U.S. Department of Transportation

Federal Highway Administration

1200 New Jersey Avenue, SE

Washington, DC 20590

202-366-4000

Federal Highway Administration Research and Technology

Coordinating, Developing, and Delivering Highway Transportation Innovations

| REPORT |

| This report is an archived publication and may contain dated technical, contact, and link information |

|

| Publication Number: FHWA-HRT-15-049 Date: April 2015 |

Publication Number: FHWA-HRT-15-049 Date: April 2015 |

© hxdyl/Shutterstock.com. The LTPP program continues to develop and distribute its data, knowledge, and software tools to improve understanding of pavement performance, the quality of pavement research, and industry practice. |

While providing a treasure trove of information for researchers, the LTPP program also focuses on providing products to pavement practitioners at the local, State/Province, and national levels. By developing and following strategic data analysis and product development plans, the program has directly supported a wide range of improvements to pavement management, design, and construction practices. These benefits have resulted in cost savings in the millions of dollars for highway agencies.

When pavement designers in Houston determine what materials and base structure an alternate truck route should incorporate, or when engineers ponder the effects of the hot dry climate on highways in Phoenix, the LTPP database is freely accessible to help them make crucial choices. Thanks to the foresight of a generation of engineers and administrators who knew the value that comprehensive pavement performance data would have for the future, the LTPP program has more than paid for itself in delivering dozens of products that have improved our highway system.

This chapter describes some of the more important contributions achieved through LTPP research, data analysis, and product development. In numerous studies over the years, pavement researchers have used LTPP data in the evaluation and development of design procedures, most recently in the development of the Guide for Mechanistic-Empirical Design of New and Rehabilitated Pavement Structures (MEPDG). Analysis has led to improvements in pavement management systems, with new insights into the performance of rehabilitation and maintenance activities. LTPP data analysis has also led to many innovations and tools that pavement researchers and engineers are using to advance pavement quality and durability.

Designing the experimental matrices, defining data collection procedures, and developing and populating the database are all critical steps to enable the LTPP program to address its end objectives. Answering key questions requires a robust data analysis program. Although LTPP data analysis activities have been impacted by funding challenges over the years, nonetheless, significant resources have been invested into analyzing the data, and substantial returns have already been realized. Some notable examples are introduced in this section.

| Key Milestones in Turning LTPP Data Into Results | |

|---|---|

| 1992 | First calibration protocol for FWDs finalized |

| 1994 | First SHRP-LTPP data analyses published |

| 1997 | NHI develops LTPP-based distress rating course |

| 1997 | Vehicle Classification Report published |

| 1998 | LTPP-ASCE Data Analysis Contest introduced |

| 1998 | NCHRP MEPDG project begins using LTPP data to develop new design software |

| 1999 | FHWA-LTPP updates SHRP Manuals of Practice |

| 1999 | AASHTO adopts LTPP-developed Standard Practice R 32 |

| 1999 | LTPP Strategic Plan for Data Analysis adopted |

| 2001 | LTPP Product Plan published |

| 2001 | ProVAL software released |

| 2006 | Pavement Performance Forecast Online developed |

| 2007 | ProVAL software's data format becomes ASTM standard |

| 2010 | Major review and update of LTPP Strategic Plan for Data Analysis |

| 2011 | LTPP Dynamic Modulus Prediction software developed |

| 2013 | Update of the LTPP Strategic Plan for Data Analysis |

| 2014 | ProQual software updated |

SHRP-P-020 Contract–Data Analysis

As the first major effort under the Strategic Highway Research Program (SHRP) to use LTPP data for specific analytic purposes, the SHRP P-020 contract supported a number of studies to accomplish a variety of research objectives:

The studies, conducted in 1992 and 1993, utilized GPS data collected during the first 5 years of the program, since collection of SPS data was just getting underway. The results were published in five volumes.2 The fifth volume, Lessons Learned and Recommendations for Future Analyses,3 was notable in its identification of problems and deficiencies of the LTPP database and changes that would improve its utility for future researchers. The report identified procedures for developing predictive models and proposed procedures for evaluating design methods. The SHRP P-020 studies laid the foundation for later analyses using LTPP data.

Pavement Maintenance Studies–SHRP-H-106 Reports

The SHRP H-106 project, Innovative Materials Development and Testing, 1991–93, was designed to evaluate the cost-effectiveness of pavement maintenance materials and procedures in the most extensive pavement surface maintenance experiment that had ever been conducted. The experiment studied the performance of unique combinations of materials and treatment methods for pothole repair (eight test sites, 1,250 potholes) and transverse and longitudinal crack sealing and filling (22,000 ft [6,700 m]) in asphalt concrete (AC) pavements and for joint resealing (1,600 joints) and partial-depth repair (four test sites, 1,600 partial-depth repairs) in Portland cement concrete (PCC) pavements. The study sites were distributed through the program’s four climatic regions, and the performance of the maintenance treatments was evaluated 18 months after the repairs were made. SHRP H-106 generated comprehensive reports and manuals of practice for each of the maintenance activities.4,5,6,7

When the SHRP program concluded, the LTPP program under the Federal Highway Administration (FHWA) continued annual evaluations of the test sites between August 1993 and December 1997 through its Long-Term Monitoring of Pavement Maintenance Materials Test Sites study. At the end of the study, the LTPP program published extensive reports on PCC partial-depth spall repair,8 joint resealing,9,10 crack treatment,11 and pothole repair.12 In 1998, a 5-year data analysis review of the maintenance of SPS-313 and -414 was published, followed by an update of the original four SHRP Manuals of Practice in 1999 with information collected during the continued monitoring, as described in the LTPP Products section.15

FHWA Broad Agency Announcement

After the LTPP program transitioned from SHRP to FHWA, a series of LTPP data analysis contracts were funded under a Broad Agency Announcement (BAA). The BAA was issued before the development of the Strategic Plan for LTPP Data Analysis, discussed below, and the majority of the work was performed between 1994 and 1996. Examples of projects completed under the BAA include the following:

Following the BAA, FHWA began to use an umbrella data analysis contract or data analysis IDIQ–indefinite delivery/indefinite quantity–contract for most LTPP data analysis activities.

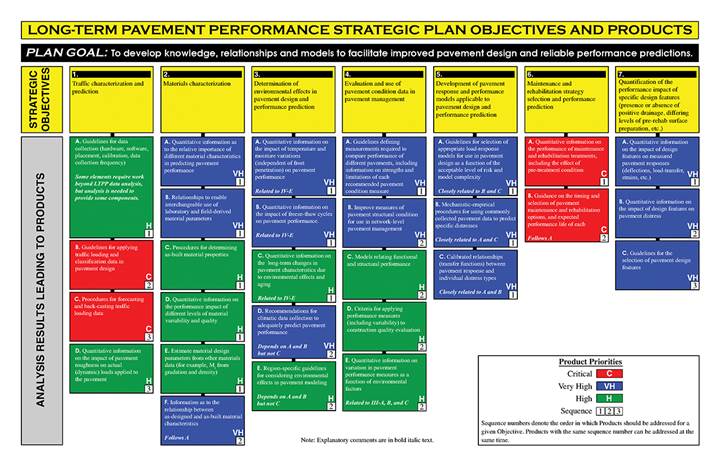

With such a wide array of potential analysis efforts, the LTPP program recognized the need to develop a strategic plan for LTPP data analysis. Led by the Transportation Research Board (TRB) Expert Task Group (ETG) on LTPP Data Analysis and the program office, this focused effort in the late 1990s benefited from the participation of subject matter experts across the pavement spectrum.23 The LTPP Data Analysis ETG took on responsibility for developing a strategic plan using LTPP data “to develop knowledge, relationships, and models to facilitate improved pavement design and reliable performance predictions.”24 Soliciting input from academic, industry, agency, and other pavement experts, the ETG identified a wide array of analysis topics and outcomes. Through a series of meetings and other interactions, these items were organized into seven strategic objectives:

Each of these objectives had multiple “product outcomes,” further grouping the analysis activities to ensure optimum return on investment.

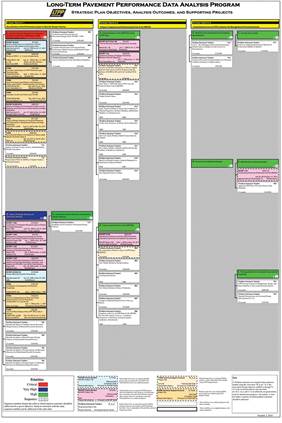

Upon reaching consensus on the Strategic Plan, the LTPP Data Analysis ETG formally voted to implement it at its meeting on November 8–9, 1999, and advocated that all partners and participants adopt it as well. The original plan is shown in figure 10.1 and figure 10.2. The LTPP program office assumed responsibility for maintaining the Strategic Plan, including periodically organizing in-depth reviews of the plan and its constituent problem statements.

