U.S. Department of Transportation

Federal Highway Administration

1200 New Jersey Avenue, SE

Washington, DC 20590

202-366-4000

Federal Highway Administration Research and Technology

Coordinating, Developing, and Delivering Highway Transportation Innovations

| REPORT |

| This report is an archived publication and may contain dated technical, contact, and link information |

|

| Publication Number: FHWA-HRT-15-033 Date: May 2015 |

Publication Number: FHWA-HRT-15-033 Date: May 2015 |

All erosion tests in the ESTD were conducted by applying one or more of the seven combinations of flow, moving belt speed, and bed roughness that reproduced open channel flow conditions to each of the 17 soil types in table 10. Distilled water was used in the ESTD system.

For testing, each soil specimen was placed in an aluminum tray with sides extending up 0.5 inches (13 mm). The remaining 0.28 inches (7 mm) of the cylindrical soil sample is unconfined and available for erosion. The tray is fixed onto the sensor disk of the force gauge. Initially, the surface of the soil specimen is flush with the bed of the test channel. The sensor disk and soil specimen are elevated as erosion occurs to maintain this flush condition. Initial roughness of the soil specimen is carefully prepared so that it is similar to the bed roughness of test channel. When successful in matching the roughness, the initial average shear stress on the soil specimen should approximate the bed shear stress.

During each erosion test, the measured bed shear stress under each flow condition should be maintained as a constant. As erosion occurs, the measured shear stress would decrease if the specimen is held at a fixed position. Therefore, the specimen is automatically raised when the measured shear stress decreases below the target value so that the remaining surface of the soil sample is flush with the fixed bed.

Raising the specimen is controlled by a feedback loop on the force gauge. A shear stress range of 0.021 lbf/ft2 (1 Pa) is applied to determine whether the soil specimen should be elevated. Readings are checked every 2 s. If the shear stress dropped by more than the allowable amount, then the platform is elevated for an increment of time referred to as the elevation period. The elevation period varies depending on the erodibility of the soil specimen. Rapidly eroding soil specimens require longer elevation periods compared with more slowly eroding soil specimens. Because any protrusion or depression will introduce form drag and potentially alter the erosion patterns, these measures are important to reduce the potential for form drag.

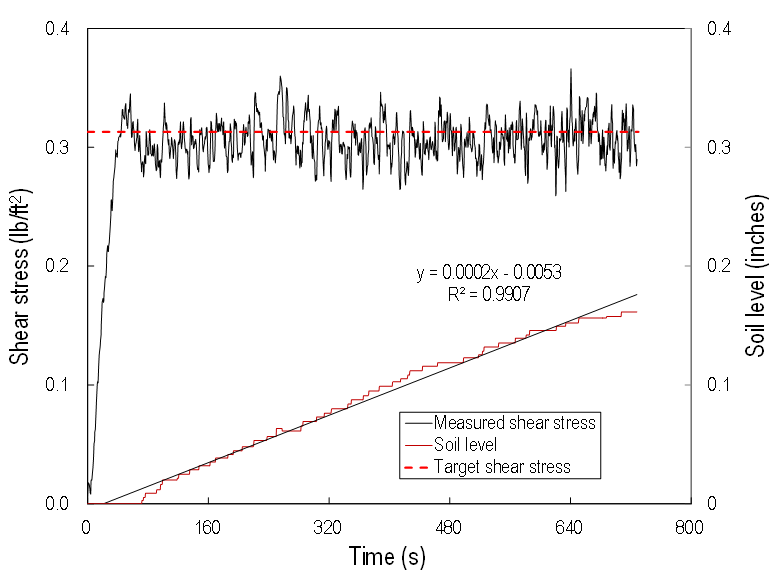

A typical set of recorded instantaneous shear stress measurements is plotted in figure 39. The instantaneous shear stress fluctuated around the target bed shear stress of 0.31 lbf/ft2 (15 Pa). The figure also shows the elevation increases of the platform and soil sample. The soil elevation curve can be approximated with a linear function. The slope of the function, in units of depth versus time, represents one estimate of the erosion rate.

Each erosion test is typically run for approximately 1 h, but the time is adjusted depending on the erosion rate. The initial and final soil masses are measured. The mass loss is divided by the erosion time to calculate a mass erosion rate (mass per unit time). This mass erosion rate is divided by the surface area of the soil sample to derive a more useful mass erosion rate per unit area.

Water content of several soils was measured again after the 1-h test. Water content increased by less than 0.5 percent for soils prepared in the pugger mixer. The water content increased by approximately 2 percent for the compacted soils. Therefore, for soils prepared in the pugger mixer, the wet density did not change significantly. Because of this result, the total eroded soil volume can be calculated along with a depth-based erosion rate. This results in an erosion rate in depth per unit time.

1 inch = 25.4 mm.

1 lbf/ft2 = 47.8 Pa.

Figure 39. Graph. Example data recorded for sample with soil index 4

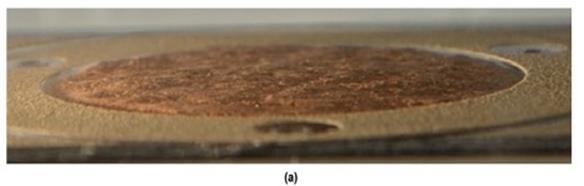

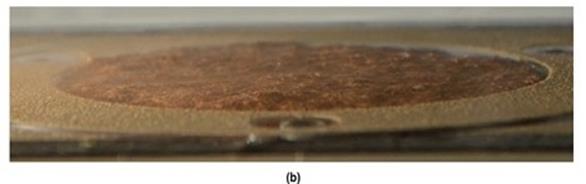

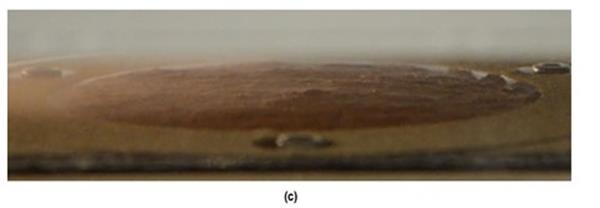

Erosion of soils prepared with the pugger mixer was in a form of soil lumps and cloudy matter. When bed shear stress was small, the primary erosion mechanism was the separation of soil lumps from the surface. The lumps were entrained from all areas of the soil surface, resulting in an irregular soil surface over time. As the bed shear stress increased, the cloudy matter appeared heavier. Figure 40 shows this change for soil sample 1W181. For the lower bed shear stress of 0.10 lbf/ft2 (4.9 Pa), there was no cloudiness (figure 40(a)). The soil was eroded in small lumps over the soil surface. When the bed shear stress was increased to 0.21 lbf/ft2 (10 Pa), increasing cloudiness was observed, and larger lumps of soil were entrained in the flow (figure 40(b)). When the bed shear stress was increased to 0.27 lbf/ft2 (13.1 Pa), the cloudiness increased, and the erosion rate increased. At this higher shear stress, shallow grooves appeared on the soil surface along the flow direction (figure 40(c)).

A summary of the test matrix and results is provided in table 15 for the erosion tests for soils prepared with the pugger mixer. The test ID-PxWyyySz-beginning with "P" indicates that these runs were completed with soils prepared by the pugger mixer. The x signifies the soil index (1-6), the yyy signifies the water content with the decimal point removed, and the z signifies the bed shear stress applied in the erosion test. S1 through S7 represent, from lowest to highest, the seven shear stress conditions described previously. The shear values are shown in table 15.

The table also includes the running time for each test and the measured soil loss in mass per unit time. The computation of the mass erosion rate (per unit area) and depth erosion rate are also summarized in the table.

Figure 40. Photo. Erosion soil sample 1W183 with increasing shear

Table 15. Erosion test matrix and results for soils prepared by pugger mixer.

Test ID |

Soil Sample |

Shear Stress, Pa |

Running Time, s |

Soil Loss, g |

Mass Erosion Rate, g/s/m2 |

Depth Erosion Rate, mm/h |

|---|---|---|---|---|---|---|

P1W156S3 |

1W156 |

4.9 |

3,763 |

3.58 |

0.30 |

0.50 |

P1W156S4 |

1W156 |

7.2 |

5,081 |

18.04 |

1.12 |

1.87 |

P1W156S5 |

1W156 |

10.0 |

3,512 |

30.14 |

2.71 |

4.53 |

P1W156S6 |

1W156 |

13.1 |

1,614 |

37.38 |

7.32 |

12.22 |

P1W156S7 |

1W156 |

15.0 |

1,199 |

40.29 |

10.62 |

17.73 |

P1W165S3 |

1W165 |

4.9 |

3,644 |

3.74 |

0.32 |

0.54 |

P1W165S4 |

1W165 |

7.2 |

3,340 |

1.58 |

0.15 |

0.25 |

P1W165S5 |

1W165 |

10.0 |

1,244 |

36.64 |

9.31 |

15.54 |

P1W165S6 |

1W165 |

13.1 |

1,331 |

39.74 |

9.43 |

15.75 |

P1W165S7 |

1W165 |

15.0 |

1,497 |

37.17 |

7.84 |

13.10 |

P1W181S2 |

1W181 |

3.6 |

7,842 |

14.14 |

0.57 |

0.98 |

P1W181S3 |

1W181 |

4.9 |

2,398 |

15.09 |

1.99 |

3.43 |

P1W181S5 |

1W181 |

10.0 |

1,115 |

40.28 |

11.41 |

19.72 |

P1W181S6 |

1W181 |

13.1 |

430 |

36.15 |

26.56 |

45.88 |

P2W147S3 |

2W147 |

4.9 |

3,627 |

1.38 |

0.12 |

0.20 |

P2W147S4 |

2W147 |

7.2 |

3,932 |

7.29 |

0.59 |

0.97 |

P2W147S5 |

2W147 |

10.0 |

4,323 |

16.60 |

1.21 |

2.01 |

P2W147S6 |

2W147 |

13.1 |

3,678 |

19.76 |

1.70 |

2.81 |

P2W147S7 |

2W147 |

15.0 |

3,875 |

31.95 |

2.60 |

4.31 |

P2W167S3 |

2W167 |

4.9 |

3,400 |

2.42 |

0.22 |

0.37 |

P2W167S4 |

2W167 |

7.2 |

3,804 |

11.70 |

0.97 |

1.59 |

P2W167S5 |

2W167 |

10.0 |

4,355 |

16.97 |

1.23 |

2.02 |

P2W167S6 |

2W167 |

13.1 |

1,964 |

39.03 |

6.28 |

10.29 |

P2W177S2 |

2W177 |

3.6 |

2,485 |

16.74 |

2.13 |

3.46 |

P2W177S3 |

2W177 |

4.9 |

1,785 |

30.26 |

5.36 |

8.71 |

P2W177S4 |

2W177 |

7.2 |

764 |

31.32 |

12.95 |

21.06 |

P2W177S5 |

2W177 |

10.0 |

628 |

31.87 |

16.03 |

26.07 |

P2W177S6 |

2W177 |

13.1 |

451 |

32.78 |

22.96 |

37.34 |

P3W160S3 |

3W160 |

4.9 |

3,935 |

0.64 |

0.05 |

0.09 |

P3W160S5 |

3W160 |

10.0 |

3,810 |

0.54 |

0.04 |

0.07 |

P3W160S6 |

3W160 |

13.1 |

1,755 |

15.43 |

2.78 |

4.63 |

P3W160S7 |

3W160 |

15.0 |

3,186 |

5.04 |

0.50 |

0.83 |

P3W180S3 |

3W180 |

4.9 |

3,379 |

3.90 |

0.36 |

0.60 |

P3W180S4 |

3W180 |

7.2 |

3,621 |

9.56 |

0.83 |

1.38 |

P3W180S5 |

3W180 |

10.0 |

3,538 |

15.67 |

1.40 |

2.31 |

P3W180S6 |

3W180 |

13.1 |

2,779 |

20.42 |

2.32 |

3.83 |

P3W180S7 |

3W180 |

15.0 |

2,014 |

20.14 |

3.16 |

5.21 |

P4W189S3 |

4W189 |

4.9 |

3,551 |

5.08 |

0.45 |

0.77 |

P4W189S5 |

4W189 |

10.0 |

3,758 |

20.60 |

1.73 |

2.97 |

P4W189S6 |

4W189 |

13.1 |

1,869 |

15.49 |

2.62 |

4.49 |

P4W189S7 |

4W189 |

15.0 |

3,790 |

38.90 |

3.24 |

5.56 |

P4W198S3 |

4W198 |

4.9 |

3,814 |

16.26 |

1.35 |

2.32 |

P4W198S5 |

4W198 |

10.0 |

1,262 |

34.76 |

8.70 |

15.02 |

P4W198S7 |

4W198 |

15.0 |

728 |

31.73 |

13.77 |

23.76 |

P4W217S2 |

4W217 |

3.6 |

3,502 |

8.31 |

0.75 |

1.29 |

P4W217S3 |

4W217 |

4.9 |

2,686 |

13.30 |

1.56 |

2.70 |

P4W217S4 |

4W217 |

7.2 |

1,090 |

34.91 |

10.12 |

17.45 |

P4W217S5 |

4W217 |

10.0 |

678 |

36.88 |

17.18 |

29.64 |

P4W217S6 |

4W217 |

13.1 |

613 |

34.39 |

17.72 |

30.57 |

P5W215S5 |

5W215 |

10.0 |

3,658 |

0.66 |

0.06 |

0.10 |

P5W215S6 |

5W215 |

13.1 |

3,565 |

2.23 |

0.20 |

0.34 |

P5W215S7 |

5W215 |

15.0 |

3,909 |

4.78 |

0.39 |

0.67 |

P5W231S4 |

5W231 |

7.2 |

3,646 |

7.80 |

0.68 |

1.20 |

P5W231S5 |

5W231 |

10.0 |

3,591 |

22.70 |

2.00 |

3.54 |

P5W231S6 |

5W231 |

13.1 |

2,782 |

26.36 |

2.99 |

5.31 |

P5W231S7 |

5W231 |

15.0 |

3,764 |

29.09 |

2.44 |

4.33 |

P5W248S3 |

5W248 |

4.9 |

3,816 |

4.82 |

0.40 |

0.71 |

P5W248S4 |

5W248 |

7.2 |

3,600 |

19.87 |

1.74 |

3.09 |

P5W248S5 |

5W248 |

10.0 |

2,946 |

32.82 |

3.52 |

6.23 |

P5W248S7 |

5W248 |

15.0 |

1,083 |

30.63 |

8.94 |

15.82 |

P6W192S4 |

6W192 |

7.2 |

3,716 |

0.33 |

0.03 |

0.05 |

P6W192S5 |

6W192 |

10.0 |

3,512 |

3.05 |

0.27 |

0.47 |

P6W192S6 |

6W192 |

13.1 |

3,135 |

2.55 |

0.26 |

0.44 |

P6W192S7 |

6W192 |

15.0 |

4,067 |

6.14 |

0.48 |

0.81 |

P6W200S5 |

6W200 |

10.0 |

3,503 |

4.34 |

0.39 |

0.68 |

P6W200S6 |

6W200 |

13.1 |

3,634 |

18.59 |

1.62 |

2.80 |

P6W200S7 |

6W200 |

15.0 |

3,513 |

32.14 |

2.89 |

5.01 |

P6W231S3 |

6W231 |

4.9 |

3,462 |

3.50 |

0.32 |

0.55 |

P6W231S4 |

6W231 |

7.2 |

3,372 |

18.17 |

1.70 |

2.94 |

P6W231S5 |

6W231 |

10.0 |

3,831 |

28.18 |

2.32 |

4.01 |

P6W231S6 |

6W231 |

13.1 |

2,730 |

29.31 |

3.39 |

5.86 |

P6W231S7 |

6W231 |

15.0 |

1,685 |

28.83 |

5.41 |

9.33 |

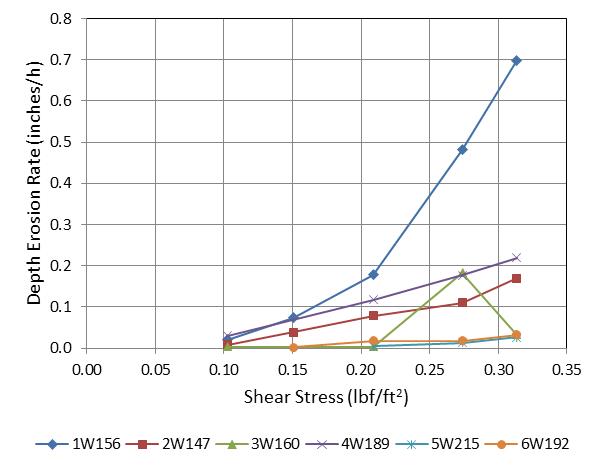

As would be expected, erosion rate increases with increasing shear stress. Figure 41 illustrates the wide variation of erosion rates for different soil samples using the soil sample with the lowest water content from each soil index. The figure also illustrates that in some cases, the measured values did not always behave in a monotonically increasing manner. (See soil type 3W160.)

The results of the erosion tests on the soils prepared by compaction were not useful because of the problem of slaking discussed previously. Therefore, these results are not reported. It may be noted, however, that the erosion of these soils was also in a form of soil lumps. The lumps were much larger than those for the soils prepared with the pugger mixer. The erosion process also featured large-scale depressions (deep valleys) in the sample surfaces.

1 inch = 25.4 mm.

1 lbf/ft2 = 47.8 Pa.

Figure 41. Graph. Representative plots of erosion rate versus shear stress