U.S. Department of Transportation

Federal Highway Administration

1200 New Jersey Avenue, SE

Washington, DC 20590

202-366-4000

Federal Highway Administration Research and Technology

Coordinating, Developing, and Delivering Highway Transportation Innovations

| REPORT |

| This report is an archived publication and may contain dated technical, contact, and link information |

|

| Publication Number: FHWA-HRT-12-048 Date: November 2013 |

Publication Number: FHWA-HRT-12-048 Date: November 2013 |

Since one of the primary goals of this task was to compare the durability performance of different pavement marking materials measured over time, the markings needed to be subjected to similar traffic conditions. Furthermore, a reasonably high traffic volume was desired to illustrate the differences between materials in the short time available for the study. It was important to consider roadway design features, traffic characteristics, and local environmental conditions when selecting the test deck locations. Together with each State transportation department office, the study sites were carefully selected so that they were representative, similar, and on newly installed pavements that would not need major maintenance during the life of this study. All the test decks were installed on asphalt pavements in good condition. All materials were installed along the edge line and right-most lane line of multilane highways. All test sections were applied along tangent sections.

PAVEMENT MARKING PREPARATION FOR INLAID MARKINGS

The intended goal of the placement of the pavement markings was to place half the length of the marking section on the surface of the road and half in a groove (inlaid). This required that within each test section, half of the section needed the current markings to be eradicated, leaving a clean surface for installation. The second half of the test section needed to be grooved to an adequate depth so that the marking would be inlaid (recessed) below the road surface. The specific parameters of the grooving for the inlaid products were based on providing a consistent difference between the height of the final pavement marking system and the height of the roadway. The goal was to have the pavement marking system, including the optics of the pavement marking system, slightly depressed in the roadway to provide protection from the wintertime plowing and studded tires.

The eradication process was not always consistent and ended up leaving a shallow groove in the road surface. A similar problem occurred when trying to create the groove for the inlaid marking section. The grooving machines would typically go somewhat deeper than specified. To account for these discrepancies in eradication and groove depths, areas where the markings were eradicated were considered to be placed in a shallow groove, and areas where the road was fully grooved (marking system below the road surface) were considered a deep groove. In some cases, markings were also applied over the preexisting markings and were considered a surface application. The various placements of the markings all occurred within the 0.5-mi test section. Markings that only had two placement types were each installed for approximately 0.25 mi.

ANCHORAGE PAVEMENT MARKING TEST DECK AREA

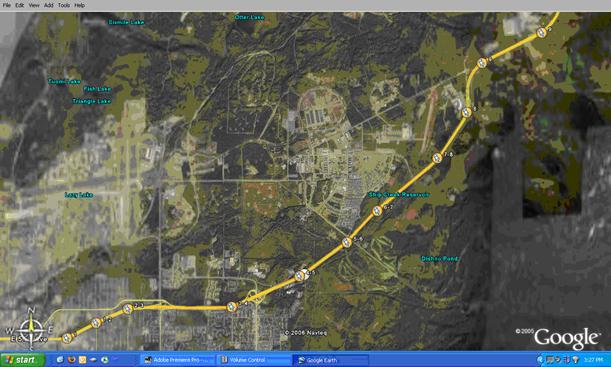

Figure 52. Photo. Glenn Highway (SR 1 in Anchorage, AK)

Figure 53. Screenshot. Proposed pavement marking installation sites (Anchorage, AK)

Figure 54. Photo. Test section 3 (Anchorage, AK)

Figure 55. Photo. Test section 5 (Anchorage, AK)

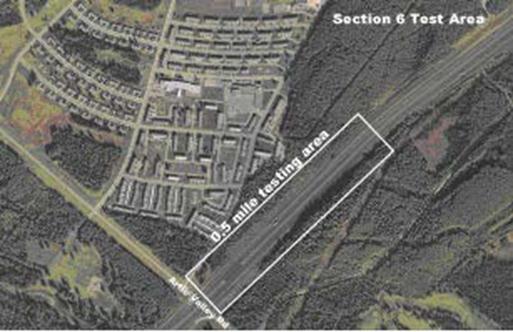

Figure 56. Photo. Test section 6 (Anchorage, AK)

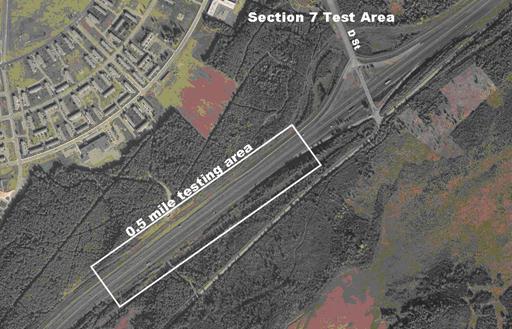

Figure 57. Photo. Test section 7 (Anchorage, AK)

Figure 58. Photo. Test section 8 (Anchorage, AK)

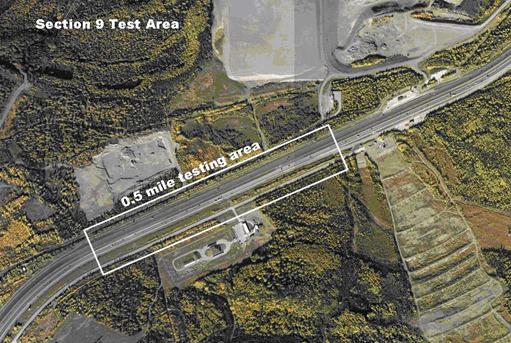

Figure 59. Photo. Test section 9 (Anchorage, AK)

Table 69. Initially installed pavement marking in Anchorage, AK.

Test Section |

Marking Type |

Application Type |

Placement |

Groove Depth (mil) |

Material Thickness (mil) |

Bead Type |

|---|---|---|---|---|---|---|

1 AK a |

AKDOT low-VOC paint |

Spray |

Surface |

0 |

12 |

AASHTO M247(33) |

Shallow (inlaid) |

65 |

12 |

||||

Deep (inlaid) |

160 |

12 |

||||

2 AK a |

3M all-weather paint |

Spray |

Shallow (inlaid) |

65 |

30 |

Swarco type 2 and 3M elements |

Deep (inlaid) |

160 |

30 |

||||

3 AK a |

MMA 98:2 (Stirling Lloyd) |

Extruded |

Shallow (inlaid) |

70 |

100 |

Type 2 |

Deep (inlaid) |

175 |

100 |

||||

4 AK a |

MMA 98:2 (Stirling Lloyd) |

Agglomerate |

Shallow (inlaid) |

90, |

200 |

Type 2 |

Deep (inlaid) |

275 |

200 |

||||

5 AK a |

3M pavement marking tape 380IES |

Rolled |

Deep (inlaid) |

175 |

100 |

N/A |

5 AK b |

3M pavement marking tape 380WR |

Rolled |

Deep (inlaid) |

175 |

100 |

N/A |

6 AK a |

MMA 4:1 (Ennis) |

Extruded |

Shallow (inlaid) |

60 |

100 |

30/50 Mesh Swarco Megalux T13 coated |

Deep (inlaid) |

120 |

100 |

||||

6 AK b |

Modified urethane (IPS) |

Spray |

Surface |

0 |

20 |

Potters type 1 AC110 coating and type 4 Visibead plus 2 |

Shallow (inlaid) |

70 |

20 |

||||

Deep (inlaid) |

120 |

20 |

||||

7 AK a |

Low-temperature acrylic waterborne paint (Ennis) |

Spray |

Surface |

0 |

12 |

Swarco AASHTO M247(33) |

Shallow (inlaid) |

140 |

12 |

||||

Deep (inlaid) |

175 |

12 |

||||

8 AK a |

MMA 4:1 (Degussa-Pathfinder™) |

Agglomerate |

Shallow (inlaid) |

120 |

200 |

Swarco AASHTO M247(33) |

Deep (inlaid) |

320 |

200 |

||||

9 AK a |

High-build acrylic waterborne paint (Ennis) |

Spray |

Shallow (inlaid) |

60 |

30 |

Swarco Megalux type 3 |

Deep (inlaid) |

145 |

30 |

||||

10 AK a |

Polyurea (IPS) |

Spray |

Shallow (inlaid) |

65 |

20 |

Potters type 1 AC110 coating and type 4 Visibead plus 2 |

Deep (inlaid) |

155 |

20 |

N/A = Not applicable.

Note: The installation of edge lines and outside lane lines occurred on August 7, 2006. Section 1 AK a was applied with long-line striping equipment; all other sections were hand cart applied.

Table 70. Pavement markings installed after the first winter in Anchorage, AK.

Date |

Test Section |

Marking Type |

Application Type |

Placement |

Groove Depth (mil) |

Material Thickness (mil) |

Bead Type |

|---|---|---|---|---|---|---|---|

6/21/2007 |

All |

AKDOT low-VOC paint |

Spray |

Over existing |

Existing |

12 |

AASHTO M247(33) |

9/24/2007 |

1 AK b |

Flint Trading Premark preformed thermoplastic |

Heat in place |

Deep (inlaid) |

160 |

125 |

N/A |

10/2/2007 |

2 AK b |

Standard AKDOT MMA |

Spray |

Shallow (inlaid) |

85 |

60 |

AASHTO M247(33) |

Deep (inlaid) |

180 |

60 |

N/A = Not applicable.

Note: Paint and MMA were applied with long-line striping equipment; preformed thermoplastic was hand cart applied.

Table 71. Pavement markings installed after the second winter in Anchorage, AK.

Date |

Test Section |

Marking Type |

Application Type |

Placement (Inlaid) |

Groove Depth (mil) |

Material Thickness (mil) |

Bead Type |

|---|---|---|---|---|---|---|---|

8/5/2008 |

9 AK b |

MMA (Ennis), paint (Pervo) |

Extruded with raised edges, double spray |

Shallow (inlaid) |

60 |

10, |

30/50 Mesh, |

Shallow and deep (inlaid) |

60 and 145 |

40 |

|||||

8/5/2008 |

7 AK b |

MMA (Ennis), paint (Pervo) |

Extruded with raised edges, spray |

(Deep) |

175 |

100 |

30/50 Mesh, |

175 |

20 |

Note: Paint was applied with long-line striping equipment; MMA was hand cart applied.

NASHVILLE PAVEMENT MARKING TEST DECK AREA

Figure 60. Photo. SR 840 (Nashville, TN)(120)

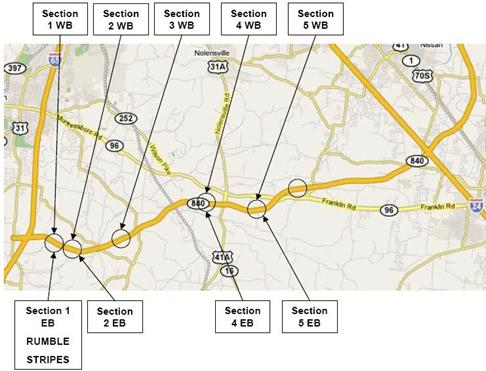

Figure 61. Illustration. Proposed pavement marking installation sites (Nashville, TN)(120)

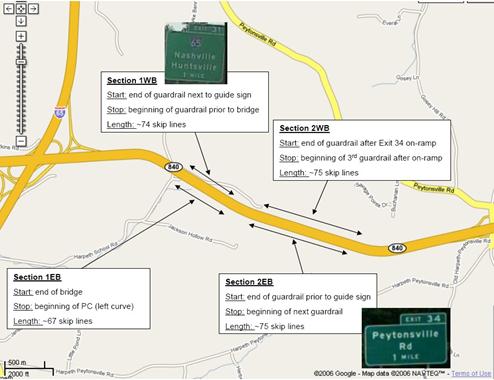

Figure 62. Illustration. Test sections 1 and 2 (Nashville, TN)(120)

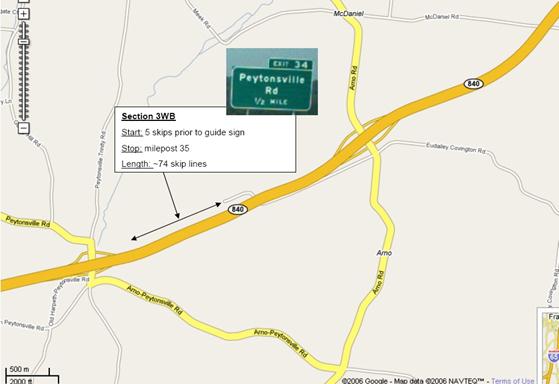

Figure 63. Illustration. Test section 3 (Nashville, TN)(120)

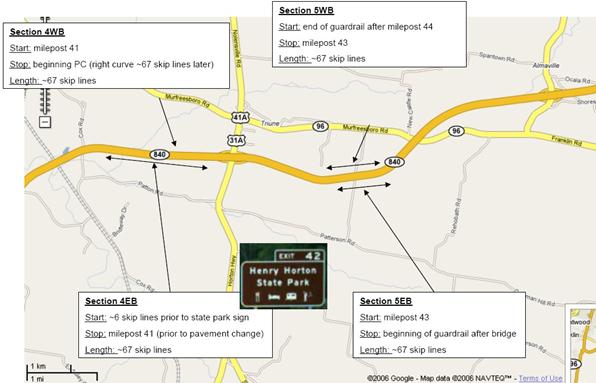

Figure 64. Illustration. Test sections 4 and 5 (Nashville, TN)(120)

Table 72. Pavement markings in Nashville, TN.

Test Section |

Marking Type |

Application Type |

Placement |

Groove Depth (mil) |

Material Thickness (mil) |

Bead Type |

Bead Rate |

|---|---|---|---|---|---|---|---|

1 TN-N |

Thermoplastic (Ennis) |

Spray |

Over rumble strip edge line only |

N/A |

40 |

Potters type 1 AC110 coating |

8 lb/100 ft2 |

2 TN-N |

Thermoplastic (Ennis) |

Spray |

Shallow (inlaid) |

75 |

40 |

Potters type 1 AC110 coating |

8 lb/100 ft2 |

Deep (inlaid) |

185 |

40 |

|||||

3 TN-N |

Thermoplastic (Ennis) |

Spray |

Shallow (inlaid) |

85 |

90 |

Potters type 1 AC110 coating |

8 lb/100 ft2 |

Deep (inlaid) |

270 |

90 |

|||||

4 TN-N |

Thermoplastic (Ennis) |

Extruded |

Shallow (inlaid) |

95 |

120 |

Potters type 1 AC110 coating and type 4 Visibead plus 2 |

6 lb type 1 and 10 lb type 4 per 100 ft2 |

Deep (inlaid) |

180 |

120 |

|||||

5 TN-N |

Thermoplastic (Gulfline) |

Inverted profile |

Shallow (inlaid) |

75 |

50/225 |

Potters type 1 AC110 coating and type 4 Visibead plus 2 |

6 lb type 1 and 10 lb type 4 per 100 ft2 |

6 TN-N |

Low-temperature acrylic waterborne paint (Ennis) |

Spray |

Shallow (inlaid) |

55 |

12 |

Potters type 1 AC110 coating |

8 lb/100 ft2 |

Deep (inlaid) |

145 |

12 |

|||||

7 TN-N |

Polyurea (Epoplex) |

Spray |

Shallow (inlaid) |

110 |

20 |

Prismo high index cluster and Potters type 4 Visibead plus 2 |

8 lb cluster and 10 lb type 4 per gallon |

Deep (inlaid) |

165 |

20 |

|||||

8 TN-N |

3M all-weather paint |

Spray |

Shallow (inlaid) |

135 |

26 |

Swarco type 2 and 3M elements |

18 g type 2 and 7.5 g elements per linear ft |

Deep (inlaid) |

175 |

26 |

|||||

9 TN-N |

High-build acrylic waterborne paint (Ennis) |

Spray |

Shallow (inlaid) |

100 |

25 |

Swarco type 3 virgin glass |

10-12 lb/100 ft2 |

Deep (inlaid) |

175 |

25 |

N/A = Not applicable.

Note: Edge and lane lines were initially installed on October 16, 2006, with long-line striping equipment.

Table 73. Lead-free thermoplastic pavement markings in Nashville, TN.

Test Section |

Marking Type |

Application Type |

Placement (Inlaid) |

Groove Depth (mil) |

Material Thickness (mil) |

Bead Type |

Bead Rate |

|---|---|---|---|---|---|---|---|

10 TN-N |

Ennis lead-free thermoplastic |

Extruded |

Surface |

0 |

80 |

AASHTO M247 with AC110 coating(33) |

8-10 lb/100 ft2 |

11 TN-N |

Swarco lead-free thermoplastic |

Extruded |

Surface |

0 |

80 |

AASHOT M247 with AC110 coating(33) |

8-10 lb/100 ft2 |

12 TN-N |

Dobco lead-free thermoplastic |

Extruded |

Surface |

0 |

85 |

AASHOT M247 with AC110 coating(33) |

8-10 lb/100 ft2 |

Note: All pavement markings were installed on June 5, 2008, with long-line striping equipment.

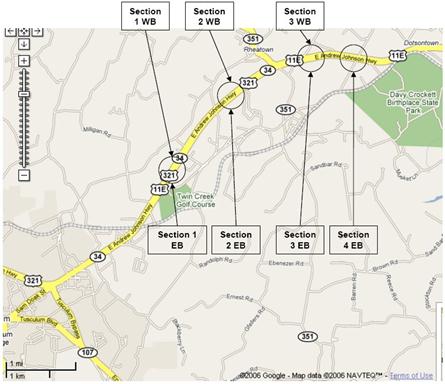

TUSCULUM PAVEMENT MARKING TEST DECK AREA

Figure 65. Photo. SR 34 (Tusculum, TN)(121)

Figure 66. Illustration. Proposed pavement marking installation sites (Tusculum, TN)(121)

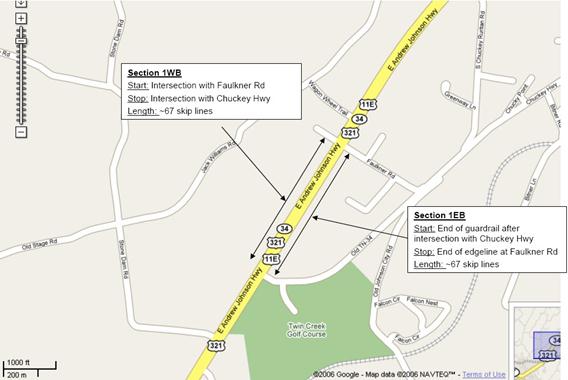

Figure 67. Illustration. Test section 1 (Tusculum, TN)(121)

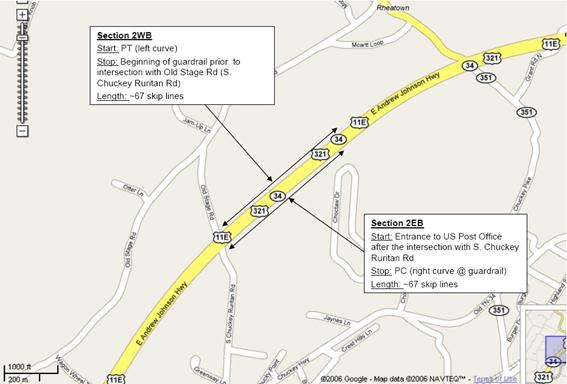

Figure 68. Illustration. Test section 2 (Tusculum, TN)(121)

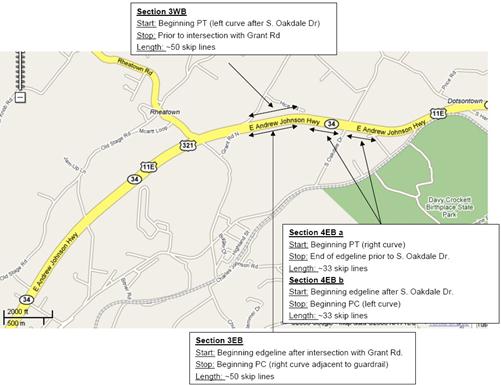

Figure 69. Illustration. Test sections 3 and 4 (Tusculum, TN)(121)

Table 74. Pavement markings in Tusculum, TN.

Test Section |

Marking Type |

Application Type |

Placement |

Groove Depth (mil) |

Material Thickness (mil) |

Bead Type |

Bead Rate |

|---|---|---|---|---|---|---|---|

1 TN-T |

Modified epoxy (Epoplex) |

Spray |

Shallow (inlaid) |

100 |

22 |

Type 4 Visibead plus 2 = E16, type 1 MnDOT spec |

10 lb type 4 and 6 lb type 1 per 100 ft2 |

Deep (inlaid) |

125 |

||||||

2 TN-T a |

MMA (Degussa) |

Extruded |

Shallow (inlaid) |

100 |

90 |

Swarco AASHTO M247(33) |

8-10 lb/100 ft2 |

Deep (inlaid) |

170 |

||||||

2 TN-T b |

MMA (Degussa-Pathfinder™) |

Agglomerate |

Shallow(inlaid) |

100 |

200 |

Swarco AASHTO M247(33) |

8-10 lb/100 ft2 |

Deep (inlaid) |

170 |

||||||

3 TN-T |

Low-temperature acrylic waterborne paint (Ennis) |

Spray |

Shallow(inlaid) |

50 |

15 |

AASHTO M247(33) |

8 lb/100 ft2 |

Deep (inlaid) |

110 |

||||||

4 TN-T |

High-build acrylic waterborne paint (Ennis) |

Spray |

Shallow(inlaid) |

105 |

24 |

Potters type 4 Visibead |

12 lb/100 ft2 |

Deep (inlaid) |

150 |

||||||

5 TN-T a |

ATM pavement marking tape 300 |

Rolled |

Shallow (inlaid) |

60 |

100 |

N/A |

N/A |

Deep (inlaid) |

130 |

||||||

5 TN-T b |

ATM pavement marking tape 400 |

Rolled |

Shallow(inlaid) |

25 |

100 |

N/A |

N/A |

Deep (inlaid) |

195 |

||||||

6 TN-T |

TN standard thermoplastic (superior) |

Extruded |

Shallow(inlaid) |

70 |

90 |

Swarco AASHTO M247(33) |

8-10 lb/100 ft2 |

Deep (inlaid) |

320 |

||||||

7 TN-T |

Modified urethane (IPS) |

Spray |

Shallow(inlaid) |

110 |

15 |

Type 4 Visibead plus 2 = E16, type 1 MnDOT spec |

10 lb type 4 and 8 lb type 1 per 100 ft2 |

Deep (inlaid) |

170 |

N/A = Not applicable.

Note: Sections 1 TN-T and 6 TN-T were applied with long-line striping equipment; all other sections were hand cart applied. Edge line and lane lines were initially installed May 14, 2007.