U.S. Department of Transportation

Federal Highway Administration

1200 New Jersey Avenue, SE

Washington, DC 20590

202-366-4000

Federal Highway Administration Research and Technology

Coordinating, Developing, and Delivering Highway Transportation Innovations

| REPORT |

| This report is an archived publication and may contain dated technical, contact, and link information |

|

| Publication Number: FHWA-HRT-15-049 Date: April 2015 |

Publication Number: FHWA-HRT-15-049 Date: April 2015 |

The challenge in LTPP data collection is to capture research-quality data of diverse types using highly specialized, state-of-the-art equipment with the involvement of many people across different geographical areas. |

Since 1989, millions upon millions of discrete data have been gathered and collected from pavement test sections across North America by highway agency personnel and the LTPP program through its contractor staff using a myriad of methods and equipment. The procedures and equipment used in the collection process were subject to careful planning and systematic quality controls designed to ensure that the data would be as consistent, comparable, and useful as possible for future research.

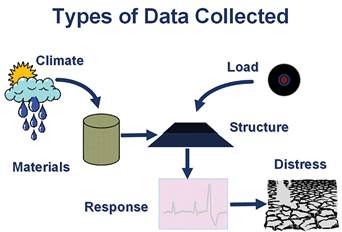

LTPP data collection focuses on understanding the performance of pavements from a mechanistic engineering perspective–the attempt to define a structure's performance by modeling the factors that lead to performance degradation and the need for maintenance, rehabilitation, or reconstruction. Figure 6.1 illustrates the relationships between data collection categories for mechanistic-based pavement performance modeling. Climate and traffic loading are two primary factors affecting a pavement structure's performance. Climate affects mainly the properties of the materials contained in the pavement structure. Traffic loads are directly supported by the pavement structure. Traffic loads and climate create responses in the materials contained in the pavement structure and subgrade that lead to various forms of distress. The data collection design for the LTPP program aims to measure, characterize, and quantify the factors that explain how and why a pavement performs as it does.

Providing high-quality data is of paramount importance to the LTPP program. Thus, collecting data with careful quality control/quality assurance (QC/QA) processes in place has been and continues to be a primary focus of the program (chapter 9). This chapter describes the development of LTPP's data collection procedures. The key data collection activities that have been adopted and continuously refined over the course of the program are the following:

| Key Milestones in Data Collection | |||

|---|---|---|---|

| 1987 | First edition of Distress Identification Manual published | 2003 | GPR study of SPS test section layer thicknesses conducted |

| 1987 | Inventory data collection begins | 2003 | FWD maintenance and overhaul manual developed |

| 1988 | First manual distress survey performed | 2004 | FWD Calibration Center and Operational Improvements Pooled-Fund Study initiated |

| 1988 | First FWD equipment purchased | 2005 | GPS data updated for test sites, weather stations, and weigh-in-motion scales |

| 1989 | FWD Operational Field Guidelines published | 2008 | Automated Weather Station data collection phase-out begins |

| 1989 | FWD data collection begins | 2009 | LTPP protocols adopted for AASHTO FWD calibration standard |

| 1989 | First inertial profiling equipment purchased | 2010 | Operation of FWD calibration centers transferred to AASHTO MRL |

| 1989 | First automated distress surveys (PASCO) performed | 2011 | FWD calibration protocol updated |

| 1991 | First FWD calibration protocol published |

2013 | FWD equipment and software upgraded |

| 1991 | First manual distress workshop conducted | 2013 | Profiling equipment and software upgraded |

| 1992 | First FWD calibration center opens | 2013 | Climate data upgraded |

| 1992 | Climate data collection begins | 2014 | Fifth edition of Distress Identification Manual published |

| 1994 | Automated Weather Station installations begin | ||

| 1994 | Global Positioning System units purchased |

||

| 2001 | LTPP SPS Traffic Data Collection Pooled-Fund Study initiated | ||

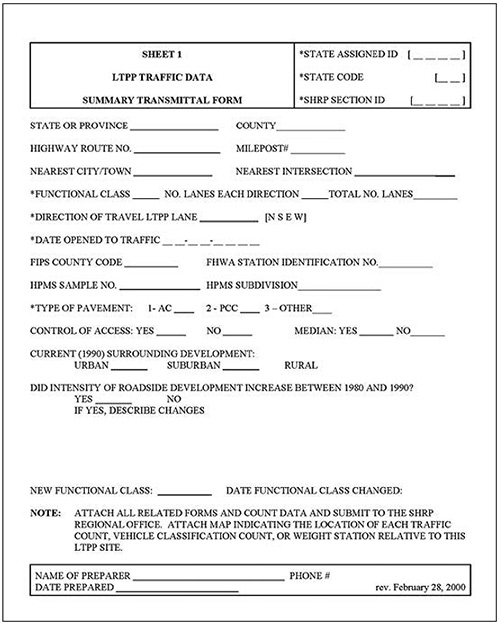

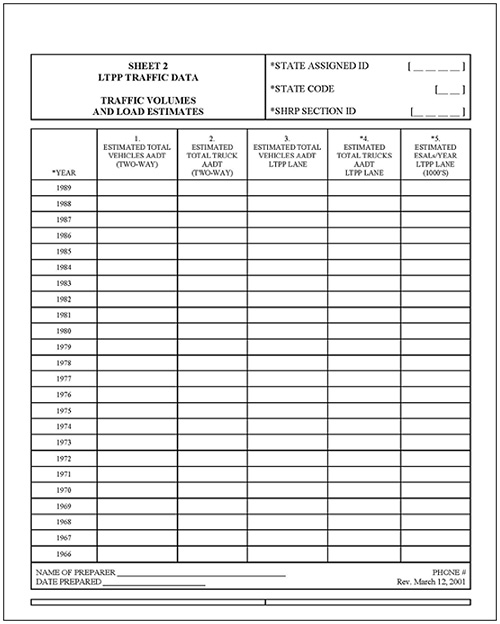

The data collection processes have involved both the highway agencies and the LTPP program's contractors. The highway agencies agreed to collect the materials and traffic data as well as friction data. In some cases, the highway agencies were not able to provide all of the data needed by the LTPP program to perform critical data analysis projects or studies. Therefore, the program initiated special data collection efforts such as the Materials Action Plan and the LTPP Specific Pavement Study Traffic Data Collection Pooled-Fund Study to collect these critical data elements (chapter 7). The remaining pavement-related data were collected by LTPP's contractor staff: regional support contractors, the technical support services contractor, equipment vendors, and service contractors.

Data QC was integral to data collection activities. Each regional support contractor is required to have a Quality Control Plan and Working Guide covering all aspects of data collection and review. The plan must be implemented and maintained. Through the years, the LTPP program has managed quality issues using various mechanisms such as unannounced field or office visits to observe data collection and processing procedures, conference calls, Data Analysis and Operations Feedback Reports, Operational Problem Reports, and Software Problem Reports.

FIGURE 6.1. LTPP data collection categories. |

The different data types described in this chapter are collected at both the General Pavement Study (GPS) and Specific Pavement Study (SPS) experiments with few exceptions. Early in the LTPP program, most of the data elements were collected annually. However, as the funding levels for the program were reduced, the frequency of data collection was reduced.1,2 Some data elements have been collected more frequently for certain LTPP experiments, but nearly all of the experiments have annual monitoring data (e.g., distress, deflection, profile) in addition to inventory, and maintenance and rehabilitation data. These data elements are stored in the LTPP database in tables that are organized by modules, listed in table 6.1.

The source, type, method of capture, quality, and quantity of the different data elements are quite varied. With the exception of the Administration module, which contains no performance-related data and therefore is not discussed here, the remainder of this chapter describes each of the LTPP database modules and its associated data element(s).

It is important to mention that LTPP data are also used to develop special data sets. One example is the Mechanistic-Empirical Pavement Design Guide (MEPDG) data sets, used by highway agencies to calibrate the design models for their local pavement conditions. The MEPDG data sets, which are part of the Traffic data module, are computed data. Nearly all of the LTPP data modules have computed data'not collected or measured data'such as dynamic load response data, falling weight deflectometer backcalculation, and equivalent single-axle load values. Also, the SPS data module actually refers to inventory data for the SPS projects (as discussed later in this chapter).

| Database Modules |

|---|

| Administration (ADM) |

| Automated Weather Station (AWS) |

| Climate (CLM) |

| Dynamic Load Response (DLR) |

| Ground Penetrating Radar (GPR) |

| Inventory (as-built) (INV) |

| Maintenance and Rehabilitation (MNT and RHB) |

| Materials Testing (TST) |

| Monitoring (MON) |

|

|

|

|

|

|

|

| Seasonal Monitoring Program (SMP) |

| Specific Pavement Studies (SPS) Inventory |

| Traffic (TRF) |

Data collection for the LTPP program aims to measure, characterize, and quantify the factors that explain how and why a pavement performs as it does. Consequently, data collection was established to support the envisioned data analyses and product development.

Automated weather station (AWS) data collected from the LTPP test sections include site-specific weather information: air temperature, humidity, precipitation, solar radiation, wind direction, and wind speed. To understand the influence of various environmental conditions on the performance of a specific type of pavement, one must first learn what those conditions are.

Weather stations with remote data collection capabilities were installed at newly constructed SPS-1 (structural factors for flexible pavements), -2 (structural factors for rigid pavements), and -8 (environmental effects in the absence of heavy loads) projects. At some locations, particularly in Delaware, Nevada, Ohio, and Wisconsin, multiple SPS projects were located within a short distance of each other, reducing the number of weather stations required. Thus, it was cost beneficial to install a single AWS at these study sites.

The weather stations collected data at 15-minute intervals: air temperature, relative humidity, precipitation, solar radiation, and wind speed and direction. These data were accumulated into hourly, daily, and monthly statistics. Measurements began in August 1994 and continued through December 2008, with the start and end of data collection varying from one weather station to another. The automated weather stations were also intended to validate the data from the virtual weather stations (discussed in the climate data section).

Before data collection began, a review of commercially available weather stations was conducted, after which a Campbell Scientific, Inc. (CSI) unit was selected and installed on the grounds of the Federal Highway Administration (FHWA) research center for further evaluation. During the evaluation period, the LTPP technical support services contractor developed an automated weather station manual covering the installation of the weather stations, data collection, and maintenance.3 The initial training for installation occurred near Phoenix, Arizona, in July 1994. In September 1994, the LTPP program issued a directive (a written communication circulated program-wide to ensure uniformity in data collection) for its contractors to follow that described the installation, data collection, and maintenance activities required for the weather station.4 As weather station activities changed, the program issued subsequent directives to update procedures and complement or change instructions provided in the AWS Installation and Data Collection Guide.5 These directives covered such topics as parts replacement, sensor calibration, remote data collection, and preventive maintenance plans.

The weather instrumentation and equipment were centrally purchased by FHWA and shipped to the LTPP regional support contractors to install at the SPS sites. In addition to providing the instrumentation, the LTPP program also performed the data collection and maintenance activities through the regional support contractor staff. The highway agency sponsoring the site provided the concrete pad for the weather tower, the tipping bucket base, and compound fencing (figure 6.2). In most cases, telecommunication and power costs were assumed by the highway agency. See appendix C for more information on the type of AWS equipment and software used to collect, store, and process the weather data.

FIGURE 6.2. Complete automated weather station installation with protective fencing. |

Maintenance became a major issue for the weather stations. One of the problems encountered at the weather stations was the tipping buckets would become clogged with various types of debris. Similarly, the relative humidity probe filter would become plugged, retain moisture, and provide false high readings. Remote access was often an issue, as the modems used to connect the dataloggers with the LTPP regional support contractor's office computers were prone to lightning damage. The onsite storage modules were also prone to data retrieval problems that required returns to the office for data extraction.

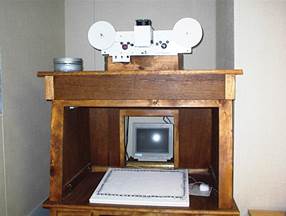

Site visits were needed more frequently than had been anticipated. Maintenance was performed on the weather stations every 2 years, and exchange of instrumentation was part of the maintenance procedure. In addition, when collecting other LTPP data elements at a site, the regional support contractors visited the weather stations to inspect the equipment and perform minor maintenance (such as unclogging a tipping bucket rain gauge). However, at some locations, the highway agencies assisted with minor maintenance. Any instrumentation that needed to be returned to the regional support contractor's office was checked for accuracy using the manufacturers' guidelines. Out-of-tolerance instruments were either calibrated in-house (figure 6.3) or returned to the manufacturer for calibration. Most of the regional support contractors purchased equipment and spare parts for servicing the tipping bucket rain gauges and the wind monitors, but preferred to return the relative humidity/air temperature probe units and pyranometers to the vendor for calibration. In addition to maintaining the instrumentation, there was often a need to service the dataloggers, storage modules, and modems or to replace batteries.

FIGURE 6.3. Prototype automated weather station used by the LTPP regional support contractors for in-house training of staff and to calibrate equipment components. |

Two DOS-based programs were developed to check the quality of the AWS data. The first was AWSScan, which performed basic data checks in the field including range, time-series consistency, and required data elements. One of the key functions of the AWSScan program was to make sure the measurement equipment was operating properly and alert the field technician to potential issues that could be corrected in the field. AWSScan was used at the time data were being downloaded, whether onsite or remotely. The second program, AWSCheck, was developed for office processing purposes and was used to combine raw data files, edit/remove invalid data, allow for time stamp corrections (that correspond with standard/daylight saving time), view additional graphical outputs for time-series consistency and logical ordering of climate statistics (i.e., maximum ≥ average ≥ minimum), generate upload files for entry into the LTPP database, re-compute daily statistics when bad hourly measurement values were deleted, and replicate the QC checks that would be performed after the data had been uploaded into the database. The time stamps needed adjustment because the time in the dataloggers did not change with standard/daylight saving time. All of the AWS data in the database are in local time (based on the location of each station's time zone). User guides for AWSScan and AWSCheck were developed in 1995 and 1996, respectively.6

The LTPP automated weather stations received regular maintenance and instrumentation replacement at 2-year intervals until 2006, when the decision was made to continue servicing only those stations that could be maintained with minimal investment of time and expenditure. As stations started to require maintenance due to component failure, they were dismantled or turned over to the respective highway agencies. Phase-out was completed in December 2008, and all sites were decommissioned. At the conclusion of the AWS data collection activities, 9 to 13 years of weather data had been collected from the SPS-1, -2, and -8 projects and stored in the LTPP database.

Unlike the AWS data which cover detailed data for a subset of the LTPP test sections, the climate data'precipitation, temperature, wind, and humidity'cover all test sections. The climate conditions at the GPS and SPS test sites have been obtained from the United States National Climatic Data Center (NCDC) and the Canadian Climate Center (CCC). The climate module includes data from both operating weather stations and 'virtual' weather stations. However, efforts are underway to improve the coverage, completeness, and quality of the LTPP climate data through the use of Modern Era-Retrospective Analysis for Research and Applications (MERRA)7 data from the National Aeronautics and Space Administration (NASA). These efforts are still ongoing, and hence the focus of this section is on the legacy approach that relied on NCDC and CCC data.

Because the LTPP test sites were not typically co-located with operating weather stations, it was necessary to extract data from nearby operating weather stations and, using a distance-weighted averaging function, create virtual weather statistics for each LTPP test site. One of the first steps in creating a virtual (i.e., statistical) weather station was to identify up to five operating weather stations (see example in figure 6.4) that met the following criteria in the order listed:

In the early years of the program, the services of a climate specialty contractor were used to obtain NCDC and CCC data, perform initial weather station selection based on the above criteria, and provide daily data from the operating weather stations to the LTPP program in ASCII format. Subsequent processing created the daily, monthly, and annual summaries for the virtual weather stations.

FIGURE 6.4. A virtual weather station (VWS). This example shows the locations of five operating weather stations used to create the VWS for GPS section 831801 on Trans-Canada Highway 1 in southwestern Manitoba. (Source: Esri, Digital Globe, i-cubed, Earthstar Geographics, CNES/Airbus DS, USDA, USGS, AEX, Getmapping, Aerogrid, IGN, IGP, Swisstopo, and the GIS User Community; created in ArcGIS 10.1) |

The climate data provided by the LTPP program are "computed parameters." In other words, they are estimates derived from measured values. Daily statistics (temperature, rainfall, wind speed, and humidity) are obtained from the operating weather stations and subjected to range and logic checks as defined in the LTPP QC Manual.8 Only data passing all data checks are used to compute the daily virtual weather station statistics. The daily statistics are aggregated into monthly and annual statistical summaries. Automated QC checks are performed on the monthly and annual statistics to verify reasonable ranges and logical relationships.

