U.S. Department of Transportation

Federal Highway Administration

1200 New Jersey Avenue, SE

Washington, DC 20590

202-366-4000

Federal Highway Administration Research and Technology

Coordinating, Developing, and Delivering Highway Transportation Innovations

| REPORT |

| This report is an archived publication and may contain dated technical, contact, and link information |

|

| Publication Number: FHWA-HRT-15-049 Date: April 2015 |

Publication Number: FHWA-HRT-15-049 Date: April 2015 |

© Lane V. Erickson/Shutterstock.com The LTPP program has mounted three major data collection efforts that have improved the quality and quantity of its climate, traffic, and materials data, and has led the way in investigating pavement performance through forensic studies. |

Only data of the highest quality, in sufficient quantity, can be relied upon to yield true and useful answers to research questions. The LTPP program, with the assistance of expert peer groups, has continually reviewed and expanded its collected data to make the LTPP database more valuable to pavement researchers.

The LTPP program has planned and executed three major efforts to enrich the LTPP database or to address areas where data did not meet the program's expectations for quality or sufficiency. These programs went beyond the original experiments in the General Pavement Studies (GPS) and Specific Pavement Studies (SPS). So that pavement responses can be correlated with climatic conditions and traffic loads, the Seasonal Monitoring Program (SMP) gathered daily and seasonal weather data. To remedy the program's lack of consistent, high-quality monitoring traffic data, the LTPP SPS Traffic Data Collection Pooled-Fund Study, supported by the highway agencies, collected continuous classification and weight data at SPS projects where various design and rehabilitation strategies were being monitored. To supplement and correct incomplete materials data, the Materials Action Plan was carried out. This chapter describes these 'special' multiyear data collection efforts and the forensic investigations that have been conducted to increase understanding of pavement performance.

Temperature and moisture-related changes in pavement structures, both within a day, from season to season, over the course of a year, and from year to year, can have significant impact on the structural characteristics of pavement layers, thus affecting the pavement's response to traffic loads and, ultimately, its useful life. To attain a fundamental understanding of the magnitude and impact of temporal (daily, seasonal, and annual) variations in pavement response and material properties due to the separate and combined effects of temperature and moisture variations, the Strategic Highway Research Program (SHRP) envisioned the SMP. The study concept received strong support from the LTPP stakeholder community and was also endorsed by the LTPP Pavement Performance Advisory Committee.

Unlike the GPS and SPS experiments, the SMP, which began in 1992, was not a planned experiment during formulation of the LTPP program in the 1985-87 pre-implementation phase. Rather, the study evolved as an extension of the ongoing LTPP deflection testing activities that began in 1989. The original study concept was to perform deflection testing on a more frequent basis on a subset of LTPP test sections to provide the data necessary to 'conquer the last frontier' in the structural evaluation of pavements'understanding the daily and seasonal variations in pavement deflections. However, the scope increased to include not only more frequent deflection basin and joint load transfer testing, but also more intensive profile and distress measurements as well as measurements of surface elevation, joint openings in Portland cement concrete (PCC) pavements, and various in situ surface and subsurface moisture and temperature parameters. The instrumented sites were widely distributed and represented a variety of climatic and soil conditions (figure 7.1).

| Key Milestones in Special Data Collection Efforts | |

|---|---|

| 1992 | Seasonal Monitoring Program begins |

| 2001 | LTPP SPS Traffic Data Collection Pooled-Fund Study initiated |

| 2003 | Traffic data collection begins for traffic pooled-fund study |

| 2004 | Seasonal Monitoring Program ends |

| 2004 | Materials Action Plan implementation begins |

| 2004 | LTPP develops framework for forensic investigation |

| 2008 | LTPP conducts four forensic studies |

| 2009 | Materials Action Plan completed |

| 2014 | LTPP SPS Traffic Data Collection Pooled-Fund Study ends |

It was envisioned that the products from the seasonal monitoring study would provide the means to link pavement response data obtained at random points in time to critical design conditions; the means to validate models for relationships between environmental conditions (e.g., temperature and precipitation) and in situ structural properties of pavement materials; and expanded knowledge of the magnitude and impact of the changes involved. When this study was terminated in 2004, it represented the end to perhaps one of the most successful undertakings within the LTPP program. The seasonal study provided input on the effects of temperature on falling weight deflectometer (FWD) deflection data, seasonal changes in performance of pavements, and the effects of heave (frost) and swell (expansive soils) on pavement performance. This information allowed for better decision making in the use of FWD data and update of current analytical models.

Detailed information about the SMP such as the scope, equipment, data collection procedures, data collected (onsite air temperature and precipitation data, subsurface temperature and moisture content data, and frost-related measurements), and monitoring frequency is discussed below.

FIGURE 7.1. Distribution of instrumented sites in the LTPP Seasonal Monitoring Program. |

Resource limitations made it impossible to monitor all LTPP test sections on a seasonal basis. Consequently, an experimental matrix of 32 cells was established addressing the following key pavement factors:

Traffic was not considered in the experimental matrix, as it was not felt critical to achieving the study objective.

During the test section recruitment effort, 3 sections were sought for each of the 16 AC pavement experiment cells and 1 section for each of the 16 PCC experiment cells'a total of 48 AC pavement test sections and 16 PCC pavement test sections. To cover different soil and environmental conditions, the LTPP program identified 16 sites in each of the four LTPP regions. Ultimately, 63 of the targeted 64 test sections were selected from the GPS and SPS studies to populate the SMP experimental matrix.1 These test sections were part of the SMP Phase I or Phase II monitoring frequency, as described later in this section.

At the start of the SMP only minimal funds were available, which meant that most of the options to be considered for instrumentation had to be "low tech" with manual data collection. Moisture data was collected with time domain reflectometer (TDR) probes connected to a Tektronics 1502B cable tester. Thermo-couples connected to a precision multi-meter were used to collect temperature readings, and similarly, a resistivity probe was used to determine frost/thaw activity. A piezometer monitoring well (figure 7.2) was chosen to monitor water levels. Rod and level surveys were also conducted at the time of FWD data collection to determine any pavement movement due to frost/thaw activates or swelling of cohesive soils. Figure 7.3 shows the SMP mobile monitoring equipment. Details of the evaluation, selection, and development of probes and other equipment used and challenges encountered are available in appendix C.

From 1990 to 1992, pilot studies and training sessions were held to select the instrumentation to be used for surface and subsurface moisture and temperature measurements, as well as to finalize the instrumentation installation, and data collection guidelines. GPS test section 361011 which is a flexible pavement on I-481 near Syracuse, New York, was selected as the first pilot. The New York State Department of Transportation (NYSDOT) had conducted various temperature and frost/thaw studies in the past and had in-house expertise that could help with assembly of the instrumentation. The pilot installation on October 22-25, 1991, was attended by the LTPP program and contractor staff, NYSDOT, and CRREL (the U.S. Army Corps of Engineers' Cold Regions Research and Engineering Laboratory). During the installation, CRREL provided insight on the instrumentation data collection along with the algorithms to analyze the voltage outputs from the thermocouples. The LTPP regional support contractors had the opportunity to review the different instrumentation and procedures. A major consideration coming out of the pilot and subsequent data collection at this site was the need to refine the instrumentation and to automate the data collection process.2

FIGURE 7.2. A piezometer monitoring well and cap, used to determine ground water levels. |

FIGURE 7.3. Mobile monitoring equipment for downloading data collected at seasonal monitoring sites. |

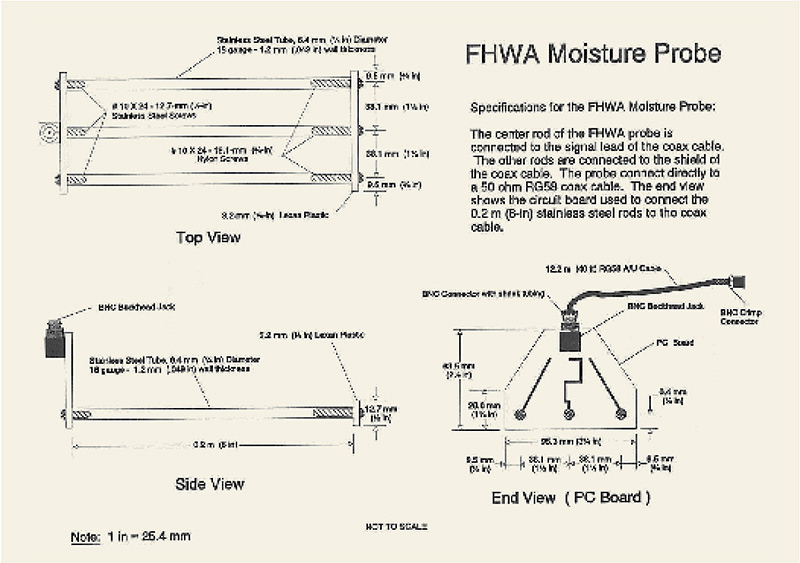

Following the initial pilot, the selection and development of instrumentation proceeded as plans were put in place for additional pilots, which were conducted at test section 163023, a rigid pavement near Boise, Idaho, in November 1991; and test section 308129, a flexible pavement near Billings, Montana, in August 1992.3,4 A Campbell Scientific, Inc. (CSI) CR10 Datalogger was purchased, and software was developed to automate the data collection. After the evaluation of the TDR alternatives, a 3-prong, 203-mm-long, stainless steel tube probe was selected because of its accuracy, repeatability, and ease of installation. However, to reduce the instability of the electronic signal caused by differences in cable length, staff from the LTPP program and the Electronics Laboratory at the Federal Highway Administration's (FHWA) Turner-Fairbank Highway Research Center designed a special TDR probe. This probe was designed to accurately measure the apparent length of the probe that is used to calculate the dielectric constant of the material surrounding the probe. The dielectric constant is an input to the calculation of moisture content in unbound base and subgrade materials. The final design was fabricated by the Electronics Laboratory specifically for the SMP data collection (figure 7.4 and figure 7.5).

FIGURE 7.4. The moisture probe designed at the FHWA highway research center. |

FIGURE 7.5. Schematic of the moisture probe that was used to obtain moisture content in unbound base and subgrade materials in the SMP, designed at the FHWA highway research center.5 |

Monitoring of select LTPP test sections that were also part of the seasonal study began in 1992 and had a more extensive and more frequent data collection monitoring schedule than the other LTPP test sections. The 63 seasonal sites were monitored in SMP Phase I and 24 of them were monitored in SMP Phase II. Although the two phases were monitored at different times throughout the year, the frequency of the data collected was monthly. However, in the spring and fall, the data were collected twice a month.

Regardless of the monitoring phase, the same data elements were collected for each SMP site. The core data elements collected were deflection, profile, and distress data. In addition, surface elevations, ambient temperature, precipitation, sub-surface moisture, subsurface temperature, frost depth, and ground water table elevation were also collected.6 It should be noted that procedures for cold weather FWD testing were developed specifically for the SMP.

Approximately half of the seasonal test sections were monitored in alternate years'one loop of test sections in 1992, 1994, 1996, and 1998 and the other loop of test sections in 1993, 1995, 1997, and 1999. This data collection schedule was used because of the limited availability of the instrumentation, equipment, and LTPP program contracting resources. Once one loop of testing was complete, the instrumentation and equipment were rotated to the second loop of test sections for monitoring. However, the initial data collection cycle was extended by a year to compensate for problems encountered early in the SMP, including battery pack failures. The D-cell battery packs were replaced with gel cell batteries that could be recharged or continuously charged through a solar panel.

It was originally envisioned that seasonal monitoring would be performed on three alternate years per test section, from 1992 to 1997, but the instrumentation performed better than expected and there was a great deal of interest in the study by the participating highway agencies, so monitoring was extended until 1999. This period of monitoring would eventually be called the SMP Phase I monitoring, and it extended over an 8-year period.

|

As a result of the success of the SMP Phase I data collection activities, many highway agencies supported the continuation of the program, and planning began in 1998 for a second phase (see sidebar). The objective of the SMP Phase II monitoring, which began in 1999, was to continue to provide the data needed to attain a fundamental understanding of the magnitude and impact of diurnal, seasonal, and annual variations in pavement response and properties due to the separate and combined effects of temperature, moisture, and frost penetration. However, unlike Phase I, this phase was limited to test sections that had available the full suite of data (i.e., monitoring, materials, and inventory data) required for pavement performance monitoring. Figure 7.6 shows the monitoring equipment installed at a Phase II seasonal site.