In September 2010, a LTPP Pavement Analysis Forum was held in Irvine, California, where 50 pavement specialists from highway agencies, universities, and consulting firms met to review and refine targeted analytical outcomes under the Strategic Plan (see sidebar). The 3-day forum was a joint effort of the LTPP program office and FHWA management, along with the TRB LTPP Committee.25 The group developed 122 analysis outcomes, project definitions, or research problem statements, which were provided to the TRB LTPP Committee for review and recommendation for implementation in future years.26,27

LTPP Pavement Analysis Forum Participants at TRB Beckman Center in Irvine, CA, September 2010. Front Row (left to right): Larry Wiser, Ahmad Ardani, David Orr, Susan Tighe, Eric Weaver, Judith Corley-Lay, Steve Jessberger, Mike Heitzman, Shie-Shin Wu, Tahar El-Korchi, Nadarajah Sivaneswaran, Gil Baladi, Newt Jackson. Second Row: Jane Jiang, Amelia Mathis, Deborah Walker, Wes Yang, Olga Selezneva, Julie Vandenbossche, Bob Lytton, Lynne Irwin, Jerry Hajek, Cheryl Richter,Neil Hawks, Danny Dawood, Ralph Haas, Tom Yu, Amir Hanna, Andy Johnson, Ray Moore, Rick Reel, Karim Chatti, Robert Raab, Becky McDaniel, Jon Epps, Tom Baker, Luis Rodriguez. Third Row: Gary Elkins, Kevin Senn, Brian Schleppi, Andy Mergenmeier, Shelley Stoffels, Jonathan Groeger, Jack Springer, Ben Worel, Charlie Churilla, Mark Gardner, Aramis López, Tom White, Frank Meyer, John Donahue. Not in the picture: Mike Ayers. Absent: Carl Monismith. |

FIGURE 10.1. Introduction to the original LTPP Strategic Plan for Long-Term Pavement Performance Data Analysis, page 1, as adopted in 1999. |

FIGURE 10.2. Graphical compilation of the 1999 LTPP Strategic Plan for Long-Term Pavement Performance Data Analysis, its strategic objectives and product priorities. |

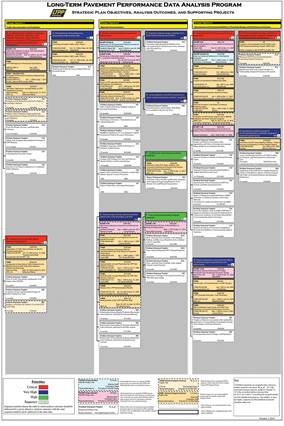

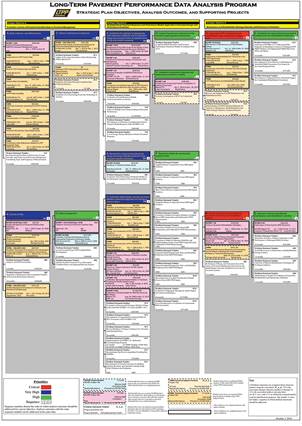

During the pavement analysis forum, the Strategic Plan was expanded with the addition of two new strategic objectives:

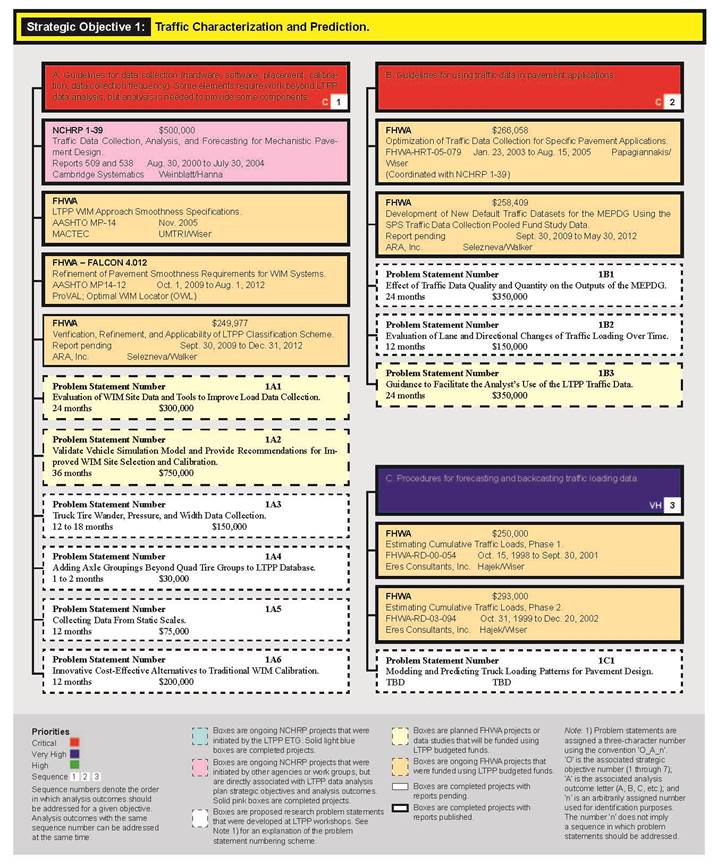

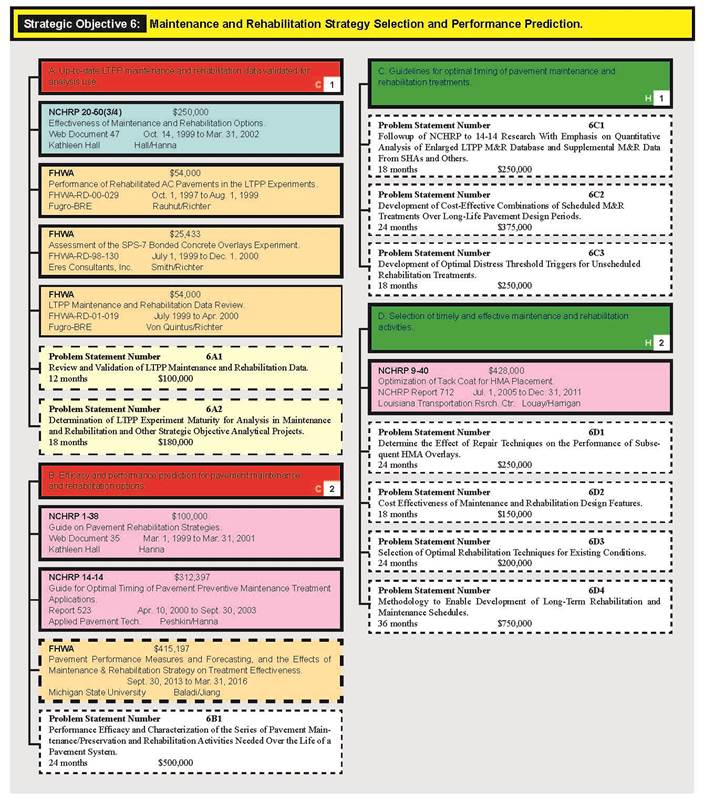

The plan is a living document, and has been revised and updated regularly since its adoption to show the status of analysis projects.28 Owing to the paper size required to legibly print the document on a single sheet of paper, the strategic data analysis plan was nicknamed the LTPP data analysis “tablecloth.” Figure 10.3 displays the plan, illustrating its size. Figure 10.4 and figure 10.5 show plan detail for Strategic Objectives 1 and 6.

Over the years, many projects have addressed areas within the Strategic Plan. The LTPP program supported some of these projects, while others were supported by non-LTPP funds from FHWA or through the National Cooperative Highway Research Program (NCHRP) (see table 4.2, LTPP Timeline–Highway legislated and other funding sources). The following sections present examples of NCHRP- and FHWA-funded analysis research; however, for a complete view of progress in LTPP data analysis–studies planned, completed, and underway–refer to the Strategic Plan for LTPP Data Analysis.

|

|

|

| FIGURE 10.3. Illustration of the expanded strategic plan for LTPP data analysis showing the extent and complexity of the plan as it has evolved since 1999 (October 30, 2014). | ||

FIGURE 10.4. Excerpt of the expanded strategic plan for LTPP data analysis, showing analysis outcomes, supporting projects, and problem statements for Strategic Objective 1: Traffic Characterization and Prediction (October 30, 2014). |

FIGURE 10.5. Excerpt of the expanded strategic plan for LTPP data analysis, showing analysis outcomes, supporting projects, and problem statements for Strategic Objective 6: Maintenance and Rehabilitation Strategy Selection and Performance Prediction (October 30, 2014). Refer to the legend in figure 10.4 for further explanation. |

LTPP Analysis Research Funded by NCHRP

In 1999 and 2000, a series of LTPP data analysis projects were awarded and administered through NCHRP under Research Field 20–Special Projects. These projects, which have all been completed (results available online), are listed in table 10.1.

| Project Number(s) | Title |

|---|---|

| NCHRP 20-50(10&16) | LTPP Data Analysis: Influence of Design and Construction Features on the Response and Performance of New Flexible and Rigid Pavements29 |

| NCHRP 20-50(10) | LTPP Data Analysis: Factors Affecting the Performance of Flexible and Rigid Pavements (folded into NCHRP 20-50(10&16)) |

| NCHRP 20-50(14) | LTPP Data Analysis: Significance of “As-Constructed” AC Air Voids to Pavement Performance30 |

| NCHRP 20-50(2) | LTPP Data Analysis: Relative Performance of Jointed Plain Concrete Pavements With Sealed and Unsealed Joints31 |

| NCHRP 20-50(3&4) | LTPP Data Analysis: Effectiveness of Maintenance and Rehabilitation Options, 200232 |

| NCHRP 20-50(5) | LTPP Data Analysis: Variations in Pavement Design Inputs33 |

| NCHRP 20-50(7&12) | LTPP Data Analysis: Daily and Seasonal Variations in Insitu Material Properties34 |

| NCHRP 20-50(8&13) | LTPP Data Analysis: Factors Affecting Pavement Smoothness35 |

| NCHRP 20-50(9) | LTPP Data Analysis: Feasibility of Using FWD Deflection Data to Characterize Pavement Construction Quality36 |

LTPP Analysis Research Funded by FHWA (Non-LTPP Funds)

Several research efforts sponsored or conducted by FHWA appear in the Products or Benefits section later in this chapter. Following is a sampling of specific studies undertaken in recent years.

Fulfilling the LTPP Strategic Plan

Completing the research projects in the Strategic Plan for LTPP Data Analysis will require continued funding. Since the conception of the data analysis plan, a total of 211 projects have been identified (table 10.2). Although scores of analysis projects defined in the plan have been completed, more than 100 defined research projects remain to be performed, and new research needs will arise in the future. Some analysis projects are not ready for development of research problem statements because other underlying research has not been performed, or more data are needed. It is also recommended that many earlier findings derived from LTPP data be re-evaluated to determine if the short-term trends were correct. The additional data collection performed since early studies were finished (e.g., Effectiveness of Maintenance and Rehabilitation Options, completed in 199943) warrant consideration of follow-up investigations.

The TRB LTPP Committee continues to monitor the status of LTPP analysis projects and provide technical advice and assistance to FHWA concerning future direction of the projects. For example, in its 2011 letter report to FHWA and AASHTO, the Committee listed 22 analysis projects they considered to be of highest priority for early starts.44

To continue the LTPP analysis research, FHWA issued a second BAA in June 2013, with the purpose of providing sponsorship for a series of research projects involving innovative analysis of data obtained through the LTPP program to better understand pavement performance. As stated in the BAA, the projects that comprise the LTPP data analysis program serve two broad functions that must be addressed if LTPP is to fulfill expectations: (1) the projects provide the basis for identifying and developing products that engineers and managers can apply to design more cost-effective and better performing pavements; and (2) the projects check whether the data being collected are of the quality and completeness needed to answer questions about how and why pavements perform as they do.

While the “tablecloth” is the guiding document for most centralized LTPP data analysis activities, a number of additional investigations have been performed internally by the LTPP program office and LTPP contractor staff to improve the program’s overall operation.

One such example is the study of variability between distress raters (discussed in chapter 9).45,46 Using data from nine LTPP distress accreditation workshops, analyses regarding rater-to-rater variation were completed. It was found that significant variability was observed from one rater to the next, particularly with regard to severity levels for individual distresses, and that variability increased as distress quantities increased. Due to this study, the program implemented changes including adding time-series reviews and enhancing rater training activities.

Many State and Provincial highway agencies have performed analyses using LTPP data and have developed their own research programs incorporating LTPP standards as a basis for data acquisition and processing. The following pages describe a sample of these analyses.

| Research Vehicle | Studies Completed | Studies Ongoing | Studies Planned | Unaddressed Problem Statements Remaining |

|---|---|---|---|---|

| FHWA-LTPP Data Analysis Contracts (using LTPP budgeted funds) | 50 | 7 | 13 | |

| National Cooperative Highway Research Program | 26 | 11 | 0 | |

| Total | 76 | 18 | 13 | 104 |

Arizona SPS Analysis

Recognizing that much could be learned by analyzing the performance of the LTPP experiments within their own agency, the Arizona Department of Transportation (DOT) sponsored analyses of their SPS projects. These efforts were specifically targeted at evaluating pavement performance and determining “lessons learned.” Specific focus was given to the distress, longitudinal profile, and falling weight deflectometer (FWD) data sets. Distresses were grouped by failure mechanism (i.e., traffic/load-related and climate/materials-related) into structural and environmental damage indices, and these indices were tracked over time. Similarly, time-series investigations were made on deflection data to examine reductions in layer moduli and effective structural number, and on longitudinal profile data to track changes in International Roughness Index (IRI) values, power spectral density, roughness profiles, and filtered profiles (for short, medium, and long wavelengths) over time.

Cross correlations were also examined to study, for example, the impact of distress propagation on longitudinal profiles. One lesson learned was that roughness and roughness progression alone cannot be used to represent the health of a test section. Many test sections did not exhibit changes in roughness in proportion to the amount of fatigue cracking experienced, and sections that had clearly reached the end of their service lives did not necessarily have roughness values that would trigger a rehabilitation event. Arizona DOT, through the Arizona Transportation Research Center, is publishing these reports for their SPS-1 (structural factors for flexible pavements),47 -2 (structural factors for rigid pavements), -5 (rehabilitation of AC pavements), -6 (rehabilitation of jointed PCC pavements), and -9 (Superpave) projects.

Colorado LTPP Implementation

Like Arizona, the Colorado DOT (CDOT) recognized that improvements to internal processes could be made by analyzing their LTPP test sections. CDOT was proactive in examining their SPS-2 (structural factors for rigid pavements) and SPS-4 (preventive maintenance of flexible pavements) projects, starting with the construction practices. In the case of the SPS-2 experiment, a follow-up study found that using a 14-ft (4.3-m) slab width instead of a 12-ft (3.7-m) width was equivalent to adding 1 inch (25.4 mm) of slab thickness. Based on this finding, CDOT adopted the 14-ft slab in 1996 based on the results of the LTPP SPS-2 experiment, and continues to follow this practice today.48,49

Before constructing the Colorado SPS-4 project, CDOT used a standard double cut for 3/8-inch (9.5-mm) joints. In building the SPS-4, CDOT learned that a single-cut, 1/8-inch (3.2-mm) joint was equally effective, while being less labor-intensive and requiring less sealant material. A cost-benefit analysis was performed, and it determined that going to the single-cut standard resulted in a savings of 57 cents per linear foot of joint, which equated to almost $1.7 million in savings for 100 mi (161 km) of two-lane concrete pavement.50

Kansas Binder Selection

When implementing the Superpave performance grade binder specifications, the Kansas DOT (KDOT) turned to a popular LTPP product to optimize binder selection: LTPPBind. KDOT uses the software as an integral part of their pavement design process. KDOT pavement designers use LTPPBind to determine the performance grades at the various depths of the pavement structure and for different traffic conditions. The software incorporates actual site temperatures, providing an improvement to the temperature information in the original SHRPBind software. In many instances, KDOT found that LTPPBind changed the binder grade, which provided improved pavement performance.51

MnROAD

Constructed near Albertville, Minnesota, in 1994, the MnROAD facility (figure 10.6) was designed to study cold weather pavement design, materials, and performance for both low-volume and interstate test sections. Primarily funded by the Minnesota DOT and the Minnesota Local Road Research Board, MnROAD activities have also been supported by industry, public-, and private-sector organizations at the State, national, and international levels.