The last update of the climate data was performed in 2013 and included data through 2012, the most up-to-date data available at the time. This update used the raw data collected from the NCDC and CCC. The LTPP program has also incorporated into the Climate module data from NASA's MERRA project, which provides much finer spatial resolution and offers more data elements that can be implemented without the use of virtual weather station interpolation concepts.

The LTPP database contains data that measure the pavement response under controlled loading conditions for two SPS projects. These data, known as dynamic load response or DLR data, were collected in North Carolina and Ohio from 1996 to 1997.

In North Carolina, four Portland cement concrete (PCC) pavement sections at the SPS-2 project were instrumented to collect DLR data. In Ohio, asphalt concrete (AC) and PCC pavement test sections from the SPS-1 and SPS-2, respectively, were instrumented to monitor the DLR of vehicles with known weights.

Three types of instrumentation were installed at the project sites:

Thus, at each project site, a comprehensive set of data was collected-DLR measurements within the pavement and on the pavement surface, subsurface moisture and temperature conditions, and ambient conditions.

Results of the DLR initiative are discussed in LTPP Data Analysis: Influence of Design and Construction Features on the Response and Performance of New Flexible and Rigid Pavements.9 The North Carolina DLR data are included in the LTPP database. An update and reinterpretation of the DLR data collected between 1996 and 1997 from the SPS-1 and -2 sites in Ohio were made available in the LTPP database starting in 2013.

Pavement structure is one of the four primary factors whose separate and combined effects influence the performance of a pavement. To understand how pavement thicknesses vary along LTPP test sections, which are generally 500 ft (152 m) long, ground penetrating radar (GPR) measurements were performed on a subset of LTPP test sections. GPR is a nondestructive technique based on reflection of radio waves transmitted in the ground to determine subsurface changes in material properties. For pavement applications GPR is typically used to determine the thickness of pavement layers and the dielectric constant of paving materials. Among other potential applications are detection of subsurface voids and moisture concentrations.

The primary interest in GPR technology by the LTPP program was to measure pavement layer thicknesses. In 1994, a study of 10 GPS LTPP asphalt test sections in the southern and eastern United States concluded that GPR could be used to accurately characterize asphalt thickness.10 In 2002, the LTPP program initiated plans to collect GPR measurements on all SPS-1 test sections and at 1 jointed plain concrete pavement section at the Arizona SPS-2 site, 10 AC overlay sections at the Oklahoma SPS-5 (rehabilitation of AC pavements) site, and 5 test sections at the Oklahoma SPS-6 (rehabilitation of jointed PCC pavements) project site. Nineteen SPS sites consisting of multiple test sections were surveyed in 17 States within a 6-week timeframe in 2003.11

To ensure the collection of high-quality data, GPR measurements took place only on dry pavement surfaces. GPR data were collected along both wheelpaths at posted highway speeds. To precisely locate the GPR data for each pass, a photo-reflective laser switch, mounted to the rear of a survey vehicle, transmitted and received a signal pulse from polarized reflectors set up along each test section. These position pulses were automatically recorded in the GPR data files for each pass. The depth of the AC, treated base, and aggregate layers can be shown in a GPR report.

Only the interpretations of the GPR data from the 2003 measurements were included in the DLR module in the LTPP database; data from the 1994 study were not included. While no report on the findings from the 2003 GPR measurements was published, the LTPP program did not implement GPR measurement technology as a routine pavement measurement device on LTPP test sections.

Inventory data include location (e.g., latitude, longitude, state, county, route, milepost) of the test section, pavement type, layer thicknesses and types, material properties, composition, previous construction improvements, and other background information. Inventory information was collected for all GPS test sections and for SPS sections originally classified as maintenance and rehabilitation experiments. The inventory data in the LTPP database are supplied by the State and Provincial highway agencies. Structural information, such as shoulder width and milepost, was derived from highway agency project records or measurements taken at the test sections by the LTPP program. The inventory data includes:

Inventory data collection began in 1988 and continues with the inclusion of the latest LTPP experiments (warm-mix asphalt and pavement preservation experiments). Because some inventory data were incorrect or missing, various efforts have been undertaken to collect or correct the missing data. This was the case with the Program Assessment and Improvement Campaign in the mid-1990s, which looked at the availability of data for the LTPP test sections (chapter 11). The regional support contractors have worked very closely with the highway agencies to collect this information, and they continue to obtain inventory data from highway agencies whenever a maintenance or rehabilitation activity occurs at a test site. The inventory data module contains structural and location data for each LTPP test section, which are discussed below.

Collecting the structural data (layer types and thicknesses) presented challenges. Significant time and effort were needed to process huge amounts of data onto forms. Highway agencies often did not have the resources (staff, time, or funds) to locate data and complete data forms. Some data elements had not been collected by agencies, and some historical data had been discarded over time and were no longer available.

The LTPP program worked with the highway agencies to retrieve as much data as possible. Some agencies sent all of their data to the LTPP regional support contractor, who completed the required forms for the agencies. In other cases, the regional support contractors visited agencies to help collect data and complete the LTPP forms.

Agency data were not necessarily representative of the test sections'the data covered highway lengths of from 1 to 10 mi (1.6 to 16.1 km) while the LTPP sections were only a 500-ft (152-m) segment of that distance. Data had to be processed to determine a 'best fit' scenario for LTPP use.

The purpose for this data element was to establish accurate location information for every LTPP test section using maps, satellite technology, and other methods. The effort began with the agencies collecting latitude and longitude coordinates, and elevation data. After some initial investigations, discrepancies were found; for example, some data had been interpolated from maps that were only approximations of accurate measurements.

In 1994, first-generation Garmin® Global Positioning System units were purchased, and a new inventory form was developed to collect data onsite.12 Around 2001, newer generation global positioning units were acquired, as the technology had improved dramatically. Magellan® global positioning tracking devices were used. Then, in 2005, updated coordinates were collected from pavement test sections using modern global positioning system receivers.13 A test section's coordinates were also collected for AWS and weigh-in-motion (WIM) scale installations. The Garmin eTrex® Global Positioning System receiver (GPSr) with trip and waypoint (Model Legend C) was employed for this purpose. Data were typically collected by the LTPP regional support contractors, coinciding with manual distress surveys. Measurements were verified by comparing the coordinates with previous measurements and plotting the locations on digital maps. In cases where field measurements could not be performed, up-to-date mapping software (MapSource® 6.0 or Google Earth™ mapping service) was used. Measurements and location estimates were based on the World Geodetic System 84 datum. The original latitude, longitude, and elevation data were replaced with the new and more accurate data, which are stored in the LTPP database.

In 2007, the global positioning component of the location data was moved from the Inventory module and placed in the Administration module. Accurate global positioning coordinates are now available for all LTPP sites. In 2013, the LTPP program began collecting location data using the new GPSr equipment connected to the falling weight deflectomter and profile units.

The maintenance and rehabilitation data tables in the LTPP database have been consolidated in a single module. The maintenance tables contain information about treatments-seal coats, patches, joint resealing, grinding, milling less than 25 mm (1 inch), and grooving-applied to test sections after (and in some cases before) the section's inclusion in the LTPP program. The rehabilitation tables contain information on resurfacing, reconstruction, joint repair, and similar activities, which typically alter pavement structure.

Maintenance-type treatments that are reported by highway agencies and stored in the LTPP database include thin surface treatments, crack sealing, joint sealing, and patching performed on in-service test sections. Obtaining the data elements that are needed to accurately and completely document maintenance activities performed on GPS and SPS test sections has been a challenge throughout the LTPP program. This effort has been complicated by the wide variations in maintenance policies, practices, and data collection procedures among agencies, and the need for coordination between the agencies and the LTPP program.

LTPP maintenance data document surface treatments that do not change pavement structure-seal coats, crack sealing, patching, joint sealing, grinding, grooving, and shallow milling.

The highway agencies were asked to follow a maintenance policy that required coordination with the LTPP regional support contractor responsible for data collection at sections located within their State or Province. Through this coordination and advanced notification that a maintenance activity is scheduled to take place, the value of the data obtained from a test section after it had been monitored for a number of years would be increased significantly because a set of performance data could be obtained prior to and after the maintenance treatment. Maintenance decisions and agreements between each agency and the LTPP program were worked out with a cooperative spirit, with consideration for the needs of the agency. The agency was asked to provide all details of the maintenance activity on the LTPP maintenance data sheets to facilitate entry into the LTPP database.

Although this cooperative spirit existed between the highway agency and the LTPP program, on many occasions a maintenance activity was completed without the program's knowledge. As a result, the last data point before maintenance took place, which is critical to understanding a pavement's long-term performance, was not collected. Also, sufficient data were not always available to establish a new starting point for the LTPP section after maintenance took place. In these cases, the LTPP regional support contractor made every effort, working with the highway agency, to obtain the details of the maintenance activity that had been performed. These efforts included visiting agencies, searching through files and archives, and talking with staff who were at the job site when maintenance was performed. Often, further information was retrieved, but some maintenance data remain missing.

The collected maintenance data provide information such as when the activity was performed and the materials, construction equipment, and practices used. The following guides have been used in collecting the data: Long-Term Pavement Performance Maintenance & Rehabilitation Data Collection Guide;14 Specific Pavement Studies, Data Collection Guidelines for Experiment SPS-3, Maintenance Effectiveness for Asphalt Concrete Pavements;15 and Specific Pavement Studies, Data Collection Guidelines for Experiment SPS-4, Maintenance Effectiveness for Portland Cement Concrete Pavements.16 LTPP program directives also provide additional information.17

LTPP rehabilitation data document a change to the pavement's original structure.

Most rehabilitation procedures, such as recycling or placing overlays, produced a test section with a modified pavement structure. Other procedures, such as undersealing, were considered to restore the existing pavement structure. Reworking shoulders and placement of edge drains are other examples of improvements that could be made without changing the primary pavement structure.

Highway agencies were asked to notify the LTPP program whenever rehabilitation was planned, so that the condition of the pavement could be observed and recorded prior to the rehabilitation activity. They were also responsible for providing the program with information about the treatment.

The LTPP program had to ensure that all rehabilitation data were complete and processed promptly and thoroughly because these data were key to successful data analyses. In many cases, not all of the required information was provided to give a new starting point for the LTPP test section. More intensive searches on the part of the LTPP regional support contractors, as with maintenance data, yielded positive results. However, rehabilitation data for many LTPP test sections are still missing. Although this missing data can be added to the LTPP database if the highway agencies are able to provide it, the rehabilitation test sections where data continues to be lacking may provide little to no value for certain data analysis studies.

LTPP documents provide guidelines regarding when a section that had undergone rehabilitation could continue to be monitored by the program. These documents include the Long-Term Pavement Performance Maintenance & Rehabilitation Data Collection Guide,18 guidelines specific to SPS sections,19 and LTPP program directives.20 Some of the rehabilitation treatment types caused a section to be removed from further study. Others resulted in the test section being moved to a new experiment. In some cases, there was overlap between SPS-5, -6, -7 (rehabilitation studies), and GPS-6 and -7 (overlays of AC and PCC) rehabilitation data. Some data for the SPS rehabilitation experiments are stored in the maintenance and rehabilitation module and not in the respective SPS module. Access to these data has been streamlined in the new LTPP InfoPave' system.

The LTPP database has materials sampling and testing information for all test sections. The primary objective for performing materials sampling and testing was to provide a comprehensive evaluation of the pavement layer structure and layer thicknesses of the pavement materials used in each section or project. The material testing data represent the condition of the material at the time of sampling and testing. The work was accomplished by core drilling, augering, test pit opening, sampling, and nuclear density testing, followed by performing a suite of laboratory material characterization tests (see sidebar, next page). To help with data collection, standard material sampling and laboratory testing protocols with data entry sheets were developed to record the data collected in the field and in the laboratory.

The GPS and SPS experiments followed different approaches to materials sampling. For GPS experiments, FHWA contracted out this task, and a drilling supervisor from the LTPP regional support contractor's office was responsible for QC. For SPS experiments, the highway agencies were tasked with the drilling. In addition, the sampling approach for each SPS experiment was different. A material sampling guide was prepared for the GPS experiments, and specific sampling guides were prepared for each of the SPS experiments.

The initial GPS Materials Sampling and Testing Guidelines were issued in May 199021 and finalized in February 1991.22 A series of SPS Materials Testing and Sampling Guidelines was developed between November 1989 and February 1996. The Laboratory Testing Guidelines were finalized in May 1992, but a series of revisions was issued between October 1992 and September 2001. In 2007, the Long-Term Pavement Performance Project Laboratory Materials Testing and Handling Guide was issued.23

For projects that received overlays that were still to be monitored by the LTPP the program, the agencies would obtain the materials with assistance from the LTPP regional support contractors, who were responsible for getting the right materials to the right location for testing. The regional staff assisted the agencies' drilling crews during the sampling operations to ensure that the onsite sampling operations were completed accurately, efficiently, and safely. The safety of the operating crews as well as the traveling public was of the utmost importance.

Before going to each of the LTPP sites to collect samples, a formal plan was prepared indicating the sections, locations of the samples, and different layers that were to be collected from each location. The location numbers and sample numbers also needed to be defined. For each SPS project, a unique sampling and testing plan had been prepared before the project was constructed. The SPS experiment-specific guidelines provided the approach to be used in preparing the project-specific plans before, during, and after construction of the SPS sections. The advance planning ensured a smooth process of sample collection, labeling, wrapping, and transportation to the designated labs.

All samples collected were marked with a pen or labeled with a keel chalk immediately after sampling. Blue (AC samples), white (PCC samples), or yellow (granular material) labels were also prepared for each sample and taped or inserted inside the bag or the box where the sample was to be stored. Labels contained the State code and LTPP test section ID, sample location, sample number, sample date, and field set number.

While the core samples were set aside to dry, the regional staff measured and recorded the length of the cores and the quality of the samples before they left the site. Cores were also marked to indicate the direction of traffic. Once the cores had dried, they were wrapped with transparent plastic film and bubble wrap to prevent damage and packaged for shipment to the designated laboratories.

Materials data included information necessary to characterize the various layers of each test section. The testing was performed by highway agency laboratories and by laboratories contracted by FHWA. For example, a laboratory hired by FHWA performed all of the resilient modulus tests. In addition, the concrete laboratory at FHWA's highway research center performed the PCC coefficient of thermal expansion testing. Each laboratory has an ID number in the LTPP database.

MATERIALS SAMPLING AND STORAGESampling Activities Materials sampling activities are performed at the LTPP test sections using special equipment such as the dynamic cone penetrometer, shown below. The materials collected are tested in a laboratory, the data are stored in the LTPP database to provide information for pavement analyses, and the samples are stored in the Materials Reference Library (MRL).

Materials Reference Library The MRL was created in the late 1980s under the Strategic Highway Research Program (SHRP) in Austin, Texas, to provide a central storage facility for asphalt cement and aggregate samples collected under the Asphalt Research program and for pavement and subsurface materials samples collected from the LTPP test sites across the United States and Canada. One of the facility's main objectives is to address a problem associated with the original American Association of State Highway Officials Road Test, conducted in Ohio in the 1950s, where there was a shortage of materials available for subsequent research. In 1993, the FHWA-LTPP program took over management of the MRL facility and moved it from Austin, Texas, to Reno, Nevada. The MRL continues to be managed by FHWA to store materials samples for the LTPP test locations. Over the years, other pavement research programs, such as the Asphalt Research Consortium, WesTrack, the FHWA Crumb Rubber Modifier Project, and the WesTrack Project have sent samples from their test sections for storage in the MRL. Materials from the research conducted at the National Center for Asphalt Technology and the Western Research Institute are also stored there. The MRL stores over 1,000 tons of asphalt cement, Portland cement, natural aggregates, and combinations of these materials in both loose and core forms. In addition to storing the samples, the MRL maintains a temperature-controlled room to house photographic film records of distress collected from the LTPP test sites. Most of the materials at the MRL are from LTPP projects, including samples taken during construction of the SPS test sections. The materials samples have been used to support more than 30 national highway research projects. The samples enable the application of as-yet undeveloped test methods to LTPP materials, thereby enabling updates of the LTPP data to reflect new technologies. The MRL will continue to provide a common pool of materials for future research. The samples are available to the public, and more detail is available at the MRL Web site (http://192.186.205.27/ltppt/mrl).

|

In the early stages of the LTPP program, all samples collected from GPS sites were sent to LTPP contractor laboratories to perform the required laboratory tests. Later, when an overlay was placed at a site, some of the cores were sent to the highway agency's laboratory for testing in addition to the LTPP contactor laboratory that ran resilient modulus tests on these cores.

The samples collected from the SPS projects before, during, and after construction were sent to both the agency lab for testing and to the LTPP contactor laboratory that ran resilient modulus testing and other tests. It is important to note that the quality of the SPS materials test data was always a concern for the LTPP program as testing was done by numerous laboratories (i.e., a different laboratory for each highway agency or, in many cases, agencies had more than one laboratory perform the testing). As a result, the LTPP program kept the option open to repeat some of the tests performed by the highway agencies. Some SPS projects were still missing materials data, as was discovered during an LTPP program assessment,24 so the LTPP program developed a plan to collect this missing data. The details of the Materials Action Plan are described in the following chapter, Special LTPP Data Collection Efforts.

Just south of Winston-Salem in North Carolina, a pilot study was conducted to field test the Materials Sampling and Testing plan and the falling weight deflectometer protocol testing patterns. The pilot took place December 7, 1988, but due to a rare snow storm that hit Winston-Salem that day, the testing was completed on December 8. This GPS test section, 373807, was the first site where data were collected for the LTPP program. Officially, LTPP data collection began in 1989.

The monitoring data module contains pavement performance information that is collected primarily by LTPP contractors. Since 1988, with the first materials and falling weight deflectometer data collected at LTPP test section 373807 in North Carolina, the LTPP program has been collecting distress, drainage, friction, rutting, and longitudinal and transverse profile data, with some exceptions. (Friction data were collected by the highway agencies and submitted to the program for inclusion in the LTPP database. The drainage data were collected by LTPP contractors for only a subset of LTPP test sections for a few months.) More information about each data type is discussed in this section.

One of the six objectives of the LTPP program is to improve pavement prediction and design models (as discussed in chapter 1). A variable needed to accomplish this objective is the change in seasonal and long-term response to pavement loads. For both GPS and SPS sections, the LTPP program uses the falling weight deflectometer (FWD) to measure the deflection response of a pavement to a load of known magnitude. The program has conducted basin tests on AC and PCC pavements and load transfer tests on PCC pavements.

LTPP program efforts have significantly improved the accuracy and precision in measuring pavement strength. Ultimately, efforts within the program to achieve greater reliability and precision in FWD data resulted in the establishment of calibration centers around the country and the development of much-improved nationwide calibration standards: LTPP protocols formed the basis for American Association of State Highway and Transportation Officials (AASHTO) Standard Recommended Practice R 32-09, Calibrating the Load Cell and Deflection Sensors for a Falling Weight Deflectometer, adopted in 2009 by AASHTO, and updated as Standard Recommended Practice R 32-11.25,26 This section highlights some of the activities that culminated in those advancements, which are detailed in chapter 10.

LTPP activities in FWD calibration led to the adoption of a national FWD calibration standard: AASHTO Standard Recommended Practice R 32-11.

FWD Data Collection and Equipment

Parts of the FWD data collection process are automated'the computer controls the operation, acquiring and processing the data at high speed. In addition to sensing and recording load and deflection data, the system measures and collects air and surface temperature, time, and distance traveled on the roadway data. Some manual measurements are required, however: the FWD operator uses a probe to measure the subsurface temperature. Initially in the LTPP program, the subsurface temperature measurements were taken at three depths, but later these measurements were taken at five depths depending on the pavement structure. In 2003, the FWD gradient temperature data collection changed from drilling temperature holes at 25 mm from the top, at the middle, and 25 mm (1 inch) from bottom of the pavement surface layers to set intervals of 25, 50, 100, 200, and 300 mm (1, 2, 4, 8, 12 inches) from the top of the pavement surface. The operator also measures the width of joints when testing load transfer efficiency on rigid pavements. Any cracks or surface distresses that might affect the measurements are included in the operator's report.

During the early years of the LTPP program, under the Strategic Highway Research Program (SHRP) and later under the management of FHWA, each LTPP regional support contractor was responsible for storing, maintaining, and operating an FWD unit and its towing vehicle. The first four FWD units were purchased in 1988. The FWD equipment has been replaced or upgraded four times over the course of the program (in 1995, 2000, 2002, and 2014), and when FWD data collection was expanded in 1995 to meet the added demands of the SMP and new SPS sites, one additional FWD was purchased for each region to permit the expanded data collection resulting from these new demands.

Figure 6.5 shows an FWD used by the LTPP program to collect deflection data. See appendix C for more information on the type of FWD equipment and software used to collect, store, and process the data over the years.

FWD equipment comparisons were held periodically, where the FWDs from the four LTPP regions were brought together to assess their performance. Referred to as 'FWD thump-offs,' these comparisons were used to qualify newly purchased equipment for acceptance and program use, to perform periodic evaluations of the equipment's operational status, and to conduct cross-training exercises for regional contractor staff (figure 6.6). The thump-offs were later dropped in favor of FWD User Group meetings, where regional FWD operators and coordinators had an opportunity to review problems and exchange information on the operation and maintenance of the FWD equipment and analysis of FWD data.

FIGURE 6.5. Van-towed falling weight deflectometer equipment used in the LTPP program. |

FIGURE 6.6. Falling weight deflectometer equipment at the first LTPP 'thump-off,' which was held at Purdue University in November 1988. |

FWD Maintenance

Continuous preventive maintenance is necessary to keep the complex hydraulic-electrical-mechanical FWDs operating under demanding conditions to collect high quality data and pass rigorous annual reference calibrations. The LTPP program developed a preventative maintenance plan to ensure that the FWDs (and other equipment) are maintained to a high standard. The manufacturer's owner's manual provides guidance on most repairs and troubleshooting; however, eventually, after years of service, FWDs require a complete overhaul, which the program has successfully done in recent years.

In spring 2003, the LTPP Southern Regional Support Contractor overhauled one of the FWDs operated for the LTPP program, documenting the complete disassembly and reassembly with instructions and photographs. This maintenance and overhaul manual provides FWD owners, operators, and technicians with instructions and guidelines that supplement the Dynatest 8000 owner's manual (figure 6.7).27 In 2014, the LTPP regional support contractors completely overhauled all of the FWD equipment with the Southern Region playing a key role in this activity.

FWD Quality Control Checks

Five validity checks (roll-off, nondecreasing deflections, overflow, load variation, and deflection variation) were built into the FWD software to alert the operator of possible problems.28 To further check the integrity of the data, the FWDScan software was created for use in the field and again in the office to check data files for completeness and readability and to flag potential problems before data are loaded to the LTPP database. Similarly, the LTPP program developed FWDCheck to allow for subdividing the FWD deflections into uniform sections and provide statistical information on the FWD readings. This check was developed because earlier backcalculation exercises lacked uniform sections, which influenced the FWD results. FWDCheck also generated an overall structural capacity in terms of effective Structural Number.

FIGURE 6.7. The cover of the FWD maintenance manual, used to keep the units operating at peak performance. |

Another QC check used by the LTPP program is a deflection sensor location program called SLIC (an acronym for the authors Stubstad, Lukanen, Irwin, Clevenson).29 This program was developed and tested on FWD data collected by the LTPP program. Its LTPP use is summarized in Study of Long-Term Pavement Performance (LTPP): Pavement Deflections.30 SLIC was a QC check for the sensor locations. The LTPP regional support contractors used engineering judgment to determine whether or not to use the FWD data based on the data's overall quality.

Because the FWD data are intended for research use, the collection protocols required many more data than would be needed for routine pavement evaluation and rehabilitation purposes. Four drop-heights of equivalent 6,000-, 9,000-, 12,000-, and 16,000-lbf loadings (26, 40, 53, and 71 kN) were selected for AC pavements and three drop-heights of 9,000-, 12,000-, and 16,000-lbf loadings for rigid pavements. Random errors in readings were handled by taking four drops at each height. Sensor history data were collected for each sensor and the load cell at the fourth drop of each height. A 60-millisecond window was used to capture the history data.31' Just as the FWD equipment has been updated over the years to improve data collection, the various software procedures used to ensure quality deflection data have also been updated as needed (appendix C).

Establishment of FWD Calibration Centers

At the first FWD thump-off, in 1988, SHRP recognized the need to ensure that data being collected from each FWD unit be comparable across the LTPP program. As a result, the early program managers developed a methodology to calibrate FWDs to an independent reference standard and established centers to carry out the calibrations.

The Dynatest FWD, which has been used by the program, repeats itself very well, but comparison of the FWDs among the regions revealed statistical differences. Efforts were begun to reference-calibrate the FWDs by adjusting the sensor readings to a reference sensor to reduce significant statistical differences between the units. The prototype for this calibration procedure was developed at Cornell University in Ithaca, New York, in 1988.32 Initial trial comparisons were conducted at Purdue University with the participation of all four LTPP regional FWDs. The results of the comparisons showed that, when calibrated, the four SHRP FWDs could be used interchangeably. A calibration protocol was published in 1991,33,34 updated in 1994,35 and revised in 2011.36

The first production calibration center was built at the Pennsylvania Department of Transportation (PennDOT) Bridge and Maintenance Office in Harrisburg and operations began in 1992. In the same year and using the same protocol, additional calibration centers were opened in Texas, Nevada, and Minnesota. At the completion of the calibration centers, a round robin "Cal Off" was conducted with all four SHRP-LTPP regional FWDs. This comparison indicated there was minimal difference between the calibration centers, although some problems specific to individual centers were noted. This activity also allowed the FWD operators to compare their regions' procedures with the other regions and refine them, if needed.

The LTPP program provided the calibration centers (1) annual QA review and certification of the center operators and (2) technical services'training, troubleshooting, equipment replacement, and annual reference load cell calibration. Figure 6.8 shows an FWD readied for testing in an LTPP calibration center.

When the need to upgrade the calibration centers exceeded LTPP program resources, FHWA initiated, in 2004, Transportation Pooled-Fund Study TPF-5(039): Falling Weight Deflectometer (FWD) Calibration Center and Operational Improvements.37 This study resulted in new, highly portable calibration equipment and in updates and improvements in the FWD calibration procedure.38 The new procedure is demonstrated in a video available at the LTPP program's InfoPave Web site.

Also among the pooled-fund study's several objectives was to identify a source of support for the calibration centers over the long term. The study determined that the AASHTO Materials Reference Laboratory (AMRL) was qualified to continue providing these calibration center support services in the future. FHWA and AASHTO worked together on transitional activities over 2 years, resulting in a complete transfer of calibration center support to AMRL on September 1, 2010.39,40 AMRL now provides the centers the review, certification, and technical services previously provided by the LTPP program.

FIGURE 6.8. An FWD being calibrated at the PennDOT regional calibration center early in the LTPP program. |

Frequency of FWD Calibrations

The LTPP program requires the regional FWDs to have annual reference calibrations, every 9 to 14 months and following any repairs or major maintenance of FWD sensors or processor.41,42

While the FWD calibration procedures have been updated over the years, the load cell calibration remained unchanged. However, the deflection sensor calibrations were modified to allow for a group of sensors to be calibrated in a stand with an accelerometer versus the linear variable differential transformer (a deformation measurement device) used as the reference device. This simplified the procedure and made it less dependent on soil and slab condition.

FWD Manuals

In 1989, the SHRP-LTPP Manual for FWD Operational Field Guidelines, Version 1.0, was published, outlining the requirements for test setups for both flexible and rigid pavements, monthly relative calibrations, and temperature data collection requirements.43 In 1992, six sets of SPS site-specific guidelines were also issued. Interim changes in protocol were provided to the LTPP regional support contractors in the form of program directives, and the FWD manuals were updated to incorporate the SPS-related guidelines, revised calibration procedures, software changes, and step-by-step instructions for FWD data collection in 1993 (version 2.0),44 2000 (versions 3.0 and 3.1),45 2005 (version 4.0),46 and 2006 (version 4.1).47

Major changes in the guidelines were occasioned by implementation of the Dynatest25 (Dyna25) software in 2000 and FWDWin in 2005. After the Texas 1996 reference center calibration comparisons and operator exchange session, the LTPP regions performed follow-up testing with the Dyna25 software, and in September 2000 were directed to fully implement the new software and Operational Field Guidelines, Version 3.1. Subsequent versions simplified some of the earlier instructions and incorporated LTPP program directives into the text.

FWD Meetings

FWD comparisons were conducted and provided an opportunity to review problems and allow for exchange of information among FWD operators. These comparisons were later dropped in favor of attendance by the LTPP regional FWD coordinators at FWD User Group meetings, which were also a venue for FWD calibration center meetings. These annual meetings were formed as a means for the exchange of information on the operation, maintenance, and analysis of FWD data. These meetings gave the LTPP program an opportunity to meet with highway agency staff which was very important in the early days of the program.

Distress surveys are performed to document the condition of the surface of LTPP test sections in terms of visible distresses-such as cracking, defects, deformations, joint deficiencies, rutting-by severity and quantity. Distress data have been collected using both photographic (film-based) surveys and manual surveys. Photographic surveys were the priority with manual surveys serving as backup at the start of the LTPP program. However, significant differences were noticed between the two methods, and so the program gradually began to depend more on the manual survey because of the known limitations with the photographic survey and the increased confidence in the distress rater accreditation process.

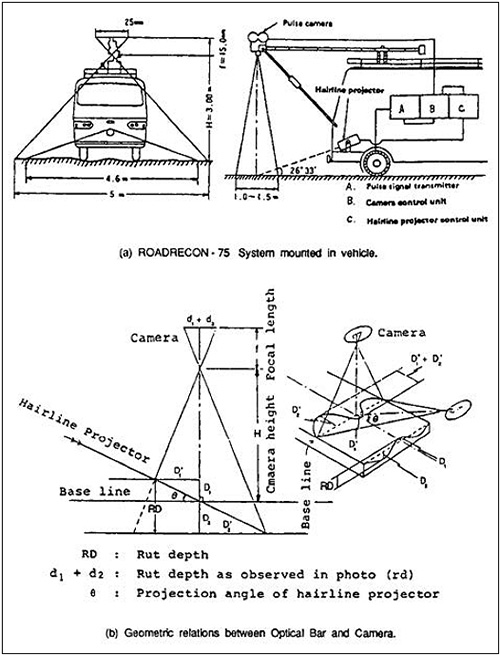

Photographic Distress Surveys

The photographic distress survey's objective was to provide a record of distress for data interpretation and archival purposes. Under SHRP management, a contract was awarded in 1989 to Pacific Aerial Survey Company (PASCO USA) of Japan to collect the permanent distress records for all test sections in each of the four LTPP regions beginning in the fall of that year. PASCO was the only vendor able to record cracks as small as 1 mm in width using backlit cameras and 35-mm film. Between contracts, PASCO sold their North American rights and equipment to Cumberledge, Gramling and Hunt (CGH) around 2000, who subsequently bid and were successful in retaining the contract with FHWA.

In the early part of the LTPP program, photographic surveys were conducted once every 2 years. As time passed, surveys were subject to budget constraints and typically occurred once every 3 to 5 years. Due to funding limitations, 2004 was the last year that CGH performed photographic surveys. At the conclusion of the last photographic survey contract, the LTPP program began collecting detailed photographs of the test sections with each manual survey, so in effect the program is still collecting a photographic record of the LTPP test sections.

The photographic distress permanent record systems in the early 1990s were housed in vans (figure 6.9). The distress was recorded on high-resolution 35-mm black-and-white motion picture film from overhead cameras directed at the pavement. Testing was conducted at night using artificial lighting to produce the highest quality images and minimize disruption to traffic.

Photographic distress or permanent record surveys had to be performed under dry conditions and were not taken at remote locations (e.g., Hawaii, Alaska, Puerto Rico, and Newfoundland). Also if the PASCO unit was not able to get to a test section prior to maintenance, rehabilitation, or closeout activities, then a manual distress survey was performed. Due to limitations with the PASCO data collection system (such as not being able to detect low-severity hairline cracking (< 1 mm) or to rate joint seal damage and crack sealant, faulting, and severity of potholes), the LTPP regional support contractors began to concentrate on doing manual distress surveys when visiting the test sites for other reasons, such as FWD testing. This ensured that distress data would be available and that data elements that were not available from the PASCO film could be obtained.

Photographic Distress Interpretation

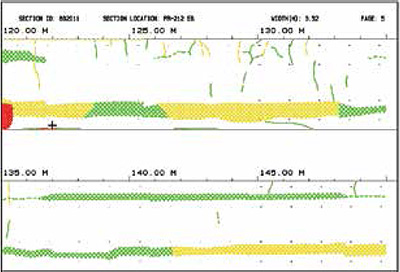

PASCO/CGH performed the initial distress rating, and sent the film to the technical support services contractor, who performed the secondary review and QA, performed distress ratings, and electronically logged the resulting distress types, severities, and quantities. The electronic copy of the data was provided to the regional support contractors for additional QA and to load into the LTPP database, and hard-copy outputs were provided for review and historical records. Computer-generated distress maps were also produced (figure 6.10).

The SHRP Distress Identification Manual (described in the Manual Distress Surveys section) for rating distress was used to determine the severity and extent of each distress. Some distress types could not be easily determined from the film. These are listed below by pavement type:

|

|

|

| FIGURE 6.9. Mobile equipment used to photograph pavement distress. Mounted on a boom extending from the front of the vehicle is the motion picture camera, synchronized with vehicle speed for continuous filming; flood lights are mounted on the custom front bumper. On a boom extending from the rear of the vehicle is a 35-mm pulse camera, which collects transverse profile. The camera is controlled by a distance measuring instrument that can trigger the camera at preset intervals; a strobe projector is mounted on the rear bumper. | ||

FIGURE 6.10. Sample of a computer-generated distress map from PADIAS 4.2 software. |

The film images were rated using the Film Motion Analyzer (figure 6.11) which PASCO USA had developed for the LTPP program. This device projected the film image onto a digitizing board. Because the film was on spools, the apparatus included a system to move the film through the projector. Initially a grid system, Pavement Distress Analysis System (PADIAS) 1.0, was used to determine the area and length of distresses; later a vector system, PADIAS 4.2, was developed. A study of LTPP distress data variability in the late 1990s found that 'Although differences in data interpreted with the PADIAS v1.x and v4.x systems exist, there is excellent overall agreement between the two systems for all pavement types, especially for total distress quantities and for cracking-related distresses.'48

Photographic Distress Quality Control Checks

The four LTPP regional support contractors performed a QA check on 10 percent of the distress data interpreted by the technical support services contractor from the film images before accepting it for loading to the database. The regions had a similar but somewhat less sophisticated apparatus and setup for checking the film as compared to the technical support services contractor. Three copies of the film were produced: a copy retained by PASCO, a copy provided to the technical support contractor for rating (which was then forwarded to the regions for secondary review and storage), and a third copy for the highway agency. Due to the sensitive nature of the film and to preserve the film's images, the canisters that were stored at the regional offices early in the program were later transferred to an environmentally controlled room at what is now the LTPP Materials Reference Library in Sparks, Nevada. (The reference library was begun under the SHRP asphalt program and later transferred to FHWA-LTPP management.)

QC/QA procedures were put in place with the automated distress survey contractor. Initial data reviews found discrepancies in the database between the photographic and manual distress ratings. This was particularly noticeable when using Distress Viewer and Analysis (DiVA), a stand-alone software tool developed in 2000 by the LTPP program to plot the historical changes in distress over time.49 This resulted in a decision to redo the ratings on all the film (except SPS-3 and -4) using the PADIAS 4.2 software.

As part of the QC/QA procedures, film distress raters were required to attend distress rater accreditation workshops to become accredited FHWA-LTPP distress raters. This was to ensure that qualified personnel were performing the distress interpretations and that the ratings would be similar to those of the manual distress surveys. Due to the different data collection methods, some discrepancies were still sometimes evident between the photographic and manual distress survey methods.

FIGURE 6.11. Film Motion Analyzer. |

Manual Distress Surveys

Manual distress surveys were initially instituted as a backup to the permanent film record distress method. These "walking surveys" were performed by trained and accredited raters. Before becoming a designated scheduled LTPP activity, manual distress surveys were not routinely performed by the LTPP regional support contractors except in the Southern Region, where manual distress surveys were performed at all sites as part of the site selection and verification process and later at sites visited for FWD testing. In 1995, the LTPP program issued a directive that outlined the measurement frequency and priorities for manual distress surveys.50

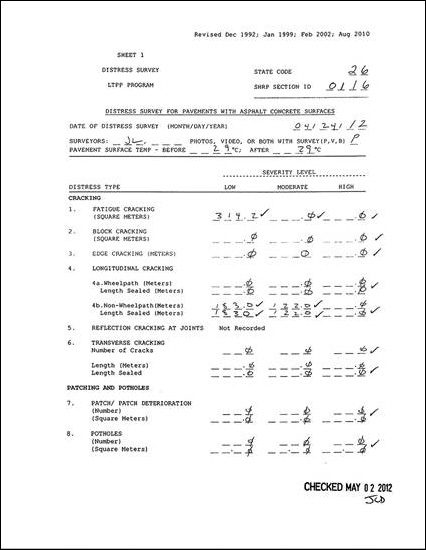

Stringent guidelines for the identification, interpretation, measurement of the quantity, and determination of the severity of the distress, and documentation of the findings were followed. Raters were also required to provide manually prepared distress maps, photographs, videos, and distress data forms as needed to record the conditions at the time of the survey and any unusual distresses observed. These requirements were described in the SHRP Distress Identification Manual (DIM), which was used to conduct the surveys. Development of the initial manual was funded by FHWA prior to the launching of SHRP, to be used in the distress data collection that would be performed under the original SHRP program. The manual was written by SHRP's technical assistance contractor and drew on various Federal and State/Provincial manuals. The photographs included came mainly from these documents.51 The manual contains the forms that surveyors use to record and summarize cracks, faulting, and other surface distresses observed on the pavement during a manual survey (figure 6.12). These forms provide input to the LTPP manual distress data module.

After a second DIM was published in 1990,52 ratings became more consistent among all of the LTPP regions. The third version of the DIM was issued in 1993,53,54 and the fourth version, released in 2003, incorporated refinements, changes, and LTPP program directives that had been issued since the previous edition.55,56 The DIM was updated in 2014 in its fifth version.57

Following release of the fourth version, the LTPP program developed four pocket editions to assist field engineers in conducting manual distress surveys. Plasticized and durable, the pocket guides covered distress identification for AC, PCC, and CRCP, with an additional AC guide designed for local agencies.58 The pocket guides were developed by the North Dakota Local Technical Assistance Program Center for use by local agencies with funding from FHWA. The Baltimore FHWA Resource Center reprinted a modified version. Both the technical assistance program center and resource center versions were printed in 2005.

The DIM is also used in workshops to provide examination and accreditation to LTPP distress raters in identifying various pavement distresses. These workshops were initiated early in the program to ensure consistency in data collection among different raters throughout the LTPP regions.

Over the course of the LTPP program, procedures for manual surveys changed as technical developments occurred or funding was adjusted. Some examples follow:

FIGURE 6.12. Example of the multipage forms used to record distresses observed during LTPP manual distress surveys. For each pavement type, a different form is used to record surface distresses. This is page 1 of the form for asphalt concrete pavement. |

Manual Distress Workshops

The first manual distress workshop was conducted in Arlington, Texas, in 1991, with representatives from all four LTPP regions attending. There were many discussions on what constituted distress, how it should be categorized, and what parameters should be used for ratings. There was also a distinct difference between how individuals from the north perceived distress and severity levels versus those coming from the south. Based on this workshop, it was evident that work would be required to get a consensus on what distresses would be categorized and how. For example, some of the more significant issues that required resolution were how to rate the distresses in the wheelpath, identify the cracks (e.g., longitudinal, fatigue), and rate the extent and severity of each distress.

Early reviews of regional distress surveys for consistency between raters indicated a need for training and standardization. Therefore, the LTPP program developed a workshop for accreditation of the LTPP regional distress raters.61 The raters were to be trained within the region and would attend the workshop to be accredited to conduct distress surveys for the LTPP program. Distress accreditation workshops were conducted every 2 years and included a distress presentation, field review of distresses, distress rating on flexible and rigid pavements, and the accreditation. The distress workshops were rotated among the regions, and accreditation expired after 24 months (or could be extended to the next available workshop). Other requirements, such as the need to conduct a minimum of 15 manual distress surveys each year, were added to ensure that only experienced raters were performing the manual distress survey duties, thus ensuring research-quality results.62 Between 1991 and 2014, the LTPP program has held 38 manual distress workshops, 32 for LTPP regional support contractor raters, and six for PASCO/CGH raters. In the early years of the program, two to three workshops were held each year; currently one workshop is held each year. Figure 6.13 shows a field exercise at a manual distress workshop.

Office Review of Surveys

Internal LTPP regional office reviews of distress surveys are also conducted. They include detailed checks for errors in math, summarization, and visual comparison with previous surveys regarding distress types and quantities.

After the initial mathematics checks and overall review, the manual distress survey is compared to the last visit for a time-series check. When noticeable discrepancies from survey to survey were found, a program directive was issued allowing the rater to take the prior survey maps into the field. Once the survey had been performed and summed, it was checked against the prior survey while on site. This allowed an explanation of the differences in distress before leaving the site.63

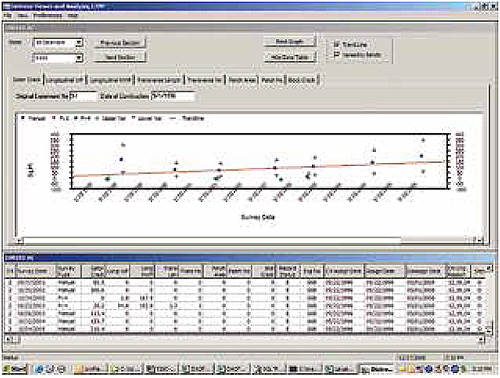

Back in the office, the LTPP regional support contractors conducted reviews of the distress data entered into the database. In 2004, the DiVA software was issued for use as an integral part of the regional office QC/QA activities, as well in the time-series evaluation of distress data (figure 6.14).64 The purpose for this software has been served, and it is no longer being used by the LTPP program for distress reviews.

FIGURE 6.13. Participants in a field review of distresses at an LTPP distress accreditation workshop. |

The drainage data contain information on the inspection of drainage features and, more specifically, information on the condition of the edge drain systems and the location of the lateral-side drainage structures. Drainage information gathered includes the presence and type of subsurface drainage features, such as permeable layers, transverse drains, and longitudinal drains. The best source of information on the effect of in-pavement drainage systems will be from comparison of the drained and undrained sections on SPS-1 and SPS-2 projects.

Two investigations were performed to explore the condition of the edge drains at the SPS-1, SPS-2, and SPS-6 projects. Although some GPS projects contain edge drains, they were not included as a primary experimental factor.

The first investigation included a video survey, wherein a camera on the end of a semi-flexible cord was inserted into the outlet and pushed into the drain pipe, recording the condition of the outlet itself as well as the drain pipes' condition (figure 6.15). Observations included crushed pipes; sags; ponding water; pipes clogged with dirt, silt and construction debris; and numerous animals and their nests. The intent of this investigation was to determine the degree to which the pipes were properly constructed, and, if it was necessary to clean them out to ensure proper operation. Edge drain videos and reports were sent to the respective highway agencies, and the completed inspection forms (and associated data) were entered into the LTPP database.

The second drainage investigation conducted at the LTPP test sites included field investigations to evaluate the effectiveness of the drains themselves. As part of the study, Effects of Subsurface Drainage on Performance of Asphalt and Concrete Pavements: Further Evaluation and Analysis of LTPP SPS-1 and SPS-2 Field Sections (NCHRP 01-34D), liquid with dye was injected into holes drilled in the pavement surface at a set distance from the drain outlet, and the length of time required for the dyed water to be detected exiting the drainage outlets was measured. In some cases the dye appeared very quickly, and in others it never appeared at all.65 This information may help explain anomalous findings in pavement performance and drainage effectiveness predictions.

FIGURE 6.14. Screen shot from DiVA software showing a time-series chart of a pavement distress along with the table for all distresses for a test section. |

FIGURE 6.15. Edge drain inspection using videography. |

The LTPP database contains the results of friction tests on pavement sections where the State/Provincial highway agency was willing to provide the data. Because friction data hold the potential risk for litigation, submission was made voluntary.

The LTPP data collection guidelines for friction data recommend using the ASTM E-274 (AASHTO T 242) procedure as the preferred method for obtaining data. The ASTM E-274 procedure uses a locked-wheel skid tester in a trailer assembly (figure 6.16). Friction test results are reported as Skid Numbers. It should be noted that although the LTPP program provided guidelines for friction testing, the program has no control over the data collection method, measurement equipment, or calibration of the equipment used for these measurements. In addition, prior to 2014, the LTPP database did not contain surface texture data or related information that are traditionally used to link pavement properties to measured friction levels.

Profile data are collected because pavement smoothness/roughness is perhaps the most important user parameter (i.e., level of service). Profile data and smoothness indices are used to track the performance of the section and provide input to the development of models, especially models that are related to user cost and benefits. Research-quality data require a state-of-the-art profiler to collect ride statistics and longitudinal profiles for long-term comparisons and the' development of future smoothness indices.

FIGURE 6.16. Locked-wheel skid tester currently in use for collecting friction data. |

Longitudinal profile data are collected almost exclusively by automated profilers, and manual Dipstick® measurements as well as rod and level measurements are sometimes used as a backup. The Dipstick is the backup device in the event an inertial profiler is unable to be scheduled or for remote sections that can not be visited due to distance (e.g., Hawaii and Puerto Rico). The Dipstick is still used for longitudinal profile comparisons because it is an ASTM standard profile measuring device. A list of profile data collection equipment used by the LTPP program over the years is shown in appendix C.

Inertial Profiler and Dipstick Equipment and Verification Tests

Inertial profiling equipment was first purchased in 1989 and was replaced in 1996, 2002, and 2013 as technologies improved and as equipment deteriorated. The profilers, purchased by SHRP and then FHWA, underwent rigorous testing to ensure that they met the requirements specified in the contract documents. After each LTPP regional support contractor took delivery of a replacement profiler, a comparison of the new and old profilers was performed before the new profiler was put into service. These verification tests compared the output from the old and new equipment.

When the first profilers were delivered to the LTPP regional support contractors in 1989 (shown in figure 6.17), some of the regions added video cameras to the equipment to provide backup evidence of pavement condition at the time of survey. The videotaping also helped in determining if maintenance had occurred at the test sections.

FIGURE 6.17. The first (DNC 690) Profilometers used in the LTPP program. Three were mounted in the Champion motor home chassis with Ford underpinning with dual rear wheels, and the fourth in a Ford E350 van chassis. |

FIGURE 6.18. The T6600 Profilometer, in use from 1996 to 2002. |

FIGURE 6.19. ICC profiler MDR 4086L3 (Ford E350 van), in use from 2002 to 2013. |

FIGURE 6.20. Ames profiler in Ford E150 van, acquired in 2013. |

The T6600 Profilometer and the ICC profiler are pictured in figure 6.18 and figure 6.19, respectively. In 2013, through a competitive process, the LTPP program replaced the ICC profilers with state-of-the-art Ames Engineering, Inc. profilers with added capabilities: macrotexture measurements are a new data collection element, and all of the data, including ambient and surface temperature, are referenced with Global Positioning System coordinates (figure 6.20). The new system's software was designed through a collaborative manufacturer/LTPP program process.

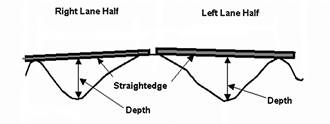

As stated earlier, the LTPP program has used the Dipstick over the years in addition to the high-speed profilers to collect profile data. (A manual Dipstick is shown in figure 6.21.) A comparison study of the profiler, the manual Dipstick, and a portable rolling surface profiler manufactured by Face was conducted at the Virginia I-95 LTPP test section (511023) to provide data for use in developing software for the manual collection of longitudinal profile data. The portable rolling profiler was found not to be an ideal tool for the LTPP program's purposes. Safety issues arose with the collection of transverse profiles because it was necessary to roll the profiler past the centerline in the adjacent lane to capture the profile at the centerline.