FIGURE 7.6. SMP Phase II seasonal monitoring equipment installation at the Lake Ontario State Parkway site on SR 947A in western New York. |

Twenty-four of the SMP Phase I monitoring test sections were selected for the SMP Phase II monitoring on the basis of data completeness, instrumentation condition, and willingness of the highway agency to support the effort. Data collection requirements remained largely the same as in the first phase, but the frequency of deflection testing was reduced, and the option was provided for either fixed-interval testing or direct-event testing, depending on the climatic regime at the site. The direct-event option was made possible in part because at 10 of the 24 test sections, equipment was upgraded to automate collection of moisture and frost/thaw data when triggered by precipitation or specified soil temperatures. Unlike temperature measurements, which were continuously collected during SMP Phase I monitoring, moisture and frost/thaw depth measurements had been collected manually at 4-hour intervals on the days of deflection testing, using the mobile monitoring equipment. During SMP Phase II, moisture and frost/thaw depth data were collected continuously when the new equipment was triggered by conditions (i.e., when the temperature reached a certain degree, frost information was collected). This direct-event testing equipment was rotated among the 24 test sections.

Software was developed for field quality control (QC) and review of the SMP data. In 1995, during Phase I, the LTPP program developed the ONSFIELD software to QC and review onsite data (temperature and rainfall), and the MOBFIELD software to review the mobile data (moisture and frost/thaw).7 In addition, Seasonal Monitoring Program Check, or SMPCheck, was developed for central office processing and loading of data into the LTPP database, with a manual released in 1996.8

During Phase II, the CR10 operating software was updated to the PC208 Windows version. This resulted in changes to the data collection routines and provided a better user interface, eliminating the need for the CR10 procedural routines developed in the DOS version.9 A CR10 procedural program along with documentation was developed to provide a systematic approach for the SMP data collection,10 and later a comprehensive data collection guidelines document was created to ensure high-quality data would be collected.11 LTPP program directives were issued to provide resolutions for data collection and processing issues from October 1993 to November 2002 and to document changes in procedures.

Training sessions were held throughout the SMP when new versions of the equipment or software were made for processing and interpreting SMP data. Editing of the plots to "null" timeframes that contained no data, the removal of bad data, and the interpretation of TDR traces were part of the training. This training was often conducted in conjunction with data training for the automated weather stations (chapter 6).

An evaluation of the moisture determination from TDR methods was also done. This method of developing and identifying inflection points, along with the Topp et al. procedure for determining the volumetric moisture content of soils from dielectric constant,12 was adapted by the LTPP program.13 As both manual TDR traces on paper and automated traces were collected, an interpretation manual was developed for the TDR traces. This manual outlined the procedures on how to interpret different trace types and generate volumetric moisture values from manual traces.14

The evaluation of the automated resistance/resistivity data to determine frost/thaw depths was more difficult, as no mathematical solution could be applied (since the input voltage was not recorded). As such, manual interpretation of the traces was required. Evaluating the 2-point and 4-point resistivity, manually collected at the time of site visits, had the same limitations. Using the 4-point resistivity to determine soil moisture and other conditions was also considered impractical as soil volume changes with weather and seasons.

TDR and resistivity data collected from the seasonal monitoring sites do not directly provide information useful to pavement engineers. Rather, the data must be interpreted to develop subsurface moisture content and frost condition information. The LTPP program has sponsored four studies to compute these parameters. Two initial studies were conducted to compute frost conditions and moisture content from data collected through 1998.15,16 After these studies were completed, additional data were collected but were not routinely interpreted. Considering this, FHWA sponsored two other studies to evaluate the methodologies used in the initial studies and to compute frost and moisture content for all of the data in the LTPP database. The procedures used were modified from the original studies, and computations were made for all collected SMP data.17,18

SMP data collection ended in October 2004, for reasons ranging from failing sensors, sections being rehabilitated or going out of study, and financial constraints.19 At the completion of Phase II data collection, the instrumentation and equipment from most of the SMP sites were removed and returned to the LTPP regional offices (with the exception of the in-ground instrumentation). Exceptions were in Arizona and Ohio, where the SMP site/equipment was transferred to the highway agency. At some of the sites, a forensic study of the condition of the instrumentation was undertaken in which the in-ground instrumentation was removed and examined. The installation, decommissioning, and re-commissioning of seasonal monitoring sites are documented in reports that detail the instrumentation, its location within the pavement layers, material properties, and any problems.20

The SMP projects have provided pavement designers and researchers with an abundance of research-quality environmental data. Combined with measurements taken at the automated and virtual weather stations, these data have already proven useful in evaluating and modifying rigid pavement design procedures, refining the selection of performance-graded binders, evaluating seasonal load restrictions, and defining moisture and frost penetration prediction models.

