U.S. Department of Transportation

Federal Highway Administration

1200 New Jersey Avenue, SE

Washington, DC 20590

202-366-4000

Federal Highway Administration Research and Technology

Coordinating, Developing, and Delivering Highway Transportation Innovations

| REPORT |

| This report is an archived publication and may contain dated technical, contact, and link information |

|

| Publication Number: FHWA- HRT-17-095 Date: September 2017 |

Publication Number: FHWA- HRT-17-095 Date: September 2017 |

The research team conducted an extensive literature review in support of this study. The review focused on various topics, including the following:

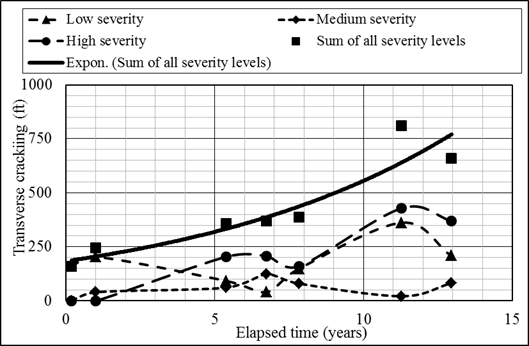

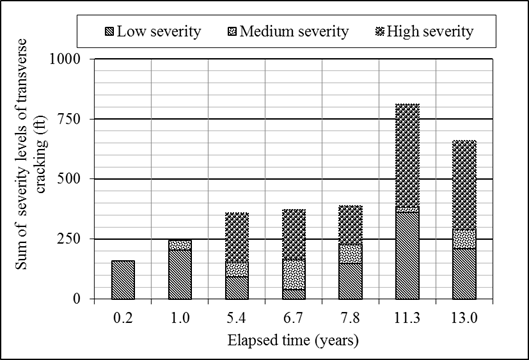

The LTPP and the majority of State transportation department pavement distress data are collected based on three severity levels: low, medium, and high. The distress severity rating can be problematic because it is a function of the judgment of the surveyor who is observing the pavement or, in the case of many State transportation departments, the surveyor who is reviewing and digitizing the electronic pavement surface images. Such judgment is a function of the degree of training and experience of the surveyors. Further, the same pavement segment may not be reviewed by the same surveyor each year or each data collection cycle. In addition, the crack severity level is a function of the crack opening, which is a function of the pavement temperature at the time of data collection. Thus, a crack may be labeled “high severity” in one year and medium severity the next year or vice versa. Figure 1 and figure 2 depict an example of the time-series data for each transverse crack severity level for LTPP test section A330 of the SPS-3 experiment in California.

1 ft = 0.305 m.

Figure 1. Graph. Time-series transverse cracking data for each severity level and the sum of all severity levels for LTTP SPS-3 test section A330 in California.

1 ft = 0.305 m.

Figure 2. Graph. Cumulative time-series transverse cracking data showing individual transverse crack severity level and the sum of all severity levels for LTTP SPS-3 test section A330 in California.

The data in the two figures indicate the following:

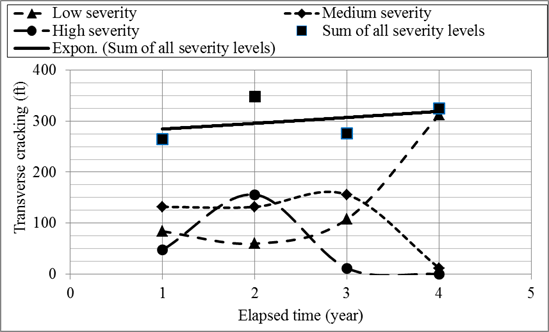

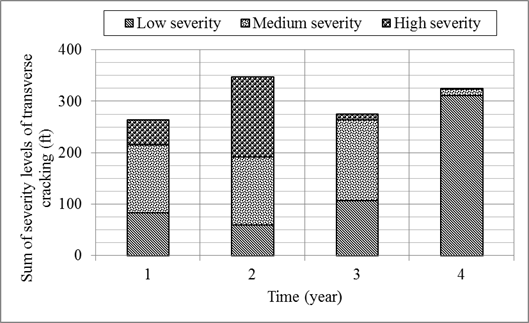

The crack severity level data could be used to roughly estimate the amount of work needed to preserve the pavement section. For example, cracks in the medium- and high-severity levels need to be sealed or patched. Low-severity cracks are typically not sealed or patched. For rigid pavements, low-severity transverse cracks may be subjected to dowel bar retrofit, while medium-and high-severity cracks typically are not.(3) Similar patterns can be found in the State transportation departments’ cracking data as shown in figure 3 and figure 4 for locations along a portion of Highway 24 in Colorado.

1 ft = 0.305 m.

Figure 3. Graph. Time-series transverse cracking data for each severity level and the sum of all severity levels, Highway 24, direction 2, BMP 329.9, in Colorado.

1 ft = 0.305 m.

Figure 4. Graph. Cumulative time-series transverse cracking data showing individual transverse crack severity level and the sum of all severity levels, Highway 24, direction 2, BMP 329.9, in Colorado.

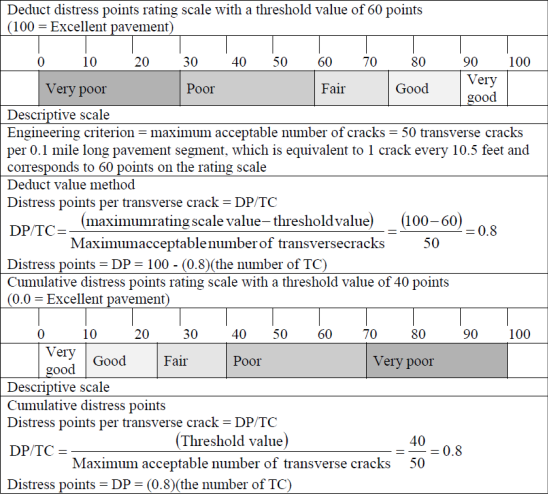

Some State transportation departments express pavement conditions and distresses using one or more of the following methods (see figure 5 and figure 6):(4,5)

1 mi = 1.61 km.

1 ft = 0.305 m.

Figure 5. Chart. Rating and descriptive scales and distress points.

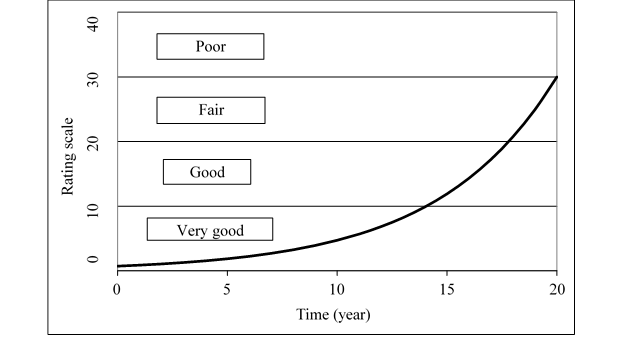

Figure 6. Graph. Descriptive rating scale for pavement condition.

It is important to note that if the threshold value is established based on engineering criteria, the pavement condition rating will be such that the relative condition of the pavement segment is constant for a given condition. The engineering criterion should be selected based on the experience of the transportation department and should address the extent of the condition or distress at which the pavement section in question is deemed in need of repair (maintenance, preservation, or rehabilitation) within the constraints of the department. An example of engineering criterion for transverse cracking could be 600 ft (183 m) of cracking or 50 transverse cracks (crack spacing of about 10.5 ft (3.2 m) along a 0.1-mi (0.16-km)-long asphalt pavement segment). Based on the engineering criterion, distress points can be assigned to each occurrence of the distress (each transverse crack) and the rating scale threshold value. To illustrate, consider the continuous rating scale of 0 to 100 (100 indicates no transverse cracks) and its threshold value of 60 points as shown in figure 5. An engineering criterion of 50 transverse cracks per 0.1mi (0.16 km) implies that the asphalt pavement score is 60 (it loses 40 distress points) when the pavement segment accumulates 50 transverse cracks. Based on a linear accumulation of distress points, each transverse crack is worth 0.8 distress points.(4) If the agency decided to change the threshold value from 40 to 50 but to maintain the engineering criterion of 50transverse cracks, then 50cracks would cause the pavement section to lose 50 distress points and each crack would be worth 1 distress point. Stated differently, the engineering criteria for establishing the threshold value should be based on the extent of the distress rather than a number on the rating scale.

Finally, the engineering criteria express the conditions of the pavement and could be based on the user or the agency. Examples of roadway user-based criteria are ride quality (IRI) and rut depth. Examples of agency-based criteria are cracking and faulting. One other factor to note is that the engineering criteria for certain distress or condition types could be global or could be established based on pavement class, traffic volume, regional needs, and so forth. Nevertheless, the methods used to develop the engineering criteria should be well documented, and the criteria should be studied and calibrated as more pavement condition and distress data become available.

Many State transportation departments, such as the LADOTD, the CDOT, the Michigan Department of Transportation, and the WSDOT, have developed engineering criteria for each distress type and severity level. Examples of such criteria for alligator cracking and the associated deduct points are listed in table 1.(6)

Table 1. Engineering criteria and deduct points for alligator cracking.(6)

| Severity | Alligator Cracking Deduct Points Extent (ft2) | |||||

|---|---|---|---|---|---|---|

| 0–51 | 51–701 | 701–1,301 | 1,301–2,401 | 2,401–3,168 | > 3,168 | |

| Low | 0 | 1–16 | 16–21 | 21–25 | 25–28 | 28 |

| Medium | 0 | 1–21 | 21–29 | 29–36 | 36–49 | 48 |

| High | 0 | 1–29 | 29–43 | 43–50 | 43–61 | 61 |

| 1 ft2 = 0.093 m2 | ||||||

Pavement distress or condition indices are often based on one or more condition or distress types. For example, the Alligator Cracking Index (an individual index) is based on the severity levels (low, medium, and high) and the extent of the alligator cracks, whereas a combined pavement distress or condition index (such as PCI) consists of two or more condition or distress types. The combined index expresses the sum of the distress points assigned to each distress or condition type and severity level divided by the number of pavement segments (see figure 7). Hence, a combined pavement distress index expresses the average pavement condition and not the actual condition based on individual distress types.(4,7)

Where:

DI = Distress index.

Σ DP = Sum of the distress points along the project.

N = Number of 0.1-mi (0.16-km)-long segments along the project (N = L/0.1).

L = Project length in mi (km).

Finally, the distress points or the pavement condition indices do not express the true nature of the pavement conditions. For example, immediately after construction, the cumulative distress points of a pavement project subjected to a 2-inch (51-mm) asphalt overlay are exactly the same as the cumulative distress points for another project subjected to a 6-inch (152-mm) asphalt overlay. The pavement surface conditions of both projects are free of distresses. Stated differently, neither the distress points nor the condition indices express the design life of the overlay or the impact of the type of pavement preservation or rehabilitation on the pavement service life. Further, the differences between the distress points and the pavement distress index before and after treatment cannot and should not be used to express the benefits of the applied pavement maintenance or rehabilitation treatments. Consider three pavement sections having the same distress points and distress index that were subjected to 2-, 4-, and 6-inch (51-, 102-, and 152‑mm) asphalt overlays, respectively. The differences in the distress points and distress index before and after treatment were exactly the same although the costs of the overlays were substantially different and so were their design service lives (DSLs) and future pavement performance. The DSL of the treatment and the pavement rate of deterioration must be accounted for in the calculation of the true benefits of the treatments.(2)

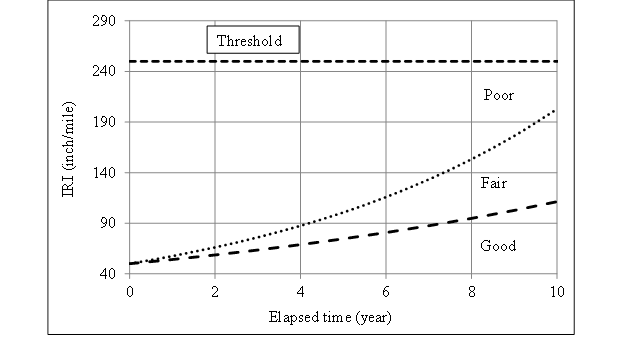

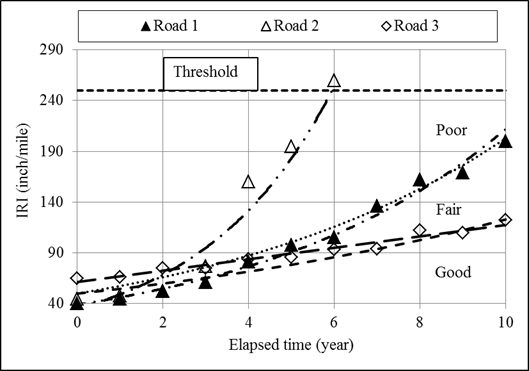

Descriptive terms (such as good, fair, and poor) are also used to express the various categories of the pavement conditions. Although the terms hide important details, they are universal and easily communicated to legislators and the general public. The three terms are typically based on the pavement appearance and/or ride quality at the time of rating. Descriptive classifications of good, normal or fair, and poorly performing AC and portland cement concrete (PCC) pavements were previously addressed in four FHWA reports published in 1998, 1999, 2011, and 2012. (See references 8–11.) The shortcomings of the first two reports are that the descriptive terms are based on the last collected pavement condition data as shown in figure 8. Figure 9 depicts the actual time-series IRI data for three in-service pavement sections located in the State of Washington. Over the 10-year period, these sections were not subjected to any pavement treatment. Figure 9 clearly shows the following:

The three descriptive terms could be improved to better express the pavement conditions if they were based on the pavement’s rates of deterioration.

1 inch/mi = 0.0158 m/km.

Figure 8. Graph. Pavement condition classification system.

1 inch/mi = 0.0158 m/km.

Figure 9. Graph. Shortcomings of the recommended classification system when dealing with real but good data (not the worst-case scenario).

On the other hand, the latter studies describe the terms good, fair, and poor and their potentially associated treatment categories as follows:(11)

Once again, the significant issue with these types of definitions is that they do not consider the changes in conditions and distresses over time. The terms do convey the current conditions of a pavement well, but pavement health is not best demonstrated by a snapshot in time. The pavement conditions and distresses generally deteriorate with time, and the pavement health depends on the current conditions and the rates of deterioration over time. The specific terms could still serve their purpose, but the criteria used to assign the rating should be modified to account for the effects of time. Consideration of condition and rates of deterioration facilitates planning and pavement management, while condition alone has limited use as a tool for managing pavement unless the deterioration rate (curve) is estimated based on the available data.

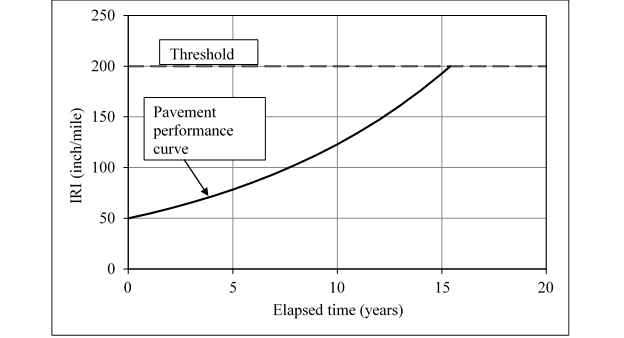

The performance of a pavement segment is often illustrated by the progression of pavement condition or distress over time, as shown in figure 10. The level of performance at any given time is equivalent to the level of pavement condition or distress at that time compared with the threshold value. Therefore, the performance of a pavement segment over its service life is defined by the level of service over time or by the accumulation of damage over time.(12)

1 inch/mi = 0.0158 m/km.

Figure 10. Graph. A typical pavement performance curve.

Most State transportation departments collect pavement condition and distress data. Some use the data to observe the condition of the pavement, while others use the time-series pavement condition and distress data to predict future pavement conditions. The combination of both practices allows the development of current and future strategies for management of the pavement network.

Many State transportation departments have studied the effectiveness of various pavement treatments using historical pavement performance data. Based on the various studies, the minimum and maximum treatment service lives listed in table 2 were published in the various sources listed for each treatment type. These estimated averages are adequate to be used in the analysis at the network level. For project-level analysis, more accurate estimates are required. Such estimates could be based on predictions of past and future pavement conditions through the modeling of pavement condition and distress data before and after treatment to create pavement performance curves.

Table 2. Estimated and reported pavement treatment service life.

| Treatment Type | Reference | Estimated Treatment Service Life Expectancy (Years) | ||

|---|---|---|---|---|

| Minimum | Average | Maximum | ||

| Thin (< 2.5-inch) hot-mix asphalt (HMA) overlay | 16–22 | 2 | 8 | 12 |

| Thick (≥ 2.5-inch) HMA overlay | 23 | 6 | 10 | 17 |

| Single chip seal | 16–18, 24, and 25 | 1 | 6 | 12 |

| Double chip seal | 17, 18, 21, 24, and 26 | 4 | 9 | 15 |

| Thin (< 2.5-inch) mill and fill | 21 and 23 | 4 | 8 | 20 |

| Thick (≥ 2.5-inch) mill and fill | 23 | 6 | 10 | 17 |

| Cold-in-place HMA recycling | 17, 26, and 27 | 5 | 10 | 20 |

| Crack sealing | 16 and 17 | 2 | 3 | 10 |

| Microsurfacing | 16, 18, 20, 22, 28, and 29 | 4 | 6 | 10 |

| 1 inch = 25.4 mm. | ||||

Several predictive pavement performance models have been developed to estimate the pavement performance curve based on parameters such as traffic, weather, and pavement type. These models include straight-line extrapolation, regression, polynomial constrained least squares, application of Shaped curves, use of probability distributions, and Markov chain models.(13) One such example, for thin HMA overlays, is presented in figure 11. The β parameters were determined for different performance indicators (IRI, pavement condition rating (PCR), and rut depth) as well as different road types (interstate, noninterstate highway, and nonhighway).(14)

Where:

PI = Performance indicator for a pavement segment in a given year.

CAATT = Cumulative average annual daily truck traffic (in millions) predicted for the pavement segment from the time of treatment to the given year.

CAFDX = Cumulative annual freeze index (in thousands of degree-days) predicted from the time of treatment to the given year.

β1, β2, and β3 = Statistical parameters.

The most common method for modeling pavement condition and distress data as a function of time is by ordinary least squares regression. It should be noted that a minimum of three time-series data points are required to model the nonlinear data. The method used to determine the parameters of the selected mathematical function (see figure 12 through figure 14) consists of minimizing the sum of squared errors. This method works when the data of the particular pavement segment indicate deterioration over time. If the method does not capture the progression of condition or distress over time, other models may be required.(15)

Where:

RD = Rut depth.

α, β, γ, ω, k, θ, and μ = Regression parameters.

Crack = Crack length, area, or percent.

t = Elapsed time in years.

Such models can be used to estimate the time until a certain threshold value is reached. Threshold is the prespecified condition or distress level indicating unacceptable pavement condition or distress has been reached and that the pavement segment is in need of maintenance, preservation, or rehabilitation depending on the level at which the prespecified threshold value is set.

Another method of modeling pavement condition and distress data is the clusterwise regression procedure, which was introduced by Spath and later modified by others. (See references 15 and 30–35.) Clusterwise regression involves splitting the data into subgroups based on their characteristics and fitting separate models to each subgroup. The resulting pavement performance models could be more accurate because they model small subsets of data with similar trends. However, the resulting models are discrete (each model represents a certain time period).

Most procedures for estimating pavement preservation benefits are based on the prediction of future pavement performance, comparison of the pavement performance before and after treatment, and immediate changes in the pavement conditions resulting from treatment. Although the commonality among all procedures is a prespecified threshold value, the actual value of the threshold varies from one procedure to another. Some procedures set one threshold value for each type of pavement distress and condition, while others use the combined distress index and an overall threshold value. Still others use one threshold value for maintenance, one for preservation, and one for rehabilitation and/or reconstruction. Further, some procedures use the term life to express the benefits. Such a term should not be taken separately from service life. For example, the term pavement design life used by the American Association of State Highway and Transportation Officials (AASHTO) Guide for Design of Pavement Structures, in reality, expresses the pavement DSL.(36) The pavement design itself is based on the following threshold values:

Table 3. Threshold values that could be used in the AASHTO MEPDG.

| Pavement Condition or Distress Type | Threshold Value | Explanation |

|---|---|---|

| Alligator cracking | 1,267 ft2/0.1 mi (73 m2/0.1 km) |

Twenty percent of lane area cracked (assuming 12-ft (3.66-m) lane width) |

| Longitudinal cracking | 1,056 ft/0.1 mi (200 m/0.1 km) |

Two cracks along the entire section length |

| Transverse cracking (Jointed concrete pavements) | 396 ft/0.1 mi (50 m/0.1 km) |

Two thirds of the slabs are cracked (assuming 16-ft (4.88-m)-long slab) |

| Transverse cracking (HMA) | 350 ft/0.1 mi (67 m/0.1 km) |

Crack spacing = 12 ft (3.66 m) |

| Faulting | 0.25 inches, average over 0.1 mi (6.35 mm, average over 100 m) |

Dowel bars have likely sheared or concrete around dowels has deteriorated and may be spalled |

Nevertheless, various procedures were developed for estimating treatment benefits. The following are some of these procedures:

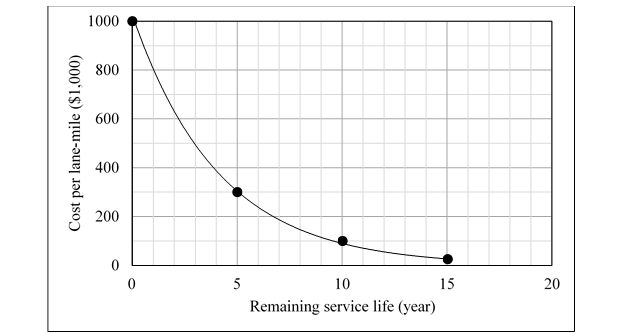

1 lane-mile = 1.61 lane-km.

Figure 15. Graph. Relationship between RSL and cost of managing pavements.

For each pavement section, the following steps are required for calculating the RSL:

In the case of a new pavement structure or a newly rehabilitated pavement, the estimated RSL must be positive and restricted to be less than or equal to the DSL of the pavement or the DSL of the treatment, as stated in figure 16.(4) The reason is that for a few years after treatment, the pavement may or may not show any distress, and hence, the estimated RSL is very large and meaningless. The restriction could be dropped when a significant number of data points indicating pavement deterioration are available. At that time, the RSL could be greater or less than the DSL, and the information could be used as feedback to the pavement design and construction processes.

Where:

t (PC = Th) = Time (the number of years) at which the pavement condition reaches the threshold value (Th).

SA = Pavement surface age in years.

DSL = Pavement design service life in years.

The important point is that the RSL does not advocate worst-first as perceived by a few people. It is a management tool that allows State transportation departments to manage their pavement asset based on engineered criteria and a long-term preservation program. It should be noted that the accuracy of RSL is a function of the accuracy and variability of the pavement condition and distress data. In addition, the accuracy of the estimated RSL decreases as the value of that RSL increases (i.e., predicts much further out in time).

The RSL of a given pavement network can be calculated as the weighted average RSL of the total number of pavement sections, n, within the network using figure 17:

![]()

Figure 17. Equation. RSLnetwork.

Where:

i = ith pavement segment.

n = Total number of pavement segments or sections in the network.

RSL = Remaining service life.

SL = Segment length.

It should be noted that any pavement segment that falls below the threshold value has an RSL of zero. In general, no negative RSL should be assigned to any pavement regardless of its condition. For a newly designed and constructed or rehabilitated pavement segment, its RSL is equal to the design life.(4)

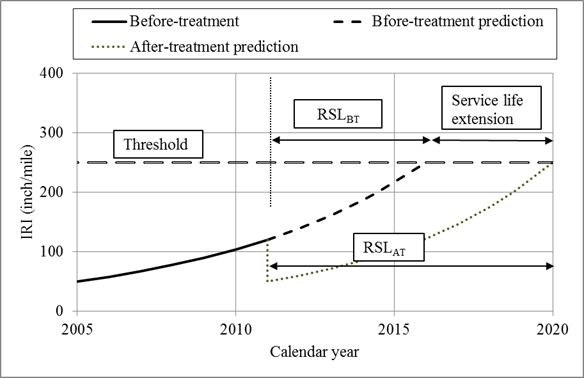

1 inch/mi = 0.0158 m/km.

Figure 18. Graph. Schematic of the definition of SLE.

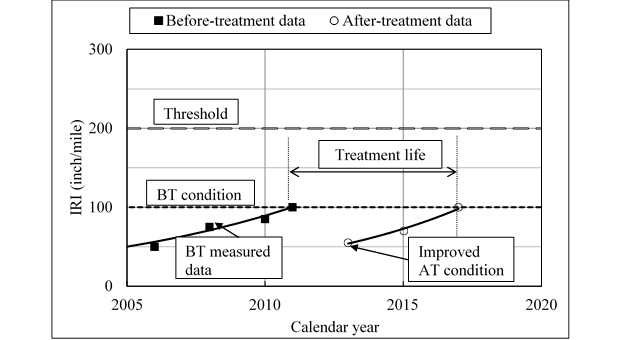

1 inch/mi = 0.0158 m/km.

Figure 19. Graph. Schematic of the definition of TL.

1 inch/mi = 0.0158 m/km.

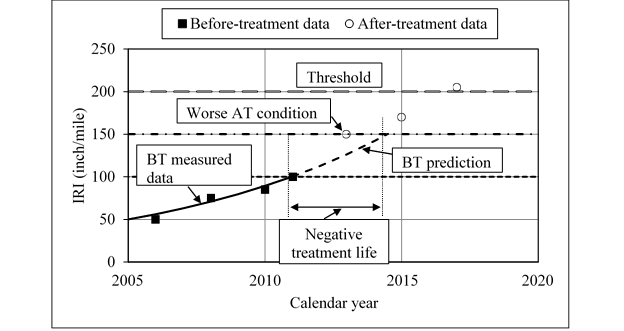

Figure 20. Graph. Schematic of the definition of negative TL.

Figure 21. Graph. Schematic of the definition of TB.(22)

1 inch/mi = 0.0158 m/km.

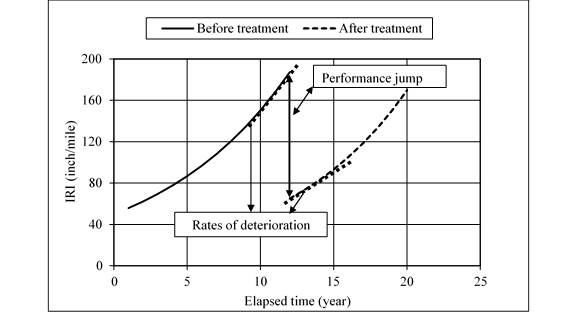

Figure 22. Graph. PJ and DRR.

The number of available pavement treatment types is large and ever growing as new techniques and materials are developed. Each State transportation department has a group of treatments it chooses to apply based on its experience and the results achieved over time. The selection of a particular pavement treatment from this pool of options is often specific to each State transportation department. The next section provides a discussion of the selection process.

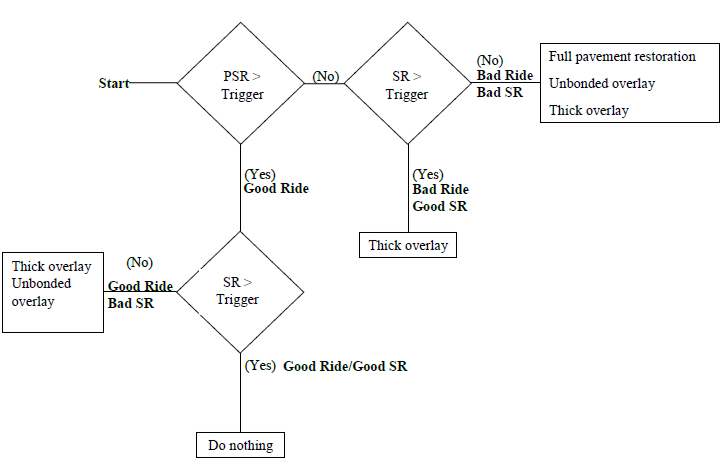

Many State transportation departments have developed plans and methodologies for selecting pavement treatments. The most common are decision trees and matrices. These are often developed from past experience and tend to focus on one or two options. An example of a decision tree is shown in figure 23 and its reference table 4, and an example of a matrix is shown in table 5. The values in table 4 indicate the trigger values corresponding to roadway functional classifications for use in figure 23. The table contains trigger values based on PQI, present serviceability rating (PSR), and surface rating (SR). These trees/matrices are rarely updated and often neglect new technology. Nonetheless, they are typically based on the following data:(17)

Figure 23. Illustration. Example of decision tree for continuously reinforced concrete pavement (CRCP).

Table 4. Trigger values for functional classifications.

| Functional Classification | Trigger Value | ||

|---|---|---|---|

| PSR | SR | PQI | |

| Rural principal interstate | 3.0 | 2.7 | 3.0 |

| Rural principal arterial | 3.0 | 2.7 | 2.9 |

| Rural minor arterial | 2.8 | 2.5 | 2.8 |

| Rural major collector | 2.8 | 2.5 | 2.6 |

| Rural minor collector | 2.8 | 2.5 | 26 |

| Rural local | 2.7 | 2.4 | 2.6 |

| Urban interstate | 3.1 | 2.7 | 3.0 |

| Urban principal arterial freeway | 3.1 | 2.7 | 2.9 |

| Urban principal arterial | 2.8 | 2.5 | 2.9 |

| Urban minor arterial | 2.7 | 2.4 | 2.8 |

| Urban collector | 2.6 | 2.4 | 2.6 |

| Urban local | 2.5 | 2.4 | 2.6 |

Table 5. Example of decision matrix.

| Problem | Possible Cause | Maintenance | Rehabilitation | |||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Structural failure | Mix composition | Temperature or moisture changes | Construction | Patching & routine maintenance | Fog seal | Surface treatment | Slurry seal | Surface recycling | Thin overlay | Open-graded surface | Structural overlay | Structural recycling | Reconstruction | |

| Alligator cracking | X | — | — | — | X | — | X | X | — | — | — | X | X | X |

| Edge joint cracks | X | — | X | X | X | — | — | — | — | — | — | — | — | — |

| Reflection cracks | — | — | — | — | X | — | X | X | — | — | X | X | X | — |

| Shrinkage cracking | — | X | X | — | — | — | X | X | X | — | X | X | X | — |

| Slippage cracks | — | — | — | X | X | — | — | — | — | — | — | — | — | — |

| Rut depth | X | X | — | X | — | — | — | — | X | X | — | X | X | X |

| Corrugation | X | X | — | X | — | — | — | — | X | X | — | X | X | X |

| Depressions | X | — | — | X | X | — | — | — | — | — | — | — | X | X |

| Upheaval | — | — | X | — | X | — | — | — | — | — | — | — | X | X |

| Potholes | X | — | X | X | X | — | — | — | — | — | — | X | — | — |

| Raveling | — | X | — | X | — | X | X | X | X | X | — | — | — | — |

| Flushing asphalt | — | X | — | X | — | — | X | — | X | — | X | — | — | — |

| Polished aggregate | — | X | X | — | — | — | X | — | X | X | X | — | — | — |

| Loss of cover aggregate | — | X | — | X | — | — | X | — | — | — | — | — | — | — |

| — Indicates not applicable. | ||||||||||||||

This subsection reviews pavement preservation costs and lifecycle cost analyses (LCCAs). Owing to a lack of available cost data required for detailed analyses, no such analyses are included in this report. However, the information is provided to assist in such analyses if more data become available.

The costs of any pavement treatment can be divided into two categories: agency costs and user costs. The agency cost is the physical cost of the pavement project, including design and construction less the residual value of the pavement section at reconstruction. This is often referred to as direct costs.(39) User costs are much more difficult to estimate than agency costs because they are not based on specific monetary value but on vehicle operating costs (VOC), delay costs, and accident costs. The three types of user costs and how they relate to normal and work zone conditions are listed in table 6 and discussed in the next few subsections.(40)

Table 6. Review of user cost components.

| Component | Normal Operation | Work Zone Conditions |

|---|---|---|

| VOC | Based on total delay-hours and driving cost caused by accidents | Based on total delay-hours caused by work zone and accidents in the work zone |

| Delay | Total delay-hours caused by accidents | Total delay-hours (caused by work zone and accidents in work zone) |

| Accidents | Number and severity of accidents | Number and severity of work zone accidents |

One problem that arises when estimating user costs is the transformation of delay, accidents, etc., to a monetary value.(41) Some believe that user costs should be defined as “user benefit” and expressed qualitatively as improvements in performance or safety.(42,43) The user benefits of one treatment compared with another or with the do-nothing alternative could be used to choose between treatments with similar agency costs. In other words, if two treatment options satisfy the pavement needs and have similar agency costs, then the deciding factor would be the user costs. This would greatly simplify the process, which is often considered complicated and deficient, especially when applicable data are not available for the various detailed user cost models.(44) However, LCCA should be completed to evaluate both the agency and user costs over the pavement lifecycle and to select the most cost-effective treatment strategy. For completion, these costs and LCCA are discussed in the next few subsections.

LCCA

Recently, State transportation departments have faced many constraints, including public demand for quality pavement and budget shortfalls. Hence, the considerations become the following:(45)

These questions cannot be properly and accurately answered unless LCCA is conducted. Such analysis should address the agency and the user costs and must be based on accurate and up-to-date data so that the costs and benefits of various pavement preservation alternatives can be compared.

The Need for LCCA

In general, highway pavements are designed and constructed to provide services for a limited time called the “service life.” Over time, the combined effects of traffic loads and environmental factors accelerate the pavement deterioration and reduce its level of serviceability. Maintenance, preservation, and rehabilitation treatments are designed and applied to pavement sections to slow their rates of deterioration and to extend their service lives. The application of most pavement treatments requires traffic control (lane closures and/or detours), which significantly affects traffic flow, increases travel time, and increases VOC. The costs and benefits of pavement treatments are composed of many elements, including the following:

Methods of LCCA

Because LCCA considers all planned pavement treatments of a given analysis period, the service life and the value of money over time should be considered. One hundred dollars in 2014 likely bought much more than $100 will in 2024. Hence, the following two common methods are incorporated in LCCA to account for this:

Where:

NPW = Net present worth.

N = Total number of preservation treatments.

i = Discount rate.

n = Number of years into the future.

k = Preservation action number.

The discount rate reflects the rate of inflation adjusted to the opportunity cost to the public. The opportunity cost is often indicated by a comparison with the discount rate of the conservative U.S. Treasury bill. The historical inflation rate trend from 1999 to 2014 indicates a range of –0.35 to 3.58 percent with an average of 2.39 percent. Table 7 lists common discount rates used by State transportation departments in the 1990s. The discount rate should reflect historical trends in the nation or region where the analysis is conducted.(50) Alternatively, the discount rate could be determined from the Consumer Price Index (CPI). The average CPI discount rate from 2001 to 2010 was about 2.54 percent.(45,51)

Table 7. Historical discount rates.1

| Year | Analysis Period (Years) | ||||

|---|---|---|---|---|---|

| 3 | 5 | 7 | 10 | 30 | |

| 1992 | 2.7 | 3.1 | 3.3 | 3.6 | 3.8 |

| 1993 | 3.1 | 3.6 | 4.0 | 4.3 | 4.5 |

| 1994 | 2.1 | 2.3 | 2.5 | 2.7 | 2.8 |

| 1995 | 4.2 | 4.5 | 4.6 | 4.8 | 4.9 |

| 1996 | 2.7 | 2.7 | 2.8 | 2.8 | 3.0 |

| 1997 | 3.2 | 3.3 | 3.4 | 3.5 | 3.6 |

| 1998 | 3.4 | 3.5 | 3.5 | 3.6 | 3.8 |

| Average | 3.1 | 3.3 | 3.4 | 3.6 | 3.8 |

| 1Effects of discount rates on $100 from 2014 to 2024 using the average CPI of 2.54 percent. One hundred dollars in 2014 has the same purchasing power as $128 in 2024. | |||||

Where:

EUAC = Equivalent uniform annual cost.

NPW = Net present worth

i = Discount rate.

n = Number of years into the future.

In the past, some State transportation departments and almost all local road agencies allowed their pavement assets to deteriorate to levels requiring major rehabilitation or reconstruction. For many years, their treatment policies were based on a worst-first policy in which severely deteriorated pavement sections were subjected to preservation treatments while the condition of the rest of the pavement network continued to deteriorate. Recently, many State transportation departments have initiated and implemented comprehensive pavement preservation programs at the entire road network level.

The programs are based on cost-effective treatment of sections of the pavement network in relatively good condition to restore their conditions, decrease their rates of deterioration, and enhance the safety of the motorists. Over time, the preservation program becomes a part of the annual pavement treatment strategy of the State transportation department.(52) The pavement preservation program typically consists of light pavement treatments, such as crack sealing, nonstructural overlay, light rehabilitation actions, mill and fill, and so forth. The alternative to pavement preservation is the old practice of letting the pavement network deteriorate until expensive rehabilitation or reconstruction actions are necessary. Several studies have been conducted on the effectiveness of pavement preservation and are summarized in the following subsections.

The effectiveness of pavement treatments can be measured in the short term and/or the long term. Short-term benefits are defined by the immediate improvement to the pavement conditions and rates of deterioration, while long-term benefits are defined over the service life of the pavement section by the performance and extension in service life. The costs can also be short term (individual treatment) or long term (LCCA).

Pavement preservation can be applied through a series of pavement treatments over the pavement lifecycle (a treatment strategy). The alternative to pavement preservation is allowing the pavement to deteriorate until reconstruction is required, the worst-first or do-nothing scenario. The cost effectiveness of pavement preservation at the project level can be quantified using LCCA. The analysis could be conducted on the various alternative pavement preservation treatments that could be applied to a pavement section over time and on the do-nothing scenario followed by reconstruction. Comparison of the results from the various strategy analyses indicates the cost savings or extra expenditures of performing preservation over the life of the pavement segment.

The cost effectiveness of pavement preservation at the project level has been well documented. Most literature agrees that pavement preservation can be conducted at minimal cost and create major savings over the life of the pavement. One study found that the cost savings of pavement preservation was as high as $5 saved for every $1 spent on preservation.(53) Another reports savings of $4 to $10 for every $1 spent on preservation.(54) Other benefits include improving ride quality and creating a pavement network with consistent needs from year to year.(55)

The effectiveness of pavement preservation at the network level is more difficult to quantify than at the project level. Funds designated for preservation reduce the funds available for rehabilitation and reconstruction. In other words, pavement preservation is thought to decrease the lifecycle cost of a given pavement project, but the effect on the network is often unknown. In addition, the public and legislators may not understand why pavements in seemingly good condition are being treated, while others in poor conditions are not. State transportation departments should document and communicate the effects of preservation maintenance on the health of the pavement network and on the lifecycle cost in a clear and consistent manner. Educating the public and the legislature is necessary to establish and maintain a successful pavement preservation program.(55)

The short- and long-term benefits and effectiveness of pavement preservation at the project and network levels should be quantified. Short-term benefits include improving ride quality and addressing safety issues, while long-term benefits (cost savings) are not realized until years or decades into the future. Therefore, pavement preservation strategies must be optimized through projection of needs and funds into the future. In this way, the effects of performing or deferring various pavement projects can be evaluated.(55,56)

Pavement treatment effectiveness is often described with a single value or a range of values, such as 5 to 10 years gained or an average 7-year service life. The probabilities of the various results are not typically reported. The probabilistic effectiveness of treatments can be quantified and communicated using an innovative matrix format called T2M.(3) T2M shows the following:

Table 8 shows an example of a T2M that lists the results of single chip seal applications in Colorado. The cells display this information in the following convenient way:

Table 8. T2M for single chip seal in Colorado.

| A | B | C | D | E | F | G | H | I | J | K | L | ||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Condition/Distress Type: Condition/Distress Causing the Minimum RSL Before and After Treatment | |||||||||||||

| Before Treatment Data | After Treatment Data | ||||||||||||

| CS or RSL Bracket Number and Range in Years and Number of the 0.1-Mi (0.16‑Km)-Long Pavement Segments Transitioned From Each Before Treatment RSL Bracket to the Indicated After Treatment RSL Brackets | Treatment Benefits in Terms of TL, SLE, and RSL of the Treatment (Years) | ||||||||||||

| CS or RSL Bracket Number | RSL Bracket Range (Years) | 0.1-Mi (0.16‑Km)-Long Pavement Segments | 1 | 2 | 3 | 4 | 5 | TL | SLE | RSL | |||

| 0 to 2 | 3 to 5 | 6 to 10 | 11 to 15 | 16 to 25 | |||||||||

| Number | Percent | ||||||||||||

| 1 | 0 to 2 | 2,329 | 58 | 125 | 453 | 1,230 | 267 | 254 | 4 | 8 | 9 | ||

| 2 | 3 to 5 | 746 | 18 | 3 | 88 | 379 | 121 | 155 | 3 | 7 | 11 | ||

| 3 | 6 to 10 | 365 | 9 | 1 | 52 | 157 | 55 | 100 | 2 | 4 | 12 | ||

| 4 | 11 to 15 | 141 | 3 | 0 | 8 | 52 | 27 | 54 | 2 | 1 | 14 | ||

| 5 | 16 to 25 | 452 | 11 | 1 | 24 | 128 | 55 | 244 | 1 | –5 | 15 | ||

| Total | 4,033 | 100 | 130 | 625 | 1,946 | 525 | 807 | — | — | — | |||

| Average | — | — | — | — | — | — | — | 3 | 6 | 10 | |||

| — Not applicable. Bold indicates the number of pavement segments where no change in the CS resulted from the treatment. |

|||||||||||||

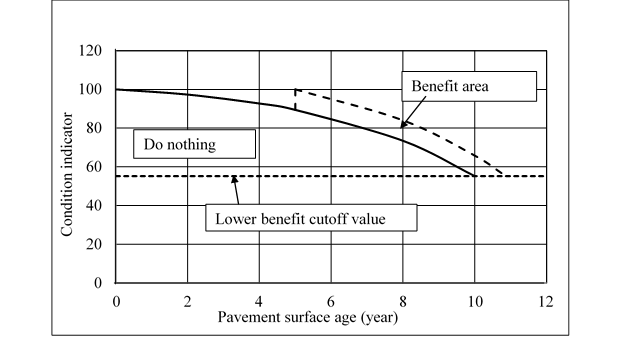

The effectiveness of pavement treatments is often determined simply based on the benefits gained, as mentioned previously. The benefits, however, do not indicate effectiveness relative to cost, which is the main constraint for all State transportation departments. Most literature agreed that treatments applied to pavements in better condition produce more benefits, and the cost of the treatment was a function of the conditions.(38,57,58) Further, the time-value relationship of money affects the cost of the treatment and its cost effectiveness. Therefore, benefits must be compared relative to costs to determine the cost effectiveness of the treatment and to select the treatment timing.(41) Performing pavement treatments at the optimum time provides the greatest benefit-to-cost ratio. The idea of optimum timing is not new; in fact, the concept was built into the AASHTO 1993 design guide.(36) Few methodologies for the determination of optimum treatment timing for preventive maintenance and rehabilitation actions were developed.(22) This methodology is designed to optimize treatment timing based on the treatment benefit (calculated by the area under the performance curve). However, the most cost-effective treatments should consider the pavement longevity and should be based on the ratio of dollars to years of service.(3) To improve lifecycle costs, State transportation departments should base their preservation strategies on maximizing the longevity of the pavement network rather than maximizing the condition of the network.

The LTPP Program was established under the Strategic Highway Research Program (SHRP) in 1987. Since 1991, FHWA has managed and funded the LTPP Program. The program houses two fundamental groups of experiments: SPS and GPS. The LTPP Program has addressed myriad studies of pavement-related issues ranging from validation of pavement design procedures to traffic and material variability, and pavement maintenance, preservation, and rehabilitation actions. The conclusions of these studies are documented in countless publications in the forms of research reports, product briefs, and techbriefs, which have substantially contributed to the development of advanced pavement technology and highlighted the importance of the LTPP Program and its associated database.

The overall objective of the LTPP Program is to collect, store, and make various data elements relating to pavement performance available to researchers, scientists, and the general public. These include the pavement structures and conditions, traffic volume and load, and environmental conditions for various pavement sections located along the existing North American highway systems. Over a more than 20-year period, the data have been used by researchers, practitioners, and other stakeholders to assess the long-term performance of pavements under various loading and environmental conditions and with different structural and material compositions. The specific established objectives of the LTPP Program include the following:(59)

The LTPP Program consists of about 2,500 500-ft (152.4-m)-long, mostly in-service test sections located in all 50 U.S. States, Puerto Rico, and 10 Canadian provinces. The test sections are divided between the two main studies, SPS and GPS. Some of the SPS test sections were reconstructed to investigate certain pavement engineering factors, while others were specially preserved to study the impacts of some preservation treatments. In contrast, the GPS test sections consist of sections of existing roads that were subjected to various typical maintenance and preservation treatments. Thus, eight types of existing in-service pavements make up the GPS and are monitored throughout North America. More details on the SPS and GPS test sections can be found throughout the remainder of this report.

SPS is a long-term program designed to study specifically constructed, maintained, or rehabilitated pavement sections incorporating controlled sets of experimental design and construction features. The main objective of the SPS experiments is to provide more detailed and complete sets of data to extend and refine the results obtained from the GPS experiments. There are nine SPS experiments grouped by the five categories listed in table 9.(59)

Table 9. The SPS categories and experiments.

| Category | Experiment | Title |

|---|---|---|

| Pavement structural factors | SPS-1 | Strategic Study of Structural Factors for Flexible Pavements |

| SPS-2 | Strategic Study of Structural Factors for Rigid Pavements | |

| Pavement maintenance | SPS-3 | Preventive Maintenance Effectiveness of Flexible Pavements |

| SPS-4 | Preventive Maintenance Effectiveness of Rigid Pavements | |

| Pavement rehabilitation | SPS-5 | Rehabilitation of Asphalt Concrete (AC) Pavements |

| SPS-6 | Rehabilitation of Jointed Portland Cement Concrete (JPCC) Pavements | |

| SPS-7 | Bonded Portland Cement Concrete (PCC) Overlays of Concrete Pavements | |

| Environmental effects | SPS-8 | Study of Environmental Effects in the Absence of Heavy Loads |

| Asphalt aggregate mixture specifications | SPS-9P | Validation and Refinements of Superpave Asphalt Specifications and Mix Design Process |

| SPS-9A | Superpave Asphalt Binder Study | |

| SPS-10 | Warm-Mix Asphalt (WMA)—in design stage |

The SPS experiments involve monitoring the newly constructed pavement sections and the existing pavement sections that were subjected to maintenance or rehabilitation treatments after assignment to the SPS. The SPS is divided into various SPS experiments numbered SPS-1 through -9. Each experiment includes multiple test sites, and each test site contains between 2 and 12 pavement test sections depending on the experiment. Following the original assignment of test sections in 1992, numerous supplemental test sections were constructed by different State transportation departments to study aspects of particular interest to them.(59) FHWA is initiating new sites for the study of WMA (SPS-10) and is currently considering new pavement preservation experiments in addition to the existing SPS experiments.

GPS is also a long-term program designed to study a series of experiments on selected in-service pavement structures with the objective of establishing a national pavement performance database. Pavement sections believed to be built with proper materials and good engineering design were selected as part of the GPS program.(59)

The pavement structures included in the GPS were constructed or reconstructed up to 15 years before the start of the LTPP Program. Unfortunately, detailed data were often not available for the period between the original construction time and the time when they were selected for the LTPP Program. However, it was believed that some beneficial insights might be drawn without this data. Finally, some SPS test sections have been reclassified as GPS test sections upon the application of rehabilitation treatments. Table 10 lists the titles of each of the GPS experiments.(59)

Table 10. The GPS experiments.

| Experiment | Title |

|---|---|

| GPS-1 | Asphalt Concrete (AC) Pavement on Granular Base |

| GPS-2 | AC Pavement on Bound Base |

| GPS-3 | Jointed Plain Concrete Pavement (JPCP) |

| GPS-4 | Jointed Reinforced Concrete Pavement (JRCP) |

| GPS-5 | Continuously Reinforced Concrete Pavement (CRCP) |

| GPS-6A | Existing AC Overlay of AC Pavement (existing at the start of the program) |

| GPS-6B | AC Overlay Using Conventional Asphalt of AC Pavement—No Milling |

| GPS-6C | AC Overlay Using Modified Asphalt of AC Pavement—No Milling |

| GPS-6D | AC Overlay on Previously Overlaid AC Pavement Using Conventional Asphalt |

| GPS-6S | AC Overlay of Milled AC Pavement Using Conventional or Modified Asphalt |

| GPS-7A | Existing AC Overlay on Portland Cement Concrete (PCC) Pavement |

| GPS-7B | AC Overlay Using Conventional Asphalt on PCC Pavement |

| GPS-7C | AC Overlay Using Modified Asphalt on PCC Pavement |

| GPS-7D | AC Overlay on Previously Overlaid PCC Pavement Using Conventional Asphalt |

| GPS-7F | AC Overlay Using Conventional or Modified Asphalt on Fractured PCC Pavement |

| GPS-7R | Concrete Pavement Restoration Treatments With No Overlay |

| GPS-7S | Second AC Overlay, Which Includes Milling Or Geotextile Application, on PCC Pavement With Previous AC Overlay |

| GPS-9 | Unbonded PCC Overlay on PCC Pavement |

In this study, previously published reports regarding the LTPP Program and data analyses were scrutinized. The topics of these reports include the effects of design factors on pavement performance measures and the selection of appropriate and cost-effective treatment type. However, the findings of these reports did not adequately address the relationships between the maintenance and rehabilitation actions and the performance of the various pavement sections or the optimal timing for treatment application. Nevertheless, some of the relevant reported findings are enumerated and summarized in the following subsections.

Impacts of Pavement Treatment on Pavement Performance

This subsection summarizes reported findings related to the impacts of pavement treatments on the collected pavement condition and distress data of various LTPP experiments.

For the SPS-3 experiment, the following findings were reported:

For the SPS-4 experiment, the findings were inconsistent. Some researchers reported the following findings:

For the SPS-5 experiment, the following findings were reported:

For the SPS-6 experiment, the following findings were reported:

Impacts of Design Variables on Pavement Performance

The findings of various studies regarding the impacts of various design factors on pavement performance are summarized in the next six subsections.

Climatic Variables

One study suggested that dowel bars should be used in JPCP to reduce joint faulting in WF climates.(8) In dryer climates, the joint spacing should be reduced to decrease transverse cracking potential due to high thermal gradients. This is because the precipitation has the following two effects on the pavement material temperatures:

In addition, IRI was found to be higher for similar pavements located in colder and wetter climates than those in other climates. Further, higher initial roughness led to higher rates of deterioration. The researchers stated that the results should be reviewed with caution because the PCC durability was not included in the analysis, which might have affected the results.(8)

One study indicated that faulting in undoweled JPCP test sections in DF regions was similar to those sections in DNF regions.(67) The mean faulting values were 0.126, 0.079, 0.063, and 0.039inches (3.2, 2.0, 1.6, and 1.0 mm) in the WF, WNF, DF, and DNF regions, respectively. On the other hand, the doweled JPCP test sections showed no significant differences in joint faulting between the WF and the WNF regions. Doweled joint faulting occurred mostly in the DF regions, followed by the DNF and the WF regions. Test sections in the WNF regions showed the lowest faulting values.

On the other hand, an initial evaluation of SPS-2 test sections indicated that for doweled joints in rigid pavements, faulting was most prevalent in the DF region, followed by the DNF, and the WF regions.(68) In addition, the total longitudinal crack length was found to be longer in the DNF region, followed by the DF and the WF regions.

A strong relationship was reported between IRI and climatic conditions for flexible pavements.(69) Higher roughness was measured in pavement sections located in areas with higher precipitation, higher freezing index, and/or higher number of freeze-thaw cycles. The researchers also stated that adequate frost protection was an important factor for good pavement performance. In hot climates, roughness values were strongly related to the number of days with temperatures above 90 °F (32 °C). In addition, the roughness was lower for pavement sections in hot regions with higher precipitation than for those with less precipitation. The researchers related this finding to the cooling effect that precipitation may have on asphalt pavements, thereby reducing deformations resulting from high temperatures. On the other hand, rigid, jointed pavements were found to have higher roughness in climates with higher precipitation.

Roadbed Soils

One study indicated that better subgrade support (higher backcalculated modulus of subgrade reaction, k-value) resulted in fewer transverse cracks with deteriorated edges and in lower roughness (IRI) for JPCP, JRCP, and CRCP.(70)

Another study concluded that PCC pavements constructed over fine-grained roadbed soils had higher joint faulting than those constructed on coarse-grained roadbed soils.(8) This was likely due to increased soil erosion and reduced water permeability. Likewise, JPCP sections constructed on coarse-grained roadbed soils had lower IRI than those constructed on fine-grained roadbed soils. The researchers recommended that a thick layer of granular material be placed and compacted beneath the aggregate base course to improve drainage and reduce faulting, especially for undoweled pavements. The study also concluded that PCC slabs supported on strong foundations, such as stabilized bases or granular roadbed soils, often had a lower initial roughness.

A study based on the SPS-8 experiment data found that the most prevalent early pavement distress was longitudinal cracking outside the wheelpath.(71) Further, this distress was most commonly observed in sections located in the WF region and on an active roadbed soil (frost-susceptible or swelling soils due to freeze-thaw cycles). It was also observed that flexible and rigid pavements constructed on active roadbed soils had the highest mean initial roughness values and the highest rates of deterioration compared with pavements constructed on fine and coarse-grained roadbed soils. This study were in agreement with other studies that a good working platform such as stabilized base and granular subgrade contributed to a smoother pavement after construction.(8,70)

Joint Load Transfer

A common finding from a few studies was that the presence of dowel bars had a significant impact in reducing joint faulting.(8,67,70) In fact, after 10 years in service, JPCP sections with dowel bars showed 50 percent less joint faulting than those without dowel bars. In wet and/or freeze climates, the use of dowel bars appeared to negate the effects of cold temperatures and increased moisture that could often lead to erosion and pumping of fines. It was also found that the use of doweled joints could have more impact on pavement performance than design features such as subdrainage, tied-concrete shoulders, and joint spacing.(67) Further, it was found that properly sized dowel bars could eliminate corner breaks and transverse cracking near the joints as well as minimize joint faulting.(72)

In an FHWA report, the impacts of various parameters on the variability of the load transfer, as quantified by the load transfer efficiency (LTE) measured over time, were documented.(73) The researchers reported the following findings:

Drainage

In a National Cooperative Highway Research Program Research Results Digest, it was stated that for properly designed doweled joints in JPCP, joint faulting was fairly low, and permeable bases had relatively small effect on reducing joint faulting.(74) Edge drains were found not to have a significant effect on joint faulting when dense-graded bases were used. For undoweled JPCP, joint faulting in general was higher, and permeable bases had a significant effect in reducing joint faulting. However, the permeable bases should be designed and maintained to reduce or eliminate the migration of fines from the lower materials. Similarly, slab cracking was found to be reduced in pavements constructed on asphalt-treated permeable bases. D-cracking was also found to be less prevalent in pavement sections constructed on permeable bases, likely because of reduced base saturation and introduction of water and various compounds into the concrete slab. Note that all of these findings were based on limited data.

Base Type

In separate studies sponsored by FHWA, it was reported that JPCP constructed over a stabilized base had less faulting and smoother surfaces than those constructed with an untreated aggregate base, especially in undoweled JPCP.(8,75) JPCP with an asphalt-stabilized base or lean concrete base had significantly lower initial roughness when compared with other base materials. In addition, JPCP sections constructed with granular and asphalt-stabilized bases had significantly lower percentages of cracked sections than JPCP with cement-treated or lean concrete bases. The cracking was not associated with an increased roughness.

In an LTPP Program sponsored study using the SPS-2 experiment data, it was found that pavement sections with permeable asphalt-treated bases developed the fewest transverse and longitudinal cracks.(76) On the other hand, pavement sections with lean concrete base developed the most transverse and longitudinal cracks during the first 10 years of pavement service life. This confirmed earlier findings.(8,75)

Slab Width

Two studies concluded that increasing slab width by 2 ft (0.6 m) reduced faulting of concrete pavements by reducing the critical deflections at the corner of the slab from heavy truck axles.(8,67) The mean faulting data for undoweled sections (10 years old or less) indicated about 50 percent less faulting with a widened slab. It was stated that this outcome agreed with previous non-LTPP field performance data. No difference was found between the faulting of doweled widened slab sections and doweled conventional-width JPCP. However, JPCP sections with widened lanes did not show any transverse cracking. In addition, the initial evaluation on SPS-2 data revealed that widened slabs have less initial roughness.(76)

This chapter presented a review of the state of the practice of various State transportation departments with regard to several aspects of pavement condition and distress data analyses and treatment selection. A summary of the results of previous studies conducted using the LTPP database was also included. The following topics were covered:

The various topics were evaluated, and the research team reached the following conclusions and made the following recommendations regarding execution of the current study: