U.S. Department of Transportation

Federal Highway Administration

1200 New Jersey Avenue, SE

Washington, DC 20590

202-366-4000

Federal Highway Administration Research and Technology

Coordinating, Developing, and Delivering Highway Transportation Innovations

| REPORT |

| This report is an archived publication and may contain dated technical, contact, and link information |

|

| Publication Number: FHWA-HRT-14-034 Date: August 2014 |

Publication Number: FHWA-HRT-14-034 Date: August 2014 |

This chapter presents the results of an in-depth literature review of performance based prequalification and the use of performance bonds in the highway industry. Sources reviewed include prequalification research studies, alternative project delivery studies that include prequalification, State transportation department literature available online, Means construction cost data, information from the SFAA, and academic sources. The literature was broken into four focus areas: previous contractor prequalification research, State contractor prequalification evaluation procedures, State contractor bidding procedures, and bonding costs. This chapter presents a summary of the literature results, as well as the details for each focus area.

The literature review included the following four focus areas: previous contractor prequalification research, State contractor performance evaluation procedure, State contractor bidding procedures, and bonding costs. Table 1 summarizes the topics of interest and types of sources for each of the focus areas reviewed.

Table 1. Literature review summary.

Focus area |

Topics of interest |

Types of sources |

Previous contractor prequalification research |

|

|

State contractor prequalification evaluation procedures |

|

|

State contractor bidding procedures |

|

|

Bonding costs |

|

|

A more detailed review of the literature for focus areas is provided in the following sections.

The authors of literature on this subject believe that the qualifications of a given contractor can have a marked impact on the success of the projects it executes. An article on design-build projects also notes that selecting the most qualified contractor “correlates to the lowest administrative burden” for the State transportation department, which implies that a well-qualified contractor requires less oversight and can be trusted to comply with contract requirements, such as contractor quality control (CQC) methods.(12) As noted above, in NCHRP Report 561, Scott et al. justifies prequalification by noting, “because of constrained staffing and budgets, it is not possible for State transportation departments to ‘inspect’ quality into the work.”(4) The same article provides a succinct definition of a prequalification process and a motivation to establish a thoughtful process:(4)

Once again, the merit of using prequalification to add value to the construction process is underscored. The idea of using performance-based prequalification as a means to motivate contractors to improve their performance during construction is also expressed by the authors. The authors note that this idea ultimately leads to the benefits of enhanced construction quality and reduced administrative burden. The New South Wales (NSW) Australia prequalification manual, which calls the process the “scheme,” describes the benefits of a performance-based prequalification process as follows:(13)

The subject of contractor qualification has generated a significant amount of research in the past decade, including five studies that specifically examine performance-based contractor prequalification. These studies are briefly summarized below.

Kentucky Transportation Center Report, KTC-01-24/SPR 212-00-1F, Quality Based Prequalification of Contractors, reports the results of an analysis of the effectiveness of the Kentucky Department of Highways’ (KDOH) contractor performance rating system and its incorporation into the prequalification process.(14) It recommends the inclusion of a given contractor’s past project quality performance record as an integral part of the prequalification process.

Wisconsin Department of Transportation Synthesis Report, Contractor Prequalification Quality-Based Rating reports the practices of 35 State transportation departments that responded to a survey on the topic.(15) The report found that the majority of both contractors and State transportation department respondents believed that performance-based prequalification can be implemented in a fair and equitable manner.

Manchester School of Management Report, Applying Evidential Reasoning to Prequalifying Construction Contractors was conducted in the United Kingdom and essentially proposes a logic-based mathematical model to optimize the contractor prequalification process.(16)

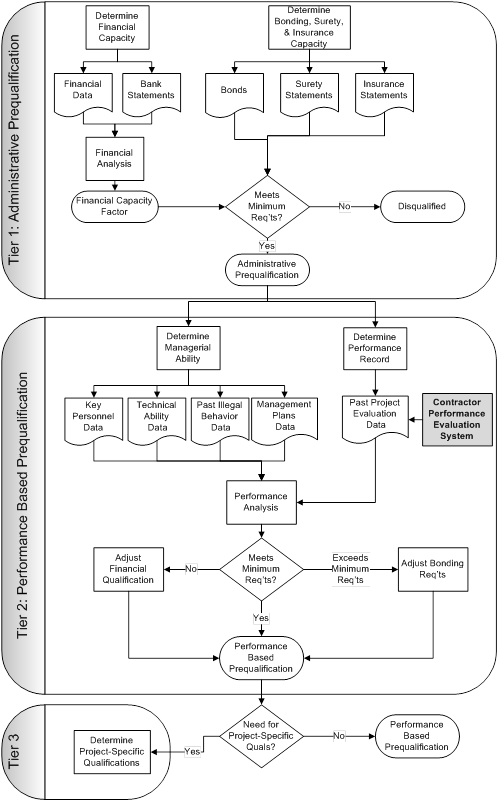

NCHRP Synthesis 390, Performance-Based Construction Contractor Prequalification,benchmarked the state of the practice using a survey of 41 U.S. State transportation departments and 7 Canadian provincial ministries of transportation.(17) The synthesis proposed a three-tiered model for performance-based contractor prequalification that will be discussed in detail in a subsequent section of this report.

Analysis conducted for the Michigan Department of Transportation (MDOT) examination, Study of Most Effective Practices for Determining Construction Contractors’ Eligibility to Bid on Construction Projects, built on the analysis work of NCHRP Synthesis 390, and focused on practices in the upper Midwest, surveying the States that border Michigan.(18) MDOT sponsored this research, which resulted in the finding that the current MDOT performance-based contractor prequalification system is both fair and equitable, and is consistent with similar systems in the region.

All five of the reports cited above concluded that implementing performance-based contractor prequalification has the potential to add value to the highway construction procurement process.

The literature summarized above suggests that most performance-based contractor prequalification programs consist of the same set of components, which are described as follows:

State transportation departments often use general past performance and experience criteria in their administrative prequalification procedures to admit a contractor to the State bidders list.(17) By using performance-based qualification factors in the selection process, a State transportation department can filter out unqualified contractors, thereby increasing the probability that the project will be completed successfully.(27) However, the key to successful public sector application of qualification parameters in a bid is that “their application must be justifiable and defensible.”(4) This observation speaks to the need expressed by Parvin to reduce the probability of bid protest by making the performance-based prequalification system transparent and easy to understand.(28) The Minnesota Department of Transportation defended its prequalification method for a design-build project in an award protest by establishing that its prequalification parameters were both “justifiable and defensible.”(5)

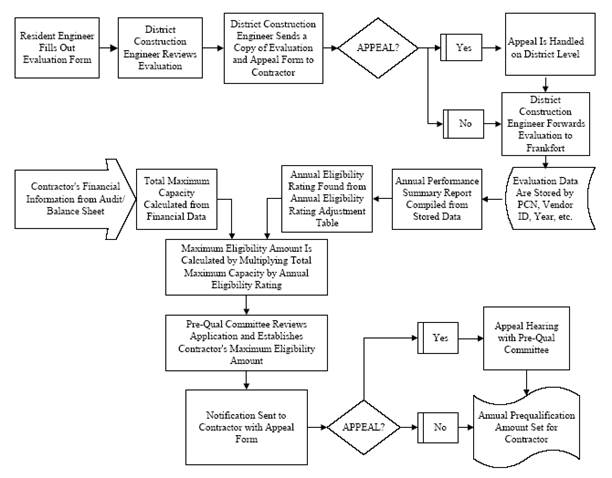

Figure 1 is taken from a paper by Hancher and Lambert that details the KDOH’s “performance-based” contractor prequalification process.(14) The process combines the calculation of total maximum financial capacity with a performance-based evaluation through the assignment of an “annual eligibility rating,” which is used to adjust the contractor’s “maximum eligibility amount.” This value equals the amount of work a contractor may be awarded in a given year. Using the formula, “lower-quality work will reduce the allowable work volume, whereas high-quality work will increase the allowable work volume” for a contractor.(14)

Figure 1. Flowchart. KDOH performance-based contractor prequalification process.(14)

Several authors have conducted research that evaluates the relative importance of the various components listed above. One early study included a survey of construction professionals from both project-owner and contractor organizations and asked them to rank order 20 prequalification factors by importance. Both rated financial stability, past project performance, and personnel availability and experience as the “key decision variables relevant for a generic contractor prequalification knowledge base.”(23) NCHRP Web Document 38 also found project management/control skills, personnel experience, quality of final project, and experience with project type to be the most important, according to a similar group of survey respondents.(1) When these two studies are looked at together, the results of one’s contractor questionnaire/application and the other’s contractor project performance evaluation match one another, which validates the importance of these program components to a prequalification process based on two independent research efforts.

Evaluating contractor performance, then integrating these evaluations into the performance-based contractor prequalification system, provides a tangible means by which to reward good contractors and a disincentive for marginal contractors to perform badly. Other countries have been motivated to implement performance-based contracts for reasons that should resonate in the United States. The motivation for the evaluation of contractor performance in New Zealand has been explained as follows:(29)

As demonstrated in NCHRP Web Document 38, these factors also motivate State transportation departments in the United States to look for methods by which to create efficiencies through contractor performance evaluations, as well as methods to mitigate the potential risk created by the trend toward the increased use of contractor QC in the project acceptance process. State transportation departments’ performance evaluation programs have to pass the tests for both fairness and equity, which are essentially reflected in the types of information the State transportation departments collects in regard to past performance.

An attention to fairness should ensure that the evaluation system is transparent and furnishes a mechanism by which contractors can appeal a negative rating. Transparency can be achieved when the evaluation system and all its components are published in advance of the evaluation and when the State transportation department performs the evaluation in line with what has been published.(30) The inclusion of guidelines for the ratings used for individual components also contributes to consistency and minimizes biases. Furnishing an appeals process demonstrates to the contracting industry that the State transportation department is open to the challenges of its evaluation system through the use of due process, before a contractor is penalized by a negative rating.(4) If implemented, these two elements can greatly ameliorate negative perceptions of potential harmful impacts of a new contractor performance evaluation system.(30)

To further increase fairness in the process, KDOH allows contractors to rate KDOH’s performance at the same time KDOH rates the contractor. These contractor ratings are used by KDOH to “determine quality improvements needed, personnel training needed, and topics for discussion at the annual meetings with the contractor associations and for evaluations of personnel and other uses, as deemed appropriate.”(14)

A contractor’s ability to appeal to have a negative rating changed or removed can also serve as a means by which to further ensure fairness. NCHRP Report 561 notes that fairness demands a contractor have recourse to “due process.”(4) While a State transportation department may not want to create a separate formal disputes resolution system for performance evaluations, it should furnish within its evaluation framework a mechanism whereby a contractor has the ability to protest what it believes is an unfair assessment of its performance. Such a mechanism can be as simple as allowing the contractor to add rebuttal comments to the evaluation form and then charging the chain of command above the evaluator to investigate to determine if the contractor’s protest has merit before the final evaluation is entered into the system. Some jurisdictions have a formal board or committee that will hear and decide appeals on qualification matters. The inclusion of such elements of independence can significantly contribute to both the fairness and, equally as important, the perceived fairness of the system.

The FHWA’s Federal Lands Highway Divisions utilize the Department of Defense Construction Contractor Appraisal Support System (CCASS). (9,31) An NCHRP study reports of the CCASS:(4)

The CCASS evaluation system has been in use for decades and serves not only to record actual contractor performance, but also as a means for Federal agencies to make a decision on the “responsibility” of bidders for a DBB project.(9,32) In this system, a low bidder with several unsatisfactory ratings can be found “not responsible,” and consequently, not be awarded the contract. CCASS requires that the agency evaluate the contractor’s performance in five areas: quality control, timely performance, compliance with safety standards, the effectiveness of management, and compliance with labor standards.

The FHWA requires that the contractor be notified if the State transportation department believes it is not performing at a satisfactory level. This kind of mandated communication between the contract owner and the contractor provides the contractor with the ability to both correct the defect found by the contract owner and, if applicable, to refute or clarify the perceived defects. The CCASS process requires that the State transportation department forward all its ratings to the evaluated contractor and give that entity 30 days to comment on the rating.(32) The State transportation department then reviews the contractor’s comments and determines whether or not to adjust the final rating.

CCASS evaluations are filed and remain in the contractor’s record for six years. They are used as part of the prequalification process on DB and other types of negotiated contracts, as well as to determine responsibility on DBB contracts. This is accomplished by adding the following requirement—that the contractor have no unsatisfactory performance evaluations on file in CCASS—to the Federal definition of a “responsible bidder.”(32)

Based on the Federal Lands Highway Divisions experiences, it appears that using some form of evaluation of a given contractor’s actual CQC performance is perceived as having a positive impact on final project quality. If these perceptions are accurate, this approach to evaluation should be part of a performance-based contractor prequalification program.

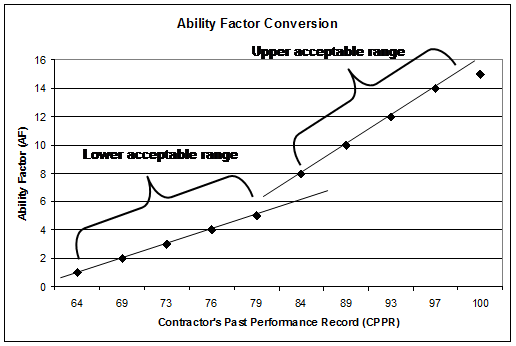

NCHRP Synthesis 390 asked, “Can performance-based construction contractor prequalification be implemented in a way to reward good contractors and encourage poor contractors to improve performance?”(32) The FDOT “ability factor,” shown in figure 2 and table 2, is designed to reward a contractor’s past performance by assigning a higher “ability factor” to those who have exceeded the minimum requirements than to those who have not exceeded them.(33) The interviews with FDOT contractors familiar with the system indicated that not only did it furnish an incentive to maintain satisfactory quality, but that it was also generally deemed a fair and equitable system.(17)

Figure 2. Line graph. FDOT “ability factor” conversion from contractor’s past performance record.(33)

Table 2. Impact of the FDOT “ability factor” on maximum capacity rating.(33)

Contractor’s Past Performance Record |

Ability Factor |

Current Ratio Factor |

Adjusted Net Worth (ANW) (in $ Millions) |

Maximum Capacity Rating (in $ Millions) |

Large Company—ANW > $100 million |

||||

98—100 |

15 |

1.3 |

$334.1 |

$6,515 |

74—76 |

4 |

1.3 |

$334.1 |

$1,737 |

64 or less |

1 |

1.3 |

$334.1 |

$434 |

Medium Company—ANW $20 million to $100 million |

||||

98—100 |

15 |

1.3 |

$52.7 |

$1,028 |

74—76 |

4 |

1.3 |

$52.7 |

$274 |

64 or less |

1 |

1.3 |

$52.7 |

$69 |

Small Company—ANW < $20 million |

||||

98—100 |

15 |

1.3 |

$1.5 |

$29 |

74—76 |

4 |

1.3 |

$1.5 |

$8 |

64 or less |

1 |

1.3 |

$1.5 |

$2 |

The Canadian province of Ontario has also successfully implemented and sustained a system that encourages good performance. Contractors are rated in five work classifications: general road, structures, electrical, structural coating, and general maintenance. Both rated and new contractors need to be demonstrate satisfactory experience in a given classification to be awarded their full “basic financial rating,” which is an MTO term for the maximum amount of awarded work a given contractor can have ongoing at any given point in time. It is similar to a surety’s bonding capacity and is determined in much the same way. If constructors do not have MTO experience, their experience with other public road agencies is considered and their “basic financial rating” may be reduced in accordance with a published formula.(34) Additionally, a fully qualified contractor’s “basic financial rating” is reduced by the amount of its ongoing work to determine an available financial rating. This subtraction parallels the approach used to determine bonding capacity in the United States.

A contractor’s “available financial rating” is determined at the point in time when a bid is tendered, and it needs to equal or exceed the contract rating. For example, a contractor with a basic financial rating of $100 million that has $80 million worth of awarded, ongoing work at the time of the bid has a $20 million available financial rating. If the estimated value of the contract being bid is less than or equal to $20 million, then this contractor is allowed to submit a bid. If the contract value is greater than $20 million, then the contractor is unqualified to bid on this particular project, due to insufficient financial rating or capacity. Contractors with a record of poor performance may also be required to equal or exceed the maximum workload rating (MWL) for the project. The contractor performance index (CPI) is calculated from the contractor’s previously approved contract performance ratings (CPR) for each project and is used to determine if a contractor needs to satisfy the contract rating and the contract maximum workload rating.

Based on the CPI, a contractor is categorized into one of the three following “zones”:

Green Zone contractors are allowed to bid on work up to their “financial basic rating” without adjustment for performance. Yellow zone contractors may have to meet the contract “maximum workload rating,” and may have their MWL reduced by a factor of up to 20 percent. Finally, Red Zone contractors will have their MWL reduced by a factor “calculated linearly 20 percent and 100 percent depending on their position in the zone (20 percent at 55 and 100 percent at 35).”(34) A contractor’s MWL is defined as the highest annual total dollar value of work awarded to a contractor in one of the five fiscal years preceding the current fiscal year.

The MTO includes an integrated infraction report system in the calculation of an adjusted financial rating that accounts for a contractor’s record of infractions issued against it. An infraction is defined as a serious breach of contract, and includes, but is not limited to, the following specific behaviors:(34)

The infraction report becomes a very serious matter for contractors who wish to compete for work in Ontario, and the imposition of sanctions (adverse contract actions, such as termination) may create a severe hardship for an Ontario-based company, which then needs to leave the province to seek work. In the case of contractor exclusion (debarment), provisions in the policy create a distinct disincentive to immediately seek redress in the court system; if a contractor sues MTO, it may not do business with (e.g., award a contract to) that contractor. The infraction report also creates an incentive to complete MTO projects in a timely manner and in a fashion that is satisfactory to the MTO. Table 3 and table 4 show how five contractors distributed across the three zones that have the same “basic financial rating” and “maximum workload rating” would be affected by this system.

Table 3. Example of several MTO qualified contractors under a maximum workload rating adjustment.(17)

Contract Financial Rating = C$8 Million; Contract Maximum Workload Rating = C$5 Million |

||||||

Contractor |

Basic Financial Rating (MWL Rating) |

Contractor Total Ongoing Work (Total Current MTO Work) |

Available Rating |

Infraction Sanctions |

Contractor Performance Index |

Impose MWL Rating? |

A |

C$12 million |

C$2 million |

C$10 million |

0 |

85 = Green zone |

No |

B |

C$12 million |

C$2 million |

C$9.4 million |

5% (Environmental infraction) |

74 = Green zone |

No |

C |

C$12 million |

C$2 million |

C$10 million |

0 |

65 = Yellow zone1 |

Yes: MWL = C$6 million |

D |

C$12 million |

C$2 million |

C$10 million |

0 |

50 = Red zone2 |

Yes: MWL = C$6 million |

E |

C$12 million |

C$2 million |

C$8.2 million |

15% (Safety infractions) |

72 = Green zone |

No |

MWL = Maximum workload |

Table 4. Example of several MTO qualified contractors under a maximum workload rating adjustment, part 2.

Contractor |

MWL Reduction Adjustment |

Exclusion? |

Adjusted Financial Rating |

Adjusted MWL Rating |

Prequalified? |

A |

N/A |

No |

C$10 million |

N/A |

Yes C$10 million > C$8 million |

B |

N/A |

No |

C$9,400,000 (5% infraction = C$600,000 reduction) |

N/A |

Yes C$9.5 million > C$8 million |

C |

0% |

No |

C$10 million |

C$4.5 million (MWL C$6 million less MTO work C$1.5 million) |

No C$4.5 million < C$5 million |

D |

40% |

No |

C$10 million |

C$2.7 million (60% of MWL C$6 million less MTO work C$1.5 million) |

No C$2.7 million < C$5 million |

E |

N/A |

Yes (ongoing lawsuit) |

Excluded |

N/A |

No Excluded, due to ongoing lawsuit |

|

N/A = Not Applicable |

The third and final question addressed by NCHRP Synthesis 390 is the following:“Can performance-based construction contractor prequalification add value to the completed construction project?”(17) Both the synthesis survey and its contractor interviews found that the implementation of performance-based contractor prequalification was perceived as having a positive impact on the quality of various components of a project, thereby enhancing the value of that project. Since Ontario has a rigorous prequalification process and has consequently omitted the performance bond requirement for contractors, it has freed up savings in bonding costs, improved project quality, and potentially reduced contract administration effort that can be applied to other projects, which demonstrates the potential that performance-based construction contractor prequalification has to add value to the public transportation construction program.(17)

The performance-based contractor prequalification programs detailed in NCHRP Synthesis 390 reduce a marginal contractor’s bidding capacity in various ways, and thereby avoid “subsidizing” poor performance (see the Minchin and Smith interviews and those cited in NCHRP Synthesis 390).(1,17) MTO’s program eliminated performance bonding altogether over 20 years ago.(17)

Since the cost of furnishing a performance bond is passed on to the State transportation department in the contractor’s bid, adjustment of the portion of a project value that requires a performance bond seems a logical approach to bonding modification within a performance-based contractor prequalification system. For example, a top performing contractor might only be required to furnish a bond on 50 percent of the contract amount, whereas less qualified contractors or contractors new to the State transportation department would need to bond 100 percent of the contract amount. A reduction in the percentage of the project value that requires a bond, based on a contractor’s past performance, would create an incentive for superior performers by reducing their bid price. U.S. performance bond rates run between 1 and 3 percent of the total bid amount, so this change in bid prices would be significant.(36) These savings would be passed on directly to State transportation departments because they would secure lower construction costs for projects. In fact, Florida, Maine, Virginia, and Washington have all experimented with using bonding for less than the entire contract amount.(17)

Many State transportation departments perceive that the purpose of bonding is to protect the State against contractor default.(14) However, the majority of U.S. and Canadian survey respondents to the NCHRP Synthesis 390 survey stated that a performance bond was not sufficient evidence of contractor prequalification. A rigorous performance-based prequalification system in place allows contractors who fail to complete a project to be penalized via a reduction in their performance rating or by their ultimate removal from the bidding list.

A rigorous performance-based prequalification system can carry more financial weight than a purely financial bonding system. As stated previously, MTO has a long history of not requiring bonds from their contractors. MTO’s annual construction program is approximately C$2.1 billion. Based on the U.S. 2007 to 2009 national average, the average performance/payment bond costs would be 1.139 percent of the total contract cost.(11) Thus, the estimated savings (not accounting for any possible contract defaults) is approximately C$24 million per year in bond costs. MTO utilizes a three-component system to thoroughly review the stability of its bidders:(35)

MTO stresses that the success of the system lies in the interrelationships between the components. While certain components of the system can function independently, the program works best when all the components are integrated.

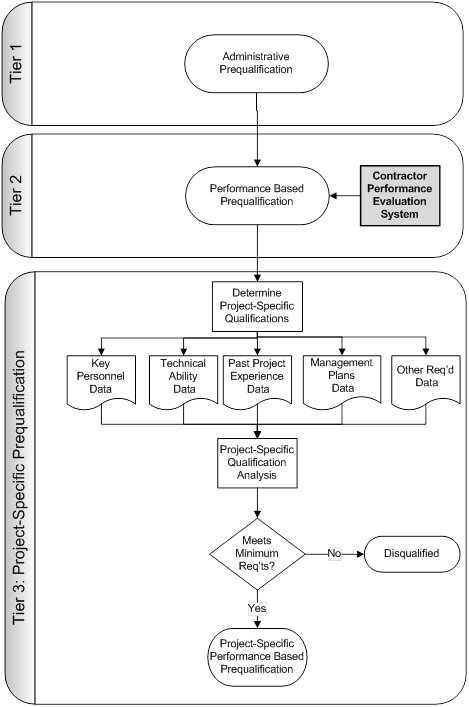

Figure 3. Flowchart. Three-tiered performance-based prequalification process.(17)

NCHRP Synthesis 390 uses the following definitions for each “tier” in the process detailed in figure 3:(17)

Figure 4. Flowchart. Three-tiered process with tier three-project-specific details.

Of the potential barriers listed above, significant focus should be placed on the implementation of administrative rules for the evaluation process.(2) The State transportation department will need to ensure that its evaluators are indeed qualified to evaluate the subject contractors. In most cases, contractors should be evaluated by the State transportation department construction personnel who administer the evaluated contract. Implementation will require that an ongoing training program for the evaluators be developed and implemented to ensure consistency between evaluators and across different types of projects. This component of the program will also be necessary to demonstrate the State transportation department commitment to fairness and to ensure the reduction of as much subjectivity in the process as possible. Agencies that currently use this type of system (such as FHWA and FDOT) have found that a review of all contractor evaluations one level above the “evaluator” is also required to make the program as consistent as possible.(31,33) This issue was highlighted in NCHRP Synthesis 390, in which 8 out of 10 interviewed contractors indicated that their major concern with performance-based prequalification is the agencies’ ability to consistently rate them from project to project.

The administrative rules of the process also need to be transparent and logically derived.(28) It is important to determine the frequency of evaluations. The literature on this topic seems to support that at least one interim evaluation is provided to the contractor before the final evaluation. (See references 31, 32, 33, and 34.) FDOT furnishes evaluations on a monthly basis. The crucial element will be to notify the contractor when it is not performing well and to provide the contractor with the opportunity to correct its deficiencies and shortcomings, before negative evaluations become part of its permanent record. There is a need for an appeals process whereby the contractor can refute an unfavorable rating, which provides the contractor with due process before it is penalized by the evaluator.

The question of the appropriate length of an evaluation’s life span should also be addressed as an integral component of the evaluation process. NCHRP Synthesis 390 found that the majority (73 percent) of its survey respondents maintained evaluations in their active record for at least three years. Survey results also support this time interval, and literature on the subject recommends a “rolling 3-year average.”(14,34) This selected duration creates an incentive for contractors to perform in a satisfactory manner, since a bad evaluation could impact the work that they can secure for a three-year period. The amount of time a contractor can remain disqualified due to certain behavior may be longer. Those that lose their qualification for criminal acts are usually debarred from participation indefinitely. In contrast, those that are disqualified for marginal performance, usually for defaulting on a contract, are able to regain their qualification after proving to the State department of transportation that they have corrected the problems that caused the default(s).

Post-qualification practices are also used by numerous State transportation departments. These typically involve consideration of a contractor’s qualifications after the contractor has been selected on a low-bid basis. These qualifications are submitted in response to a State transportation department questionnaire to verify compliance with requirements of the contract. Post-project performance evaluation practices that impact contractor eligibility are in use at many State transportation departments.(18) Ahn conducted a survey of U.S. States in 2008 and found that 28 States rely on some form of post-project evaluation.(67) The New York State Department of Transportation and the Rhode Island Department of Transportation both currently use post-qualification for contractor selection. Neither State currently has a specific performance-based rating evaluation scale for contractors. They rely on post-qualification instead of performance evaluations.(18)

State transportation departments generally review multiple factors in order to prequalify or post-qualify contractors. They typically assign a maximum amount of work a contractor can perform and the type of work they are allowed to perform, based on qualification determinations. The factors most commonly used by State transportation departments to evaluate contractors are as follows:(18)

Not only may State transportation departments rely on different factors, but they may also require slightly different forms of documentation as proof from contractors. The actual amount of effort required for review by each State transportation department depends on the factors evaluated and the type and amount of proof required and reviewed.

State transportation department prequalification and post-qualification practices share certain similarities and differences across States. A majority (25 out of 33) of the States surveyed in Dye Management Group’s eligibility practices reported that they only use prequalification methods to prequalify prime contractors. In addition, most States prequalify contractors in different work categories to ensure that the prequalification process accurately accounts for the fact that construction disciplines are varied and require different skills. The number of work classifications used varies by State transportation department. Most States (31 of 48 surveyed in NCHRP Synthesis 390, and 7 Canadian ministries of transportation) monitor contractor performance on projects, though the information obtained through monitoring is not used in the prequalification/eligibility determination process in all States. While some State transportation departments change a contractor’s prequalification status based on their project performance, others do not. Policies regarding how to modify State limits are well documented and standardized in some State transportation departments, while others use a more subjective, less standardized approach.(17)

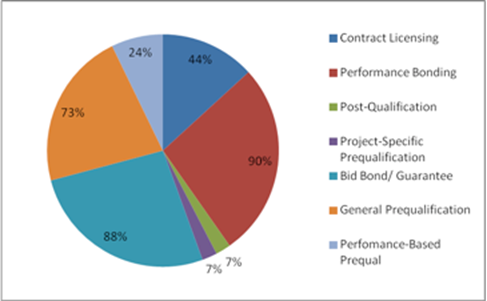

Most State transportation departments use a combination of methods to determine contractor eligibility. The results of 40 State transportation department surveys, as presented in Dye Management Group’s report, along with information from NCHRP Synthesis 390, show that performance bonding and bid bonding/guarantee are the most widely used methods to determine the eligibility of contractors, followed by general prequalification.(17,18) Any contractors that do not submit a bond/guarantee are almost always disqualified.

Figure 5. Common eligibility determination methods.(17,18)

MDOT currently determines a contractor’s financial rating (also referred to as financial capability) by requiring that proof of financial capability be provided; this requirement needs to be met in order for a contractor to be prequalified. The financial rating for a contractor is calculated as follows: working capital (either positive or negative) is multiplied by nine; depreciation expenses on construction and transportation equipment allowed on contractor/bidder’s book of accounts is multiplied by nine; net booked construction and transportation equipment values, minus any long-term debt the equipment secures, is multiplied by four. The sum of all three factors is the total finance rating. If the contractor is applying for a financial rating of over $1 million, the contractor is required to provide a certified audit (i.e., an audited financial statement). If the contractor is applying for a financial rating of less than $1 million, the contractor submits a compiled financial statement, a reviewed financial statement, or an accounts receivable and bank statement verification form.

MDOT has used this formula to calculate financial rating for a number of years. The financial rating calculated is truncated to the number of thousands of dollars for ease of use and reporting, and is a general rating that applies to all of the 53 different work areas. The more specific financial rating for a work classification, which is calculated separately, can be lower than the overall financial rating. For specific work classifications (e.g., clearing and grubbing, asphalt, concrete, etc.), a contractor requests approval and submits information regarding their equipment, personnel, and team experience, which are considered components of the specific work class financial rating. A review of these factors is subjective, with no specific weights assigned to each, and a financial rating is determined for each work classification.(18)

State transportation departments that perform post-project evaluations use a variety of rating systems for their performance evaluations. The rating scales range from 4 to 11 numbers. Many State transportation departments use similar categories to one another to evaluate performance, but group them in different combinations. The narrowness or breadth of categories used varies from State transportation department to State transportation department. Twenty-five of the 26 State transportation departments surveyed that conduct post-project evaluations cited quality and management as categories used in their rating evaluation process. Scheduling was cited by 21 State transportation departments, while safety, traffic, and U.S. Department of Transportation (USDOT) cooperation were cited by 19 State transportation departments.(18)

The frequency of evaluation for post-project evaluation practices varies among State transportation departments. Nearly all evaluations are conducted at specific intervals. The Oregon Department of Transportation (ODOT, presented as ODOT-OR for the purposes of this report) evaluates the firm contractually responsible for a project annually, on the anniversary date of the notice to proceed for a project. Once completed, contractor performance evaluations are combined in a 12-month rolling average. The Virginia Department of Transportation (VDOT) incorporates their contractor evaluations into their monthly interim reports and into an annual or final report. In Connecticut, evaluations are conducted annually, as well as after the completion of projects.(18)

The South Dakota, North Carolina, Florida, Utah, and Maine transportation departments have minimum thresholds for prequalification that range from $50,000 to $250,000. By contrast, the city of Clearwater, FL, determines its prequalification threshold on a contractor-by-contractor basis that is dependent upon previous project performance. The Delaware Department of Transportation uses a project-specific prequalification process and the Detroit Metropolitan Wayne County Airport uses prequalification based specifically on the technical complexity of a project. VDOT changed its practice in 2006 and 2007 to allow contractors who have consistently performed well to bid on any amount of work, so long as they can provide a performance bond. Newer or marginal contractors are assigned specific limits and may be put on probationary status or given conditional prequalification. VDOT also reserves the right to review applications on a case-by-case basis. VDOT reported consistent contractor performance after it implemented the change, and is able to apply its savings-achieved through the elimination of internally conducted detailed financial reviews-in order to conduct more safety and quality reviews.

Table 5. Summary of State transportation department contractor performance evaluation categories.

State |

Quality-Workmanship and Materials | Safety | Sche- dule |

Home Office Support | Compli- ance |

Environ- mental |

Organiza- tion |

Equip- ment |

Payment of Accounts | Project Management | Prosecution of Work | Relations/ Cooperation | Traffic Control |

| Connecticut | x | x | x | x | x | ||||||||

| Florida | x | x | x | x | |||||||||

| Illinois | x | x | x | x | x | x | x | ||||||

| Indiana | x | x | x | x | x | ||||||||

| Iowa | x | x | x | x | |||||||||

| Kansas | x | x | x | x | x | x | |||||||

| Kentucky | x | x | x | x | x | x | x | x | |||||

| Maine | x | x | x | x | x | ||||||||

| Maryland | x | x | x | x | x | x | x | ||||||

| Massachusetts | x | x | x | x | x | x | x | x | x | ||||

| Michigan | x | x | x | x | |||||||||

| Missouri | x | x | x | ||||||||||

| Nebraska | x | x | x | x | |||||||||

| New Jersey | x | x | x | x | x | x | x | ||||||

| Ohio | x | x | x | x | |||||||||

| Oklahoma | x | x | x | x | x | x | x | x | |||||

| Oregon | x | x | x | x | x | x | x | x | |||||

| Pennsylvania | x | x | x | ||||||||||

| South Carolina | x | x | x | x | x | ||||||||

| Utah | x | x | x | x | x | x | x | x | |||||

| Vermont | x | x | x | x | x | x | x | x | |||||

| Virginia | x | x | x | x | |||||||||

| Washington | x | x | x | x | |||||||||

| West Virginia | x | x | x | x | x | x |

Interestingly, INDOT also uses the same form to rate subcontractors. The positive and negative consequences associated with each rating are noted in the form in terms of positive and negative numbers, which trigger investigatory meetings with INDOT to remedy the specific issues.(39)

KYTC requires a Contractor’s Performance Report on every project. Both prime contractors and subcontractors receive a performance evaluation. Prime contractors receive an annual report and a report at contract completion. Subcontractors receive a Performance Report at project completion or annually if they undertake a significant amount of work in a given year. The Contractor’s Performance rating is reviewed by both a section engineer and a chief district engineer. Contractors have an opportunity to appeal the rating within 10 business days. KYTC’s Instructions and Guidelines for Contractor’s Performance Report notes that the contractor’s average performance rating will be used to determine the Contractor’s Maximum Eligibility Amount: “The Contractor’s average performance rating (weighted by dollar amount of work performed) for the previous year will be used in the calculation of the Contractor’s Maximum Eligibility Amount. Utilizing the scores from the Contractor’s Performance Report will provide incentive for the Contractor to consistently perform at a high level of quality.”(44)

MassDOT recently updated its policy through the issuance of an Engineering Directive on

April 20, 2010. This directive introduced new Contractor Performance Reports for both contractors and subcontractors. The Contractor Performance Reports indicate that a deduction in the contractor’s maximum amount of work rating is assessed if the rating is below 80 percent or if the project was completed late, due to the contractor’s fault. The contractor’s performance is evaluated in 9 categories with ratings of between 4 (poor) and 10 (excellent) assigned. Different weights are also applied to the individual category ratings. The categories rated and their respective weights out of a total of 10 are as follows:(47)

MDOT revised its Contractor Performance Evaluation (CPE) procedure on January 13, 2011. All contracts let through the MDOT letting process require a CPE. Both contractors and subcontractors are evaluated, and the evaluations are completed in Field Manager. Evaluations are completed at the end of each project or annually for multi-year projects. As described in the memorandum, contractors are evaluated in the following four prime categories:(48)

MoDOT undertakes contractor evaluations in the form of a questionnaire. The questionnaire consists of nine sections, with a considerable number of measures included in each. The sections are as follows:(49)

NDOR uses a single form to conduct contractor evaluations. The form consists of nine categories, which are evaluated with a rating scale of unsatisfactory, poor, fair, good, excellent, and superior. The NDOR construction manual indicates that poor contractor performance ratings may be considered when determining the contractor’s bid rating.(50) The construction manual also indicates that this form is normally completed within a computer program, although paper versions are permitted. The date on this form is November 1978, which indicates that it may be an outdated version; an updated version may be available in Nebraska’s SiteManager.

ODOT-OK (the Oklahoma Department of Transportation is known as ODOT but is represented as ODOT-OK for purposes of this report) uses a Contractor Performance Evaluation Form, along with supporting information, and the form is available on their website. The evaluation form provides guidance on how to use five numerical ratings to rate contractors. ODOT-OK evaluates contractors in the following six areas:(53)

The process to evaluate contractors is described in detail in the Oregon Administrative Rules. ODOT-OR evaluates prime contractors annually, and then within 60 days of a project’s substantial completion. (This is termed “second notification” in ODOT-OR’s materials, and is defined as “the date on which required construction work, including change order work and extra work, has been satisfactorily completed, except for minor corrective work, and the recording of daily time charges cease.”)(54) Contractor performance evaluations are collected and combined in a 12 month rolling average. Should a contractor’s performance fall below a score of 80, varying degrees of consequences are imposed, with provisions for multiple occurrences of poor performance. Oregon evaluates contractors in nine categories; several sub-criteria are examined within each category. The evaluation is presented in a questionnaire-type format, and each question is answered with a five-point scale. The evaluated categories are as follows:(54)

PennDOT completes all contractor performance evaluations electronically, in a system called the Engineering and Construction Management System. The most current contractor performance evaluation and the preceding five evaluations are used in a semi-annual determination of the Contractor’s Ability Factor. This ability factor is then used to determine the contractor’s maximum capacity rating. The Contractor’s Past Performance Report has three main rated categories (listed below); each consists of several subcategories. The evaluation is conducted in a questionnaire format, with several questions included within each subcategory. The rating scale uses decimal numbers less than or equal to 1.00. The following three categories are evaluated:(55)

SCDOT has an extensive CPE system. Their system is particularly unusual in that 80 percent of the rated categories are objective measures. SCDOT has provisions in their system to address the entry of new contractors, whereby these firms are prequalified on the basis of their safety records, as expressed by the Experience Modification Rate, which is assigned based on their workers’ compensation insurance premiums.(56) As performance evaluation data is collected, it is integrated into the new contractor’s ratings. SCDOT can choose to create a project-specific prequalification by designating a minimum CPS (Contractor Performance Score) required to be permitted to bid. Such projects are typically more complex than normal or have some requirement that SCDOT deems a justification to restrict the pool of potential bidders to those with CPSs that are above the minimum required CPS. The contractor performance evaluation has 6 categories, each of which can be assigned up to 100 points. The first five scoring categories are all objectively derived from specific performance measures. The different performance measures and their respective weights are as follows:(56)

SCDOT statistically analyzes the entire population of CPSs for a given year and establishes the Contractor Performance Threshold (CPT), defined as the “CPS below which performance is judged to be substandard.” The year’s CPT is the point equal to the mean CPS, minus two standard deviations. For example, if the mean CPT is 77.9, and the standard deviation of the population is 4.4, the CPT will be 69.0. Once set, a contractor whose CPT falls below 69.0 will not be allowed to bid on projects that have a minimum required CPS.

VTrans evaluates contractor performance in 11 categories and asks a series of questions in each category. The Prime Contractor Project Performance Evaluation is considered in the prequalification process by the prequalification committee and is used as the basis from which to accept, deny, or modify the number of projects a contractor is permitted to bid on at any given time. The evaluated categories are as follows:(58)

VDOT has a contractor evaluation process that consists of monthly interim reports and an annual, or final, report. The CPE Interim Report is completed monthly for 48 possible work categories. Monthly interim reports are completed for both contractors and subcontractors. Several questions are included for each work category and are scored on a scale from 0 to 4. The annual or final report consists of several sections, the first two of which relate most specifically to the contractor evaluation. The first section of the report combines all of the monthly scores from the interim reports. The second section of the report consists of an evaluation of the contractor in four categories by the district/area construction engineer. There are several questions within each category, which are scored from one to five, and five is the highest score possible. VDOT uses these performance evaluations in their prequalification process. The consequences for poor performance are laid out in a VDOT directive/memorandum: “a contractor/Subcontractor will be removed from the list of qualified bidders if it receives one score below 60 or three scores in a 24-month period below 70.”(59) The four rated categories are as follows:(60)

WSDOT’s contractor performance evaluation system has two evaluation components. The first component is the numerical rating of contractor performance in four categories, while the second component of the contractor evaluation is comprised of a narrative. The quantitative component’s categories are as follows:

The second component of the contractor evaluation is comprised of a three-part narrative. The purpose of this narrative is to furnish factual explanations with specific citations from the project record to document both good and poor work. The narrative, qualitative categories are as follows:

Contractors with poor performance may be assigned a “conditional qualification” status, which may limit their bidding ability as follows: “[c]onditional qualification of a contractor may be affected when the overall performance of the contractor has become less-than-standard... A contractor placed in conditional status may be restricted in bidding ability for highway projects or other sanctions may be placed in effect.”(61) WSDOT does have an appeals process for both the contractor’s performance rating and for restrictions placed on bidding.(61)

WYDOT evaluates contractors using a six-level scale and a “not applicable” rating option. Contractors are evaluated in 10 categories; each category consists of several subcategories. The categories are as follows:(59)

Through contact with State transportation departments’ staff, it was determined that 10 States do not rate contractor performance. These States are Alabama, Arizona, Arkansas, Hawaii, Idaho, Minnesota, New Mexico, North Dakota, South Dakota, and Texas.

The USDOT Bonding Education Program proactively encourages small contractors to conduct an assessment of the administrative functions of the business to mitigate risks and using the surety prequalification process to build a profitable and a sustainable business, and ultimately become bondable. This contractor development program is a resource that assists small business chief executive officers to not only achieve capacity building goals; it connects federal technical resources to state transportation projects, and increases the pool of viable DBE contractors available in the market.

Most States (45 of 50) require that performance bonds be used in conjunction with other contractor eligibility evaluation methods. Most States also require that performance bonds be secured for contracts over a specific dollar amount, typically $25,000, although the minimum contract amount ranges from any dollar value (in California) to much higher values (in Indiana, where the minimum is $200,000). The dollar amount of the required performance bond also varies by State, ranging from a percentage of the contract amount to the full contract amount. Performance bonding requirements may also extend to subcontractors.(18)

Several States do not always require performance bonds for the full value of the project. FDOT requires that the secured performance bond value be equal to the contract price, except for contracts greater than $250 million (an amount in excess of which is generally too great for a single performance bond to be issued), or if the State otherwise finds that a bond in the amount of the contract is not reasonably available, in which case the bond amount will be set at the largest amount reasonably available. For contracts greater than $250 million, the State transportation department can use a combination of bonds equal to a portion of the contract amount, along with an alternative means of security applied to the remaining portion, such as letters of credit, U.S. bonds and notes, parent company guarantees, and/or cash collateral to replace bond requirements.(18)

For design-build contracts, States need to include the cost of design and other non-construction services in the bond amount in order for the bond to be conditioned on performance of those services and for the persons who perform those services to be protected by the bond. In Illinois, the Public Construction Bond Act requires only one bond for the completion of a contract; this includes performance, payment, subcontractors used, and all labor performed. In Louisiana, the performance and payment bond needs to be issued either by a U.S. Treasury, a listed bonding company, or by a Louisiana insurer with a Best’s credit rating of “A-” or better.(18)

According to the survey reported on in the effectiveness report, most States (28 of the 41 surveyed) require a 100 percent performance bond on projects. A review of State procurement laws found that only five States, Arkansas, Connecticut, Oregon, Vermont, and Wisconsin, do not always require some type of performance bond on projects. In each case, a performance bond may be waived or the contractor may provide a substitute type of security, such as a cashier’s check for 100 percent of the contract amount.(18)

Determining a generalized cost of performance bonds is not a particularly straightforward task. The surety industry rates each contractor individually, in the context of a specific contract, and develops a separate premium for each individual project performance bond. Hence, it is nearly impossible to generalize or infer a specific cost for the bonding of a given project. A work written by Peurifoy and Oberlender, provides the following guidance:(63)

Table 6. Representative costs of performance bonds per $1,000.(63)

Project Size |

Building Projects ($/$1,000 of project value) |

Heavy Civil Projects ($/$1,000 of project value) |

First $500,000 |

$14.40 |

$12.00 |

Next $2 million |

$8.70 |

$7.50 |

Next $2,500,000 |

$6.90 |

$5.75 |

Next $2,500,000 |

$6.90 |

$5.25 |

> $7,500,000 |

$5.75 |

$4.80 |

Means Construction Cost Data (Means), a well-recognized source of construction costs for project estimation, provides percentage values for performance bond costs. In Mean’s construction data book for Heavy Construction, the cost of bonds for Highways and Bridges is listed as a range from 0.4 to 0.93 percent of total contract value.(64) A thesis on the cost effectiveness of performance bonds, written by Lorena Myers of the University of Florida in 2009, collected State construction data from September 2007 to September 2009. As part of this study, the SFAA reported that the cost of performance bond premiums on projects typically ranged from 2 percent of total contract cost for small projects (i.e., those valued at less than $100,000) to 0.5 percent for very sizeable projects (i.e., those valued at more than $50 million). Table 7 shows one-time performance bond premiums for different ranges of contract amounts, as reported by the SFAA.

Table 7. State transportation department construction performance bond rates.(11)

Contract Amount |

Performance Bond Premium |

Project Size Category |

Percent |

$100,000 |

$1,200-$2,500 |

< $1 million |

2.50 |

$1 million |

$7,700-$13,500 |

$1 million-< $10 million |

1.35 |

$10 million |

$56,950-$81,000 |

$10 million-< $50 million |

0.81 |

$50 million |

$206,475-$341,000 |

> $50 million |

0.68 |

Myers’ thesis also provided data for 19,135 construction projects for 30 States, shown in table 8, and found that the 2007 to 2009 U.S. national average of bond premiums was 1.139 percent. Surprisingly, only six States reported contractor defaults between 2007 and 2009: Alabama, Georgia, Idaho, Mississippi, South Carolina, and Texas. For these States, there were a total of 10 defaulted contractors over 34 projects, while the rate of default was 0 for all other States. The benefit-cost analysis concluded that only one State realized a net benefit as a result of using secured performance bonds.

Table 8. State default rates.(11)

State |

Number of Defaults |

Total Projects |

State |

Number of Defaults |

Total Projects |

Alabama |

7 |

631 |

Michigan |

0 |

1,303 |

Alaska |

0 |

187 |

Minnesota |

0 |

447 |

Arizona |

0 |

205 |

Mississippi |

2 |

392 |

Arkansas |

0 |

408 |

Montana |

0 |

231 |

California |

0 |

1,237 |

New Jersey |

0 |

256 |

Colorado |

0 |

326 |

New Mexico |

0 |

126 |

Connecticut |

0 |

134 |

New York |

0 |

559 |

Delaware |

0 |

170 |

Ohio |

0 |

1,393 |

Georgia |

19 |

513 |

South Carolina |

6 |

681 |

Hawaii |

0 |

129 |

South Dakota |

0 |

292 |

Idaho |

2 |

188 |

Texas |

1 |

1,333 |

Illinois |

0 |

2,682 |

Washington |

0 |

650 |

Iowa |

0 |

1,424 |

West Virginia |

0 |

945 |

Kansas |

0 |

643 |

Wisconsin |

0 |

901 |

Maine |

0 |

545 |

Wyoming |

0 |

204 |