A 1996 program assessment (chapter 11) revealed major traffic data deficiencies in the LTPP database. To address this issue, the LTPP program and the Transportation Research Board Expert Task Group (ETG) on LTPP Traffic Data Collection and Analysis studied the problem and developed an action plan.21 This 1999 action plan provided guidelines to improve traffic monitoring by assuring uniformity of data collection equipment across States and Provinces, establishing regular equipment calibrations, and ensuring that a sufficient quantity of data would be collected to support research and product development.22

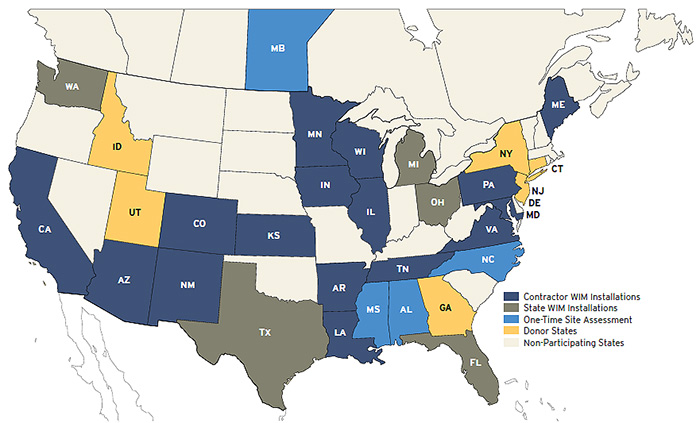

Around this time, weigh-in-motion (WIM) technologies were greatly improved; however, their cost and the additional staff needed to maintain, calibrate, and operate the systems properly made it impossible to install a permanent WIM system at every LTPP test site. Therefore, the LTPP program and the Traffic ETG (figure 7.7) decided to collect traffic loading data only at SPS experiments, specifically SPS-1 (structural factors for flexible pavements), -2 (structural factors for rigid pavements), -5 (rehabilitation of AC pavements), and -6 (rehabilitation of jointed PCC pavements).23 To implement the traffic monitoring action plan, FHWA, with the support of the American Association of State Highway and Transportation Officials (AASHTO) and the participation of many highway agencies, initiated the LTPP SPS Traffic Data Collection Pooled-Fund Study, TPF-5(004), in 2001.

The objective of this study was to improve the quality and increase the quantity of monitored traffic data (volumes, classifications, and weights) at selected LTPP SPS test sites. Since 2003, this multiyear study has collected 'research-quality data' for at least 5 years at 28 of the 84 SPS sites using bending plate, load cell, and quartz WIM sensors. For the purpose of this study, research-quality data was defined to be at least 210 days of data (in a year) of known calibration meeting LTPP's performance requirements for steering and tandem axles, gross vehicle weight, bumper-to-bumper vehicle length, vehicle speed, and axle spacing, as listed in table 7.1. In this study, the first contracted WIM equipment was installed in 2005 in Illinois; the last installation was in Indiana in 2008. These two locations along with others are still producing research-quality data.

The LTPP SPS Traffic Data Collection Pooled-Fund Study aimed to improve the quality and increase the quantity of monitored traffic data at select LTPP SPS test sites.

FIGURE 7.7. Traffic ETG members who provided technical guidance and direction to the traffic pooled-fund study (left to right: Andrew Nichols, Elizabeth Stolz, Patricia Hu, David Cebon (Chair), Anne-Marie McDonnell, and Richard Reel). Not pictured but also instrumental in developing the study were members Larry Scofield (former Chair), Richard Quinley, Richard Rogers, and James Kramer. |

| Pooled-Fund Site Factor | 95 Percent Confidence Limit of Error |

|---|---|

| Loaded Single Axles | ±20 percent |

| Loaded Axle Groups | ±15 percent |

| Gross Vehicle Weights | ±10 percent |

| Vehicle Length | greater of 1.5 ft or ' 3 percent |

| Vehicle Speed | ±1 mi/h |

| Axle Spacing Length | ±0.5 ft [150 mm] |

Many pooled-fund studies use the funds contributed by participating States for any area of the study. In this study, however, each State's contribution goes to its own data collection needs at its SPS projects. Six of the 28 participating States (figure 7.8) recognized the value of the study'as well as the potential for advancing their own traffic data collection activities–and decided to become donor States. Their contributions allowed the LTPP program to expand data collection.

