U.S. Department of Transportation

Federal Highway Administration

1200 New Jersey Avenue, SE

Washington, DC 20590

202-366-4000

Federal Highway Administration Research and Technology

Coordinating, Developing, and Delivering Highway Transportation Innovations

| REPORT |

| This report is an archived publication and may contain dated technical, contact, and link information |

|

| Publication Number: FHWA- HRT-17-095 Date: September 2017 |

Publication Number: FHWA- HRT-17-095 Date: September 2017 |

To address the objectives of this study, as described in chapter 1, a dual pavement rating system was developed that considered both the pavement condition and its rates of deterioration. The rationale for the development of the system is expressed in chapter 2 and further detailed in this chapter. An accurate pavement condition rating system represents pavement behavior best when based on the current and future pavement conditions. The main benefit of including the estimation of future conditions is the ability of pavement managers to plan, budget, and create long-term treatment strategies to preserve the pavement network. Pavement condition ratings based on the current conditions alone only allow decisions to be made for the given data collection cycle. As interpreted by AASHTO Transportation Asset Management Guide—A Focus on Implementation, the Moving Ahead for Progress in the 21st Century Act of 2012 (MAP-21) sets forth the following directive for asset management:(77)

Asset management is a strategic and systematic process of operating, maintaining, and improving physical assets, with a focus on engineering and economic analysis based upon quality information, to identify a structured sequence of maintenance, preservation, repair, rehabilitation, and replacement actions that will achieve and sustain a desired state of good repair over the lifecycle of the assets at minimum practicable cost. (from section 1103)

The two key statements are the following:

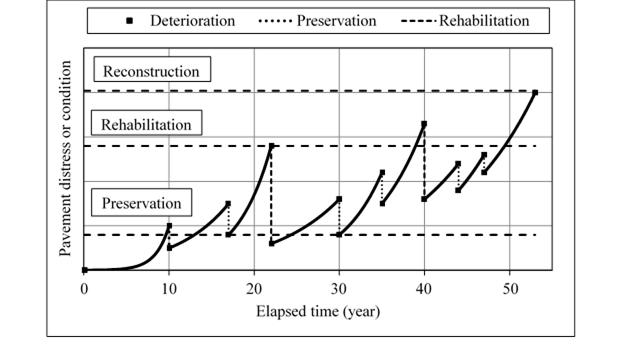

The measured pavement distresses and conditions generally increase over time as the pavement deteriorates as a result of traffic loads and environmental conditions. Periodically over the pavement lifecycle, preservation and rehabilitation treatments are applied to reduce the pavement distresses and improve its conditions, as illustrated in figure 26. The costs of these treatments generally increase as the pavement deteriorates and the distresses or conditions worsen. Pavement condition ratings based on current distresses and conditions are most commonly found to be problematic because they do not include the pavement rates of deterioration. The current condition alone does not support LCCA. Two pavement sections in equally good condition this year may or may not be in similar good or fair condition 2 or 3 years later. Consequently, an accurate pavement rating system should include the current distresses and conditions as well as the pavement rates of deterioration.

Figure 26. Graph. Typical pavement condition or distress over the pavement lifecycle.

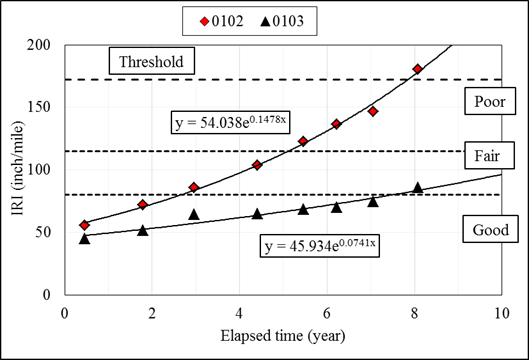

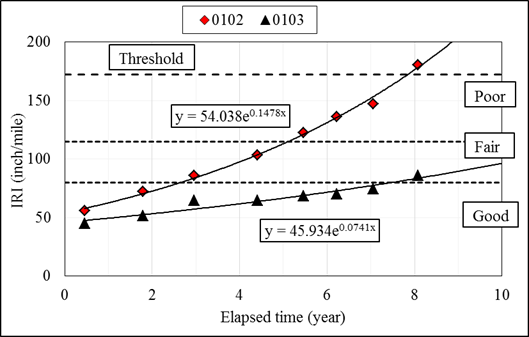

Figure 27 illustrates the progression of roughness, as described by the IRI, of SPS-1 test sections 0102 and 0103 in Iowa. The figure also provides an example rating system based on the current condition (IRI). The data in this figure indicate the following:

1 inch/mi = 0.0158 m/km.

Figure 27. Graph. IRI versus elapsed time for LTTP SPS-1 test sections 0102 and 0103 in Iowa.

These observations indicate that test section 0102 changed from good to fair condition in about 1year and from fair to poor in about 4 years, whereas 8 years after construction, test section 0103 was in the middle of the fair condition range. This example indicates that the latest measured IRI data of any test section should not be used alone to predict future condition and consequently to plan possible treatment actions. The time-series data must be used. The reason is that almost all pavement sections deteriorate over time, and their rates of deterioration vary substantially from one pavement section to the next. Hence, to effectively and comprehensively plan pavement preservation actions for a pavement network, the rate of deterioration with respect to each condition and distress type of each pavement section must be known. Therefore, an accurate pavement rating system should be based on each measured pavement condition and distress type and the corresponding rates of deterioration.

A balanced and comprehensive pavement condition rating system should be based on the two types of pavement conditions, functional and structural. In this study, the functional rating was based on ride quality (IRI) and safety (skid resistance and rut depth) and was expressed by the RFP. (A detailed definition of this measurement is provided later in this section.) For a given pavement section and when supported by the available data, three RFPs should be calculated; one based on IRI, one on rut depth, and one on skid resistance. The shortest RFP was assigned to the pavement section in question to flag that section for potential treatment actions.

The structural rating was based on cracking and rut depth or faulting and was expressed by RSP. (A detailed definition of this measurement is provided later in this section.) For any given pavement section, six RSPs should be calculated; one for each of transverse, longitudinal, alligator, edge, and block cracking, and one for either rut depth for flexible pavements or faulting for rigid pavements. The shortest of the six RSPs was assigned to the pavement section in question to flag it for potential treatment actions.

Based on this discussion, RFP is defined as the shortest time period in years from the time of the last data collection to the time when a functional condition or distress reaches its corresponding prespecified threshold value. Although in this study two RFP measures (IRI and rut depth) were used to define RFP, the pool of functional measures could be expanded by State transportation departments to include, as an example, skid resistance. Nevertheless, in this study, after calculating two RFPs (one for rut depth and one for IRI), the shortest RFP was assigned to the pavement section in question to flag that section. The other RFP was retained in the database. RSP, on the other hand, is defined as the shortest time period in years from the time of the last data collection to the time when a structural distress reaches its corresponding prespecified threshold value. In this study, for each test section, six RSPs were calculated, and the shortest RSP was assigned to the pavement section in question to flag it for potential action Once again, the pool of structural measures used in this study for calculating RSPs could be expanded by the State transportation departments. It is important to note that once a pavement section is flagged for potential action, all available functional and structural data should be downloaded and examined before a treatment strategy is selected. Also note that the recommended threshold values for each pavement condition and distress are presented in a later section in this chapter.

These definitions indicate that RFP and RSP are not combined condition indices. Each condition and distress type is analyzed separately, and the results are retained for further analyses. It is the minimum RFP or RSP assigned to the pavement section that flags that section for potential actions. In addition, RFP and RSP do not indicate the treatment to be applied to a pavement section. Rather, they flag mechanisms for identifying pavement sections that are in need of further attention. Once again, the stakeholder should review all available data for the flagged pavement sections and examine the distress, condition, and other related data. After this examination, the stakeholder can select treatment alternatives that address all or most defects and their causes. Ideally, each treatment alternative should then be subjected to LCCA and its impact on the entire pavement network should be determined before the treatment is selected.

The RFP and RSP concept differs from the condition indicators evaluated in chapter 2 of this report. RFP and RSP account for the pavement rates of deterioration. The RFP and RSP are calculated based on nonlinear mathematical functions that model the progression of the condition or distress over time. These equations are flexible and can be selected by the users or can be replaced with the equations of their choosing.

RFP and RSP is a dual rating system; RFP can be considered a pavement rating for the users, whereas RSP is an agency rating. The rating scale of the dual rating systems and the corresponding descriptive terms are listed in table 11. The scale is divided into three CSs numbered 1, 2, and 3 that correspond to poor (red), fair (yellow), and good (green) conditions, respectively, and to the three RFP and RSP ranges listed in table 11. Note that the main reason for using the same year ranges for RFP and RSP is ease of communication.

Table 11. Pavement condition rating based on three CSs.

| CS | RFP Range (Years) | RSP Range (Years) | ||

|---|---|---|---|---|

| Code | Color | Descriptor | ||

| 1 | Red | Poor | < 4 | < 4 |

| 2 | Yellow | Fair | 4 to < 8 | 4 to < 8 |

| 3 | Green | Good | > 8 | > 8 |

| Note: The dual rating systems could be used to select treatment categories at the network level. For example, preservation treatments should generally be applied to pavement sections with fair or better CSs. Heavy preservation treatment, or more likely rehabilitation, should generally be applied to pavement sections with poor RSP CSs. The treatment selection should be verified at the project level. |

||||

The dual rating system shown in table 11 was expanded to the five-level CS dual rating system presented in table 12. The main advantage of this five-level rating system is that the condition of the pavement sections in one CS or within a given RFP or RSP range is more uniform. It is recommended to use the three-level rating system for communication while the five-level rating system should be used for analyses and management. Note that this is possible because the poor and good ratings of the three-level CS system encompass the two additional CSs from the five-level CS system, while the fair CSs are equivalent.

Table 12. Pavement condition rating based on five CSs.

| CS | RFP Range (Years) | RSP Range (Years) | ||

|---|---|---|---|---|

| Code | Color | Descriptor | ||

| 1a | Red | Very poor | < 2 | < 2 |

| 1b | Pink | Poor | 2 to < 4 | 2 to < 4 |

| 2 | Yellow | Fair | 4 to < 8 | 4 to < 8 |

| 3a | Light Green | Good | 8 to < 13 | 8 to < 13 |

| 3b | Green | Very good | > 13 | > 13 |

The main advantage of using RFP and RSP together is that each should decrease 1 year for every calendar year (i.e., RFP and RSP are linear functions of time although they are modeled as nonlinear functions of the pavement distress and conditions). To illustrate this point, consider the power function (see figure 28) that is typically used to model the rut depth data as a function of time.

![]()

Figure 28. Equation. Rut depth.

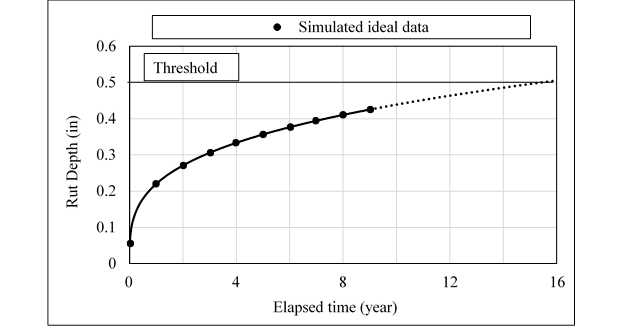

The time t in figure 29 is constant and is equal to the time in years between the end of construction of the last treatment action and the time when the RD threshold value is reached. RSP is then calculated as the time t minus the surface age of the pavement section in question as stated in figure 30.

Where:

RD = rut depth.

α and β = Statistical parameters of the nonlinear function of figure 28.

Th = Threshold value for rut depth (typical value is 0.5 inch (12.5 mm)).

SA= Surface age (years).

DSL = Design service life of the last treatment (years).

ln = natural logarithm.

e = Exponential function.

Finally, RSP should be positive and is limited to the DSL minus the SA of the pavement section in question. Such limitation is required until at least three time-dependent RD data are measured and available in the database.

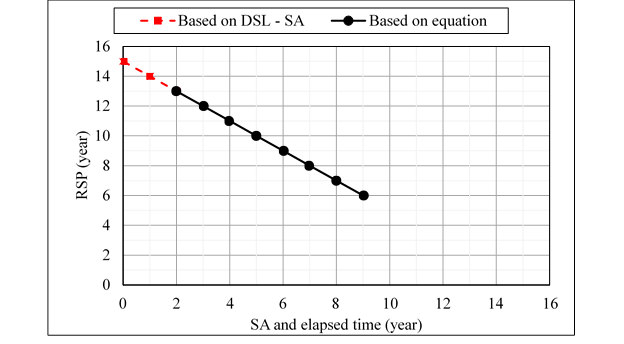

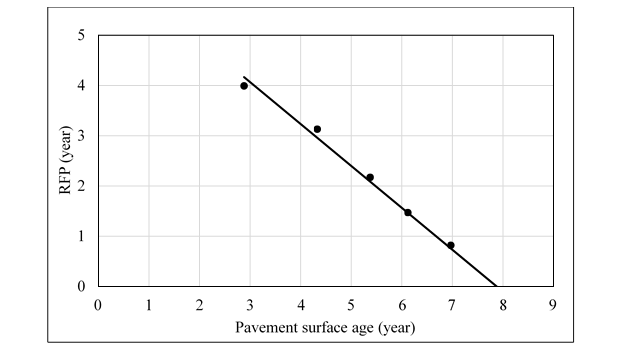

Because the time t in figure 30 is constant, RSP decreases by 1 year as the surface age of the pavement section increases by 1 year. To illustrate, consider the idealized rut depth power function of figure 28 and the corresponding idealized data shown in figure 31. The solid circles and curve in figure 31 simulate the idealized measured data whereas the dotted curve simulates the predicted rut depth data. At time 0 (end of construction), no rut depth data were available, and RSP of the pavement section was equal to the DSL of 15 years minus the pavement SA of 0years. Similarly, 1 and 2 years after construction, RSP was equal to the DSL minus the pavement SA. In the future, when the third measured rut depth data point becomes available, the data could be modeled using a power function, and the time at which the rut depth reaches the prespecified threshold value of 0.5 inch (12.5 mm) can be estimated using figure 29. RSP at that time was equal to the calculated time to threshold minus the pavement surface age. This procedure was repeated when a new data point became available, and a new RSP was calculated as displayed in table 13. RSPs and SAs listed in table 13 were plotted in figure 32. It can be seen that RSP decreased by 1 year as SA increased by 1 year. Similarly, the IRI data measured as a function of time along LTPP test section 0102 in Iowa and depicted in figure 27 (repeated herein for easy reference as figure 33), were modeled with an exponential function, and six RFPs were calculated based on sets of three, four, five, six, seven, and eight time-series data points. The results are presented in table 14 and depicted in figure 34. Once again, the actual measured IRI data when modeled using an exponential function yielded RSPs that decreased by 1 year as the pavement SA increased by 1 year. Once again, similar results were obtained from the analyses of other LTPP test sections using various cracking data. They are included in chapters 6 and 7.

1 inch = 25.4 mm.

Figure 31. Graph. Example of idealized rut depth data and function versus elapsed time.

Table 13. Progressive calculation of RSP of the idealized rut depth shown in figure 31.

| Number of Available Data Points |

Surface Age (Years) |

Values from Figure 28 |

RSP (Years) |

Calculation Equation | |

|---|---|---|---|---|---|

| α | β | ||||

| 1 | 0.01 | N/A | N/A | 14.99 | See figure 30 |

| 2 | 1 | N/A | N/A | 14 | |

| 3 | 2 | N/A | N/A | 13 | |

| 3 | 2 | 0.2217 | 0.3 | 13 | See figure 30 |

| 4 | 3 | 0.2217 | 0.3 | 12 | |

| 5 | 4 | 0.2217 | 0.3 | 11 | |

| 6 | 5 | 0.2217 | 0.3 | 10 | |

| 7 | 6 | 0.2217 | 0.3 | 9 | |

| 8 | 7 | 0.2217 | 0.3 | 8 | |

| 9 | 8 | 0.2217 | 0.3 | 7 | |

| 10 | 9 | 0.2217 | 0.3 | 6 | |

| N/A = Not applicable. | |||||

Figure 32. Graph. RSP versus the pavement surface age for an idealized power function.

1 inch/mi = 0.0158 m/km.

Figure 33. Graph. IRI versus elapsed time for LTPP SPS-1 test sections 0102 and 0103 in Iowa.

Table 14. RFP of LTTP test section 0102 in Iowa based on the IRI data shown and depicted in figure 34.

| Number of Data Points |

Pavement Surface Age (Years) |

IRI (Inches/Mi) |

IRI See Figure 28 |

RFP (Years) (See Figure 30) |

|

|---|---|---|---|---|---|

| α | β | ||||

| 3 | 2.88 | 85.75 | 52.771 | 0.1721 | 3.99 |

| 4 | 4.32 | 103.62 | 53.864 | 0.1559 | 3.13 |

| 5 | 5.37 | 122.53 | 54.067 | 0.1535 | 2.17 |

| 6 | 6.13 | 136.45 | 54.251 | 0.1518 | 1.47 |

| 7 | 6.98 | 146.89 | 54.933 | 0.1464 | 0.82 |

| 8 | 8 | 180.64 | 54.721 | 0.1478 | –0.25 |

| 1 inch/mi = 0.0158 m/km. | |||||

Figure 34. Graph. RFP versus pavement surface age for LTPP test section 0102 in Iowa.

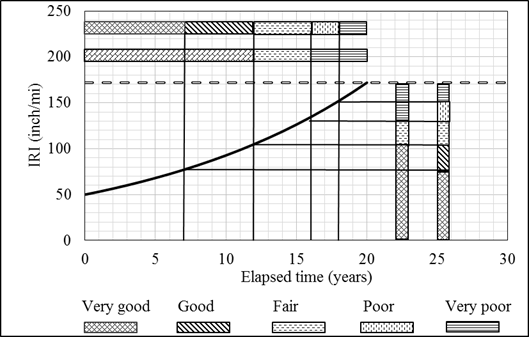

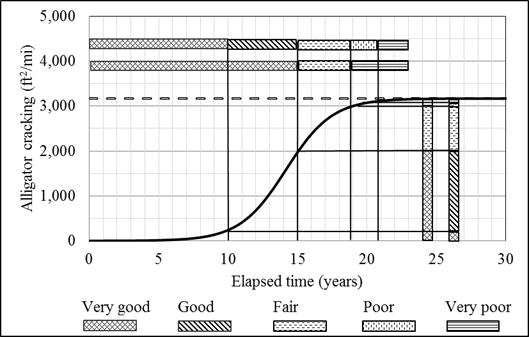

The three- and five-level CS systems in terms of RFP and RSP are depicted for an idealized and untreated pavement section shown in figure 35 and figure 36. The threshold values in the figures are 172 inches/mi (2.73 m/km) and 3,168 ft2 of alligator cracking per 0.1 mi (180 m2 of alligator cracking per 0.1 km), respectively.

1 inch/mi = 0.0158 m/km.

Figure 35. Graph. RFP CSs.

1 ft2/mi = 0.0581 m2/km

Figure 36. Graph. RSP CSs.

In addition, RFP and/or RSP can be used for the following purposes:

1 lane-mile = 1.61 lane-km.

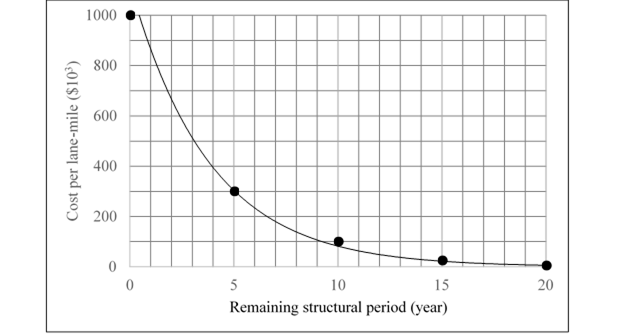

Figure 37. Graph. Conceptualized cost of pavement preservation versus RSP.

1 lane-mi = 1.61 lane-km.

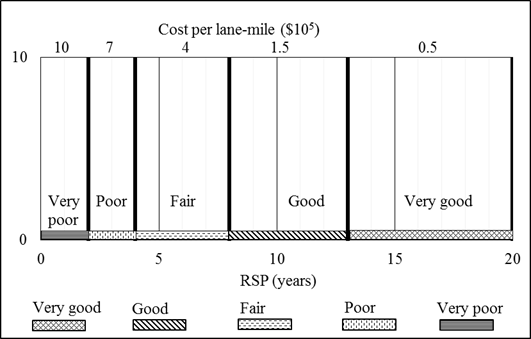

Figure 38. Graph. Correlations among RSP, cost of preservation, and descriptive pavement classification.

Figure 37 and figure 38 show that as RSP decreases, the pavement condition worsens and the cost of pavement preservation increases. For example, the average cost per lane-mile of maintaining the pavement when RSP was 13 or more years was about $50,000 per lane mi ($31,250 per lane km). If the pavement deteriorated to fair condition (RSP between 4 and 8years), the average cost of pavement preservation would increase to $400,000 per lane-mi ($250,000 per lane km) (or eight times more). Such average cost data could be obtained from past pavement project records and shared with legislators and the general public. When the relationship between costs and the RSPs or the pavement classification descriptive terms is established, the data could be used to arrive at the optimum pavement preservation strategy at the network level and for LCCA at the project level.

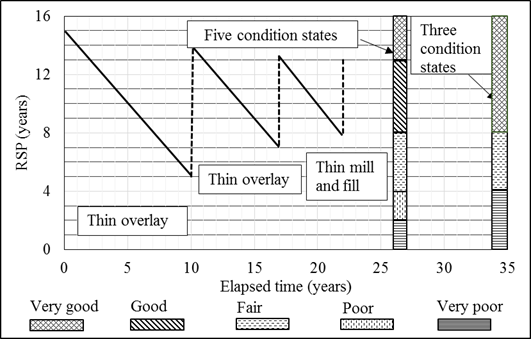

The RSP concept and the benefits of preservation treatments can be demonstrated by considering a flexible pavement section that was designed and constructed to last 15 years (DSL = 15 years). After construction, the section was in very good condition. (RSP was estimated at 15 years.)

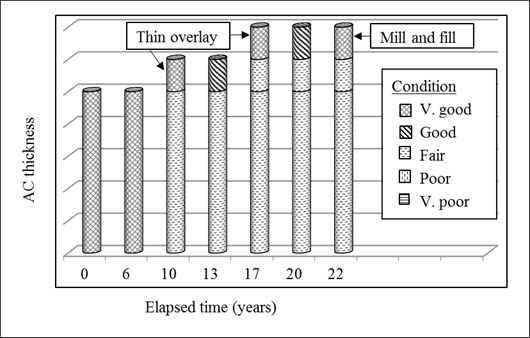

Over time, the section deteriorated (started showing some cracks), and the pavement condition dropped from very good to good in 6 years and to fair in 10 years, as shown in figure 39 and figure 40. When the pavement condition reached fair status (RSP = 5 years), a thin (less than 2.5‑inch (63.5-mm) HMA overlay was applied, and the pavement surface condition was restored to very good. Over the next 7-year period, the pavement surface condition deteriorated again from very good to good and then to fair. At 17 years after the original construction, another thin overlay was applied, and the surface condition was restored to very good status. Five years after the second overlay, the pavement surface condition dropped from very good to good. At that time (22 years after construction), the section was subjected to thin mill-and-fill treatment, and the pavement surface condition was restored once again to very good condition. To summarize, the first HMA overlay was applied 10 years after the original construction (when the condition of the pavement surface reached the fair CS). A second overlay was applied when the surface of the first overlay reached the fair CS. Finally, a thin mill-and-fill treatment was applied when the second overlay treatment was still in good condition. As illustrated in figure 39 and figure 40, the HMA overlays provided a better surface condition initially and decreased the rate of deterioration of the lower layers (the original HMA layers). Indeed, the original asphalt layer was still in fair condition 22 years after construction.

Figure 39. Graph. Example of pavement condition over time with two thin HMA overlays and one thin mill-and-fill action.

Figure 40. Graph. Example RSP over time with two thin HMA overlays and one mill-and-fill action.

It should be noted that the timing for the first and second overlays or any other treatment type should be selected after LCCA is conducted. Any pavement section can be treated at any time during its service life. Some sections may be treated when RSP is 15 years, while others may be treated when RSP is 8 years, and still others when RSP is at 3 years. Once again, the time and the type of the treatment should be selected based on the results of LCCA. In this regard, the following data are required for LCCA:

The preferred treatment type(s) and time of treatment are those that yield the minimum cost and maximum benefits.

Threshold values are defined herein as the magnitude of a measurable pavement condition or distress that constitutes the minimum level of pavement functionality acceptable to the agency and users or the minimum acceptable level of structural integrity. All threshold values should be established based on suitable engineering criteria of appropriate pavement performance measures. For example, functionality thresholds should be established based on ride quality and safety (such as IRI, skid resistance, and rut depth), whereas, structural thresholds should be established based on each cracking type, rutting or faulting. The units of measurement for the threshold values should be the same as those used in measuring the corresponding pavement condition and distresses. The engineering criteria for the threshold should include the impacts of their values on pavement condition and distress, the lifecycle cost, and the optimum timing for pavement preservation. The recommended threshold values for the calculation of RFP and RSP are presented in table 15 and table 16. The reasons for the selection of these values are shown in each table. Note that the recommended threshold values are flexible and can be adjusted based on the agency and user needs and constraints and on the posted speed limit or road class.

Table 15. Threshold values describing RFP.

| Pavement Condition Type |

Threshold Values Used in the Analyses | AASHTO MEPDG(37) | |

|---|---|---|---|

| Threshold Value |

Explanation | ||

| IRI | 172 inches/mi (2.7 m/km) | Minimum acceptable ride quality at 55 mi/h (90km/h); driver speed and comfort may be reduced above this value | Interstate: 160 inches/mi (2.5m/km) Primary: 200 inches/mi (3.16m/km) Secondary: 200 inches/mi (3.16m/km) |

| Skid resistance | To be determined by the agency | Depends on the method of measurement and pavement type | Not included |

| Rut depth | 0.5 inches (12.7mm) | Maximum allowable depth to control hydroplaning potential in wet conditions at 55mi/h (90km/h) | Interstate: 0.40 inches (10.6 mm) Primary: 0.50 inches (12.7 mm) Others (< 45 mi/h (72km/h)): 0.65inches (16.5 mm) |

Table 16. Threshold values describing RSP.

| Pavement Condition or Distress Type |

Threshold Values Used in the Analyses | AASHTO MEPDG(37) | |

|---|---|---|---|

| Value | Explanation | ||

| Alligator cracking | 1,267 ft2/0.1 mi (73 m2/0.1 km) |

Twenty percent of the lane area cracked (assuming 12-ft (3.66-m) lane width) | Interstate: 10-percent lane area Primary: 20-percent lane area Secondary: 35-percent lane area |

| Longitudinal cracking | 1,056 ft/0.1 mi (200 m/0.1 km) |

Two cracks along the entire section length | Not included |

| Transverse cracking (JPCP) | 264 ft/0.1 mi (50 m/0.1 km) |

Two thirds of the slabs are cracked (assuming 16-ft (4.88-m)-long slab | Interstate: 10 percent Primary: 15 percent Secondary: 20 percent |

| Transverse cracking (HMA) | 350 ft/0.1 mi (67 m/0.1 km) |

Lane is divided into 12-ft (3.66-m) squares, assuming 12-ft (3.66-m) lane width and even crack spacing of 12 ft (3.66 m) | Interstate: 500 ft/mi (94.7 m/km) Primary: 700 ft/mi (132.6 m/km) Secondary: 700 ft/mi (132.6 m/km) |

| Faulting | 0.25 inches (6.35 mm), average over 0.1 mi (100 m) |

Dowel bars have likely sheared, or concrete around dowels has deteriorated and may be spalled | Interstate: 0.15 inches (3.8mm) Primary: 0.20 inches (5.8 mm) Secondary: 0.25 inches (6.4mm) |

| Deflection | See chapter 7 | Certain deflection or differential deflection could indicate structural or load transfer issues or void beneath the slab | Not included |

The threshold values listed in table 15 are representative of the average minimum level of serviceability that the State transportation departments strive to provide their users. Therefore, these values are somewhat subjective; where one State transportation department may strive to provide pavement with no more than 150 inches/mi (2.4 m/km) IRI, another may set the maximum acceptable pavement roughness at 225 inches/mi (3.6 m/km) IRI for its pavements. Neither value is wrong, right, or otherwise; the value should be determined by the State transportation department by considering the users’ needs and expectations as well as the practicality and the lifecycle costs associated with maintaining its pavement network given the agency constraints. Safety-related threshold values, such as rut depth and skid resistance, should also be determined by the State transportation department based on an assessment of the typical driving conditions, speeds, and vehicle characteristics and their role in a risk assessment analysis. For example, the potential for hydroplaning increases in wet climates, on roads with minimal cross-slope for surface drainage, and in areas with higher speed limits. The maximum allowable rut depth should be determined to provide reasonably safe travel for most roadway travelers in an economically feasible manner.

Further, the threshold values do not imply that the State transportation department must or should wait to take action until the pavement sections reach the threshold values, nor do they imply that a roadway must be closed to traffic if the threshold is surpassed. The threshold value is a management tool that helps planners and managers evaluate, assess, and make reasonable and potentially cost-effective decisions regarding the conditions and serviceability of the pavement network.

On the other hand, the engineering criteria for most of the structural threshold values listed in table 16 are much more difficult to establish for various reasons, including the following:

Nevertheless, the pavement community generally agrees that pavement preservation and maintenance actions applied over time are more cost effective than allowing pavements to deteriorate until reconstruction is required. Reconstruction is rarely required because pavements can be preserved indefinitely. The problem lies in where the tipping points occur in the economics of preservation, maintenance, and rehabilitation. Typical pavement structures are subjected to reconstruction after numerous cycles of pavement preservation, maintenance, and rehabilitation. The number of these cycles and the corresponding lifecycle costs are functions of the pavement preservation strategy used and the timing of the various pavement preservation cycles.

The establishment of the RSP threshold values should be based on the assumption that RSP would flag the pavement sections for preservation actions at the proper time. For example, consider a flexible pavement section that has begun to develop block cracking (top-down type cracks) owing to surface aging. Several surface treatments, such as mill and fill or HMA overlay, could reduce or eliminate the block cracking and its rate of propagation. If the threshold value for block cracking is set very high or if RSP is allowed to decrease to zero and beyond the threshold value, the block cracks extend in depth and the cost effectiveness of these treatments generally decreases until the conditions (the tipping point) for reconstruction are reached. This tipping point could be when the cracks pass the mid-depth of the asphalt layer or when they penetrate the entire asphalt layer. The specific condition(s) under which reconstruction becomes most cost effective depends on many factors, including the following:

The concept of structural integrity thresholds is even further complicated by the false notion that pavements that have reached the threshold value must be reconstructed. Some pavement sections reach the threshold for structural integrity yet may still provide acceptable level of service. For example, for a concrete pavement that has 100 percent of slabs with two or more transverse cracks, it would likely be more cost effective to reconstruct than to perform full-depth patching at each transverse crack. However, if the cracks are not faulted, the roadway may still have an acceptable IRI. In this scenario, the pavement has an RFP greater than 0 years while its RSP is 0years. The preferred alternative in this scenario would be to schedule pavement reconstruction for when RFP reaches 0 years. In other words, an RFP of 0 years implies that action is needed but an RSP of 0 years does not necessarily imply that reconstruction is needed immediately. However, the latter is a function of the threshold value and the type of distress. For example, a pavement rut of typical depth can be removed using certain treatments. However, if the rut is due to shear failure in the lower pavement layers, reconstruction may be required to eliminate the causes of rutting. Likewise, if the threshold value is set too high (for example, 100-percent alligator cracking), reconstruction may be required.

The concept of long-life pavement can also add an extra nuance to the RSP concept. The idea behind long-life pavement is to construct a significant pavement structure that will resist structural deterioration due to traffic and environmental loading, throughout the pavement cross section. Pavement deterioration in long-life pavement would be limited to areas near the pavement surface (upper few inches), which can be perpetually replaced (i.e., with mill-and-fill treatment). In this scenario, RSP is virtually constant because any structural deterioration is periodically repaired.

One last important note on RFPs and RSPs is the concept of negative RFP or RSP. A value of zero implies that either the pavement is providing less than the standard level of service or the pavement structure has deteriorated to the point (depending on the threshold value) where major rehabilitation or reconstruction may be the most cost-effective treatment option. A negative value of RFP or RSP indicates the number of overdue years passed after the due date for major rehabilitation or reconstruction. This information is not of particular use to pavement managers, because a pavement section with 0 or –5 years RFP or RSP yields the same conclusion—reconstruction or heavy rehabilitation might be needed. For this reason, RFP or RSP could be limited to 0. Note that there is no technical upper limit on RFPs or RSPs. However, the maximum value should be reasonably set based on the average DSL of the pavement structure.

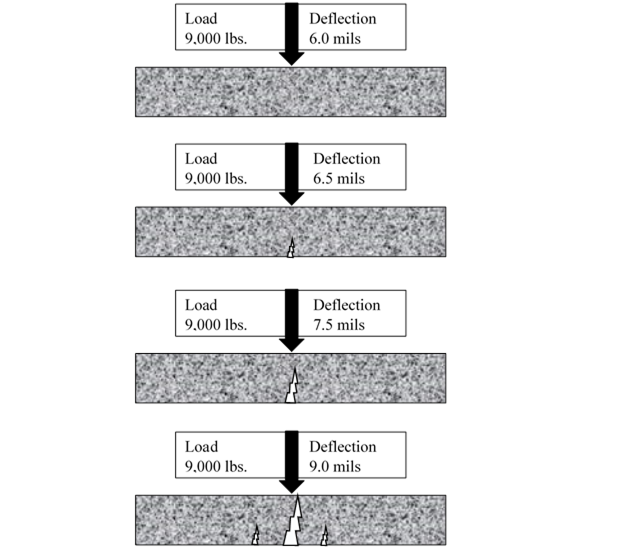

Finally, the previous discussions are primarily based on the use of data observed or measured to characterize the pavement surface. Unfortunately, the damage has already occurred by the time the distresses appear on the pavement surface. An early indicator of impending surface distress would support early actions and the selection of cost-effective pavement treatments. Such an early indication could come from the pavement deflection data measured using an FWD. The measured deflection and the rates of change over time could indicate the beginning of pavement deterioration before surface manifestation. Hence, it may be possible to establish deflection thresholds and incorporate FWD data into the RSP concept, as discussed in chapter 8. It is envisioned that a relationship may exist between deflection and its rate of change and the initiation and growth of pavement surface defects. For example, consider the increasing deflection likely to be measured on a pavement segment experiencing the initiation and propagation of alligator cracking, as shown in figure 41. The envisioned data in the figure indicate that the pavement deflection increases as the cracks initiate and propagate upward.

1 lb = 0.454 kg.

1 mil = 25.4 microns.

Figure 41. Illustration. Envisioned change in deflection through the progression of alligator cracking.

Unfortunately, such a relationship between crack initiation and increases in the measured pavement deflection has not received significant attention. The main reason is that the crack initiation time is not known; most cracking data start when the cracks appear on the pavement surface. Further, no deflection threshold value has been established that indicates the initiation of cracks. The difficulty in developing a deflection threshold is that each pavement structure is designed to have a different deflection under the same load. For example, a section of interstate freeway may be designed to deflect about 4 to 8 mil (101.6 to 203.2 microns) under 9,000 lb (4,086 kg) (half of an 18-kips single-axle load) while a suburban arterial may be designed to deflect 20to 32mil (508 to 813 microns) under the same load. Further, the frequency of pavement loading has an enormous impact on the initiation of alligator cracking and deflection.

Because no applicable relationships between deflection and pavement surface distress have been developed or published, in this study, the LTPP deflection data were analyzed to explore the potential for developing such relationship. The measured pavement deflections of several LTPP flexible and rigid pavement test sections were analyzed in an attempt to establish threshold values based on the pavement structural integrity. Results of the analyses are discussed in chapter 8 of this report. It should be noted, however, that most, if not all, State transportation departments collect FWD data at the project level as needed. The data are not collected on a regular basis at the network level.

The dual pavement condition rating systems are designed to be adaptable to the needs and constraints of the users. The dual systems are based on three types of information: (1) time-series pavement condition and distress data, (2) threshold values, and (3) applications of the results, which can be adjusted by any State transportation department to work for almost any dataset and for many different tasks. The three information types are the following:

Likewise, the pavement conditions and distresses used to comprise the functional and structural integrity rating could have a wide range from user to user. For example, this report uses IRI and rut depth to rate the pavement function and uses alligator, longitudinal, and transverse cracking, and either rut depth or faulting to describe structural integrity. However, an agency may choose to use only traffic load or wheelpath related distresses such as alligator cracking and transverse cracking (rigid pavement). Finally, an agency may choose to include additional data that were not included in the ratings in this report (such as edge cracking and block cracking). The data elements collected by the State transportation departments are not consistent and some may have more or less available data for use in the dual rating systems.

For example, pavement surface friction data are not often available at the network level. However, a State transportation department with significant friction data may choose to include the data in its functional rating or in a safety rating system. The addition or subtraction of the rating systems data does not affect the process of the rating systems. The rating is based on the minimum RFPs and RSPs, respectively, regardless of the number of elements.

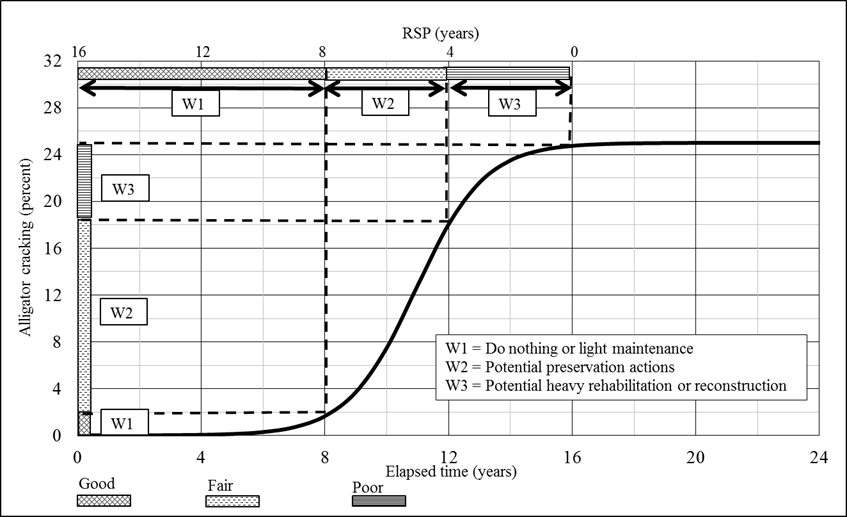

The dual rating systems cannot be used alone for the selection of treatment categories unless the boundaries of these categories are established. Figure 42 depicts the classic S-shaped curve for alligator cracking (expressed in the figure as percent of the total area). The figure also shows the following boundaries for three treatment categories:

Figure 42. Graph. Idealized S-shaped curve for alligator cracking showing three windows (threshold values) for various treatment actions.

The final selection of the treatment category and treatment type within a given category should be accomplished after the actual pavement condition and distress data and results of the forensic investigation of the causes of distresses are carefully examined.

The previous discussion implies that the RSP and RFP spectrum could be divided into various ranges to aid in the selection of pavement preservation type and estimation of cost. For example, an RSP longer than 8 years implies light maintenance, whereas RSPs between 4 and 8 years imply preservation treatments (i.e., no preservation treatment should be applied to pavement section having an RSP of less than 4 years). Finally, an RSP shorter than 4 years implies rehabilitation and/or reconstruction. The interested State transportation department could assign an average cost to each of these RSP ranges based on its cost data. When such cost estimates can be accomplished based on the ranges of RSP, the data indicate that early preservation (at high RSP) yields the least lifecycle cost.

This chapter presented the basis for and development of the dual pavement condition rating systems. Topics covered included the condition classification, dual pavement condition rating systems, recommended threshold values, and a discussion of the flexibility of the systems. The various topics were evaluated, and the research team made the following recommendations: