U.S. Department of Transportation

Federal Highway Administration

1200 New Jersey Avenue, SE

Washington, DC 20590

202-366-4000

Federal Highway Administration Research and Technology

Coordinating, Developing, and Delivering Highway Transportation Innovations

| REPORT |

| This report is an archived publication and may contain dated technical, contact, and link information |

|

| Publication Number: FHWA-HRT-15-033 Date: May 2015 |

Publication Number: FHWA-HRT-15-033 Date: May 2015 |

This chapter describes the preparation of soil specimens for testing in the ESTD and soil properties determined from standard testing protocols.

Soil specimens must be prepared so that they will maintain their shape prior to the initiation of erosion in the ESTD. With some approaches to soil preparation in a laboratory, the specimens will slake in water. (See appendix C for a description of slaking.) Because slaking is a completely different mechanism for soil loss than the erosion process, slaking should be avoided.

Traditional geotechnical preparation of soil specimens follows procedures from the standard compaction test (ASTM D698). This protocol requires that a moisturized clay mixture matures for a minimum of 16 h before it is compacted in a standard 4-inch (100-mm)-diameter mold. Next, a 5.5-lb (2.5-kg) hammer is dropped for 25 blows per lift on three separate lifts. This compaction approach is appropriate for many geotechnical applications at low water contents.

In the wet environment in which erosion tests are conducted, a soil specimen prepared in this way immediately slakes and releases air bubbles into the water. This phenomenon is not observed in the field. Therefore, preparation of soils for erosion testing by this approach is not appropriate. Moreover, when a soil mixture is too plastic, as are many of the cohesive soils of interest in this study, it adheres to the hammer and makes compaction difficult.

Some investigators have attempted to address this limitation. In one study, Red Art Kaolin clay specimens were prepared using a consolidometer cell in air.(32) Like the compaction method, use of a consolidometer shortens the preparation time. However, if the extruded clay specimen is immediately immersed in water, then it slakes and releases air bubbles. Subsequent soil preparation attempts included leaving the specimens in a closed zip bag for 2 h. In this case, soils demonstrated a somewhat greater resistance to slaking. However, the soil was eventually affected by slaking.

This behavior has been described as resulting from the swelling and bursting of pressurized air bubbles formed during consolidation. The swelling and bursting destroys the connections among soil particles and causes the soil to collapse.(33) If pressurized air bubbles account for the slaking of specimens, then it is vital to eliminate them during the soil preparation process. Therefore, vacuum extraction of the trapped air is desired. A pugger mixer serves this purpose.

A pugger mixer is commonly used in pottery studios. It features a vacuum pump for de-airing the mixing chamber. The pugger mixer at the Hydraulics Lab in the Turner Fairbank Highway Research Center can pug out 3-inch (76-mm)-diameter cohesive soil specimens after sufficient mixing. A 2.5-inch (63.5-mm) cutting ring was used to prepare 2.5-inch (63.5-mm)-diameter soil specimens. Figure 32 is a picture of the pugger mixer pugging soil.

The pugger mixer is capable of mixing sands with a maximum particle size of 0.20 inches (5 mm). Clay, commercial silt, and non-uniform sands in varied percentages can be mixed into cohesive soils with a range of characteristics. Soil specimens prepared with the pugger mixer do not slake in water, which is necessary for testing the erosion characteristics of the soil specimens under water.

Figure 32. Photo. The pugger mixer used for soil preparation

All cohesive soil specimens prepared for erosion testing in the ESTD contained mixtures of Red Art clay, commercial silt, and non-uniform sands with specific gravities of 2.80, 2.63, and 2.69, respectively. The Red Art clay contains 40 percent Illite, 27 percent chlorite, and 28 percent quartz. The chemical components are mainly SiO2 (61.3 percent) and Al2O3 (17.6 percent).

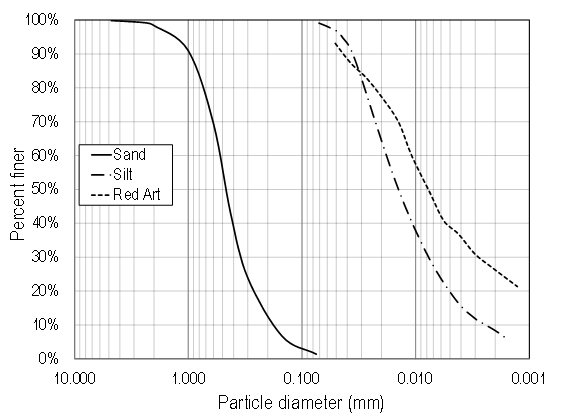

None of the three component soil materials are well graded, as summarized in figure 33. The particle size ranges are as follows:

As defined by ASTM D2487-10, sands are those particles that will pass a No. 4 sieve (0.19 inches (4.75 mm)) and be retained on a No. 200 sieve (0.003 inches (0.075 mm)). Fines-clays and silts-are those particles that pass the No. 200 sieve (0.003 inches (0.075 mm)). The distinction between clays and fines further relates to their PI and liquid limit (LL). Soil specimens were classified according to the ASTM standard D2487-10. It classifies inorganic fine-grained soils into five categories based on the LL and PI of a soil. The LL, plastic limit (PL), and PI, also known as the Atterberg limits, apply only to the portion of a soil that passes the No. 40 sieve (0.017 inches (0.425 mm)).

25.4 mm = 1 inch.

Figure 33. Graph. Particle-size distributions for Red Art clay, silt, and non-uniform sands

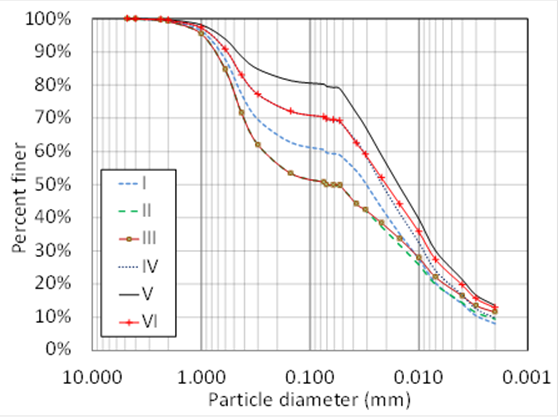

Six types of soils were prepared for the ESTD erosion tests with different proportions of the Red Art clay, silt, and non-uniform sand. Table 9 summarizes the component mixtures, soil classification, and general grain size properties for the soils. They are categorized in the broad classifications of CL and CL-ML.

The particle-size distributions of these six soils are provided in figure 34. All six soils are gap graded because none of three components was well-graded.

Table 9. Classification and composition of soils for testing.

Soil Index |

Soil Classification |

Source Mix (%) |

Fraction (%) |

Specific Gravity |

Plastic Limit (%) |

Liquid Limit (%) |

Plasticity Index (%) |

|||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|

Red Art |

Silt |

Sands |

< 2 µm |

< 50 µm |

< 75 µm |

< 425 µm |

||||||

1 |

CL-ML (sandy silty clay) |

20 |

40 |

40 |

8.1 |

58.9 |

60.6 |

77.2 |

2.69 |

16.7 |

21.0 |

4.3 |

2 |

CL (sandy lean clay) |

30 |

20 |

50 |

9.5 |

49.5 |

50.7 |

71.5 |

2.71 |

14.3 |

21.3 |

7.0 |

3 |

CL (sandy lean clay) |

40 |

10 |

50 |

11.5 |

49.7 |

50.7 |

71.5 |

2.73 |

14.4 |

24.1 |

9.7 |

4 |

CL-ML(Silty clay with sand) |

25 |

45 |

30 |

9.8 |

68.8 |

70.4 |

82.9 |

2.69 |

17.4 |

22.5 |

5.1 |

5 |

CL (Lean clay with sand) |

40 |

40 |

20 |

13.5 |

78.9 |

80.3 |

88.6 |

2.71 |

17.7 |

26.4 |

8.7 |

6 |

CL (Lean clay with sand) |

40 |

30 |

30 |

12.9 |

69.2 |

70.4 |

82.9 |

2.72 |

16.6 |

25.5 |

8.9 |

25.4 mm = 1 inch.

Figure 34. Graph. Particle-size distributions of the cohesive soils tested in the ESTD

Each soil mixture was prepared with a range of water contents to create 17 unique soil samples for testing. Three additional unique soil samples were prepared by the compaction method. All soil specimens were prepared in the shape of a cylinder with a diameter of 2.5 inches (63.5 mm) and a height of 0.79 inches (20 mm).

To prepare the soil samples, the previously specified mixes of dry Red Art clay, silt, and sand were thoroughly mixed. Distilled water was added gradually to achieve a uniform soil texture. The mixture was pugged out and cured for 16 h. After the curing, the mixture was remixed in the pugger. It was then vacuumed near the end of mixing. Finally, the soil was pugged out, cut to the desired size, and saved in water before the erosion test. If a soil mixture was too wet, then it would slip in the pugger chamber and could not be pugged out.

The water content (weight of water divided by weight of soil) and the dry bulk density were measured. The wet bulk density, void ratio, and saturation degree were calculated. Table 10 summarizes the properties of the soil samples prepared by the pugger mixer. The soil sample name is in the form of xWyyy, where "x" represents the soil index and "yyy" represents the measured water content without the decimal point.

For comparison, three soil samples were compacted following the procedures of the compaction test (ASTM 698-00a). These samples all had lower water contents than those prepared by the pugger mixer. After the soil specimen was prepared, it was saved in a closed zip bag for 2 h before the erosion test. Table 11 summarizes the properties of the soil samples prepared by compaction.

Table 10. Mass and moisture properties of soils prepared by pugger mixer.

Soil Index |

Soil Sample |

Measured Water Content, w (%) |

Wet Bulk Density (lb/ft3) |

Wet Bulk Density (kg/m3) |

Dry Bulk Density (lb/ft3) |

Dry Bulk Density (kg/m3) |

Void Ratio, e (%) |

Degree of Saturation, S (%) |

|---|---|---|---|---|---|---|---|---|

1 |

1W156 |

15.6 |

134.4 |

2,155 |

116.3 |

1,865 |

44.2 |

94.6 |

1 |

1W165 |

16.5 |

134.4 |

2,156 |

116.3 |

1,865 |

44.2 |

94.9 |

1 |

1W181 |

18.1 |

129.9 |

2,084 |

110.1 |

1,765 |

52.4 |

92.8 |

2 |

2W147 |

14.7 |

135.7 |

2,177 |

118.3 |

1,898 |

42.8 |

93.1 |

2 |

2W167 |

16.7 |

137.0 |

2,197 |

117.2 |

1,880 |

44.1 |

103.5 |

2 |

2W177 |

17.7 |

138.1 |

2,214 |

117.0 |

1,876 |

44.5 |

109.8 |

3 |

3W160 |

16.0 |

134.6 |

2,159 |

116.2 |

1,864 |

46.5 |

93.0 |

3 |

3W180 |

18.0 |

136.0 |

2,181 |

115.0 |

1,845 |

48.0 |

103.6 |

4 |

4W189 |

18.9 |

131.0 |

2,101 |

110.3 |

1,769 |

52.1 |

97.0 |

4 |

4W198 |

19.8 |

130.1 |

2,086 |

108.8 |

1,745 |

54.2 |

97.1 |

4 |

4W217 |

21.7 |

130.1 |

2,087 |

106.8 |

1,713 |

57.0 |

103.0 |

5 |

5W215 |

21.5 |

130.0 |

2,085 |

107.1 |

1,717 |

57.8 |

100.4 |

5 |

5W231 |

23.1 |

126.6 |

2,031 |

102.8 |

1,649 |

64.3 |

97.6 |

5 |

5W248 |

24.8 |

126.8 |

2,033 |

101.7 |

1,631 |

66.2 |

101.0 |

6 |

6W192 |

19.2 |

132.1 |

2,119 |

111.2 |

1,783 |

52.6 |

97.5 |

6 |

6W200 |

20.0 |

129.6 |

2,078 |

108.1 |

1,733 |

57.0 |

95.1 |

6 |

6W231 |

23.1 |

130.0 |

2,085 |

105.8 |

1,697 |

60.3 |

103.2 |

Table 11. Mass and moisture properties of soils prepared by compaction.

Soil Index |

Soil Sample |

Measured Water Content, |

Wet Bulk Density (lb/ft3) |

Wet Bulk Density (kg/m3) |

Dry Bulk Density (lb/ft3) |

Dry Bulk Density (kg/m3) |

Void Ratio, |

Degree of Saturation, |

|---|---|---|---|---|---|---|---|---|

1 |

1W133 |

13.3 |

131.0 |

2,101 |

115.9 |

1,858 |

44.8 |

78.6 |

2 |

2W127 |

12.7 |

130.3 |

2,090 |

115.5 |

1,853 |

46.2 |

74.9 |

3 |

3W126 |

12.6 |

132.8 |

2,129 |

117.8 |

1,889 |

44.5 |

77.9 |

Additional geotechnical properties of the soils were measured in accordance with the applicable ASTM standards. These properties included drained cohesion, friction angle, and unconfined compression strength.

The direct shear test measures the cohesion and friction angle of a soil. Cylindrical soil specimens with a diameter of 2.5 inches (63.5 mm) and a height of 1 inch (25.4 mm) were used in the direct shear test. The soil specimens were identical to those for the ESTD erosion test except that the cylinders were shorter. During the direct shear test, 0.5-inch (12.7-mm) shear displacement was achieved within either 50 or 75 min. Four normal stresses-5, 10, 20, and 30 lbf/inches2 (34, 69, 138, and 207 kPa)-were used. Test results for the soils prepared using the pugger mixer are found in table 12, while those prepared by compaction are found in table 13. For the same soil index, soils prepared by compaction exhibited higher values of cohesion than soils prepared by the pugger mixer.

Table 12. Additional geotechnical properties of soils prepared by pugger mixer.

Soil Index |

Soil Sample |

Cohesion, c (lbf/inches2) |

Cohesion, |

Friction Angle, |

Unconfined Compressive Strength, qu |

Unconfined Compressive Strength, qu |

|---|---|---|---|---|---|---|

1 |

1W156 |

1.01 |

6.96 |

37.2 |

2,378 |

113,764 |

1 |

1W165 |

1.23 |

8.48 |

35.9 |

2,162 |

103,421 |

1 |

1W181 |

1.14 |

7.86 |

37.3 |

1,661 |

79,497 |

2 |

2W147 |

0.58 |

4.03 |

38.6 |

3,961 |

189,537 |

2 |

2W167 |

1.42 |

9.79 |

37.6 |

1,000 |

47,850 |

2 |

2W177 |

0.72 |

4.96 |

38.7 |

1,009 |

48,263 |

3 |

3W160 |

0.92 |

6.36 |

36.3 |

1,723 |

82,461 |

3 |

3W180 |

1.03 |

7.10 |

36.3 |

1,216 |

58,192 |

4 |

4W189 |

1.15 |

7.93 |

37.4 |

2,144 |

102,594 |

4 |

4W198 |

0.74 |

5.10 |

39.8 |

1,242 |

59,433 |

4 |

4W217 |

1.30 |

8.96 |

37.7 |

990 |

47,367 |

5 |

5W215 |

1.29 |

8.89 |

35.3 |

3,012 |

144,100 |

5 |

5W231 |

1.12 |

7.72 |

35.2 |

1,366 |

65,362 |

5 |

5W248 |

1.04 |

7.17 |

36.1 |

1,055 |

50,470 |

6 |

6W192 |

3.32 |

22.89 |

27.8 |

3,373 |

161,406 |

6 |

6W200 |

1.26 |

8.69 |

31.8 |

1,636 |

78,256 |

6 |

6W231 |

1.42 |

9.79 |

32.5 |

993 |

47,505 |

Table 13. Additional geotechnical properties of soils prepared by compaction.

Soil Index |

Soil Sample |

Cohesion, c (lbf/inches2) |

Cohesion, c (kPa) |

Friction Angle, |

|---|---|---|---|---|

1 |

1W133 |

2.63 |

18.13 |

37.4 |

2 |

2W127 |

2.42 |

16.69 |

34.9 |

3 |

3W126 |

1.24 |

8.55 |

35.8 |

Based on laboratory testing and field observation on 12 channels in 6 western States, Flaxman concluded that the unconfined compressive strength was an indicator of soil resistance to erosion.(34) He defined a linear relationship between tractive stream power (product of flow-induced shear stress and flow velocity) and the logarithm of the unconfined compressive strength that could be used to separate conditions in eroding versus stable channels. The R2 value of this relation was 0.4. Straub and Over found a linear relationship between soil critical shear stress and the logarithm of unconfined compressive strength in 15 field cohesive soils in Illinois.(8) The R2 value of this relation was 0.95. In their study, the critical shear stress of undisturbed field soil specimens were deduced from erosion results in the EFA.

Because of these findings, unconfined compressive strength was determined for each of the soil samples. Cylindrical soil specimens with a diameter of 2.5 inches (63.5 mm) and a height of 6 inches (152 mm) were used in the test. The soil specimens were identical to those for the ESTD erosion test except that the cylinders were longer. Test results for the soils prepared using the pugger mixer are found in table 12.

Slaking is a soil loss mechanism that should be avoided by proper preparation of test specimens for erosion testing. Slaking results in soil loss even without the shear stresses of flowing water and results in accelerated erosion rates from what would be expected in the absence of slaking.

Berghager and Ladd defined slaking as the progressive breaking-up of a soil when immersed in water.(33) The break-up of the soil is accompanied by the release of small air bubbles. Higher degrees of saturation means less air is present and makes a soil less vulnerable to slaking. Slaking results in soil loss but from a completely different mechanism than erosion caused by bed shear stresses.

Although the actual mechanism of slaking is not well understood, it is generally accepted that the slaking of cohesive soil is because of air pressure change in the soil capillaries.(16) When a wet unsaturated soil is soaked in water, the dipolar water molecules are attracted by the clay particles, and thus the water moves into the pores. Water forms menisci within the pores, which compress air in the soil pores. The entrapped air exerts enormous pressure, which breaks the tensile strength of the soil and explains why slaking is always accompanied by the release of air bubbles. In addition, because the capillary menisci pull water into the pores, the capillary walls are in tension. If the tensile strength of the pore walls is less than the tension applied by the menisci, then the walls will fracture and the soil will break up.(35)

Researchers have experimentally demonstrated the significance of slaking in compacted soils using the CCFED.(36) Others have identified four slaking modes: dispersion slaking, swelling slaking, body slaking, and surface slaking.(37)

Excluding surficial layers of mud containing significant quantities of microorganisms, such as snails, river bed soils near bridge piers are anticipated to be well compacted and saturated. Therefore, it is realistic to assume those soils are free of slaking. To reproduce these conditions in a laboratory, prepared soil specimens must also be free of slaking in order to study their erosion characteristics. However, most tested soil specimens in laboratories are prepared by the method outlined in the standard ASTM compaction test, which rarely prepares soils that will not slake.(33,36,38)

Researchers working with the CCFED identified slaking as a concern, noting that samples made directly in the mold contained air voids and cracks.(38) To remedy this problem, a Vac-Aire extruding machine was used to remove air from the soil. Others concluded that compacted soil cannot be tested in the CCFED, although no reason was given.(16)

In general, however, slaking of compacted soils has not been widely recognized for the following reasons:

Constraining compacted soil specimens may delay slaking. If exposed to water for a sufficient time, a soil specimen inside a Shelby tube may slake and generate cracks, which means that the erosion test measurements will not be accurate unless the test is sufficiently short enough that slaking is not allowed to begin.

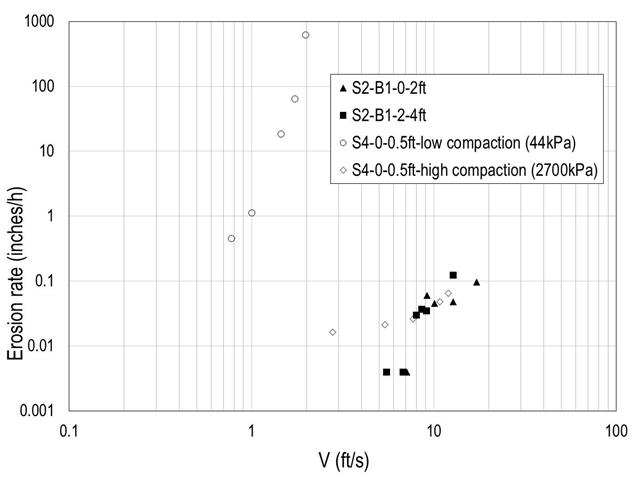

Researchers tested field and laboratory compacted New Orleans levee soils with the EFA.(39) The field samples (labeled S2) and the laboratory samples (labeled S4) are summarized in table 14. The two laboratory soils were compacted with different levels of effort. The low compaction effort was 920 ft-lbf/ft3 (44 kN-m/m3), which is 1.6 percent of the modified Proctor compaction effort (ASTM D1557). The high compaction effort was 56,200 ft-lbf/ft3 (2700 kN-m/m3), which is 100 percent of the modified Proctor compaction effort. (The saturation degree is calculated by assuming that the soil specific gravity is 2.65. Because S2-B1 contains nearly 17 percent organic content, the saturation estimate is an underestimate. It is likely that the saturation degree of S2-B1 approaches 100 percent.)

Table 14. Properties of four soils from a New Orleans levee.

Sample |

Soil Type |

Wet Specific Weight (lbf/ft3) |

Dry Specific Weight (lbf/ft3) |

Organic Content (%) |

Water Content (%) |

Liquid Limit (%) |

Plastic Limit (%) |

Plasticity Index (%) |

Saturation Degree (%) |

|---|---|---|---|---|---|---|---|---|---|

S2-B1-(0-2ft)-TW |

CL |

126 |

108 |

16.94 |

16.11 |

46 |

17 |

29 |

81 |

S2-B2-(2-4ft)-SW |

CL |

129 |

106 |

1.62 |

21.23 |

41 |

16 |

25 |

100 |

S4-(0-0.5ft)-LC-SW |

CL |

88 |

66 |

8.16 |

33.14 |

60 |

30 |

30 |

59 |

S4-(0-0.5ft)-HC-SW |

CL |

113 |

84 |

8.16 |

33.14 |

60 |

30 |

30 |

93 |

Figure 35 summarizes the EFA erosion testing results for the levee soils. The S4 (low compaction) soil has the lowest degree of saturation and, therefore, the most air bubbles. It also exhibits the highest erosion rates of the four tested soils. Conversely, the highly compacted S4 soil, with a much higher degree of saturation, exhibits the lowest erosion rates in line with the field soils. The erosion rates differed by over four orders of magnitude. The high compaction effort may have eliminated more air mimicking the field conditions, while the low compaction effort merely trapped and pressurized the air.

Figure 35 also indicates that the erosion rates of the highly compacted S4 soils are close to that of both prototype S2 soils when flow velocities are greater than 8 ft/s (2.4 m/s). Below that velocity, S2 soils exhibit minimal erosion rates. However, the highly compacted S4 soils have somewhat larger erosion rates (0.02 inches/h (0.4 mm/h)) at the flow velocity of 2.6 ft/s (0.8 m/s). This might be explained by slaking. When flow velocities exceed 8 ft/s (2.4 m/s), erosion is more dominant than slaking. Several researchers have considered whether gradation influences slaking behavior.

One research effort compared compacted clay and sand mixtures prepared in the laboratory with field-collected cohesive soils compacted in the laboratory.(36) These included well and poorly graded soil samples.

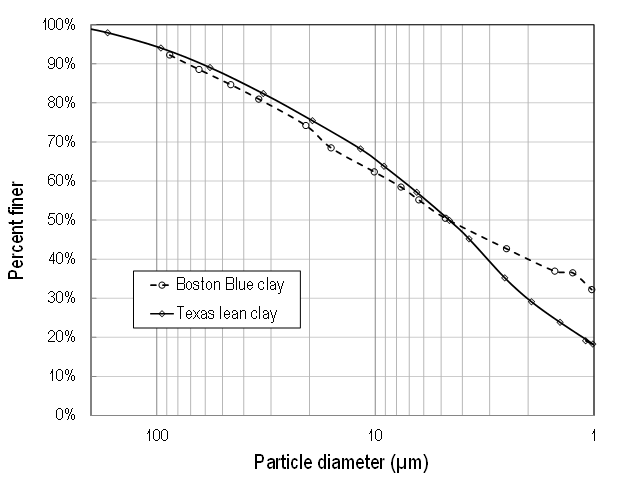

Another study assessed a well-graded reconsolidated Boston Blue clay with an LL of 30 percent and a PL of 17.5 percent.(33) Most of the Boston Blue clays were reconsolidated with a low compaction effort of approximately 2,100 ft-lbf/ft3 (100 kN-m/m3). The standard compaction test (ASTM D698) applies a compaction effort of 12,400 ft-lbf/ft3 (600 kN-m/m3).

Another study evaluated a well-graded Texas lean clay with an LL of 47 percent and a PL of 21 percent.(38) The gradations for the latter two clays are shown in figure 36. None of these assessments suggested that soil gradation plays a significant role in slaking.

1 ft = 0.3 m.

1 inch = 25.4 mm.

1 kPa = 0.15 psi.

Figure 35. Graph. Erosion curves of soils from a New Orleans levee

It may be concluded that lower compaction efforts contribute to slaking because these soils contain pressurized air bubbles. These air bubbles will release pressure once the soil becomes unconstrained. This process might happen in a quick or slow burst into the soil inner structure, which leads to small disconnected cracks in the soil structure. With the existence of water, the air pressure increases, and stronger bursts occur, creating still more cracks. Once the cracks are connected, the water easily penetrates into and breaks up the soil. Much higher compaction efforts are needed to actually force the air out of the sample.

Once a soil sample prone to slaking is immersed in water, the potential for slaking is likely to increase the longer the sample is submerged. Therefore, if such a sample must be tested for its erosion properties, then the test should be conducted as quickly as possible. However, this process does not guarantee a meaningful result. Generally, compaction methods cannot be used in preparing soils for erosion testing. Soils should be vacuumed in their preparation to eliminate trapped pressurized air and, therefore, slaking.

1µm = 0.00003937 inches.

Figure 36. Graph. Gradation of compacted clays

The soil samples prepared by compaction in this study were evaluated for slaking to generate quantitative information regarding the slaking phenomenon. The compaction effort applied was 12,400 ft-lbf/ft3 (600 kN-m/m3) per ASTM D698. The cylindrical test specimens had a diameter of 2.5 inches (63.5 mm) and a height of 1 inch (25.4 mm). Properties of these soil samples are summarized in table 11 and table 13.

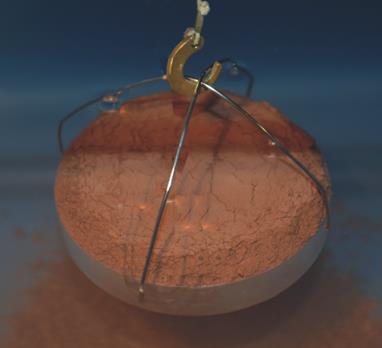

The samples were placed in an aluminum tray and suspended beneath a balance. The soil extended above the rim of the tray so that the top 0.28 inches (7 mm) was unconfined. The samples were then submerged in still water for a duration of at least 1 h. After soaking in water, cracks appeared on the surface of the soil specimen. Air bubbles were released from inside of the soil specimen. The soil started to crumble until a stable condition was reached. The soil sample was removed from water and typically appeared as shown in figure 37.

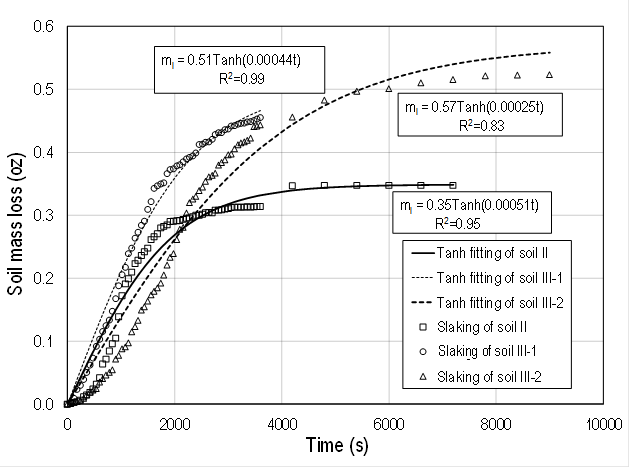

The initial and final soil masses were measured as well as the total mass of the aluminum tray and wire when empty. Continuous balance readings were recorded after submergence through the end of the test. Figure 38 summarizes three sets of slaking data for soil indices 2 and 3. All three slaking curves have an S-shape. Initially, the slaking was slow, but after several minutes, the rate of soil loss increased. After about 30 min, the slaking rate slowed until no further soil loss was observed. The final shape of the remaining soil was that of the frustum of a cone. The slaking curve can be approximated by a hyperbolic tangent function as shown in figure 38. The two constants should be functions of soil composition, compaction effort, and sample size.

Figure 37. Photo. Slaking test on a compacted soil specimen

1 oz = 28.3 g.

Figure 38. Graph. Slaking test results for soils 2 and 3 in still water

These tests demonstrated that over the hour-long test periods anticipated for erosion testing in the ESTD, slaking would be a significant contributor to the soil loss. Therefore, the soil samples prepared using the standard compaction effort (ASTM D698) could not be used for erosion testing.