Before the traffic pooled-fund study began, the LTPP program field-tested the installation of the WIM equipment and the calibration and validation protocols at five pilot locations. These pilot studies are discussed in the next section.

The LTPP program developed a series of protocols and guidelines to acquire uniformly collected, research-quality traffic data. The guidelines include a suggested performance-based equipment specification for equipment replacement, a performance specification for validating equipment operation in the field, and pavement smoothness criteria. In addition, a field protocol addressing the calibration and validation procedures was prepared for all traffic data collection activities.24

Over the summer and fall of 2001, LTPP staff oversaw five pilot studies to verify that the new performance specifications and field procedures were feasible. The pilots looked at both piezoelectric cable and bending plate sensor systems installed in AC and PCC pavements. One of the pilot sites was used to test the reinstallation process, and a side-by-side comparison of the principal sensor systems, piezoelectric cable, and bending plate was performed at another site.25

The following sites were examined as part of the pilot studies in 2001:26

FIGURE 7.8. Participating States in the LTPP SPS Traffic Data Collection Pooled-Fund Study. Map shows the donor States, States with assessments only, and weigh-in-motion equipment installed by the State or the LTPP contractor. |

As a result of the pilot studies, the following conclusions were reached:

Although the LTPP pavement smoothness specification was found to be too restrictive, further testing in several States resulted in revisions to the specification, which later was adopted as the AASHTO Standard Specification for Smoothness of Pavement in Weigh-in-Motion Systems.27 The pilot studies also verified that WIM equipment options used in the pooled-fund study should include load cells (figure 7.9), bending plates (figure 7.10), or quartz piezoelectric sensors (figure 7.11). Following the pilots, the data collection and processing methods were adopted for use in the traffic pooled-fund study.

To satisfy the requirements for SPS traffic data collection and implement the objectives of the traffic pooled-fund study, FHWA selected two independent contractors. One contractor installed, maintained, and replaced WIM equipment; performed daily QC checks of the data; and submitted the data on a weekly basis to the LTPP regional support contractors for further QC and processing. The second contractor performed field evaluation and validation of all WIM equipment installations, including equipment installed by highway agencies. Highway agencies that installed and maintained their own WIM equipment sent the data directly to the LTPP regional support contractors for processing.

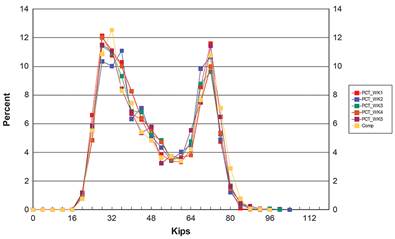

An extra step in processing the traffic data was to check for gross data changes over time. The LTPP regional support contractors used the LTPP Traffic Analysis Software to check the weekly data against a reference data set. The reference data set covers the 14 days immediately following a successful calibration and validation of the WIM system and provides the typical vehicle classification and loading conditions for the site. Data reviewed after the 14-day period are expected to reasonably match the reference data set (figure 7.12).

Although the pooled-fund study ended in 2014, its field validation, data collection, and other activities continue to be centrally managed by the LTPP program (at select sites) with the support of the contractors and highway agencies.

Figure 7.9. Load cell WIM installation. |

Figure 7.10. Staggered bending plate WIM sensors installed in concrete pavement. |

FIGURE 7.11. Installation of quartz piezoelectric WIM sensor spanning a full lane. |

Some of the products that have been developed as a result of the traffic pooled-fund study are the LTPP Field Operations Guide for SPS WIM Sites (WIM Data Quality Guidelines), a glossary of WIM terms, LTPP vehicle classification table, and new traffic defaults for use with the Mechanistic-Empirical Pavement Design Guide, as well as the AASHTO smoothness specification. Guidelines for equipment calibration checks and equipment model specifications were also developed and are available through the LTPP Customer Support Service Center (Email: ltppinfo@dot.gov). The information gathered, documentation produced, and lessons learned from this effort were shared with pavement and traffic engineers and traffic data collectors in WIM workshops that were held by the States. This study led to significant advances in the accuracy and reliability of permanent traffic monitoring equipment and has significantly improved the availability and quality of monitored traffic data for pavement, bridge, and other analysis studies.

Collection of accurate and reliable materials data is a critical element of the LTPP program. As discussed in chapter 11, in 2004 the LTPP program undertook a major effort, the SPS Materials Action Plan, to fill identified gaps in the materials data for the SPS projects. Efforts begun in 1997 had brought improvement, but serious gaps remained. The plan for resolving materials data deficiences was laid out in an internal LTPP document, 'LTPP SPS Materials Data Resolution: Update and Final Action Plan, August 2004.' The plan addressed three major areas of materials data needs for SPS-1, -2, -5, -6, and -8 projects:

New Mexico, SPS-1 Test Section 350100 FIGURE 7.12. Screen shot from LTPP Traffic Analysis Software showing loadings of Class 9 traffic over a 5-week period in March 2011. "Comp" line represents the reference data set. |

The sampling and testing requirements that addressed these three areas were based on criteria defined in the internal Final Action Plan. These criteria were based on missing data per layer type and the requirement that three test results were needed for each layer. The initial Materials Action Plan pilot took place in Maryland in 2005.28

To get the plan underway, the LTPP regional support contractors developed site-specific sampling plans and coordinated all activities with the highway agencies. The regional contractors were present during the sampling operations to ensure that the plans (approved by the LTPP program and the highway agencies) were followed. They identified and marked all sampling locations, performed some of the field testing, and were responsible for labeling, packing, and shipping samples to the laboratories involved in the testing and for completing the sampling data sheets.

The highway agencies' responsibilities were to provide traffic control, perform field sampling, and patch the holes where samples were taken. Due to the multiple activities at the site, coordination between the agency's field crew and the regional support contractor's crew was essential to ensure that samples were properly collected and tests were performed without interruption. A new, Web-based system was developed to track the layers and samples as they were collected, shipped, and tested, and as laboratory results were loaded into the database.

One challenge encountered during the SPS materials sampling was the lack of material to perform some of the laboratory tests. To resolve this, samples were combined for testing. A special form was used to log the different samples that should be combined for performing certain tests. For example, two or more bags of unbound granular material were combined to perform the resilient modulus testing (P46), and four cores were used to perform the asphalt resilient modulus testing (P07).

In the field, the regional contractor staff had the responsibility of performing some of the tests, mainly the dynamic cone penetrometer for unbound layers, as shown in figure 7.13, and also thickness measurements and moisture determination.

The plan was to use two laboratories, one to perform the resilient modulus testing and one to perform the remaining tests. In the end, the contract for both testing functions was awarded to a single contractor; thus all testing was performed at one location with the exception of the coefficient of thermal expansion (P63) test, which was performed in the Concrete Laboratory at the FHWA highway research center.

The contracting laboratory was AASHTO-certified for performing standard procedures on soils, aggregates, asphalt binder, asphalt emulsion, and hot-mix asphalt and also had a current laboratory assessment from the ASTM Cement and Concrete Reference Laboratory. The contracted laboratory's quality management system was certified for compliance with AASHTO Standard Practice R 18, Standard Practice for Establishing and Implementing a Quality Management System for Construction Materials Testing Laboratories. The contractor was required to have a QC program to provide control over the activities that can affect the quality of materials laboratory testing. The LTPP program conducted a startup inspection visit in October 2005, with additional visits in the following years to inspect resilient modulus testing procedures and quality management compliance with AASHTO Standard Practice R 18. Upon approval, data that passed the quality assurance (QA) review were transmitted to the LTPP regional support contractors for input to the LTPP database. The primary objective of the QC/QA activities was to ensure that the required data collected were of high quality.

FIGURE 7.13. LTPP regional support contractor staff use the dynamic core penetrometer to determine the strength and density of the subgrade at the SPS-5 site in Minnesota. |

Under the Materials Action Plan, approximately 95 percent of the materials tests ordered from the LTPP contract laboratory were able to be tested using the rigorous LTPP test protocols, with a total of 10,863 tests performed. Although the collection of samples for future use was strongly supported by the LTPP program, it was assigned a lower priority due to financial constraints. Of the desired samples, 74 percent of the 12-inch (305-mm) core samples and 61 percent of the 4-inch (102-mm) core samples were delivered to the Materials Reference Library (1,544 cores in total), and 1,488 samples of bulk material were added to the collection. Data from tests not previously performed were added to the database, corrections were made to some pavement structure information from new field investigations, and, where possible, previous data deficiencies were corrected. The final report for this effort provides extensive detail on the amount of data collected and the reduction in missing data elements in the LTPP database.29

Data that can be collected at the end of a test section's life can help to improve understanding of the causes of premature pavement failure and, in exceptionally long-lasting pavements, the reasons for superior performance. Ideally, whenever an LTPP pavement test section fails, is scheduled for replacement or rehabilitation, or is removed from an LTPP experiment for other reasons, a forensic study would be conducted to investigate in detail the processes of pavement deterioration and failure. By illuminating the causes and mechanisms of pavement distresses, forensic data can be used to design and implement an effective rehabilitation strategy for the pavement and prevent similar failures from occurring in the future. Forensic data are essential to improving design practices and updating construction techniques and can be valuable in the development or calibration of performance-prediction models. End-of-life evaluations also provide an opportunity to collect missing or incomplete test section data for the LTPP database.30

Forensic investigations are considered an important element of the LTPP program; however, funding constraints made implementation difficult. In 2004, the program developed a manual, Framework for LTPP Forensic Investigations–Final, to promote consistency in forensic studies and maximize their benefits.31 In 2008, FHWA funded four LTPP forensic studies. These studies examined hot-mix asphalt pavements that were exhibiting cracking and rutting:32

Other highway agencies have conducted their own forensic studies as well, notably Connecticut in connection with the Seasonal Monitoring Program, Texas (SPS-1), Colorado (SPS-5), Arizona (SPS-9, Superpave), Virginia (SPS-1), Quebec (GPS-3), and North Carolina (GPS-2).

In November 2012, in support of NCHRP Project 01-49, Guidelines for Conducting Forensic Investigation of Highway Pavements, the LTPP program sponsored a national workshop that brought together representatives of highway agencies to discuss their current agency practices and review the new national guidelines developed in Project 01-49.36 The workshop presented the complete forensic investigation process that was established in the guidelines, from study initiation through the use of nondestructive and laboratory techniques to investigation closeout.

The LTPP program has played an important role in developing national guidelines that promote the effectiveness and efficiency of future forensic investigations of LTPP test sections as well as other pavement studies by highway agencies. Future forensic investigation of LTPP test sections that have failed prematurely or have shown unexpectedly good performance will contribute great value to the understanding of the variables that affect pavement performance.

The LTPP program mounted three successful multiyear data collection efforts to improve the quality and quantity of the program's monitoring of climate, traffic, and materials data. The SMP was a 12-year study with the goal of enriching the understanding of the effects of climatic variations in temperature and moisture on pavement responses. This program resulted in a wealth of new environmental data.

The LTPP SPS Traffic Data Collection Pooled-Fund Study was organized to improve the LTPP traffic data by providing uniformity in data collection equipment, regular equipment calibrations, and daily QC checks of the data. This 11-year data collection effort gathered upwards of 400 million vehicle records and 2.3 billion individual axle-load records–the largest quantity of research-quality traffic data ever assembled. These traffic data are now available to researchers in raw form or summarized as axle-load probability distributions.

The Materials Action Plan was carried out over 5 years to address priority materials data needs for SPS-1, -2, -5, -6, and -8 projects. Under this effort, 10,863 materials tests were performed under the rigorous LTPP test protocols. The materials data were improved significantly, and more than 3,000 cores and other samples were added to the Materials Reference Library.

FIGURE 7.14. Workers prepare a trench for forensic investigation of an SPS-5 test site in Arizona. |

Finally, a rich source of performance data is the forensic investigation of test sections as they reach the end of their useful lives. The LTPP program has developed a framework for forensic evaluation of pavements, participated in the development of national guidelines for forensic studies, and conducted four studies on hot-mix asphalt test sections.

The investment in the special efforts described above and the ongoing, routine data collection activities discussed in chapter 6 have yielded an unprecedented amount of pavement performance information. The systems developed to store, manage, secure, and distribute this information to the public are described in the next chapter.