The LTPP program and MnROAD staff work closely together, and many LTPP data collection activities have taken place on MnROAD sections, including manual and automated distress surveys (MnROAD uses a modified LTPP manual distress process), longitudinal and transverse profile measurement, and FWD testing. MnROAD has LTPP-like seasonal monitoring data, and once housed an onsite FWD calibration center. There are 11 LTPP test sections located at the MnROAD facility of which three remain active today.

MnROAD has gone through two phases since it opened to traffic in 1994. As the first set of MnROAD studies was nearing completion, a second phase of research was begun that largely involved reconstructing many of the original test sections. Phase 2 activities are guided by the Transportation Engineering and Road Research Alliance (a research governance structure formed in 2004), and construction/reconstruction activities are nearing completion. Phase 3 will begin in 2016 with a focus on maintenance and rehabilitation. It is very possible that the LTPP test sections will be used during this phase.

Among key findings from the first generation of MnROAD studies were revised spring load restriction and winter load increase policies, improved low temperature cracking resistance and pavement sealing practices, and mechanistic-empirical design methods for concrete and flexible pavements. These results save Minnesota $33 million annually.

© Minnesota Department of Transportation FIGURE 10.6. MnROAD low-volume road and mainline test roadways owned and operated by the Minnesota Department of Transportation (2003). |

New Jersey Seasonal Monitoring Program

As part of its preparations to implement the MEPDG, the New Jersey DOT initiated a seasonal variation and material characterization study in 2001. Twenty-four test sections across the State were instrumented following LTPP SMP protocols. FWD and seismic testing were performed monthly over a 2-year period to supplement the continuous climatic data collection and to investigate the impact of environmental parameters on pavement response. Through regression analyses, temperature and seasonal correction factors were developed specific to New Jersey conditions.52

New Jersey IRI Models for Pavement Management System

The New Jersey DOT has also used LTPP data to verify and refine models that are used in its pavement management system to determine when a pavement is in need of repair. The State’s system had a default IRI performance model that triggered rehabilitation at 170 inch/mile (0.0027 m/km) or 9 years. To validate these criteria, the State accessed the data from its SPS-5 (rehabilitation of AC pavements) and SPS-9A (Superpave) test sites using DataPave Online. The results predicted pavement life as long as 20 years before an IRI of 170 inch/mile would be reached and any type of treatment would be required. Neither New Jersey’s data set (using some of the State’s 1999 construction projects) nor data from DataPave Online (using LTPP SPS test sites) ever reached the trigger IRI value of 170 inch/mile. Access to LTPP data allowed New Jersey to develop realistic IRI prediction models.53

Pennsylvania Joint Design

The Pennsylvania DOT (PennDOT) has a pavement network with over 3,200 mi (5,150 km) of PCC pavements. Based on LTPP pavement performance data, PennDOT modified its PCC joint designs from using skewed joints to constructing perpendicular joints. Multiple benefits were realized with this modification, including reduced construction and maintenance costs, fewer maintenance-related disruptions to traffic, and a smoother ride for motorists.54

Texas SMERP–Supplemental Maintenance Effectiveness Research Program

The SMERP study was designed to “establish the effectiveness of typical and promising maintenance treatments used in Texas to prolong the life of asphalt pavements.”55 The Texas DOT (TxDOT) allocated $1 million to build test sections of preventive treatments that were of interest to Texas but were not being studied in the SHRP-LTPP national experiment. By analyzing the data from the LTPP SPS-3 experiment (preventive maintenance for flexible pavements), with 16 sites in Texas, and the SMERP studies, TxDOT hoped to identify the best treatment selection strategies and get the best return on its preventive maintenance funds. In designing the experiment, TxDOT followed the basic design of the LTPP SPS-3 experiment and used an ASCII data format that would be compatible with output from the LTPP database so that SMERP and LTPP data could be combined for analysis. In 1993, at each of 20 test locations throughout the State, six treatment sections and a control section were established: asphalt rubber chip seal, polymer-modified emulsion chip seal, latex-modified asphalt cement chip seal, unmodified asphalt cement chip seal, fog seal, and a microsurfacing treatment (two sites did not have a fog seal or control section).56 The sites were inspected at 6 months and annually for 8 years, with nine sections surviving the full 8 years. The SMERP study resulted in treatment selection recommendations for TxDOT districts that were based on actual performance data. An important finding was that the pre-treatment condition of a pavement is a major determinant of a treatment’s effectiveness when deterioration is measured over time.57,58,59

Texas Evaluation of LTPP Data and Implementation of the Texas Transportation Institute Overlay Tester

Performance data from LTPP test sections were used by TxDOT to develop its performance prediction models for the Texas mechanistic-empirical flexible pavement design system. The proposed rutting model for HMA pavements was calibrated using rutting and traffic data from the Texas LTPP SPS-5 (rehabilitation of AC pavements) test sections and the National Center for Asphalt Technology Pavement Test Track. Predicted rutting was compared with measured rutting in the LTPP database. In investigations of the use of the Overlay Tester in predicting fatigue cracking in HMA pavements, LTPP data were used to develop and calibrate the transfer function in calculating the amount of fatigue cracking.60,61

The Texas Flexible Pavements Database

TxDOT used the LTPP database as an example to design its Texas Flexible Pavements Database.62 This database is being used to develop guidelines for local calibration of the MEPDG. A 5-year project was initiated to collect materials and pavement performance data on a minimum of 100 highway test sections around the State, incorporating both flexible pavements and overlays. Besides being used to calibrate and validate mechanistic-empirical design models, the data collected will also serve as an ongoing reference data source and diagnostic tool for TxDOT engineers and other transportation professionals.

External to the LTPP program, NCHRP Project 1-37(A), Development of the 2002 Guide for the Design of New and Rehabilitated Pavement Structures,63 was initiated to develop a replacement for the 1993 AASHTO Pavement Design Guide. Using increased computational speeds and improved understanding of key inputs (i.e., traffic loads, environment, and material properties), the project’s objective was to develop a more mechanistic-based design methodology. It soon became apparent to the project team that developing a mechanistic-empirical pavement design guide was going to require pavement data from coast to coast, and the LTPP database provided access to this critical information.

The LTPP database has contributed significantly to the enhancement of pavement evaluation and design through the development of the MEPDG and, later, the AASHTOWare® Pavement ME Design software developed to implement the MEPDG.64 It has been said that “without LTPP data for the national calibration, the MEPDG distress models could not have been validated for use throughout the country.” The distress and smoothness prediction models that are key to the MEPDG required calibration with measured long-term performance data that were available only from the LTPP database. The database is also serving as an extremely valuable tool in implementation of the new guide. For the guide to be efficient for individual agencies, the national models will need to be evaluated against local and regional performance data. The LTPP test section data provide a resource for highway agencies to use in determining whether local calibration is required.

“ Without LTPP data for the national calibration, the MEPDG distress models could not have been validated for use throughout the country. In addition, the LTPP data is invaluable to each State highway agency for its own local validation and calibration purposes.”

– Michael Darter, Applied Research Associates, Inc.65

Twice each year the TRB Data Analysis Working Group (DAWG), sponsored by the TRB LTPP Committee, organizes an international forum on the analysis of pavement performance data in connection with a major highway pavement conference (appendix A).66 Researchers are invited to informally present their work in progress, usually concerning the development of techniques for extracting and analyzing data and the early results of applying these techniques. Typical topics are model building, sensitivity analysis, and development of transfer functions linking structural response to distress. These forums have provided a venue where researchers can benefit from the input of others who are engaged in pavement research, design, maintenance, and rehabilitation and are interested in collecting, processing, and analyzing data and in developing insights into pavement performance. The analysis of LTPP data has frequently been the subject of research presented at DAWG forums, which serve to support and promote LTPP data analysis.

The ASCE-LTPP International Data Analysis contest is designed to encourage student involvement in analyzing LTPP data. As a result of the contest, several universities are using the LTPP data as part of their pavement curricula.

As a means to both further LTPP data analysis activities and introduce the next generation of pavement engineers to the LTPP database, FHWA and the American Society of Civil Engineers (ASCE) teamed up in 1998 to create the LTPP International Data Analysis Contest.67 The contest provides incentive for innovative use of LTPP data to solve common pavement engineering problems. Recently revamped, the contest offers general and challenge topics to contestants each year and has four entry categories (Challenge Topic, Partnership, Undergraduate Students, and Graduate Students). Winners are invited to present at the TRB Annual Meeting in Washington, DC, and winning papers are published by FHWA. The 2012 winner is pictured in figure 10.7.68

This successful competition has resulted in many universities implementing the LTPP data in their undergraduate and graduate curricula, and use of the LTPP data has expanded significantly since the contest began. The success of the contest has been due to the partnership between the LTPP program and ASCE and a great number of contributions through the years from ASCE’s Transportation and Development Institute’s Pavements Committee and its many members.

As analyses are performed, whether by the LTPP program office, NCHRP, or highway agencies as discussed in the previous pages, the logical next step is to develop useful and usable highway engineering products from these analyses that help to explain how and why pavements perform as they do. The following section covers some of the key products that have been developed as a result of the program.

FIGURE 10.7. Daniel Franta, a graduate student at the University of Minnesota, receives the 2012 ASCE-LTPP International Data Analysis Contest Winner award for his winning paper “Classification of Features of Pavement Profiles Using Empirical Mode.” Presenting the award is C. Michael Walton, then President of ASCE’s Transportation and Development Institute. |

After the first few years of data collection, the LTPP program began work on developing products that could be used by highway agencies to improve their practices. Product development became a requirement in 1998 under the Transportation Equity Act for the 21st Century (TEA-21). This act continued support of the program for 6 years with the following stipulation:

Under the program, the Secretary shall make grants and enter into cooperative agreements and contracts to (A) Monitor, material-test, and evaluate highway test sections in existence as of the date of the grant, agreement, or contract; (B) Analyze the data obtained in carrying out subparagraph (A); and (C) Prepare products to fulfill program objectives and meet future pavement technology needs.69

In the early days of the program, when data collection, processing, and quality control/quality assurance (QC/QA) procedures were being established, many products were developed in support of LTPP operations. The program has played a major role in the development of pavement-related guidelines and standards throughout its history. A partial listing of these achievements includes:

LTPP product development was elevated to a higher level by the language of TEA-21. In response to this charge, the program office with the support of FHWA management, requested that the TRB LTPP Committee evaluate five potential changes to the program:

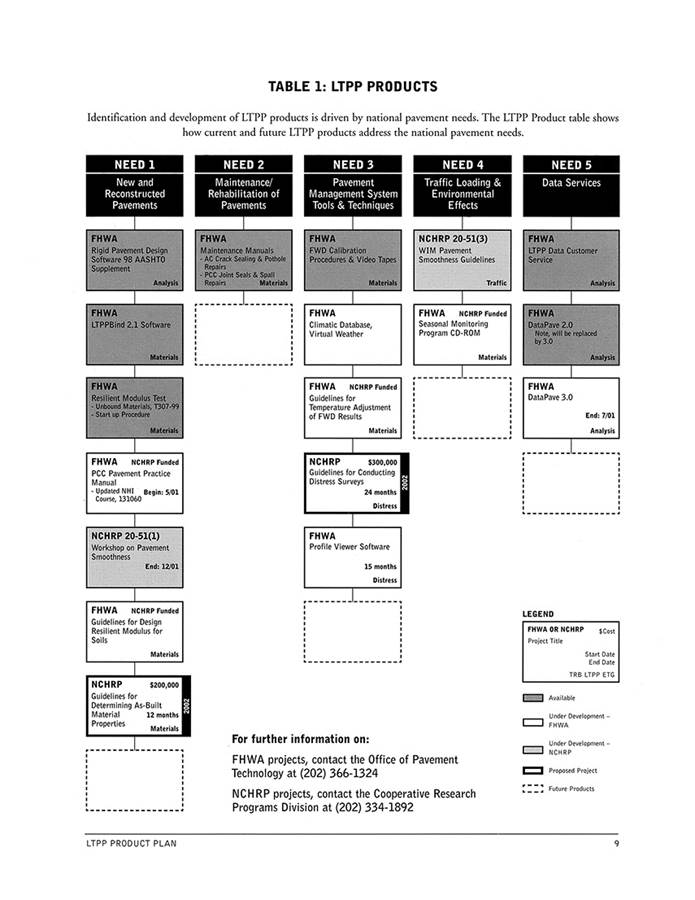

The TRB LTPP Committee supported the LTPP Product Subcommittee recommendation and asked the subcommittee to assist in creating the LTPP Product Plan. This document was published in 2001 (figure 10.8), and identified five “national pavement needs” on which product development activities would be focused:70

To achieve a fully integrated plan, the Product Subcommittee related these national pavement needs to the objectives in the Strategic Plan for LTPP Data Analysis. Research knowledge and findings contained in analysis reports are not ready to use and are only building blocks for future products. The goal articulated in the product plan, however, is to develop and deliver products that meet the following definition: LTPP products are ready-to-use guidelines, procedures, protocols, best practices, software, equipment, and other tools that are packaged for and delivered primarily to the management and technical staff in the highway agencies. It should be noted that a research report is not considered to be an LTPP product as defined in the plan.

LTPP products are ready-to-use guidelines, procedures, protocols, best practices, software, and equipment that are packaged for and delivered primarily to the management and technical staff in the highway agencies.

As part of the LTPP Product Plan, FHWA’s Office of Pavement Technology was charged with coordinating product development activities both internally with the LTPP program office and externally with supporting organizations such as the AASHTO Research Advisory Committee, Standing Committee on Highways, Subcommittee on Materials, and the Joint Task Force on Pavements. Funding issues have impacted the products area severely, with reductions in FHWA Office of Pavement Technology staffing and in dedicated moneys for product development. Nevertheless, the LTPP program has made significant advances in product development. In some cases, highway agencies have contributed money through pooled-fund studies for these activities (see sidebar). The program has frequently polled customers from highway agencies, industry, and academia to determine the needs of potential data users. In particular, chief engineers from the highway agencies have played a key role in identifying products needed to address national pavement needs.

LTPP products have benefited the pavement community by improving existing practices and providing tools to improve decisionmaking. Some of these products are described in the following sections. Although the listed products were developed both before and after the LTPP Product Plan was created, the products discussion is organized around the national needs and the goals included in the product plan. In addition, the objectives from the Strategic Plan for Data Analysis are listed for each national need. More products are listed in figure 10.8 and in the LTPP Benefits Report.71

FIGURE 10.8. LTPP Product table from the 2001 LTPP Product Plan showing how existing and planned LTPP products address national pavement needs. |

LTPP LEVERAGES FHWA'S TRANSPORTATION POOLED-FUND PROGRAMThe LTPP program and NCHRP were not the only sponsors of projects developing LTPP-related benefits. The transportation pooled fund program is a way for FHWA, States, and other organizations to partner when significant or widespread interest is shown in solving transportation-related problems.72 Under this arrangement, the partners pool funds and other resources to solve problems through research, planning, and technology transfer activities. The quality and accessibility of LTPP data lends itself to supporting a wide range of pavement-related activities as in the pooled-fund studies named below.

These are studies in which the LTPP program led the effort, but many other projects completed at the local, State/Province, and national levels have used LTPP data for the benefit of other operations and the pavement community as a whole. |

GOAL: Identify improved designs and design features with more accurate service predictions, tendencies, or trends.

To address the national need for improved design and construction of new and reconstructed pavements, the LTPP program has created software tools and test procedures. In addition, the pavement performance data played an important role in the development of the MEPDG as discussed above. This section covers a few of the LTPP products related to pavement design.

Rigid Pavement Design Software 1998 AASHTO Supplement

The LTPP Rigid Pavement Design software was developed to facilitate the application of the 1998 Supplement to the Guide for Design of Pavement Structures.73,74 The guidelines in this publication were developed based on studies conducted during NCHRP Project No. 1-30. The software automates the computations required to use the 1998 supplemental guidelines and includes separate tables for determining accumulated traffic loading, seasonally adjusted k-values, and depth to rigid layer, and for performing corner break and faulting checks. The magnitude of the cost savings from following the 1998 supplemental guidelines and using the software will vary with site conditions, with a 30 percent reduction being a reasonable average.

LTPPBind Software

Based on an analysis of the LTPP data and on the original binder selection software known as SHRPBind, LTPPBind is a Microsoft® Windows®-based program that can help highway agencies select the most suitable and cost-effective Superpave asphalt binder performance grade (PG) for a particular site. LTPPBind features a database of high and low air temperatures (minimum, mean, maximum, standard deviation, and number of years) for U.S. and Canadian weather stations, along with several modifications that provide users with the ability to (1) select PGs based on actual temperature conditions at their site and at the level of risk designated by their highway agency; (2) use either the original temperature models developed by SHRP or LTPP’s revised temperature models for determining a site’s binder PG; and (3) adjust PG selection for different levels of traffic loading and speed.75

Resilient Modulus Test Procedures for Bound and Unbound Layers The LTPP program has made significant contributions in characterizing material properties by improving test protocols as well as in providing a database of properties that are linked to actual field performance–both of which have furthered the development and use of mechanistic approaches in pavement engineering.

When establishing characteristics in the unbound layers–including subgrade, subbase, and base materials–resilient modulus is the property most relevant to pavement design. Consequently, establishing granular layer resilient modulus values has been a priority activity for the program. In the program’s early days, no concise test protocol existed for resilient modulus testing. This was observed when samples from the same location were tested (both in the same laboratory and in different laboratories) with wide variation in the test results.

Engineers use LTPPBind to more accurately determine the asphalt binder (cement) grade needed for their specific environmental conditions. A national review of LTPPBind shows it helps highway agencies save at least $50 million in construction costs each year by reducing the need to apply modified binders, a factor that can drive up the costs of construction.76

To address variability in the laboratory equipment and procedures, the program developed the LTPP laboratory startup procedure. This comprehensive procedure was developed to test the ability of the equipment and personnel to perform resilient modulus testing.77

At the same time, the program made a considerable investment in establishing LTPP Test Protocol P46–Resilient Modulus of Unbound Materials.78 This protocol has been widely adopted,79 a process that was accelerated first by a series of videos and then by a CD-ROM containing the videos and additional documentation.

Similar to its role in the development of Test Protocol P46, the LTPP program was responsible for developing a highly repeatable test protocol to determine asphalt resilient modulus–LTPP Protocol P07.80 The LTPP asphalt resilient modulus CD-ROM contains a 15-minute video describing the startup and QC processes as well as a comprehensive package of information and data related to resilient modulus. The P46 and P07 CD-ROMs are available through the LTPP Customer Support Service Center (Email: ltppinfo@dot.gov).

|E*| Computation of LTPP Sites

An FHWA-funded project was undertaken using the LTPP database to compute estimates of the dynamic modulus of HMA layers on LTPP test sections. Dynamic modulus, |E*|, is a fundamental property of AC mixtures that characterizes strain response as a function of loading rate and temperature. |E*| is one of the primary material property inputs in AASHTOWare® Pavement ME Design software;81 it is one of the primary properties measured in the Asphalt Mixture Performance Test protocol that complements volumetric mix design with mechanical properties; and it is one of the fundamental linear viscoelastic material properties that can be used in advanced pavement response models based on viscoelasticity.

FIGURE 10.9. LTPP |

In addition to populating the LTPP database with |E*| data, the project developed a user-friendly software, LTPP (known as LTPP Star), to facilitate |E*| computations (figure 10.9). The software can batch process data from a file to compute large quantities of |E*| estimates in accordance with the model hierarchy. This software can be very useful for agencies that would like to estimate |E*| using legacy data sets or those limited to older test procedures,82 and it is available free on the LTPP InfoPaveâ„¢ Web site or from the LTPP Customer Support Service Center (Email: ltppinfo@dot.gov).

Researcher’s Guide to the Long-Term Pavement Performance Thickness Data

A byproduct of the LTPP-sponsored research, “Review of LTPP Layer Thickness Data” is the new guide, Researcher’s Guide to the Long-Term Pavement Performance Thickness Data, which helps database users understand the differences between (and, thus, appropriate uses of) the layer thickness data found in different database tables.83

GOAL: Identify cost-effective methodologies and strategies for the rehabilitation and maintenance of existing pavements.

Many highway pavement engineers and managers have asked the question, what type of treatment do I apply and when do I apply the treatment to extend the life of my pavements? These questions have been and continue to be major issues for highway agencies. Although there are no easy answers, the LTPP program has developed the following products to address these concerns.

Pavement Treatment Effectiveness

A national site evaluation conducted by the LTPP program on the preventive maintenance experiments after 5 years of service yielded new understanding of the effectiveness and optimal timing of the treatments.84,85 The SPS-3 (structural factors for flexible pavements) and -4 (structural factors for rigid pavements) experiments were constructed in 1990, and in 1995, early field performance information was collected.

Crack sealing, slurry seals, chip seals, and thin hot-mix overlays were evaluated in the SPS-3 analysis,86 and under sealing and joint sealing in SPS-4.87 The analyses considered three important characteristics of the preventive treatments: performance, timing of application, and cost-effectiveness.

The field review and evaluation of the SPS-3 and -4 test sections were valuable technology transfer tools, and involved a sharing of experiences among the highway agencies as part of the process. As a result, maintenance treatments are better understood throughout the industry, and improved materials and construction specifications have been identified.

Pavement Maintenance Manuals of Practice

As mentioned in the LTPP Data Analysis section, the SHRP-H-106 project (Innovative Materials Development and Testing) monitored 22 sites throughout the United States and Canada to evaluate the performance and cost-effectiveness of maintenance materials and procedures. The project resulted in the publication of a set of manuals on asphalt and concrete repair. In 1999, the LTPP program revised and updated the original four SHRP manuals with the latest long-term performance and cost-effectiveness information generated by its continued monitoring of the SHRP-H-106 project sites. The manuals cover the performance of repair materials and methods, the availability and relative costs of repair materials, and the planning, designing, construction, and performance monitoring for the repair activities.

GOAL: Identify improved measurement and prediction tools.

The LTPP program is a project-level program, but the data collection guidelines and procedures and equipment protocols are also useful for network-level programs, such as pavement management systems. The following products have contributed to the quality of the pavement condition data collected by highway agencies to populate their pavement management systems and to help them determine which pavement sections should receive some type of treatment or rehabilitation.

Distress Identification Manual

The LTPP program developed the Distress Identification Manual for the Long-Term Pavement Performance Program (Standard Edition)92 to establish a consistent, uniform basis for collecting pavement distress data. The manual is divided into three sections, each focusing on one type of pavement: AC, PCC, and continuously reinforced concrete pavement (CRCP). It provides a common language for describing cracks, potholes, rutting, spalling, and other distresses being monitored by the program, and contains color photographs, drawings, and text that clearly label, describe, and illustrate each type of distress. Many highway agencies have adopted the manual’s procedures and definitions.

The Local Technical Assistance Program, with assistance from the FHWA Resource Center, developed four pocket versions of the manual:

Created with the field technician in mind, the pocket editions are made of durable plasticized material (figure 10.10). They have not been updated, however, and do not reflect the most recent definition for every distress type.

The fifth and latest version of the standard edition was published in May 2014. The manual and the pocket guides are available by contacting the LTPP Customer Support Service Center (Email: ltppinfo@dot.gov).

FIGURE 10.10. Distress Identification Guide, Asphalt Concrete Pavements , one of the five pocket versions of the Distress Identification Manual that were created for use by field technicians. |

FWD Calibration Procedures

Early in the LTPP program, the need for FWD calibration procedures and regional calibration centers was identified as a priority. The original calibration protocol was finalized in 1992, and calibration centers were established in Pennsylvania, Texas, Minnesota, and Nevada (the latter eventually was moved to Colorado). These centers provided calibration services not only for LTPP FWDs, but also for FWDs operated by highway agencies and private consultants. In the first 3 years of center operation, many of the non-LTPP units were found to be significantly out of calibration. Hence, the LTPP calibration centers provided an essential public service that resulted in significant construction savings, especially in situations where design is driven by FWD measurements, such as flexible pavement overlay design and jointed rigid pavement load transfer rehabilitation design. Since 1997, more than 500 FWD calibrations have taken place at these centers.

Considering that the LTPP FWD calibration centers had been operating with essentially the same equipment and procedures since 1992, the Falling Weight Deflectometer Calibration Center and Operational Improvements Pooled-Fund Study, TPF-5(039), was initiated in 2004 to improve the calibration process and update the calibration center equipment and software.94 The study’s reports contain the new protocol, equipment specifications, and other updated specifications of interest to engineers and technicians who perform structural evaluation of pavements.95,96 The new calibration equipment is highly portable and allows calibrations to be performed at a location of the FWD owner’s choosing. The new protocol has been implemented at all of the FWD calibration centers operated by State highway agencies, for which technical support and QA audits have been assumed by the AASHTO Materials Reference Laboratory, as noted in chapter 6. These centers continue to be used by highway agencies and private consultants to calibrate their FWDs. Accurate data that are a direct result of the calibration procedure yield large dividends to stakeholders in the form of improved decisions and increased efficiency.

Perhaps the most significant outcome of the FWD pooled-fund study was AASHTO’s adoption of the new calibration system as Standard Practice R 32-09, Calibrating the Load Cell and Deflection Sensors for a Falling Weight Deflectometer, in 2009 (updated in 2011).97,98 The new procedure is demonstrated in a video.99 It has been adopted by Denmark and Australia, and other countries are considering using the procedure, as well.

The most significant outcome of the FWD pooled-fund study was AASHTO’s adoption of the new calibration system as Standard Practice R 32, Calibrating the Load Cell and Deflection Sensors for a Falling Weight Deflectometer.

ProVAL is the first and only software application that can read data from different pavement profilers and unify them using a common data format.

Pavement Profiler Standards

In 2002, FHWA initiated a pooled-fund study, Improving the Quality of Profiler Measurement, TPF-5 (063), to assist in developing AASHTO standards for QA programs related to ride quality data collection, and to establish a level of integrity to pavement profiler measurements through calibration processes and verification procedures.100 The resulting standards included:

One of the main objectives of this multiyear, multitasked, $2.4 million study was to deliver a profile analysis software program. The Profile Viewing and Analysis (ProVAL) software was released in 2001, and its native data format became an ASTM International standard in 2007, E 2560-07, Standard Specification for Data Format for Pavement Profile. The free software enables users to view and analyze pavement profiles collected by profile measurement equipment.105 Different equipment manufacturers use different data formats and standards, making it difficult to compare profiles collected by diverse brands of equipment. ProVAL is the first and only software application that can read data from numerous pavement profilers and unify them using a common data format.106 The software is continually upgraded, and new features are added.

GOAL: Identify improved weigh-in-motion (WIM) technology and data interpretation that will more accurately determine specific traffic volumes and determine the environmental effects on pavement performance.

Understanding the performance of pavements requires knowing the traffic loading and environmental conditions imposed on them. Over the years, the LTPP program has contributed to improving traffic data monitoring by objectively examining the types of traffic data collection equipment, developing standard equipment calibration and validation protocols, and identifying quality checks to perform on the data. In addition, the program has improved its climatic database by using data from the National Aeronautics and Space Administration’s (NASA) Modern Era Retrospective Analysis for Research and Applications (MERRA) to establish weather data for the LTPP test sites. This section covers some of the LTPP products related to the impact of traffic and climate on pavement performance.

Traffic Data Collection Advancements

The LTPP program has been on the leading edge of traffic monitoring technology. The program has developed and continues to refine several procedures to address variability in traffic data that can be attributed to multiple factors: equipment type, calibration procedures (or lack thereof), and duration of monitoring. These procedures include the WIM calibration protocol and smoothness specifications for pavement in the vicinity of the traffic monitoring equipment. Also, work in improving how vehicles are classified continues to be an important aspect of LTPP’s traffic data monitoring work.107

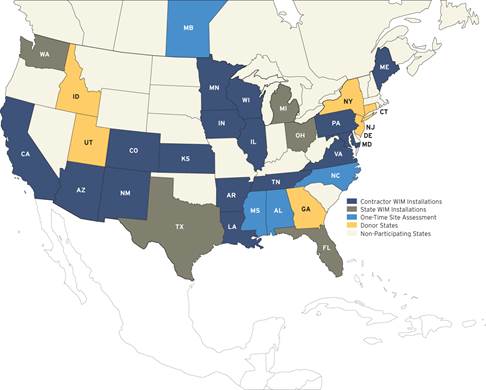

FIGURE 10.11. Participating States in the LTPP SPS Traffic Data Collection Pooled-Fund Study. Map shows the donor States, States with assessments only, and weigh-in-motion equipment (WIM) equipment installed by the State or the LTPP contractor. (28 highway agencies, with 26 weigh-in-motion (WIM) installations in 22 States). |

Initiated in 2001 by FHWA, the LTPP SPS Traffic Data Collection Pooled-Fund Study, TPF-5 (004), was established to install, calibrate, and validate continuous traffic data for as many as 84 SPS sites throughout the United States and Canada.108 Ultimately, only 28 SPS sites were selected to collect the data because of the high costs of equipment installation, calibration, and maintenance (figure 10.11). Although highway agencies contributed millions of dollars to this study with the LTPP program also contributing millions, funding simply was not available to install and maintain adequate traffic monitoring equipment at each of the proposed SPS sites for a minimum of 5 years. The number of study sites was limited to assure that the work conducted at each site would be of high quality. This study has resulted in the development of equipment and WIM site selection specifications, pavement smoothness specifications, data collection and processing protocols, and a standard vehicle classification algorithm. More importantly, the availability and quality of monitored traffic data has improved significantly because of this data collection effort.

Products related to the traffic data pooled-fund study include the LTPP Field Operations Guide for SPS WIM Sites, as discussed in chapter 7, as well as several others:

LTPP Seasonal Monitoring Program CD-ROM

The LTPP SMP was an intensive monitoring effort undertaken on a subset of the LTPP test sections to obtain data to improve understanding of seasonal variations in pavement structures and the factors that cause those variations. An SMP CD-ROM was created to provide a project summary and supporting documentation needed to facilitate future application of the LTPP data. The CD-ROM includes videos produced by the North Carolina and Colorado DOTs that show how the monitoring instrumentation was installed at the SMP test sections in both States. The CD-ROM can be obtained from the LTPP Customer Support Service Center (Email: ltppinfo@dot.gov).

Pavement Performance Forecast Online Tool

Funded through the pooled-fund study, Effect of Multiple Freeze-Thaw Cycles versus Deep Frost Penetration on Pavement Performance, TPF-5(013), and procured under the LTPP Data Analysis program, pavement performance comparisons were made for different frost climates using prediction models developed specifically for the study.115 In light of this analysis, a thorough review of agencies’standard practices for mitigating frost-related damage was conducted. Consideration was given to the new MEPDG. Additional analysis was performed to quantify the cost implications of maintaining pavements in frost areas. The final report has been published,116 and an online tool providing pavement performance predictions (i.e., roughness and distress) for both flexible and rigid pavements using the models developed in this project is available on the LTPP InfoPave Web site or by contacting the LTPP Customer Support Service Center (Email: ltppinfo@dot.gov). The online program can be used by State, Provincial, county, and local highway agencies to estimate performance trends for pavement sections within their jurisdictions.

Arizona SPS-2 Curl and Warp Report

An analysis was conducted of the roughness and roughness progression of 21 test sections on the SPS-2 (structural factors of rigid pavements) site in Arizona over the first 16 years of the experiment. Traditional profile analyses revealed roughness was caused by transverse and longitudinal cracking on some test sections and some localized roughness was caused by built-in defects. However, the analyses showed that curl and warp contributed to, and in some cases dominated, the roughness on many of the test sections. The study applied objective profile analyses to quantify the level of curl and warp on each section, using automated algorithms to estimate the gross strain gradient needed to deform each slab into the shape present in the measured profile. This study demonstrated the potential value of applying the methods used to other jointed concrete pavements, including other SPS-2 sites.117

GOAL: Establish and maintain an accurate, accessible, and high-quality database.

As the LTPP program continues, the database is and will continue to be the primary and pivotal product of the program. An important role for the program is to support this national need by providing pavement performance data that are accessible and usable not only to the pavement community, but other possible users such as bridge engineers, air quality researchers, freight policy makers, and transportation statisticians. In conjunction with the data, the program has developed tools to disseminate the data and to support potential users in working with the data effectively. The LTPP database is unique not only in its size and quality, but also in that access to the data is freely provided.

Dissemination Tools

As the database has matured, the LTPP program has improved access to the data with each advancement in computer and communications technology. This section briefly describes some of these dissemination tools in chronological order, with details provided in chapter 8.

LTPP Customer Support and Feedback Mechanisms

The LTPP program has always made it possible for users to obtain data–from the early days, sending out data on floppy disks, to today, assisting customers with identifying and downloading data that meet their analysis needs. In 1997, the LTPP Customer Support Service Center was formally established to handle data requests and to also provide a feedback mechanism for data users. Since the center was established, more than 8,000 requests for data, research reports, products, software, and other LTPP program information have been received.

The program also plays a role in educating data users. With the development of DataPave, the program staff created a demonstration workshop to help data users transition to the new way of accessing LTPP data. In 1998, in partnership with ASCE, the LTPP program presented the workshop in 16 locations to an audience of highway agency personnel, practitioners, and university professors.118

In 2011, the program began hosting Webinars to provide updates and important information to users. Examples of Webinar topics include the history and future plans for the program, the program’s impact on industry, roles and responsibilities of the LTPP State Coordinators, and LTPP’s new initiative to construct and monitor warm-mix asphalt pavements. Most of the Webinar sessions are recorded and are available on the LTPP Web site.

The emergence of new technologies over time and the LTPP program’s emphasis on continuously improving operations led to improvements in the program’s practices that have benefited the entire pavement community. For instance, LTPP QC/QA processes were developed to fill a void in pavement engineering practice, as no formal procedures existed for many of the activities conducted by the program. These procedures were necessary because the size and scope of the program required the use of different pieces of equipment (although of the same make and model) and the involvement of multiple individuals in different locations. Standard equipment protocols, training, and data collection procedures were needed to assure reliability of the data. As the program addressed these needs, highway agencies and the pavement industry benefited from the knowledge, improved standards, and QC procedures that resulted.

The LTPP data analyses have addressed a broad array of topics, from field validation of pavement design procedures, to the study of variability in traffic and materials data, to investigating pothole repair techniques. Many findings from these studies provide information that is critical for the improvement of pavement technology.

To identify some of the key findings, the LTPP program reviewed studies reported between 1990 and 1999 and published a roster of more than 60 key findings for that decade.119 The summarized results were organized by topic: site conditions, structural features, materials, initial roughness, pavement maintenance, pavement rehabilitation, AASHTO design validation, and performance modeling. In 2004, a second review and report drew on results published from 2000 to 2003. Again, more than 60 significant findings were identified and summarized, and scores of related publications were listed.120

In the 2000–2003 report, local calibration of the 2002 Pavement Design Guide was added as a new topic area, but the AASHTO validation and performance modeling were not included.

The goal of these data analysis reviews was to provide LTPP partners with information that would help them in their efforts to design, build, and maintain cost-effective and long-lasting pavements, and to make the partners aware of the vast amount of information available to them. Most of the documents identified in the reports are available at the LTPP, NCHRP, and TRB Web sites.

To capture the wide array of benefits resulting from the LTPP program, a formal data analysis project was awarded in 2006. Multiple objectives were part of the project scope, including:

Hundreds of reports, products, and other information were collected and summarized, and in examining all this, three primary areas were identified within which benefits resulting from LTPP activities to date could be categorized:121

LTPP Database

As discussed in the previous section, the single most significant product of the LTPP program is the pavement performance database. The database supports national, State/Provincial, and local research projects, as well as a variety of international analysis efforts. With appropriate maintenance and update activities in place, the database will continue to be the primary source of information for future generations of pavement and other researchers.

An outcome that has benefitted the education community is the introduction and use of LTPP data in university engineering curricula. A number of engineering schools with pavement engineering classes have developed course curricula around the database. This application has dual benefits: students are challenged with computational problems based on actual field data, and they learn to use database manipulation tools. Students emerge with conceptual and practical knowledge that will benefit the pavement engineering community into the future.

Improved Measurement Processes

The LTPP program has advanced data quality procedures in both the field and the office, as discussed in chapter 8 and chapter 9. This section highlights advances in equipment specifications and maintenance procedures, software, and laboratory and data collection protocols that have led to a higher quality standard for pavement performance measurement for the pavement community (see sidebar).

LTPP protocols have formed the basis for improved measurement standards, and the pavement industry has been proactive in using these standards to support their chartered objectives. For example, efforts within the LTPP program to achieve greater reliability and precision in FWD data resulted in the establishment of calibration centers and the adoption of much-improved nationwide calibration standards (chapter 6). In addition, traffic data collection equipment suppliers have improved their hardware and software, and some have incorporated more stringent data checks as a result of the program’s requirements (chapter 7). Equipment manufacturers have also adopted the program’s resilient modulus protocols as a QC check during equipment production.

The program has significantly improved other data collection practices for a wide range of operations including manual and automated distress surveys and longitudinal and transverse profiles. Numerous LTPP data collection procedures have been adopted by industry. The most widely implemented of these procedures is the LTPP Distress Identification Manual. The manual is used by more than 20 State highway agencies and numerous local entities. In 1997, the National Highway Institute (NHI) developed a distress training course using the LTPP Distress Identification Manual and LTPP distress accreditation procedures. The LTPP program funded the course, offering it to the States free of charge. Although the course is no longer offered by NHI, it was delivered to many domestic and international participants.

The program has purchased a variety of sophisticated data collection equipment and systems. The process by which the equipment specifications were prepared, achievement of the specifications was confirmed, and the final selection of equipment was made have become a model for many highway agencies planning to acquire similar equipment for their own use. As a recent example, procurement for the current LTPP profilers involved developing a set of specifications for the vendors and then performing a field verification to prove the specifications could be met before moving forward with the selection process. Some highway agencies have expressed interest in using this model for future major equipment purchases.

Pavement Design and Management

An original LTPP objective was to acquire data for use in evaluating existing design methods and in developing new ones. The LTPP program is the only national research program that has collected pavement performance data reflecting different climates and different materials, using standard data collection protocols and equipment. This consistent manner of collecting long-term pavement performance data and ensuring its quality using verified QC/QA practices has had a tremendous impact in advancing new pavement design procedures, particularly the development and implementation of the MEPDG. In addition, LTPP data has been implemented by State/Province and local agencies in network-level and project-level pavement management systems to predict future performance and determine maintenance and rehabilitation needs.

LTPP QC/QA RESOURCESSoftware Programs LTPP software QC/QA programs such as FWDCAL, ProQual, SMPCHECK, DiVA, and LTAS are discussed in earlier chapters. While much of this software was tailored specifically for LTPP operations, some of these programs have been used throughout the pavement community in processing and checking data for highway agency needs and research analysis projects. Documentation In the service of QC/QA, the LTPP program has developed a wide variety of reports, protocols, and other documents that are assisting highway agencies and researchers alike. Several of these have been addressed previously, including the Distress Identification Manual for the Long-Term Pavement Performance Program and the LTPP Manual for Falling Weight Deflectometer Measurements. The FWD calibration centers established under the program are a major benefit to the highway agencies and industry. To capture the entire laboratory testing inputs and results as recommended during the peer review process, the LTPP program developed its own LTPP Laboratory Materials Testing and Handling Guide.122 For most elements, the laboratory protocols were modeled on ASTM and AASHTO standards. However, in the conduct of resilient modulus testing for both bound and unbound layers, existing protocols did not meet LTPP’s data quality standards and therefore new protocols (LTPP Protocols P07 and P46, respectively) were developed. To supplement this development, the LTPP program prepared a series of videos to instruct testing laboratory personnel not only on how to conduct the test procedures, but also on how to ensure that the equipment is functioning properly. Initially, an LTPP review found a large variability in test results from different laboratories, which was partially attributed to problems with laboratory equipment electronics. After implementing the startup procedures, the variability was greatly reduced. Seeking to reduce variability is a constant part of the LTPP QC/QA process; eliminating variability entirely is rarely practical. Therefore, quantifying data variability is the subject of many analysis activities. A few of these analyses were discussed earlier in this chapter, and following is a partial list of additional studies:

Understanding variability, bias, and precision allows practitioners to properly incorporate data points into their decision processes. |

The LTPP program lends support to various U.S. DOT and FHWA programs and initiatives. Data and processes developed during the program have been used and continue to be used in research efforts of national significance. Some examples include:

Beyond the benefits themselves, what is remarkable is how widespread–both geographically and throughout the public and private sectors–the use of LTPP products and data has become.

Turning data into results that are of value and use to the highway community is an important function in understanding pavement performance. The LTPP program’s return on investment, while challenging to fully quantify, is already estimated at over $2 billion in savings and will continue to grow.133 The many research studies and their products conducted under the program are too numerous to mention in this chapter, and their numbers continue to grow as the LTPP program continues to improve the functionality of the database and revisit the data with advancing knowledge. The program has had a significant positive impact on the quality of pavement construction and rehabilitation by influencing the AASHTO and ASTM standards. It has advanced the capabilities of modern pavement monitoring equipment through its equipment requirements and new software tools. The program continues to develop products needed by highway agencies and distribute the tools and knowledge gained through the program. Through these program activities, LTPP data can fulfill its potential to improve industry practices, pavement engineering studies, the quality of pavement research, and, ultimately, the performance and cost-effectiveness of the Nation’s highways.

On the road to achieving the results reported in this chapter, the LTPP program encountered many obstacles and problems. As the first pavement performance data collection effort of its breadth and depth, the program often faced a steep learning curve, and lessons were dearly earned. The next chapter reviews some of the lessons learned in the program.