suffice for the majority of cases.

The procedure for recreational areas is then to define the areas or routes based on available data (as shown by the analysis of continuous and control data) and knowledge of the highway systems to subjectively determine which short counts will be factored by which continuous count (recreational) location. The remaining short counts should be assigned based on the groups defined by the State.

The minimum group specification can be expanded as desired by each State to account for regional variation or other concerns. However, more groups result in the need for more continuous count stations, with a corresponding increase in program cost and complexity. Each State highway agency will have to examine the trade-offs carefully between the need for more factor groups and the cost of operating additional continuous count stations.

The above definition of these seasonal patterns based on functional class provides a consistent national framework for comparisons among States and more importantly, provides a simple procedure for allocating short duration counts to the factor groups for estimating annual average daily traffic (AADT). It also provides a direct mechanism for computing the statistical precision of the factors being applied.

The precision of the seasonal factors can be computed by calculating the mean, standard deviation, and coefficient of variation of each adjustment factor for all continuous count locations within a group. The mean value for the group is the adjustment factor that should be applied to any short count taken on a road section in the group. The standard deviation and coefficient of variation of the factor describe its reliability. The error boundaries can be expressed in percentage terms using the coefficient of variation, where the error boundaries for 95 percent of all locations are roughly twice the coefficient of variation.

Typical monthly variation patterns for urban areas have a coefficient of variation under 10 percent, while those of rural areas range between 10 and 25 percent. Values higher than 25 percent are indicative of highly variable travel patterns, which reflect recreational patterns but which may be due to reasons other than recreational travel.

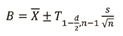

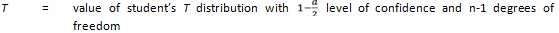

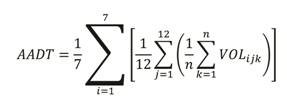

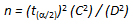

Having analyzed the data, established the appropriate seasonal groups, and allocated the existing continuous count locations to those groups, the next step is to determine the total number of locations needed in each factor group to achieve the desired precision level for the composite group factors. To carry out this task, statistical sampling procedures are used. Since the continuous count locations in existing programs have not been randomly selected, assumptions may be made. The basic assumption made in the procedure is that the existing locations are equivalent to a simple random sample selection. Once this assumption is made, the normal distribution theory provides the appropriate methodology. The standard equation for estimating the confidence intervals for a simple random sample is:

Where:

B = upper and lower boundaries of the confidence interval

n = number of locations

d = significance level

s = standard deviation of the factors

The precision interval is:

Where:

D = absolute precision interval

s = standard deviation of the factors

Since the coefficient of variation is the ratio of the standard deviation to the mean, the equation can be simplified to express the interval as a proportion or a percentage of the estimate.

The equation becomes:

Where:

D = precision interval as a proportion or percentage of the mean

C = coefficient of variation of the factors.

Note that a percentage is equal to a proportion times 100, i.e., 10 percent is equivalent to a proportion of 1/10.

Estimating the sample size needed to achieve any desired precision intervals or confidence levels is possible using this formula. Specifying the level of precision desired can be a difficult undertaking. Very tight precision requires large sample sizes, which translate to expensive programs. Very loose precision reduces the usefulness of the data for decision-making purposes. Traditionally, traffic estimates of this nature have been considered to have a precision of plus or minus 10 percent. A precision of 10 percent can be established with a high confidence level or a low confidence level. The higher the confidence level desired, the higher the sample size required. Furthermore, the precision requirement could be applied individually to each seasonal group or to an aggregate statewide estimate based on more complex, stratified random sampling procedures.

The reliability levels recommended are 10 percent precision with 95 percent confidence for each individual seasonal group, excluding recreational groups where no precision requirement is specified. When these reliability levels are applied, the number of continuous count locations needed is usually five to eight per factor group, although cases exist where more locations are needed. The actual number of locations needed is a function of the variability of traffic patterns within that group and the precision desired; therefore, the required sample size may change from group to group.

Recreational factor groups usually are monitored with a smaller number of continuous counters, simply because recreational patterns tend to cover a small number of roads; it is not economically justifiable to maintain five to eight stations to track a small number of roads. The number of stations assigned to the recreational groups depends on the importance assigned by the planning agency to the monitoring of recreational travel, the importance of recreational travel in the State, and the different recreational patterns identified.

Once the number of groups and the number of continuous count locations for each group have been established, the existing locations can be modified if revision is necessary. The first step is to examine how many continuous counters are located within each of the defined groups. This number is then compared to the number of locations necessary for that group to meet the required levels of factor reliability. If the examination reveals a shortage of current continuous count locations, the agency should select new locations to place continuous counters within that defined group. Since the number of additional locations may be small, the recommendation is to select and include them as soon as possible. Additional issues that should be considered when selecting locations to expand the sample size are reviewed in the following paragraphs.

If a surplus of continuous counters within a group exists, then redundant locations are candidates for discontinuation unless needed for ramp balancing and anchors. If the surplus is large, the reduction should be planned in stages and after adequate analysis to ensure that the cuts do not affect reliability in unexpected ways. For example, if 12 locations are available and six are needed, then the reduction could be carried out by discontinuing two locations annually over a period of three years. The sample size analysis should be recomputed each of the three years before the annual discontinuation to ensure that the desired precision has been maintained. Location reductions should be carefully considered. Maintaining a few (two to three) additional surplus locations may help supplement the groups and compensate for equipment downtime or missing data problems.

Matters for consideration are as follows:

MOY factors are most accurately developed and applied on a year-by-year basis. That is, a short count taken in 2009 should be adjusted with factors developed exclusively from continuous count data collected in 2009. This allows the adjustment process to account for economic and environmental conditions that occurred in the same year the short count was taken.

This recommendation creates problems for the timing of factor computation and application. That is, if a short count is taken in the summer of this year, the true adjustment factor for this year cannot be computed until January of next year at the earliest, which may not be timely enough for many users. The recommendation is to compute temporary adjustment factors for estimating AADT before the end of the year, and then to revise that preliminary estimate once the year’s true adjustment factors can be computed in January.

Temporary factors can be developed in one of three ways:

The first of these approaches is the easiest but also the least accurate, because the effects of this and last years’ economic/environmental conditions are likely to be different. The second approach reduces the biases that occur from using a single year’s factors. The last approach produces the most accurate adjustment factor but also requires the most labor-intensive data handling and processing effort. (See Appendix D, Case Study #6 for an example of computing monthly rolling average.)

The procedures for developing and using monthly factors to adjust short volume counts to produce AADT estimates follow directly from the structure of the program. The individual monthly factors for each continuous count station are the ratio of the AADT to MADT. Alternatively, the State can combine the DOW adjustment and monthly adjustment into a single factor, for example the ratio of annual average daily traffic to monthly average weekday traffic (AADT / MAWDT). This term, or a similar seasonal adjustment, can be substituted directly for the ratio of AADT / MADT in the factor grouping and application process if desired.

For a counter site that operates 365 days per year without failure, the AADT can be computed by adding all of the daily volumes and dividing by 365. Similarly, the MADT can be computed by adding the daily volumes during any given month and dividing by the number of days in the month.

Challenges with this approach are that few continuous count stations operate reliably during any given year. Most suffer at least small amounts of downtime because of power failures, communications failures, and other equipment or data handling problems. These missing hours or days of data can cause biases and other errors in the calculations, particularly when a moderate amount of data is lost in a block. As a result, a modified formula for computing these types of statistics that directly accounts for missing data has been adopted.

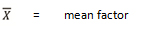

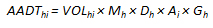

The following methodology has been adopted by AASHTO, has been researched and verified by FHWA, is used by many States, and is recommended by FHWA.

Where:

VOL = daily traffic for day k, of DOWi, and month j

i = day of the week

j = month of the year

k = 1 when the day is the first occurrence of that day of the week in a month, 4 when it is the fourth day of the week

n = the number of days of that day of the week during that month (for which you have data

This formula computes an average DOW for each month, and then computes an annual average value from those monthly averages, before finally computing a single annual average daily value. This process effectively removes most biases that result from missing days of data, especially when those missing days are unequally distributed across months or days of the week. The method used should be detailed in the Traffic Monitoring System (TMS) that States keep on record with the local FHWA district office.

The calculation of MADT is similar to that of AADT. An average DOW is first computed for a given month, and then all seven-day values are averaged. MAWDT is similarly computed. However, each State can define the specific days present in the MAWDT calculation. For example, some States do not count Fridays for routine short duration traffic counts and therefore, choose not to include Fridays in the computation of MAWDT.

Monthly factors for each continuous count are computed by the ratio of AADT to MADT or AADT to MAWDT. Group monthly factors are computed as the average of the factors for all continuous counter locations within the group. Both the individual continuous count and the group factors should be made available to users in tabular and computer accessible form. (See Appendix K for examples of these computations. See Appendix D, Case Study #5 for an example from Alabama regarding incorporating data collected by local governments.)

Measurements of vehicle speeds are used for a wide variety of studies, but particularly for safety studies and roadway performance monitoring. The data needed for these two types of studies are highly related but can be significantly different in both content and format. Safety studies rely on statistically valid measures of vehicle speed distributions during the study periods. Of particular interest in most safety studies is the speed distribution that occurs under free flow conditions (e.g., how many vehicles are speeding and how fast are they going? Is there a large difference in speed between the fastest and slowest vehicles in the traffic stream?). On the other hand, those conducting roadway performance monitoring are more interested in how the average speed of the facility changes by time of day and from one day to the next (e.g., is congestion forming, and if so, how often, how badly, and how long does it last?).

Consequently, speed data for most safety studies are gathered with traditional traffic monitoring devices, which collect speed data for all vehicles passing a selected point in the roadway over a defined period. Speeds are then reported either as individual vehicle observations or as summary data that indicate the volume of vehicles moving within defined speed ranges (speed bins).

Conversely, speed data for performance monitoring purposes traditionally come from sensors used for traffic management purposes. Average facility speeds are the primary reporting statistic calculated with data from these sensors, and individual vehicle speeds are often not collected. Recent decreases in the cost of both GPS equipment and wireless communications costs have also meant that privately collected vehicle probe data sets can now also meet many performance-monitoring needs. Unfortunately, these probe vehicle data only include a small sample of vehicles using a roadway, which can be used to estimate average facility speeds along entire roadway corridors across all days of the year. These data sets are less useful for most safety studies because they do not capture an unbiased measure of the distribution of speeds.

This edition of the TMG provides guidance on the collection and submission of speed data that are of particular use for safety studies. It does not contain guidance on the collection and use of vehicle probe based speed data useful for more general, area-wide, or corridor long roadway performance monitoring.

Travel speed data is used to determine travel time reliability, and is important for planning, program effectiveness evaluation, and investment analysis. Many other divisions within State DOTs need speed data for travel time, performance measures, safety studies, and other analysis. Multiple divisions within an agency could consider funding a permanent site, collecting the data once and using it many times across divisions/agencies.

Many continuous traffic-monitoring devices are deployed specifically to collect vehicle speed data; others collect speed data as a by-product of some other traffic data collection function. By taking advantage of all of their devices collecting speed data—whether intentionally or as a by-product—highway agencies frequently have access to a wealth of vehicle speed data. Many continuous counters are equipped with dual loops simply because the cost of the second loop is low in comparison to the initial investment at that site, and the provision of the second loop both provides redundancy in volume data collection and allows that location to be used for other purposes (speed monitoring and length classification).

The deployment of continuous equipment specifically to collect vehicle speed data is becoming popular in States. In an effort to leverage the capabilities of the current equipment, FHWA investigated speed data collection practices of States and found that 94 percent have speed data; all of the States collect speed data themselves, and five of the States use third parties to collect speed data.

Chapter 5, Transportation Management and Operations discusses ideas for sharing resources with other offices to collect speed data.

Data already collected at States are as follows:

This flexible structure would enable the reporting of spot speed without changing the data collection methodology currently being used by States. The final format for submission is identified in Chapter 7.

A well-designed monitoring program stores, summarizes, and makes available the speed data already collected by these devices for both internal agency use and submittal to U.S. DOT.

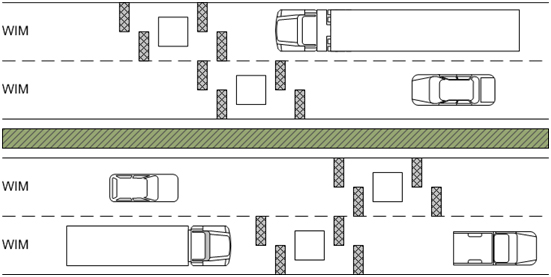

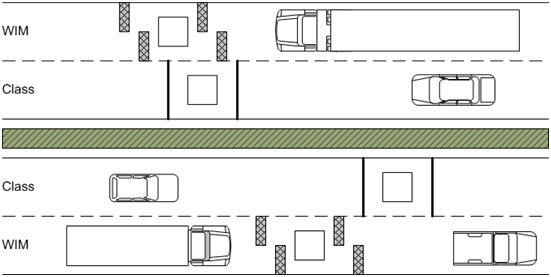

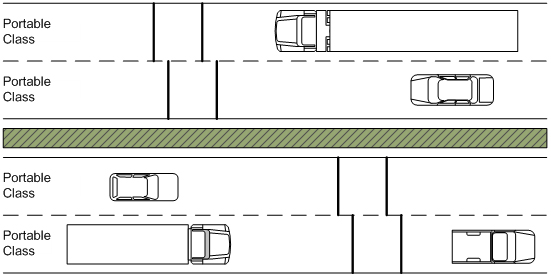

This section discusses the process for establishing a continuous vehicle classification count program and presents two alternative methods for the development of factor groups for classification. The continuous vehicle classification data collection program is related to, but can be distinct from, the traditional continuous count program. In addition, factoring of vehicle classification counts (i.e., heavy vehicle volume counts) may be performed independently from the process used to compute AADT from short duration volume counts. Highway agencies should collect classification data (which also supply total volume information) in place of simple volume counts whenever possible.

Figure 3-5 shows the steps for the classification process and are explained in the following paragraphs.

FOR DEVELOPING AND USING KNOWLEDGE OF THE TRAFFIC PATTERNS FOR EACH CLASS OF VEHICLE

Source: Federal Highway Administration.

A. Current Program – The first step in developing the continuous vehicle classification count program is to define, analyze, and document the current program. This assessment should include the historical design, procedures, equipment, personnel, objectives, and uses of the information. This review should begin with an inventory of the State’s continuous vehicle classification data collection equipment. The uses of the data should be identified, as well as who is using it and how it might be used if additional application tools were available

B. Traffic Patterns – The data should be reviewed to determine what unique traffic patterns exist for each major classification of vehicle in the State and whether previously identified patterns have changed in order to establish whether the monitoring process should be adjusted.

C. Data Adjustment – The details of the data adjusted/processed should be reviewed with attention to whether the data adjustment steps can be improved or otherwise made more efficient. Of considerable interest in this review is how the quality of the data being collected and reported is maintained. Establishing the quality of the vehicle classification data reported and the outputs of the data analysis process is a prerequisite for future improvements. Continuous traffic data collection is subject to discontinuities due to equipment malfunctions and errors. The way a State identifies and handles errors in the data stream is a key component of the vehicle classification program. Subjective editing procedures for identifying and imputing missing or invalid data is discouraged, since the effects of such data adjustments are unknown and may bias the resulting estimates. Instead, the quality control procedures listed below should be followed to ensure that invalid data is appropriately and consistently identified and replaced.

D. Quality Control – Each State highway agency should have formal rules and procedures for these important quality control efforts. The implementation of truth-in-data concepts as recommended by the AASHTO Guidelines for Traffic Data Programs will greatly enhance the analytical results and help in establishing objective data patterns. Truth-in-data implies that agencies maintain a record of how data is manipulated, and that each manipulation has a strong basis in statistically rigorous analysis. Data should not be discarded or replaced simply because they appear atypical. Instead, each State should establish systematic procedures that provide the checks and balances needed to identify invalid data, control how those invalid data are handled in the analysis process, and identify when those quality control steps have been performed

E. Finally, the State highway agency should periodically review whether these procedures are performed as intended or need to be revised. For States that currently do not have formal quality control procedures, Appendix E provides several examples of how States use data quality control procedures. In addition, AASHTO has also provided guidance on how to develop and implement a quality control process for traffic data collection.

F. Summary Statistics – The last portion of the review process should entail the steps for creating summary statistics from the raw data collected by vehicle classification equipment. These procedures should be consistent and should accurately account for the limitations that are often present in continuously collected classification data.

Correctly manipulating continuous vehicle classification count data after they have been collected is vital.

A. Existing Data Sources – The inventory of existing (and planned) continuous vehicle classification ensures that the State’s traffic monitoring effort is comprehensive and effective. As noted earlier, the key to the inventory process is for the agency to identify not only the traditional continuous vehicle classification, but also other data collection devices that can supply continuous class data. These secondary sites include, but are not limited to:

B. When available, data collection devices operated by the same group that operates the vehicle classification sites are the easiest from which to obtain data, but a number of State highway agencies do not make use of this data as part of their vehicle classification process.

C. Other Sources – Posing more challenges are devices operated by other divisions within the State highway agency. Obtaining this data can be difficult, particularly when internal cooperation within the agency is limited. However, the current emphasis on improved cost-efficiency in government means that in most States there is strong upper management support for full utilization of data resources, wherever they exist. The key to taking advantage of this support is to make the transfer of the data as automated as possible, so that little or no staff time is expended outside of the traffic data collection group to obtain the data.

D.The State highway agency should also seek data outside of its own agency. (See Chapter 5, case study examples.) While it may not be possible to obtain this data at the level provided by continuous vehicle classification equipment, it is often possible to obtain useful summary statistics from these locations. These summary data can be used to supplement the State’s data at those locations and geographic areas. The availability of data from supplemental locations reduces the cost of collecting and increases access to useful data. To obtain this data, the State highway agency may have to acquire software that automatically collects and reports this data. The intent, once again, is to reduce the operating agency’s staff time needed to collect and transmit the data. The easier this task is for the agency collecting the data, the more likely it is that this data can be obtained. However, data should only be used from calibrated sites (all sites including classification should be calibrated yearly).

E. Uses of Data – Another element is to inventory data uses and users. This step involves determining how the vehicle classification data is currently being used, who the customers are for those data, and which data products are being produced. Data should be collected for a purpose, and the users and uses of those data should be prioritized. Data only have value when they answer important questions. By understanding how the data is being used, it is possible to develop a clear understanding of what value the data collection effort has to the organization. Understanding this value, and being able to describe it, is crucial to defending the data collection program when budget decisions are made.

F. States should be checking the accuracy of their class data and taking appropriate action to evaluate and adjust their vendor-specific classification algorithm to correctly classify all of the vehicle types on their roadways (within 10% by class).

G. This inventory process may uncover the circumstance that some data and/or summary statistics are not being used. If that is the case, then those data and statistics may be eliminated in favor of the collection of data or production of statistics that will be used. This results in better use of available resources, makes the data collection system more focused on products actively desired by agency users, and results in more support for the data collection program from others in the agency. Several State DOTs find the use of a data business plan to be a useful tool for documenting the business needs for data and information (Chapter 2). Data business plans help to document how data systems support current business operations, identify data gaps (i.e., where new data and information are needed to support current needs), and provide a structured plan for the development of enhanced data systems to meet future needs.

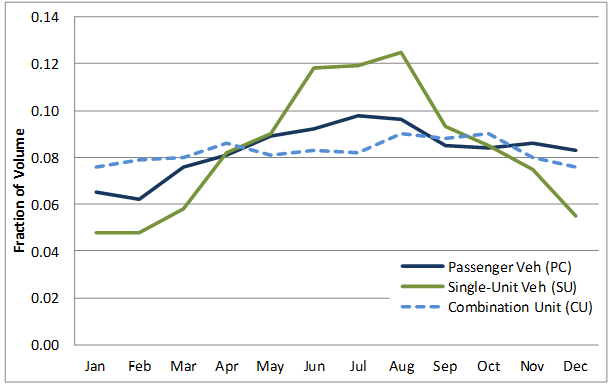

If sufficient data is available, it should be evaluated to determine what unique traffic patterns exist for each of the different classes of vehicles. For example, motorcycles have different DOW and monthly travel patterns than single unit trucks. The development of factor groups and factor procedures for different classes of vehicles should be undertaken. At a minimum, States should investigate whether they need different factor groups and processes for six aggregate classes of vehicles: motorcycles (MC), passenger cars (PV), light duty trucks (LT), buses (BS), single unit trucks (SU), and multi-unit combination trucks (CU). In some cases, two or more classes of vehicles may be included in one set of factors when these vehicles can be shown to have similar travel patterns.

The inventory process should document whether and how the continuous vehicle classification program is being used to create and apply adjustment factors to short duration vehicle classification traffic counts to estimate annual average volumes by type of vehicle. The inventory review process should also determine which highway locations require continuous vehicle classification equipment to capture the travel patterns effectively of all vehicle classes with a high degree of confidence.

The review of seasonal patterns can be undertaken using one of a number of analytical tools. Two of the most useful are cluster analysis, which can be performed using any one of several major statistical software packages such as SAS or SPSS, and the graphic examination, using GIS tools, of seasonal pattern data from individual sites.

The intent of the seasonal pattern review is to assess the degree of seasonal (monthly) variation that exists in the State as measured by the existing vehicle classification data and to examine the validity of the existing factor grouping procedures that produce the seasonal factors. The review consists of examining the monthly variation (attributed to seasonality) in vehicle traffic volume for each class of vehicles (at a minimum of MC, PV, BS, LT, SU and CU) at the existing vehicle classification locations, followed by a review of how roads are grouped into common patterns of variation. The goal of this review is to determine whether the State’s procedures successfully group roads with similar seasonal patterns, and whether individual road segments can be correctly assigned to those groups.

It is not necessary for the factor groups to be identical to the cluster analysis output for two reasons. For any given year, the cluster output is likely to be slightly different, as minor variations in traffic patterns are likely to be reflected in minor changes in the cluster analysis output. In addition, the cluster analysis output will require adjustment to create intuitively rational and identifiable groups of roads. The use of cluster analysis is explained in further detail in Appendix G.

The remaining review step is to make sure that the groups are defined by an easily identifiable characteristic that allows easy assignment of short counts to the group. The definition of each group must be complete enough to allow analysts to select the appropriate factor for every applicable roadway section.

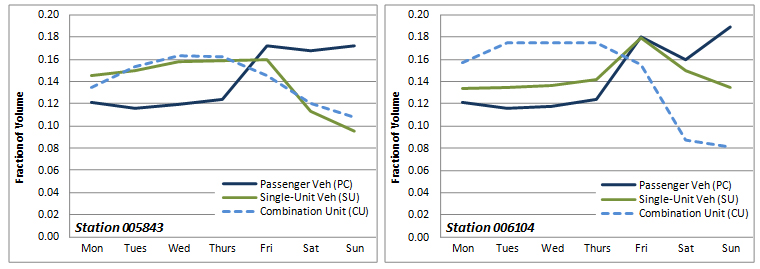

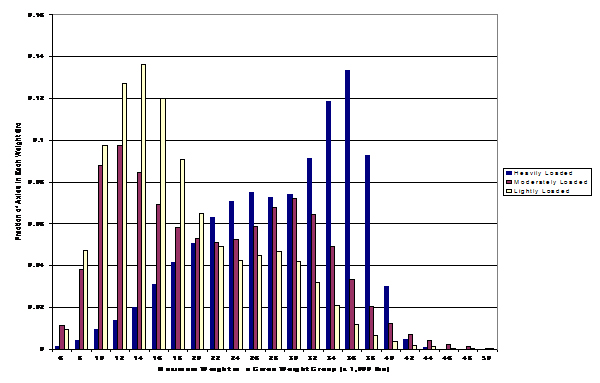

Each State highway agency should operate a set of continuous classification counters to measure vehicle-travel patterns and provide the factors to convert short classification counts to annual averages. As an example of one vehicle type, research has shown that truck travel does not follow the same time-of-day, DOW, and seasonal patterns as total volume (Schneider and Tsapakis 2009, Hallmark and Lamptey 2004, Hallenbeck and Kim 1993, Weinblatt 1996, Hallenbeck et al 1997). For example, see Figures 3-6 and 3-7 below.

Analysis of continuously collected data sets also indicates that truck volumes on many roads (even high volume interstate) can change significantly due to changes in the national and local economy. Similarly, continuous count data have shown that motorcycle traffic follows different patterns than other passenger vehicles with much more travel occurring on weekends than weekdays, especially on some rural roads used for recreational travel by motorcyclists. Continuously operating classification counters are needed to monitor these travel patterns so that these patterns can be detected and accounted for in engineering and planning analyses. For example, if the large increases in weekend motorcycle travel are not accounted for, short duration classification counts will significantly underestimate the number of miles traveled annually on motorcycles, thus biasing national and State safety analyses.

Source: Federal Highway Administration

Source: Federal Highway Administration

All State highway agencies have been operating permanently installed continuous count stations (CCS) (commonly referred to as ATRs) for many years. It has only been since the mid-1980s that technology allowed the installation and operation of similar counters to collect continuous classification data. A significant increase in the number of these counters has taken place since 1990 because of the start of traffic data collection for the Strategic Highway Research Program’s (SHRP) Long Term Pavement Performance (LTPP) project. Many States have also converted continuous installations to classification as the old equipment was replaced.

Data from these continuous classification devices have shown that motorcycle, single unit truck, and combination unit truck volumes have time-of-day, DOW, and by month variations that are different from those of cars. In addition, sources of continuous classification data may be obtained from installations from regulatory, safety, and traffic management systems installed to operate and manage the infrastructure. To obtain these existing data, highway agencies often need to establish working relationships with other public agencies, including MPOs, county and regional planning councils, to coordinate count programs and sharing of data. The effort may result in considerable improvement to the available classification data. FHWA is working on establishing length-based classification (see Appendix J, FHWA Memo on Establishing Length Based Classification).

The objective of seasonal factor procedures is to remove the temporal bias in current estimates of vehicles with unique temporal variances that are different from the total volume. Four primary reasons for installing and operating permanent, continuously operating, vehicle classifiers for traffic monitoring purposes include the ability to:

Regardless of the approach taken for the computation and application of factors, it is recommended that adjustment factors be computed for a maximum of six generalized vehicle classes (see VM-1 and HPMS Summary types). These are:

Table 3-3 compares the six-vehicle class groupings used in one of the HPMS datasets to the FHWA 13 vehicle category classes.

| HPMS Summary Table Vehicle ClassGroup* | FHWA 13 Vehicle Category Classification Number |

|---|---|

| Group 1: Motorcycles (MC) | 1 |

| Group 2: Passenger Vehicles equal to or under 102” (PV) | 2 |

| Group 3: Light trucks over 102” (LT) | 3 |

| Group 4: Buses (BS) | 4 |

| Group 5: Single-unit vehicles (SU) | 5,6,7 |

| Group 6: Combination Unit (CU) | 8,9,10,11,12,13 |

* These groupings are used to report travel activity by vehicle type in the Vehicle Summaries dataset for HPMS.

Highway agencies may adjust these categories to reflect their vehicle fleets and travel patterns best, as well as the capabilities of the classification equipment in their programs. (Note that where data shows similar patterns, the passenger car and light truck categories can be combined into one set of factor groups.)

Several reasons support these recommendations. The factoring process does not work well with low traffic volumes. With low volumes, even small changes result in high-percentage changes that make the computed factors highly unstable and unreliable. Even on moderately busy roads, many of FHWA’s 13 category vehicle classes (illustrated in Appendix C) will have mathematically unstable vehicle flows simply because their volumes are low. Aggregating the vehicle classes provides for more stable and reliable factors.

A second reason is that computing factors for the individual 13 vehicle classes may introduce too much complexity. There is no gain in separately annualizing extremely variable and rare vehicle classification categories.

Some issues presenting challenges to the factor development and application process remain unanswered, such as adequate editing procedures, resolution of the assignment of vehicles to classification categories, inability of equipment to collect a standard set of vehicle classes in all conditions, and disparities in the available equipment. Unnecessary complications at this stage of development should be avoided.

The following alternative truck volume factor procedures both have advantages and disadvantages. Both are complementary and can be combined as appropriate. States are encouraged to develop these alternative factor procedures or other alternatives that effectively remove temporal bias

The first procedure involves the use of roadway-specific factors. The second is an extension of the traditional traffic volume factoring process involving the creation of groups and the development of average factors for each of the groups.

Either applying factors to a road or fitting road segments into groups involves making decisions to resolve difficulties. A factor process may result in one set of factors for cars, another set of factors for trucks, and the combination of both to arrive at a total volume. A factor process may also require more than one set of factors for trucks where different truck types are factored separately. Some roads could conceivably fit in one factor group for cars, a second factor group for single unit trucks, and a third factor group for combination trucks. Resolutions should be made by each State between the need for accuracy and reductions in unnecessary complexity in the approach to removing temporal bias.

Two basic elements to the factoring process are the computation of the factors to apply to the short counts and the development of a process that assigns these factors to specific counts taken on specific roadways. The roadway-specific and the traditional procedures approach these two aspects of the factoring process differently. The result is two different mechanisms for creating and applying factors, each with its own strengths and weaknesses.

One option is the process that was developed by the Virginia Department of Transportation (VDOT) in the late 1990s. VDOT operates continuous counters on all major roads and the counters are used to develop road-specific factors. A short classification count taken on a specific road is adjusted using factors taken from the nearest continuous classification counter on that road. A factor computed for a specific road is not applicable to any other road.

As a result, a continuous classification counter should be placed on every road for which an adjustment factor is needed. This requires a large number of continuous vehicle classification counters and substantial resources. However, it ensures that a road can be directly identified with an appropriate factor and provide considerable insight into the movement of freight and goods within the State. The rule for assigning factors to short counts is simple and objective.

Identifying a specific road with a specific factor removes a major source of error in the computation of annual traffic volumes by removing the spatial error associated with applying an adjustment factor. Further, it produces factors that are applicable to all trucks using that road. The fact that different truck classes (single-unit versus combination trucks) exhibit different travel patterns is irrelevant, since all patterns are computed for that road. Having road-specific continuous classification counters also greatly reduces the number of short duration counts that are needed, since the continuous counters provide classification data for road sections near the count locations. The quality of data from continuous classification counters is superior to that of short counts.

Finally, this approach has the advantage of simplifying the calculation of adjustment factors, the application of those factors, and the maintenance of the program. For example, there is no need to develop groups and the application is performed one road at a time. Problems with continuous counters only apply to the affected roads and prioritization of counter problem correction can be based on road priority.

The most important disadvantage with this approach is cost. It is expensive to install, operate, and maintain large numbers of continuous traffic counters. The larger the system to be covered, the larger the cost. Even for smaller States, the cost to install a large counter base may be prohibitive. However, this approach may apply effectively to the interstate, where sufficient continuous counters may be available. It can also be applied to roads where current counters are installed.

A second disadvantage is that many roads are quite long and the character of any given type of vehicle traffic over their length can change drastically. This is why short count short duration programs are valuable. An adjustment factor taken on a road segment may not be applicable to another segment a few (two to three) miles down the road, particularly if a significant vehicle generation activity takes place along that stretch of roadway. Traffic patterns change because of economic activity, traffic generators, or road junctions. Not only does this further increase the number of continuous counters required, it also creates difficulty in selecting between the two continuous classification counters when a short count falls in between.

That is, specific road factors may be used for the most important truck roads and the traditional factor groups for routes without continuous classification counters. When continuous counters fail, traditional factoring techniques can then be used to provide adjustment factors on those roads. This combination of the traditional and roadway-specific factors may be an effective compromise between these two techniques

One final consideration with the roadway-specific technique is that there is no mathematical mechanism that allows computation of the accuracy/precision of the factors as they are applied to a given roadway section. Caution is recommended when significant traffic generators in the intervening space between the count and the continuous counter exist. When these factors are applied to count locations that are close to the continuous counter, they can be assumed to be quite accurate. However, as the distance between the short count and the continuous counter grows, and particularly as more opportunity exists for trucking patterns to change, the potential for error in the factor being applied grows, and at an unknown (but potentially substantial) rate.

The traditional factor process involves categorizing roads that have similar individual vehicle traffic patterns. A sample of data collection locations is then selected from within each group of roads, and factors are computed and averaged for each of the data collection sites within a group. A definition is provided for each group to describe characteristics that explain the observed pattern, which is used to allow the objective assignment of short counts to the groups. For example, a group might be defined as all roads in counties that experience heavy beach traffic, as these roads have unique seasonal and DOW recreational traffic. Similarly, for truck factors a logical grouping might be all roads serving heavy north/south or east/west through trucking movements, versus those roads that serve primarily local delivery movements.

For traffic volume, the traditional characteristics for grouping roads have been the functional class of the road (including urban or rural designation) and geographic location within the State. These groups are then supplemented with an occasional recreational (or geographic) designation for roads that are affected by large recreational traffic generators.

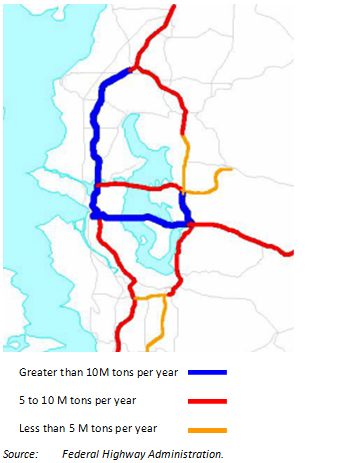

This same technique can be applied to truck traffic patterns. However, the characteristics that need to be accounted for can be different. Functional class of roadways has been shown to have an inconsistent relationship to truck travel patterns (Hallenbeck et al 1997, Schneider and Tsapakis 2009). Instead, truck travel patterns appear to be governed by the amount of long distance truck through-traffic versus the amount of locally oriented truck traffic, the existence of large truck traffic generators along a road (e.g., agricultural or major industrial activity), and the presence or absence of large populations that require the delivery of freight and goods. Understanding how these and other factors affect truck traffic is the first step toward developing truck volume factors. Developing this understanding requires analysis of the existing continuous vehicle classification data already being collected by the State, and analyzing it within the context of the commodity movements happening in the State. The steps required to gain this understanding are described below.

The creation and application of adjustment factor groups (time of day, DOW, and monthly) by class of vehicle is a topic that is still new. Most State DOTs have yet to develop these factoring procedures, and considerable research still needs to be accomplished.

States should depend on available classification data and knowledge to begin the development of truck traffic patterns. Truck traffic patterns are governed by a combination of local freight movements and through-truck movements. Extensive through-truck movements are likely to result in higher night truck travel and higher weekend truck travel. Through-traffic can flatten the seasonal fluctuations present on some roads while creating seasonal peaks on other roads not associated with the economic activity occurring in the land abutting that roadway section. Similarly, a road primarily serving local freight movements will be highly affected by the timing of those local freight movements. For example, if the factory located along a given road (not subject to significant amounts of through-traffic) does not operate at night, there may be little freight movement on that road at night.

Functional road classification can be used to a limited extent to help differentiate between roads with heavy through-traffic and those with only local traffic. Interstates and principal arterials tend to have higher through-truck traffic volumes than lower functional classes. However, there are interstates and principal arterial highways with little or no through-truck traffic, just as some roads with lower functional classifications can carry considerable through-truck volumes. Therefore, functional classification of a road by itself is a poor identifier of truck usage patterns. To identify road usage characteristics, additional information should be obtained from either truck volume data collection efforts or the knowledge of staff familiar with the trucking usage of specific roads. The truck volume data patterns, especially time of day patterns from short counts and DOW and monthly patterns from continuous classifiers, identify travel patterns for different types of vehicles. These patterns should then be discussed with staff working on freight planning activities to understand and help identify trucking patterns in ways that allow both grouping of continuous counters and assignment of short count location to those groups.

Among the types of patterns that can be identified through this combination of data and communication with staff are various local, regional, and through travel patterns. For example, local truck traffic can be generated by a single facility such as a factory, or by wider activity such as agriculture or commercial and industrial centers. These point or area truck-trip generators create specific seasonal and DOW patterns, much as recreational activity creates specific passenger car patterns. Truck trips produced by these generators can be highly seasonal (such as from agricultural areas) or constant (such as flow patterns produced by many types of major industrial plants). Where these trips predominate on a road, truck travel patterns tend to match the activity of the geographic point or area that produces those trips. In addition, changes in the output of these facilities can have dramatic changes in the level of trucking activity. For example, a labor problem at a West coast container port may produce dramatic shifts in container truck traffic to other ports. This results in significant changes in truck traffic on major routes serving those ports. Expansion or contraction of factory production at a major automobile plant in the Midwest can cause similar dramatic changes on roads that serve those facilities.

Truck trip generators can also affect the types of trucks found on a road. Specific commodities tend to be carried by specific types of trucks. However, State-specific truck size and weight laws can mean that trucks typical in one State may not be common in others. For example, multi-trailer trucks are common in most western States, while they make up a much smaller percentage of the trucking fleet in many eastern States. Understanding the types of trucks used to carry specific commodities is critical to understanding the trucking patterns on a road and how those patterns are likely to change (e.g., coal trucks in Kentucky and Pennsylvania).

Many other elements affect truck travel. For example, construction trucks operate in an area’s roads until the construction project is completed and then they move somewhere else. This type of truck movement is difficult to quantify. Roads near truck travel generators, such as quarries or trash dumps, carry consistent truck traffic and the type of truck is well known. Summarizing the different patterns in a way that allows creation of accurate factor groups is difficult. Obviously, the more knowledge that exists about truck traffic on a road, the easier it is to characterize that roadway.

Geographic stratification and functional classification can be used to create truck factor groups that capture the temporal patterns and are reasonably easy to apply. An initial set of factor groups might look something like that shown in Table 3-4. However, the two keys to the creation of groups is that the data should show that traffic patterns within grouped sites are in fact similar, and those groups should be designed in such a manner that short counts can be easily and accurately assigned to the correct factor groups. Therefore, as groups are formed, specific roads may need to move from one group to another to ensure that both of these constraints remain true.

Definitions like those above group roads with as homogenous truck travel patterns as possible, and provide easy identification of the groups for application purposes. They present a starting point to begin the identification process necessary to form adequate groups.

Performing a cluster analysis using truck volumes (as illustrated in Section 3.2.1 for total volume) will help to identify the natural patterns of variation and to place the continuous counters in variation groups. This will help in identifying which groups may be appropriate and in determining of how many groups are needed. One of strengths of the cluster analysis is that it identifies groups only by variation. The weakness is that it does not describe the characteristics of the group that allow application of the resulting factors to other short counts. The example definition in Table 3-2 does exactly the opposite. It clearly establishes group characteristics but cannot indicate whether the temporal variation is worth creating separate groups or not. As is the case for AADT group procedures, a combination of statistical methods and knowledge should be used to establish the appropriate groups.

| Rural | Urban |

|---|---|

| Interstate and arterial major through-truck routes | Interstate and arterial major truck routes |

| Other roads (e.g., regional agricultural roads) with little through traffic | Interstate and other freeways serving primarily local truck traffic |

| Other non-restricted truck routes | Other non-restricted truck routes |

| Other rural roads (e.g., mining areas) | Other roads (non-truck routes) |

| Special cases (e.g., recreational, ports) | |

All roads within the defined factor groups should have similar types of vehicle volume patterns. To verify this condition, the continuous counter data available within the groups should be examined. For each continuous classification counter in a group, compute the temporal adjustment factors of interest (DOW, month, or combined) for each of the vehicle types desired, and then compute the mean and standard deviation for the group as a whole. Plots of the volumes and the factors over time can also help to determine whether the travel patterns at the continuous sites are reasonably similar.

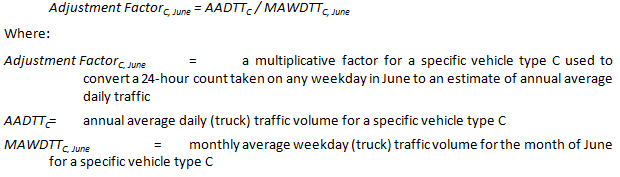

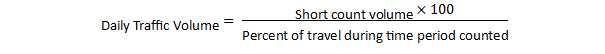

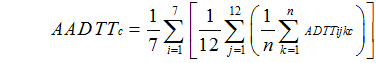

In most cases, only a few roads within each group will have sufficient data (continuous classification counters) needed to estimate travel patterns. The assumptions this analysis makes are similar to those made for AADT factors. The implication is that the continuous counters typify the existing temporal variation. Then the continuous counter variation reflects the variation existing at locations where no continuous counters exist. A combined monthly and weekday factor is computed as follows (This formulation assumes a multiplicative application. AADTT is equal to the average 24-hour count times the adjustment factor. Many States use the inverse of this formula and apply the resulting factor by dividing the average 24-hour volume obtained from their short count by the adjustment factor. See Table 3-9 for example):

An example of how these monthly adjustment factors differ by vehicle class is shown below in Table 3-5.

| MC | Car and Light Trucks | Buses | Single Unit Trucks | Combination Trucks | Total Volume | |

|---|---|---|---|---|---|---|

| MADTVehicle_Class | 35 | 4,874 | 52 | 227 | 1,639 | 6,826 |

| AADTVehicle_Class | 33 | 5,499 | 57 | 288 | 1,653 | 7,530 |

| Monthly Factor(AADTc/MADTc) | 0.95 | 1.13 | 1.10 | 1.27 | 1.01 | 1.10 |

Computing the mean (or average) for the June factor for all sites within the factor group yields the group factor for application to all short counts (weekdays in June) taken on road segments within the group. The standard deviation of the factors within the group describes the variability of the group factor. The variability can be used to determine whether a given factor group should be divided into two or more factor groups, to compute the precision of the group factor, and to estimate the number of continuous classification counter locations needed to compute the group factor within a given level of precision. An example of this is in Table 3-9.